Si@ MXene nano composite material and preparation method thereof

A nano-composite material and nano-silicon technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems of unsuccessfully perfecting the application of silicon and MXene battery anode materials, material pulverization structure damage, uneven dispersion, etc. Achieve the effects of easy control of shape, change of shape and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Si@MXene composites were prepared according to the following steps:

[0037] 1) Add 2g precursor Ti 3 AlC 2 Mix with 30mL hydrofluoric acid, stir at room temperature for 30min, then stir at 35°C for 24h, separate, adjust the pH to weak acidity, and then dry at 60°C for 12h to obtain MXene in the form of black powder.

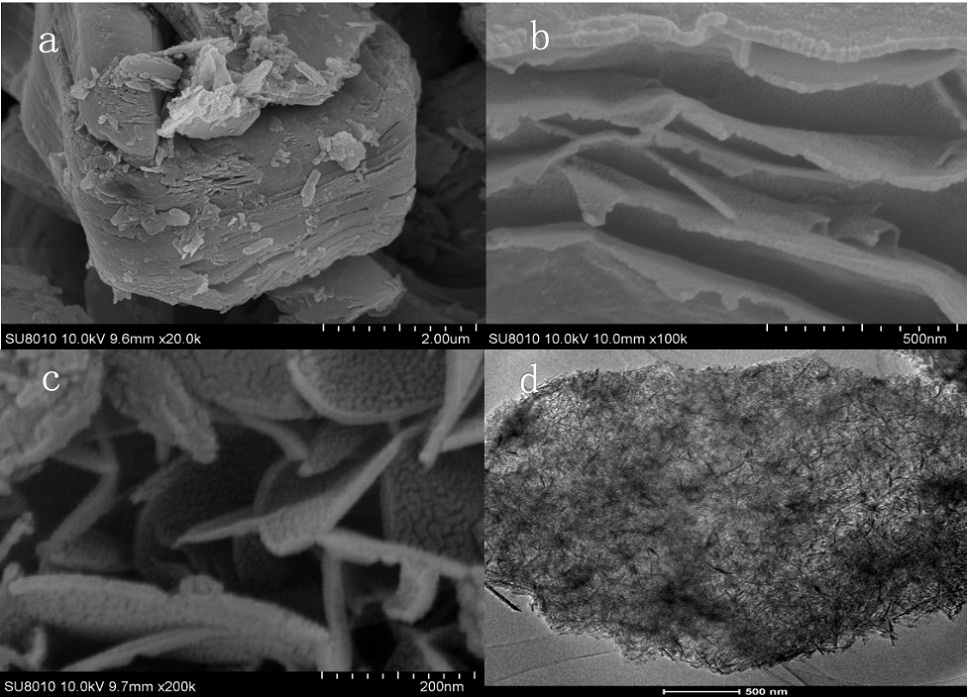

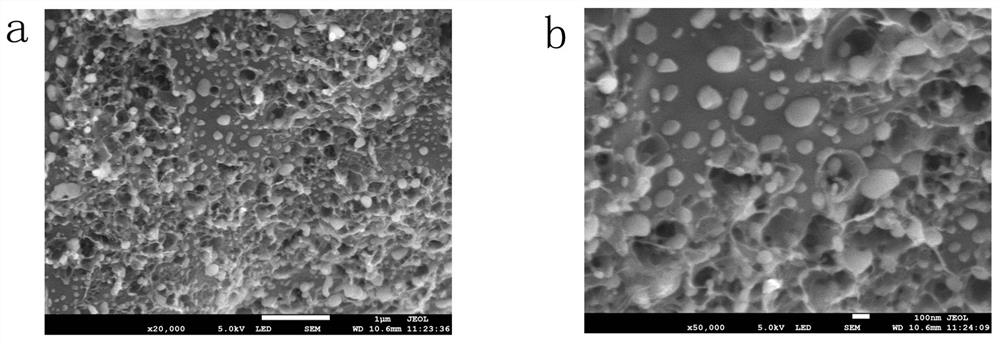

[0038] 2) Take 0.2g of the prepared MXene sample, add 30mL NaOH with a concentration of 1M and mix well, then add 0.68mL H 2 o 2 , after ultrasonication for 10 min, heat at 140°C for 12 h, then adjust the pH to weak alkaline, separate and dry to obtain a gray three-dimensional-MXene sample. Using the JSM-7001F scanning electron microscope to photograph the material morphology, it can be found that the MXene before treatment is layered and stacked ( figure 1 a), The morphology of the treated MXene changes obviously, the interlayer distance increases, and the three-dimensional structure of the flower bouquet ( figure 1 b), zooming in on one of the regi...

Embodiment 2

[0043] Si@MXene composites were prepared according to the following steps:

[0044] 1) Mix 2g lithium fluoride and 30mL HCl with a concentration of 9M, stir for 30min and add 2g precursor Ti 3 AlC 2 , stirred at room temperature for 30 min, then stirred at 35°C for 24h, separated, adjusted the pH to weak acidity, and dried at 60°C for 12h to obtain MXene in the form of black powder.

[0045] 2) Take 0.2 g of the prepared MXene sample, add 30 mL of 1M NaOH and mix well, then add 0.68 mL of H 2 o 2 , after ultrasonication for 10 minutes, store at 140°C for 12 hours at a constant temperature, then adjust the pH to weak alkaline, separate and dry to obtain a gray three-dimensional MXene sample.

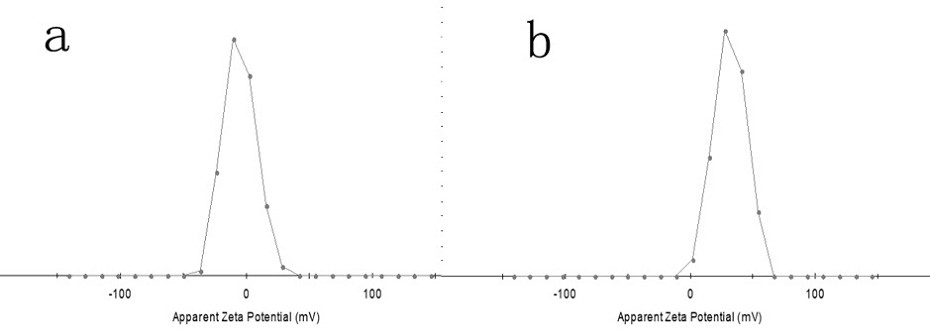

[0046] 3) Disperse 0.12g of nano-silicon in 30mL of PDDA-water with a concentration of 10mg / mL, and the resulting mixed solution is a silicon-modified solution with a concentration of 4mg / mL. In addition, 0.24 g of MXene was used to prepare a water-three-dimensional MXene dispersion w...

Embodiment 3

[0049] Si@MXene composites were prepared according to the following steps:

[0050] 1) Mix 2g lithium fluoride and 30mL HCl with a concentration of 9M, stir for 30min and add 2g precursor Ti 3 AlC 2 , stirred at room temperature for 30 min, then stirred at 35°C for 24h, separated, adjusted the pH to weak acidity, and dried at 60°C for 12h to obtain MXene in the form of black powder.

[0051] 2) Take 0.2 g of the prepared MXene sample, add 30 mL of 1M NaOH and mix well, then add 0.68 mL of H 2 o 2 After ultrasonication for 10 min, the temperature was maintained at 140°C for 12 h, then the pH was adjusted to weak alkaline, separated and dried to obtain a gray three-dimensional MXene sample.

[0052] 3) Disperse 0.12g of nano-silicon in 30mL of iodine-acetone with a concentration of 10mg / mL to obtain a silicon-modified solution with a concentration of 4mg / mL of the mixed solution. In addition, 0.12 g of MXene was used to prepare a water-three-dimensional MXene dispersion with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com