Patents

Literature

134results about How to "Raise the annealing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

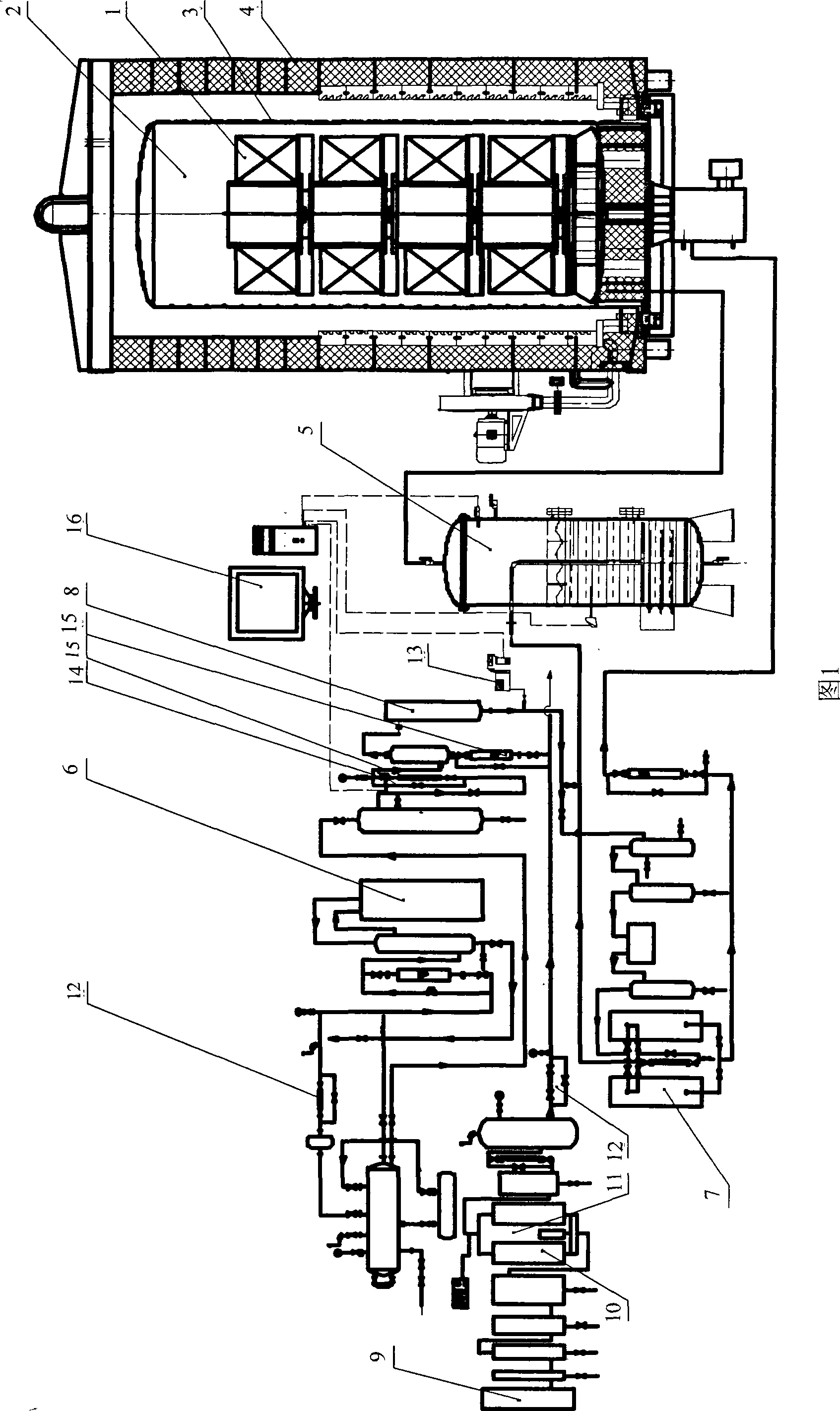

Method and apparatus for rapid thermal processing and bonding of materials using RF and microwaves

ActiveUS20070108195A1Heating fastMicrowave heating is fastSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInterconnection density

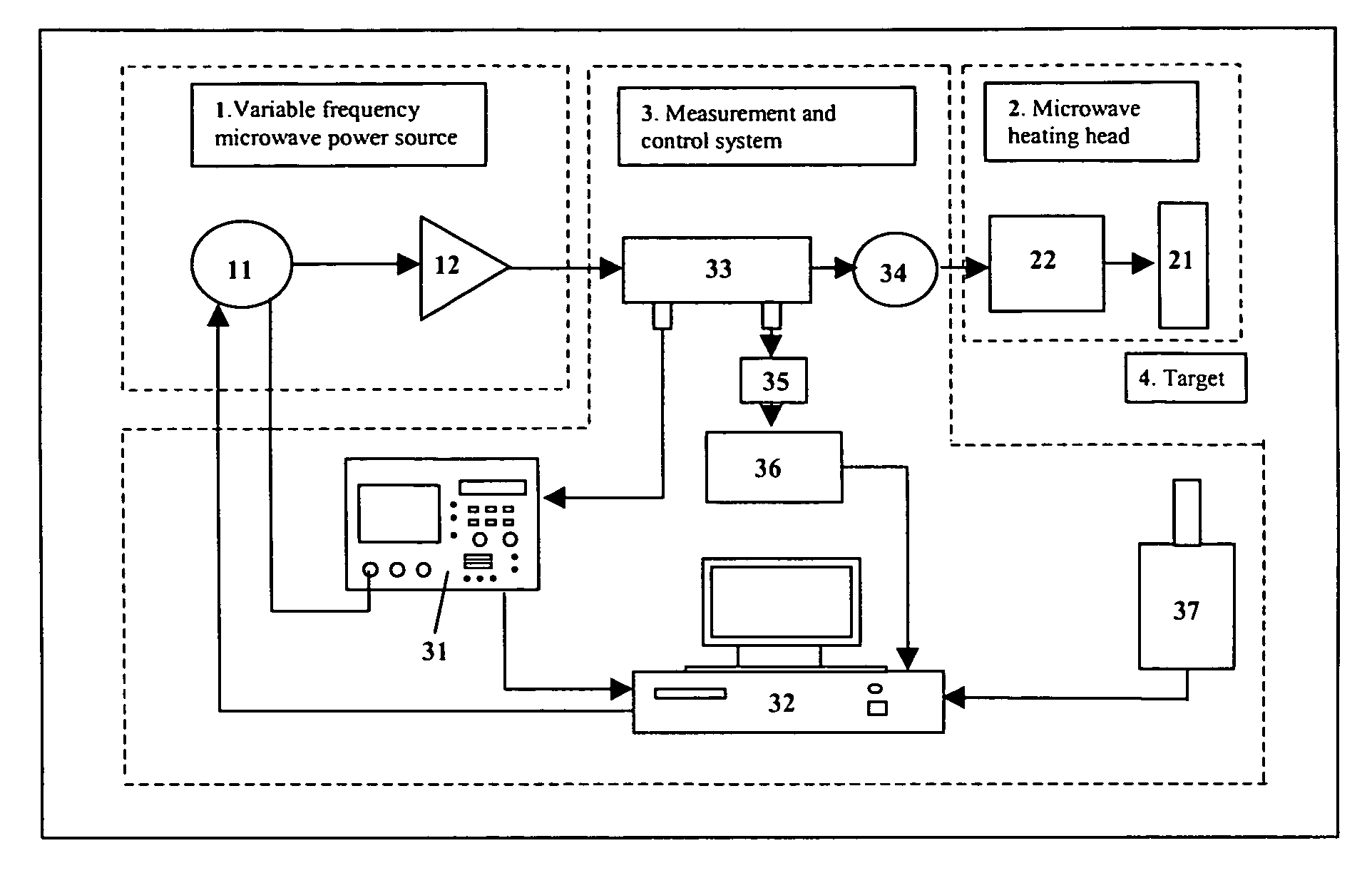

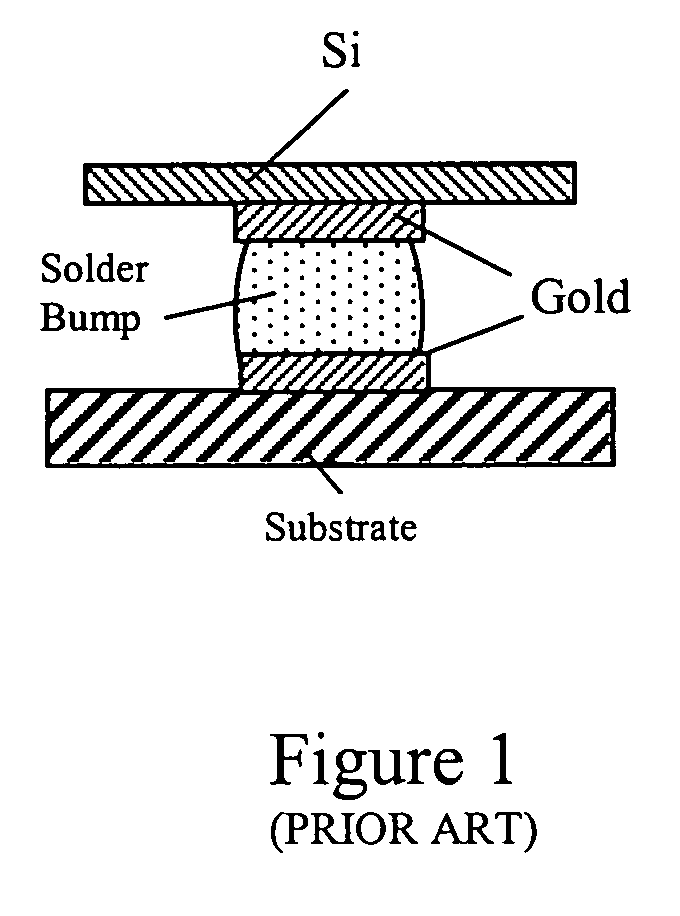

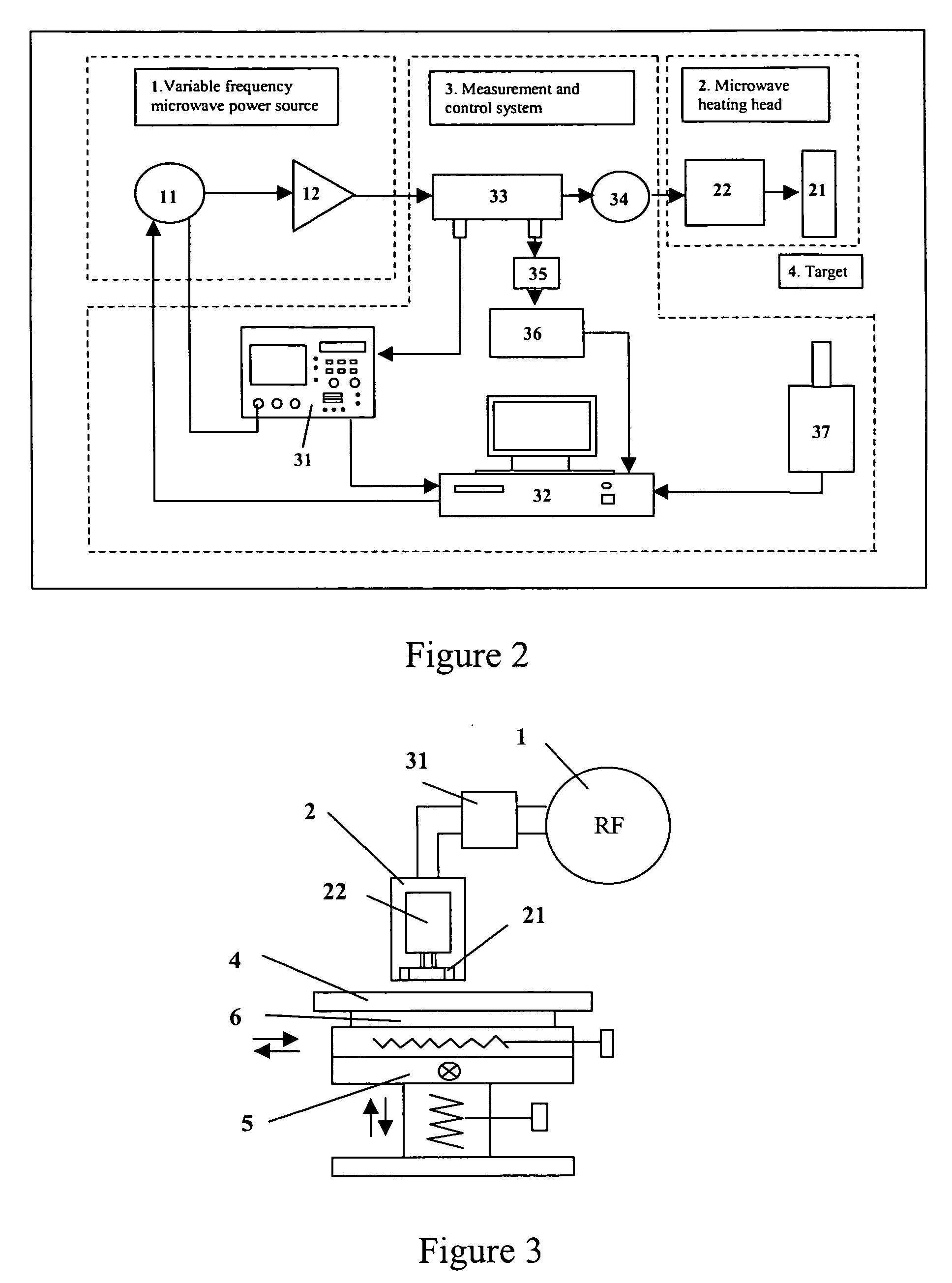

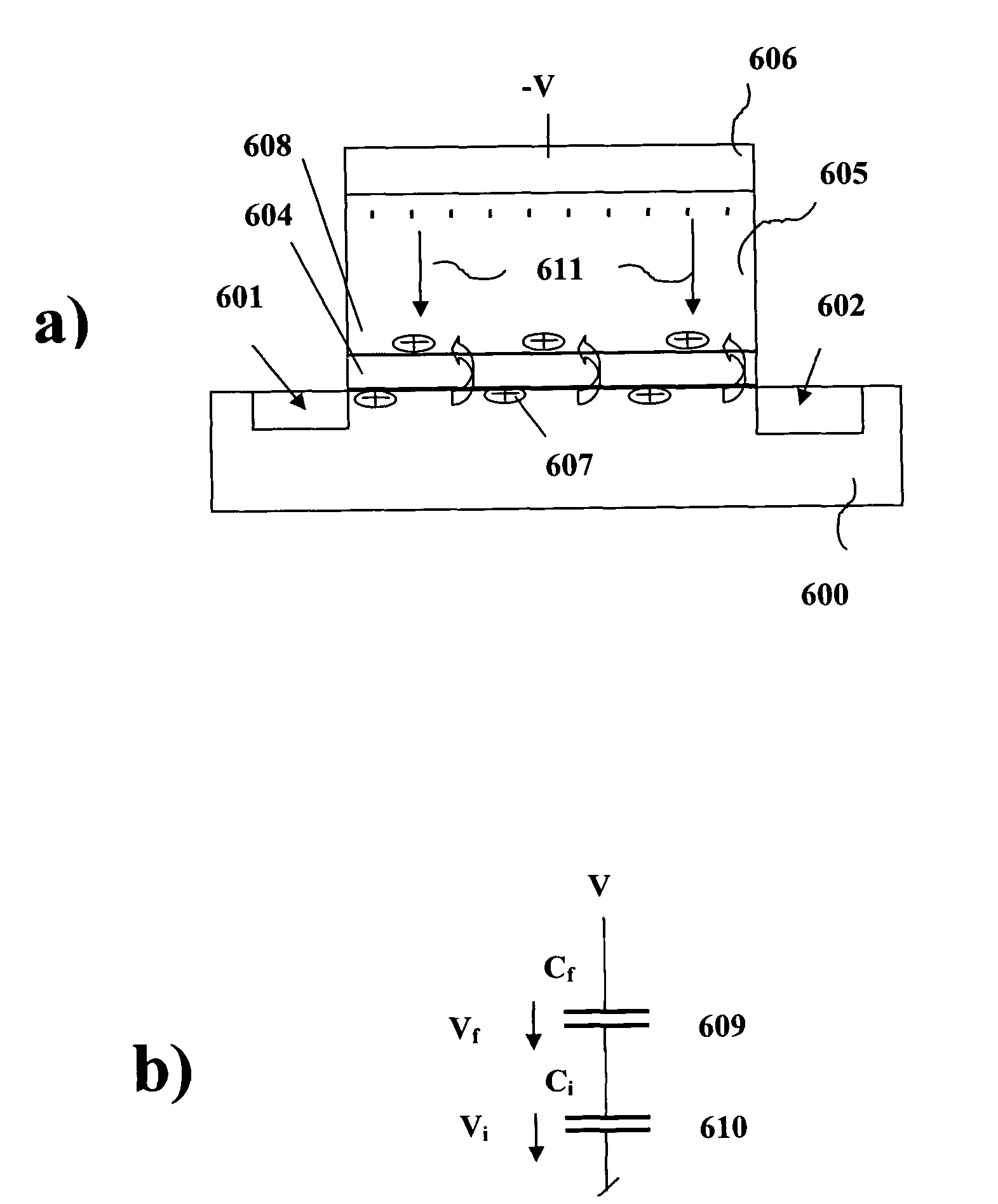

A method and apparatus for rapid and selective heating of materials using variable frequency RF and microwaves. The apparatus uses variable frequency solid state electronics as a microwave power source, a novel microwave heating head to couple microwave energy to the target materials and a match-up network to tune the frequency and impedance match between the microwave source and the load. An electronic and computer measurement and control system is employed to monitor and control the microwave heating process. The method teaches the use of inductive microwave coupling for thin conductive materials such as metal film and impurity doped silicon wafers. The method also teaches the use of capacitive microwave coupling for dielectric material such as glass and ceramics. The method further teaches the use of rapid and selective heating of heterostructure for bonding and sealing of mems and integrated circuits. The method and apparatus can provide ultra-high heating speed along with ultra-high heating temperatures for rapid thermal processing of semiconductors and other materials. It also allows the use of bonding materials with high melting temperature for strong bonding and sealing of mems and IC devices. The apparatus further provides for high interconnection density of integrated circuits as connections are made without the use of solder bumps.

Owner:TIAN YONGLAI +1

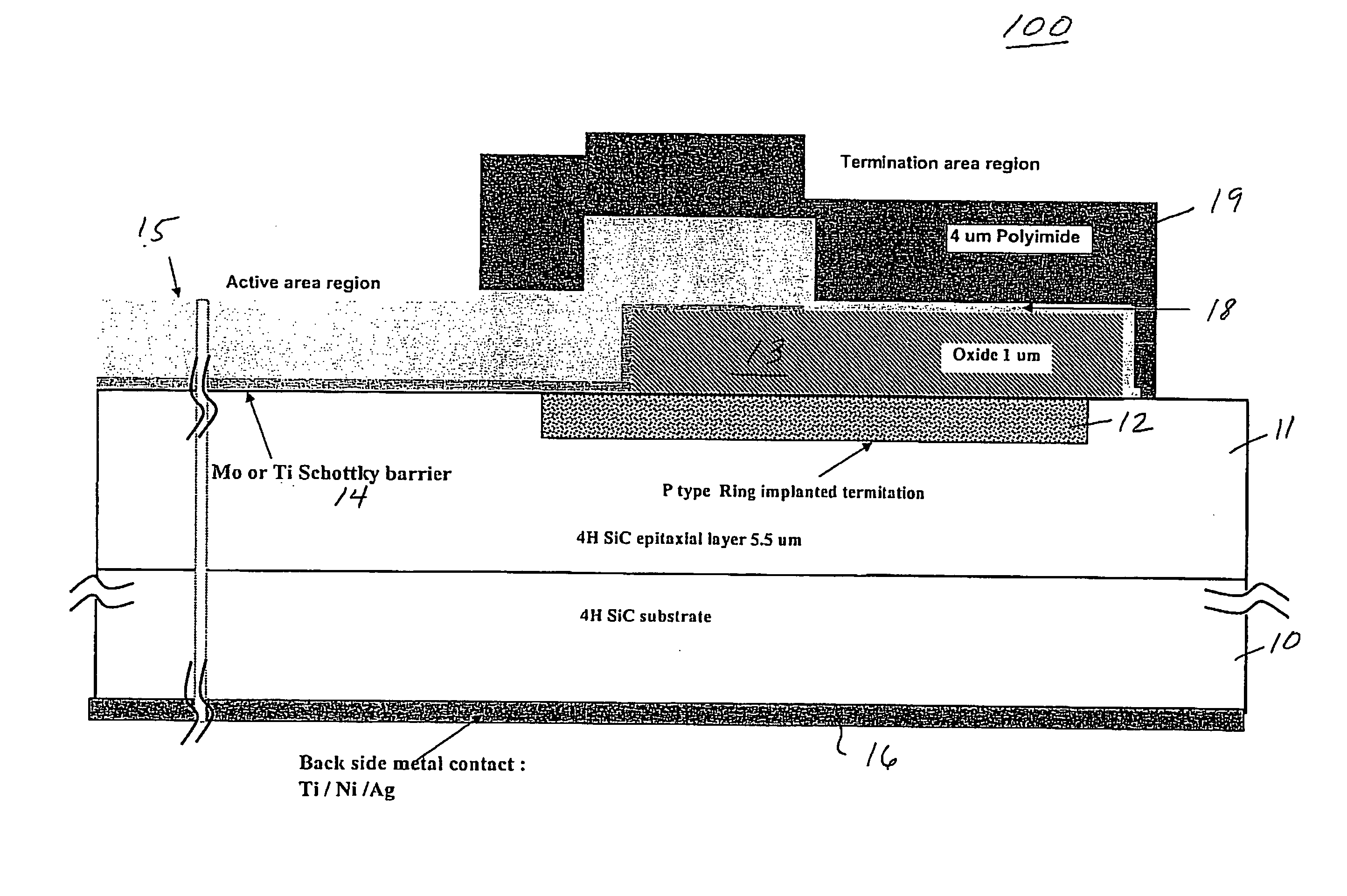

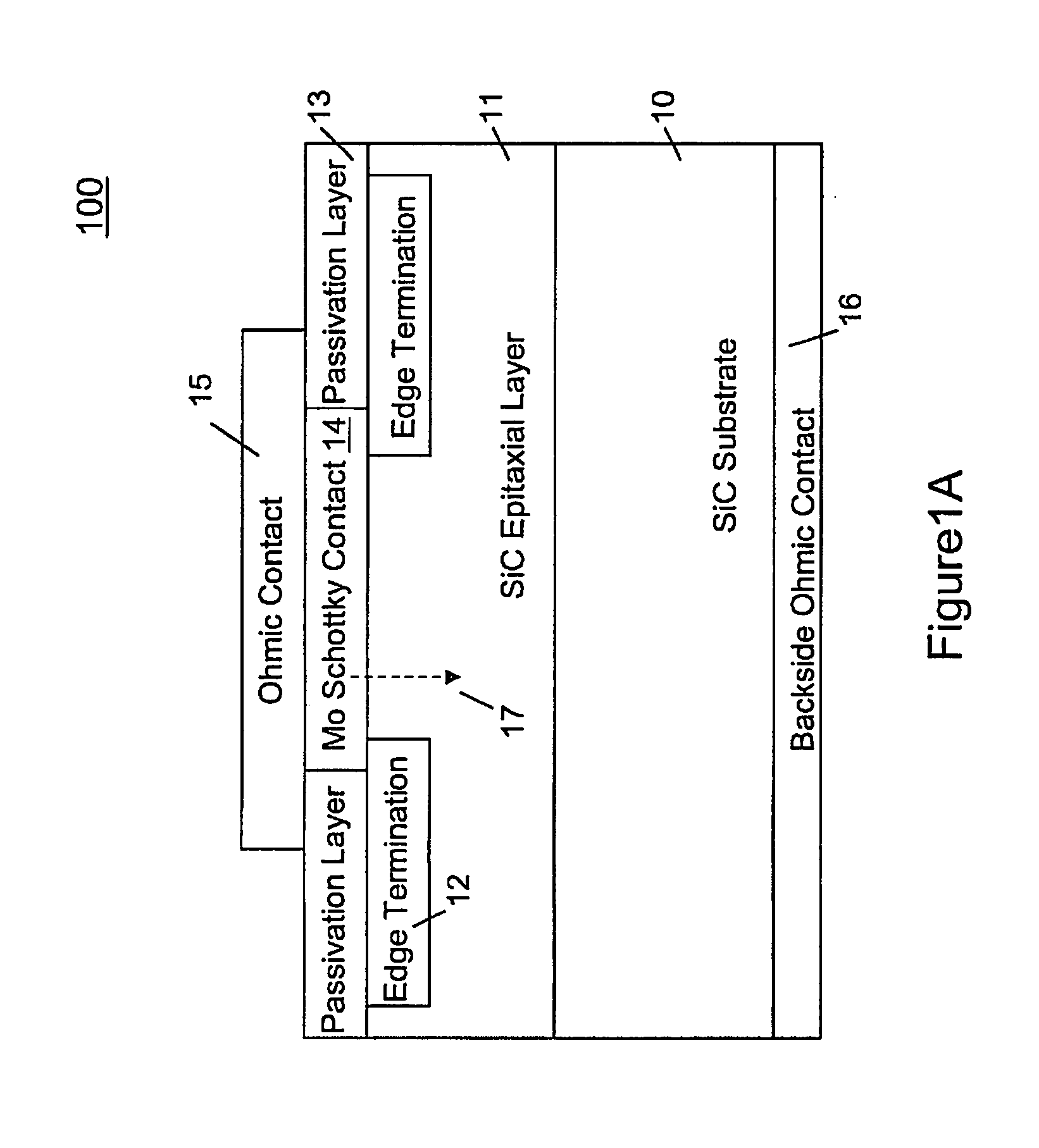

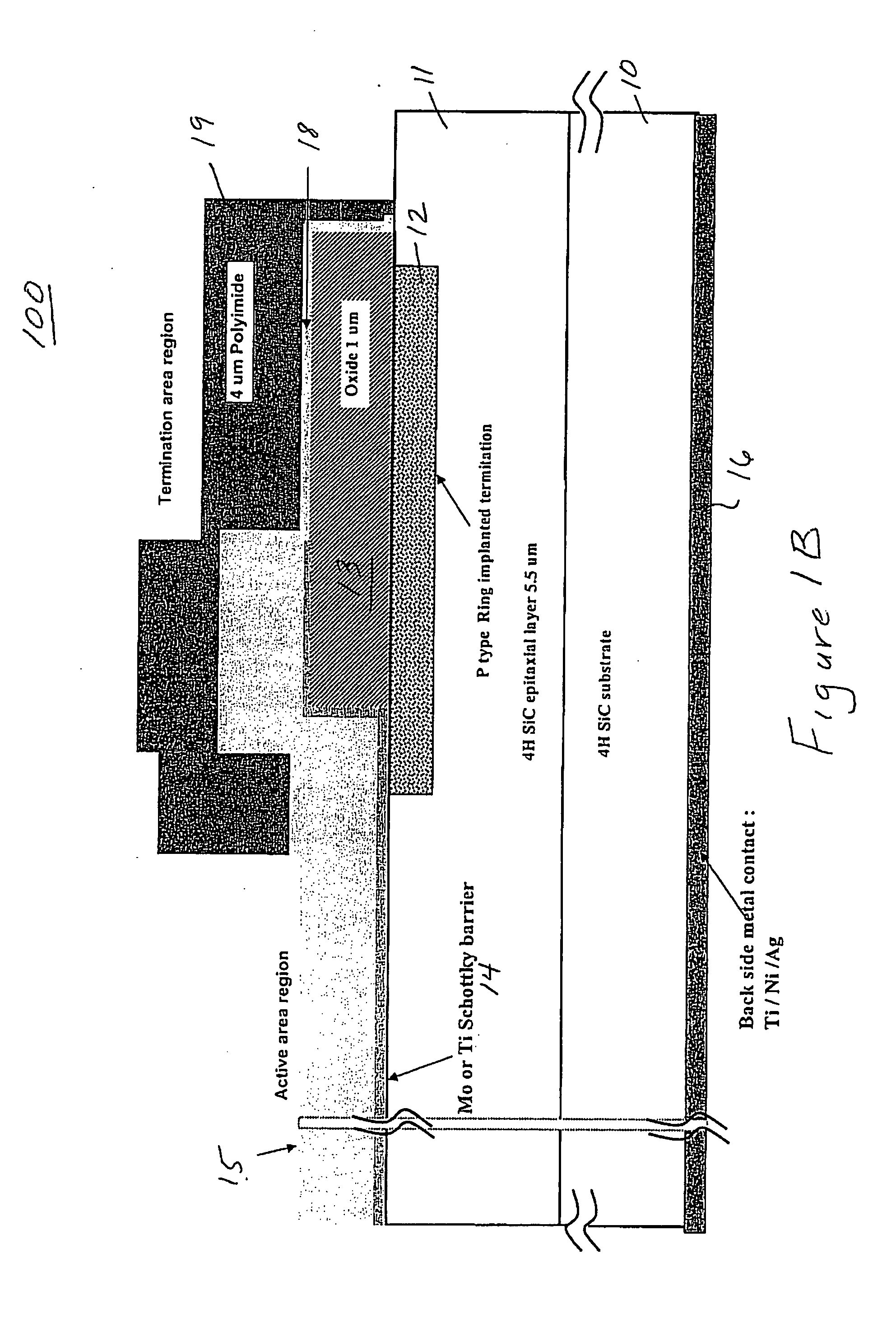

Molybdenum barrier metal for SiC Schottky diode and process of manufacture

ActiveUS20080237608A1Height barrier valueImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky diodeMetal

A method for fabricating a diode is disclosed. In one embodiment, the method includes forming a Schottky contact on an epitaxial layer of silicon carbide (SiC) and annealing the Schottky contact at a temperature in the range of 300° C. to 700° C. The Schottky contact is formed of a layer of molybdenum.

Owner:VISHAY SILICONIX LLC

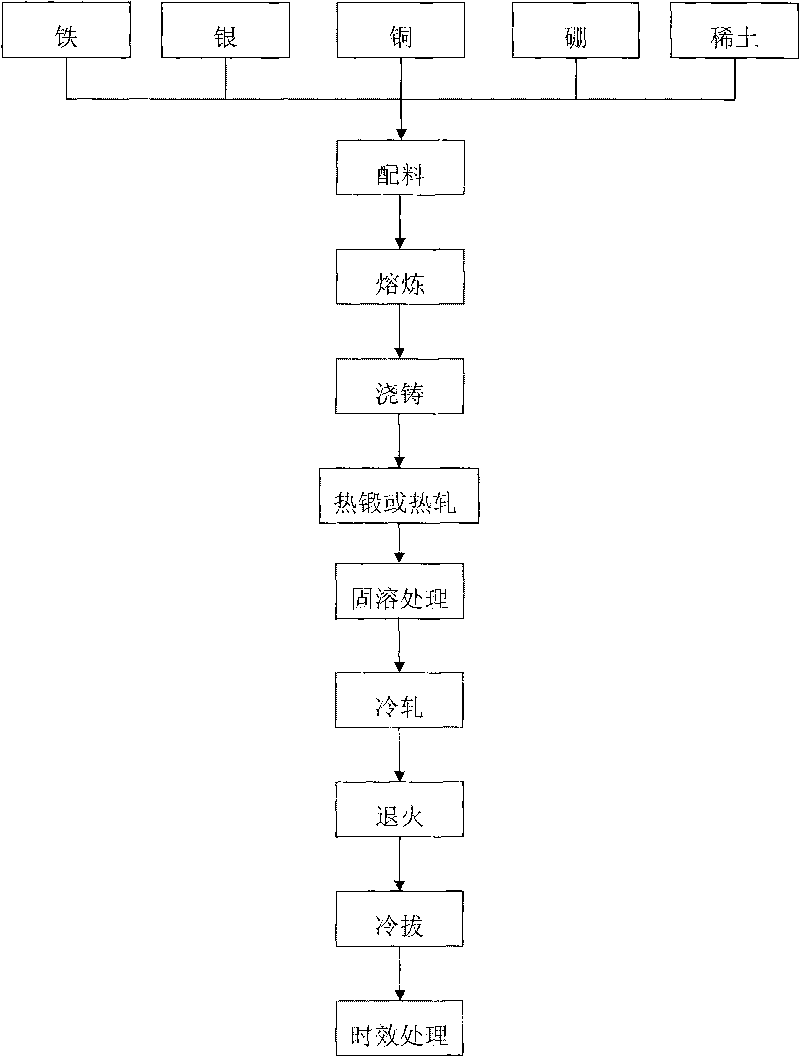

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

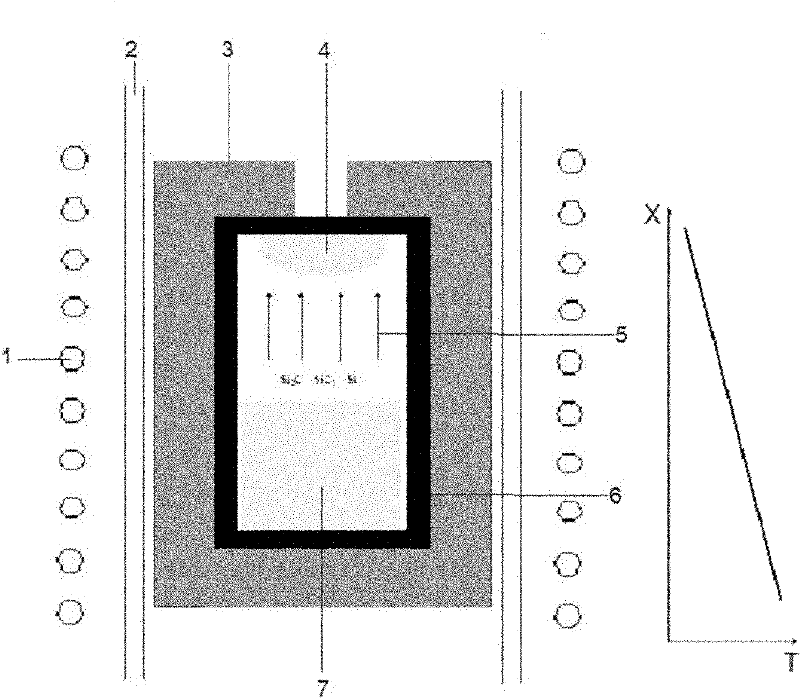

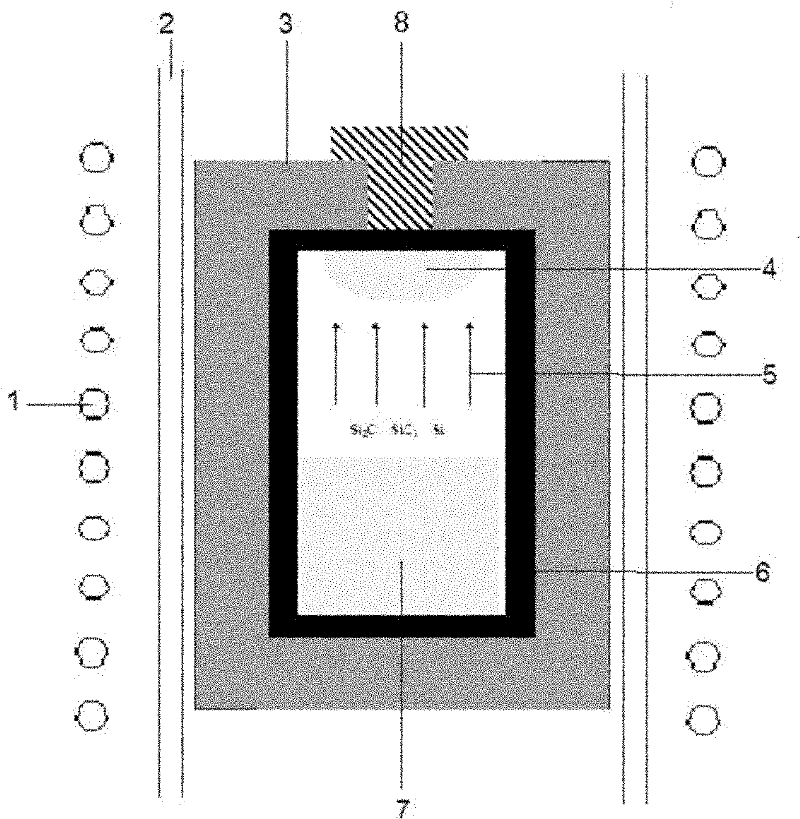

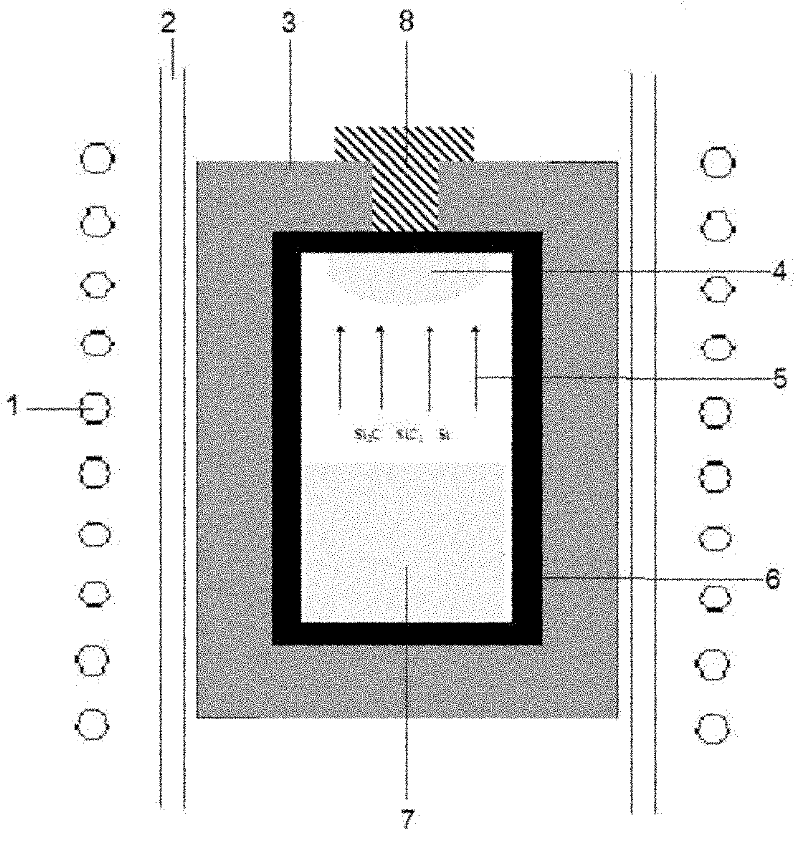

Silicon carbide crystal annealing process

ActiveCN102534805AReduce stressReduce temperature gradientPolycrystalline material growthAfter-treatment detailsCrystal growthTemperature gradient

The invention is mainly applied to the field of treatment after silicon carbide crystal growth completion and particularly relates to a silicon carbide crystal annealing process which is specifically characterized by reducing the temperature gradient (the temperature gradient of the crystals is 1-10 DEG C / cm), spending 1-5 hours in raising the temperature to the annealing temperature under the inert gases with pressure of above 0.01-0.08MPa and then spending 10-50 hours in reducing the temperature after keeping the constant temperature for 10-40 hours, wherein the annealing temperature is 2300-2500 DEG C. By adopting the annealing process, the stress between the crystals and a crucible cover and the stress inside the silicon carbide crystals are reduced, thus reducing the damage rate of the silicon carbide crystals in the follow-up processing course and improving the yield of the silicon carbide crystals.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

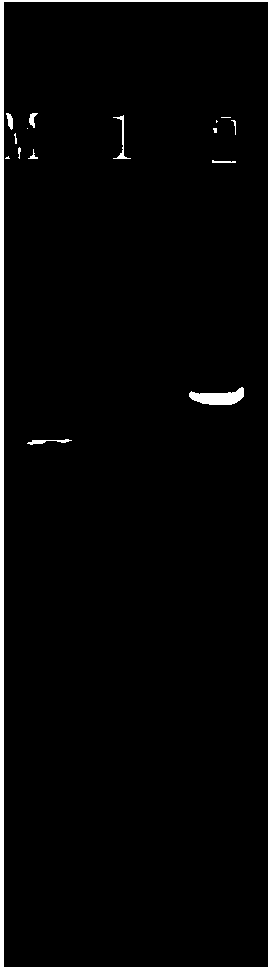

DNA sequencing method and next generation sequencing library

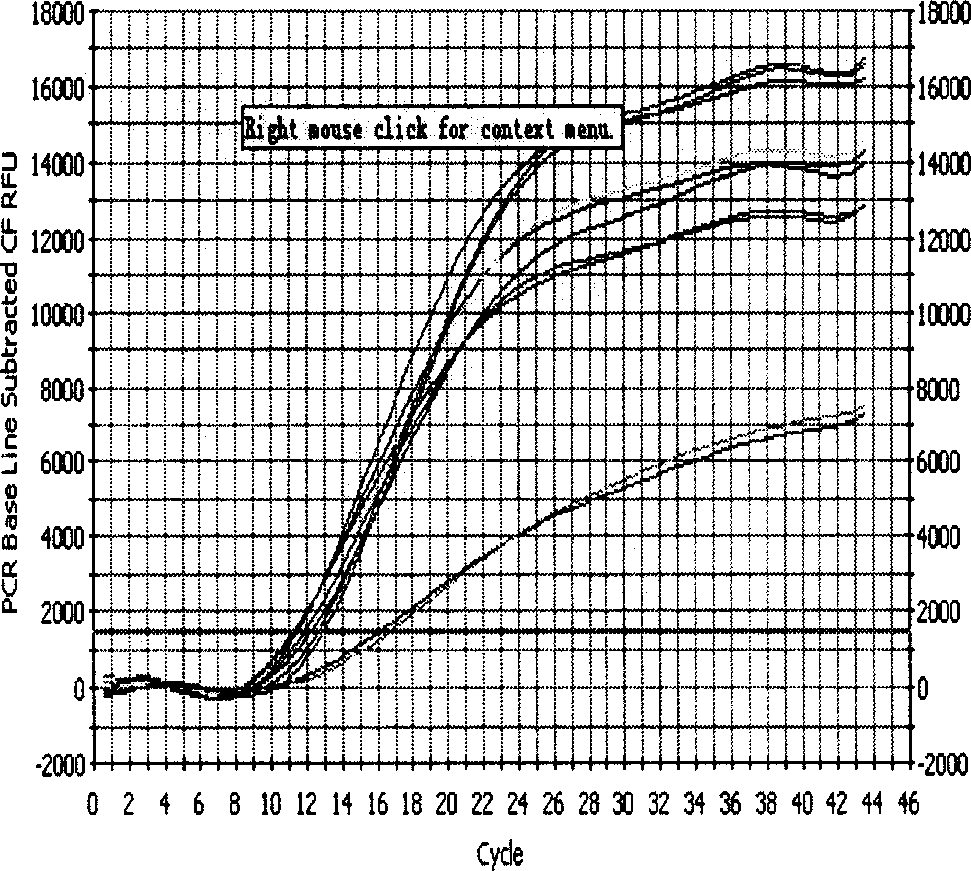

ActiveCN105506125AClear chain of justiceReduced amount of starting DNANucleotide librariesMicrobiological testing/measurementDNA fragmentationA-DNA

The invention discloses a DNA sequencing method and a next generation sequencing library. The sequencing method comprises the steps of mixing a DNA fragment to be measured with a random primer Read2-NB, conducting an extension reaction, connecting the 3' end of an obtained extension product with a chain b which is in a double chain joint Read1-Adapter and contains a sequencing platform specific sequence, and taking amplification connection products of specific primers T1 and T2, so that construction of the next generation sequencing library is completed, and subsequently, conducting sequencing. By means of the DNA sequencing method and the next generation sequencing library, library construction and sequencing can be conducted on double chain DNA and / or single chain DNA, the amount of required initial DNA is lowered, applicability of limited samples for template DNA is great, and the original template sequence of the target single chain DNA can be directly distinguished out of the sequencing result.

Owner:SHANGHAI MAJORBIO BIO PHARM TECH

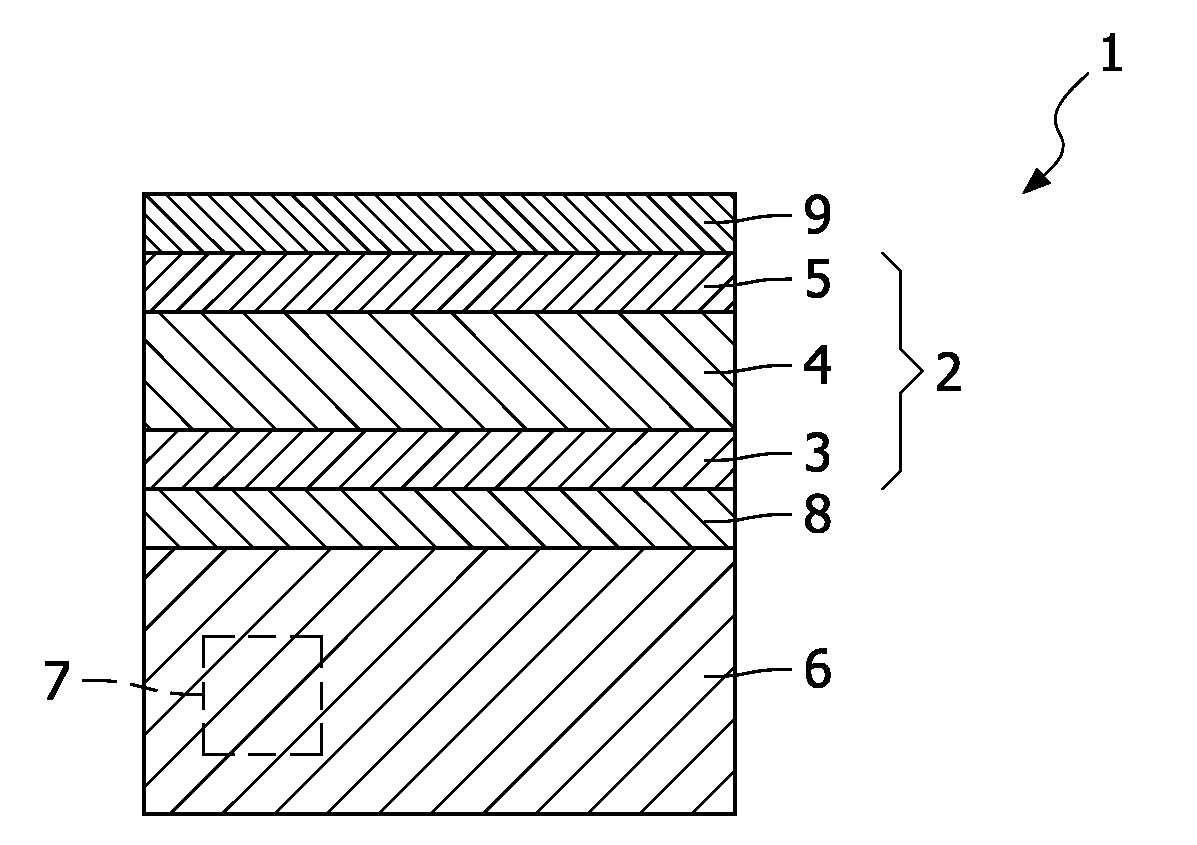

Electrochemical energy source, and method for manufacturing of such an electrochemical energy source

InactiveUS20090317664A1Process stabilityImprove performanceAlkaline accumulatorsFinal product manufactureSolid state electrolyteEngineering

An electrochemical energy source, comprising: a substrate, and at least one stack deposited onto said substrate, the stack comprising at least the active layers: an anode, a cathode, and an intermediate solid-state electrolyte separating said anode and said cathode. An electronic device provided with an electrochemical energy source according to the invention and a method for the manufacturing of an electrochemical source according to the invention.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

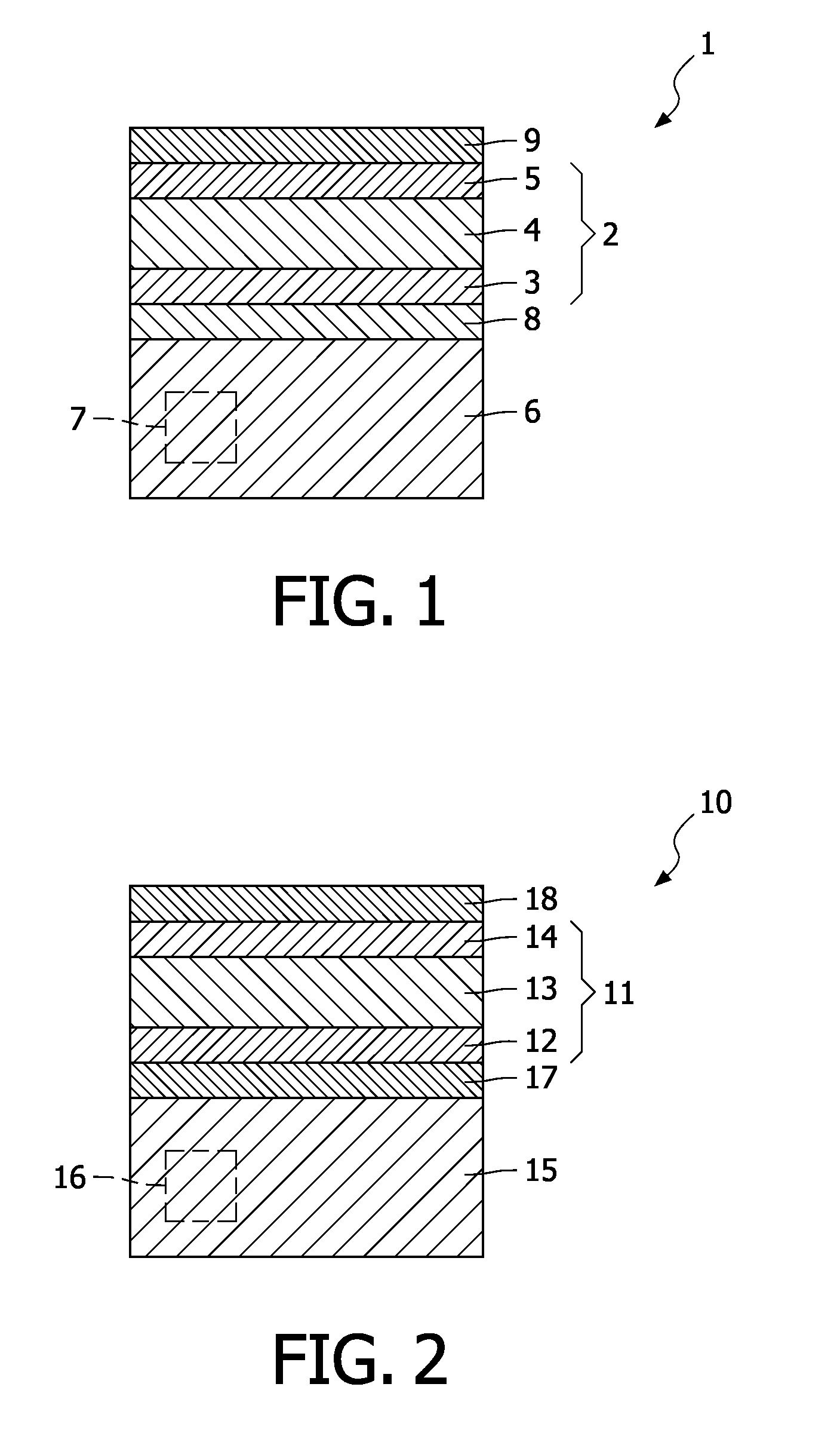

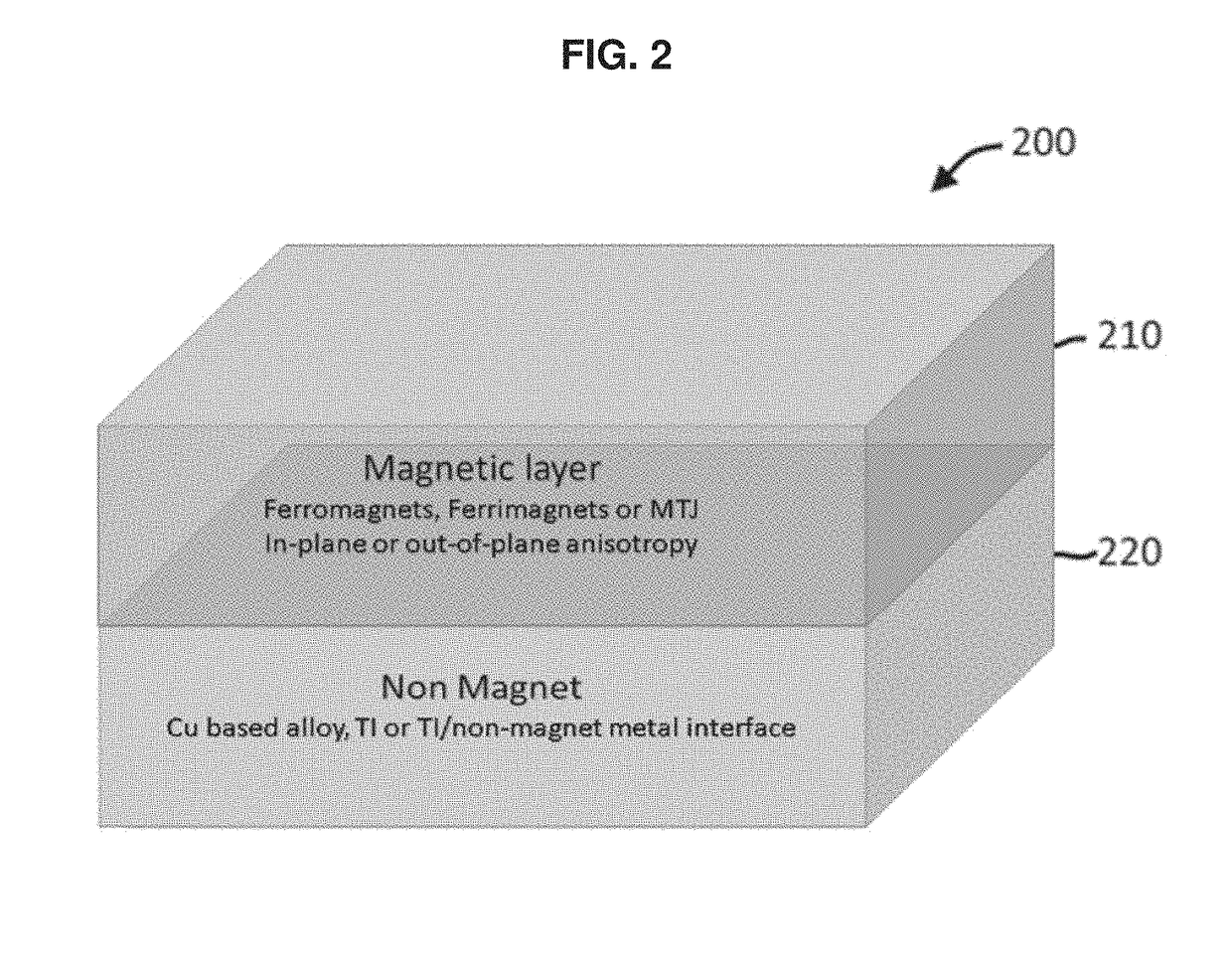

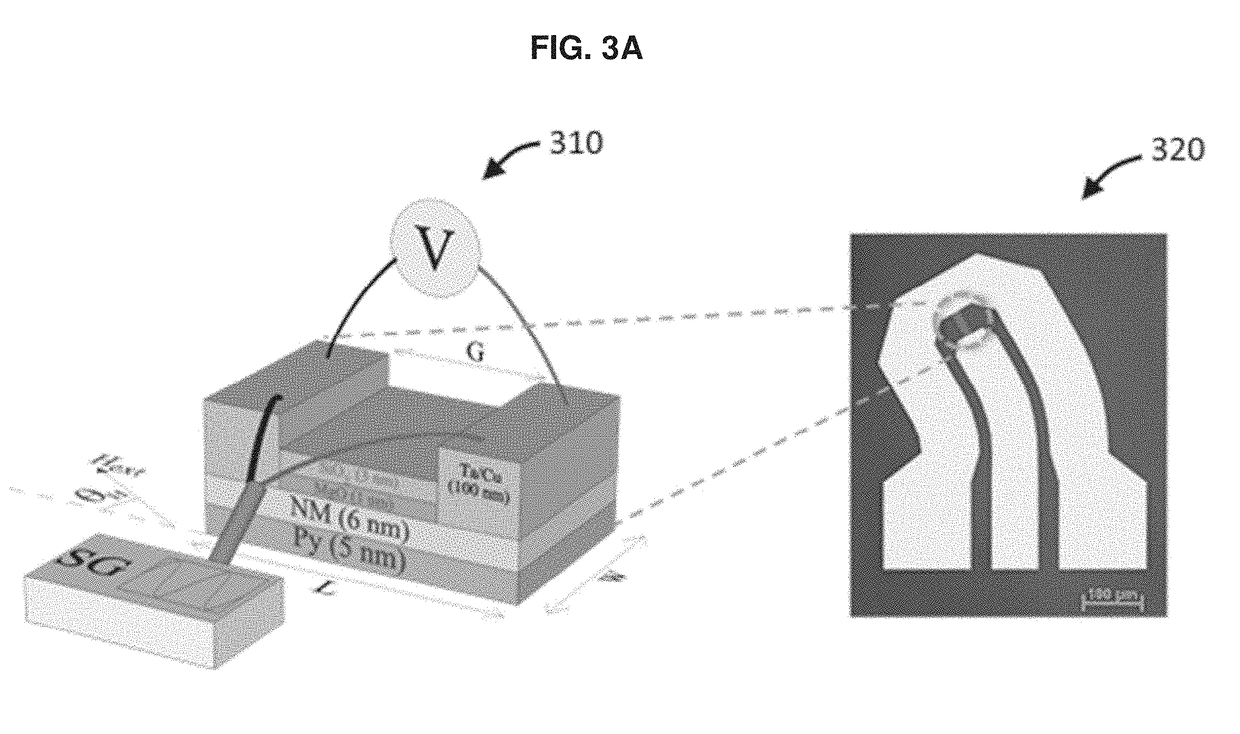

Spin orbit materials for efficient spin current generation

ActiveUS20190058113A1Current generatedEasy to integrateSolid-state devicesGalvano-magnetic material selectionCMOSSpins

In one embodiment, a SOT device is provided that replaces a traditional NM layer adjacent to a magnetic layer with a NM layer that is compatible with CMOS technology. The NM layer may include a CMOS-compatible composite (e.g., CuPt) alloy, a TI (e.g., Bi2Se3, BixSe1-x, Bi1-xSbx, etc.) or a TI / non-magnetic metal (e.g., Bi2Se3 / Ag, BixSe1-x / Ag, Bi1-xSbx / Ag, etc.) interface, that provides efficient spin current generation. Spin current may be generated in various manners, including extrinsic SHE, TSS or Rashba effect.

Owner:NAT UNIV OF SINGAPORE

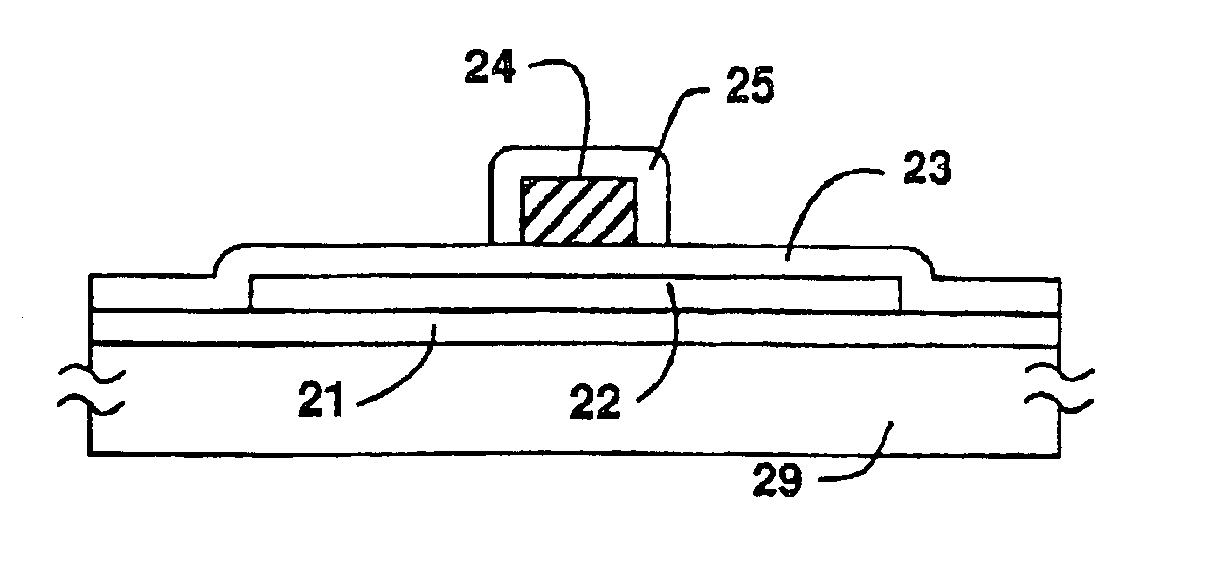

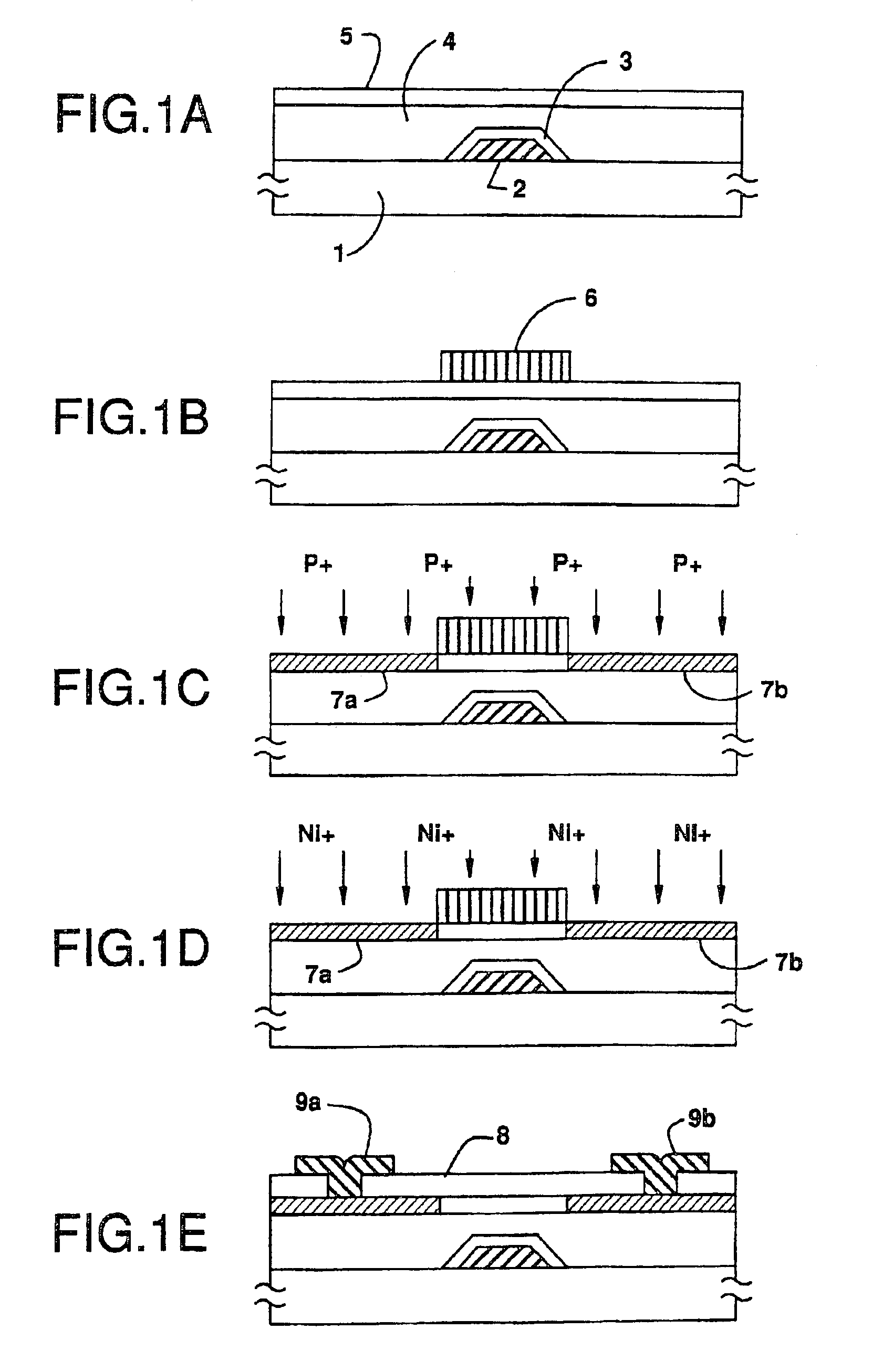

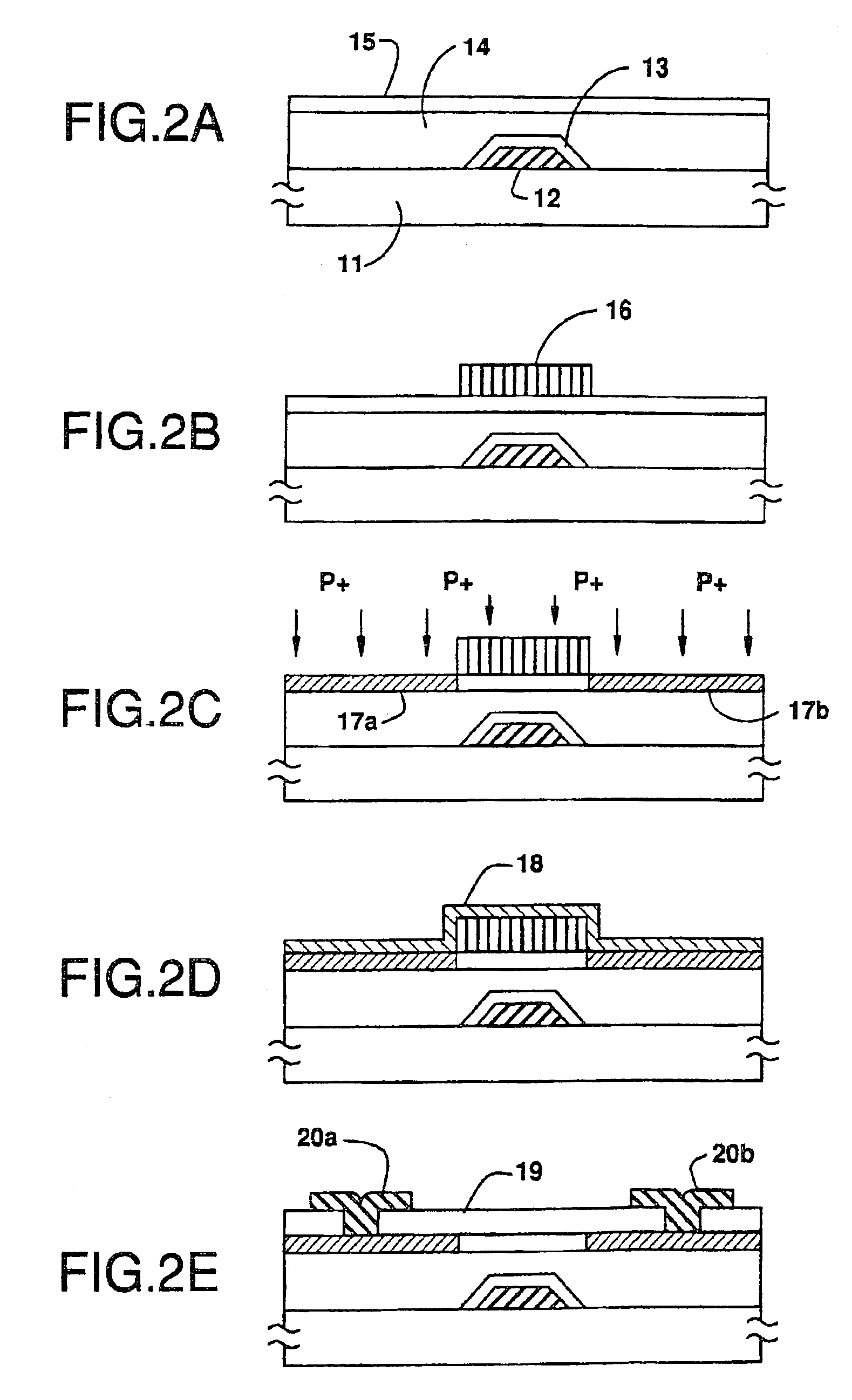

Method of manufacturing a semiconductor device that includes heating the gate insulating film

InactiveUS6939749B2Short durationImprove crystallizationTransistorSemiconductor/solid-state device manufacturingAmorphous siliconIon implantation

A process for fabricating a thin film transistor, which comprises crystallizing an amorphous silicon film, forming thereon a gate insulating film and a gate electrode, implanting impurities in a self-aligned manner, adhering a coating containing a catalyst element which accelerates the crystallization of the silicon film, and annealing the resulting structure at a temperature lower than the deformation temperature of the substrate to activate the doped impurities. Otherwise, the catalyst element can be incorporated into the structure by introducing it into the impurity region by means of ion implantation and the like. Also a process for fabricating a thin film transistor, which comprises forming a gate electrode, a gate insulating film, and an amorphous silicon film on a substrate, implanting impurities into the amorphous silicon film to form source and drain regions as the impurity regions, introducing a catalyst element into the impurity region by adhering a coating containing the catalyst element of by means of ion doping and the like, and annealing the resulting structure at a temperature lower than the deformation temperature of the substrate to activate the doped impurities.

Owner:SEMICON ENERGY LAB CO LTD

Carbon elimination process for non-oriented silicon steel production

The invention discloses a decarbonization process for producing non-oriented silicon steel. The method adopts a water-based quantified decarbonization hood type bright annealing furnace. 20 to 30 percent of hydrogen gas and 70 to 80 percent of nitrogen gas enter the furnace through a warm water humidifier together with water vapor. The ratio of the water vapor differential pressure to the hydrogen gas differential pressure in the furnace is kept 0.2 to 0.5; and multistage heating is carried out so as to reach the temperature of 800 to 850 DEG C. In the weakly oxidizing atmosphere, the water vapor is used for quick decarbonization; and the decarbonization time is controlled between 12 and 15 hours. The decarbonization process for producing the non-oriented silicon steel has good effects and high efficiency, and can remarkably improve the product quality.

Owner:新万鑫(福建)精密薄板有限公司

Aluminum alloy substrate for high-cap bottle cap and production method thereof

The invention discloses an aluminum alloy substrate for a high-cap bottle cap. The aluminum alloy substrate comprises, by weight, 0.4 percent to 0.8 percent of Si, 0.6 percent to 0.9 percent of Fe, 0.02 percent to 0.04 percent of Cu, no larger than 0.1 percent of Mn, no larger than 0.05 percent of Mg, no larger than 0.1 percent of Zn, no larger than 0.05 percent of Cr, 0.01 percent to 0.03 percent of Ti, no larger than 0.15 percent of impurities and the balance Al. The invention further discloses a production method of the aluminum alloy substrate for the high-cap bottle cap. The production procedure comprises batching, casting, homogenization treatment, hot continuous rolling, cold rolling, heat treatment, cold rolling, stretching bending and straightening and cropping. In the procedure of homogenization treatment, the temperature of homogenization treatment is 550 DEG C to 600 DEGC, and heat preservation time is 6 h to 10 h; in the procedure of cold rolling, cold rolling is carried out on blanks obtained through the hot continuous rolling procedure till the blanks are 0.4 mm to 0.5 mm, then heat treatment is carried out, the temperature of heat treatment ranges from 300 DEG C to 330 DEG C, heat preservation time ranges from 5 h to 9 h, and discharging cooling is carried out. Finally, cold rolling is carried out the blanks till the designed thickness is achieved.

Owner:CHINALCO SWA COLD ROLLING

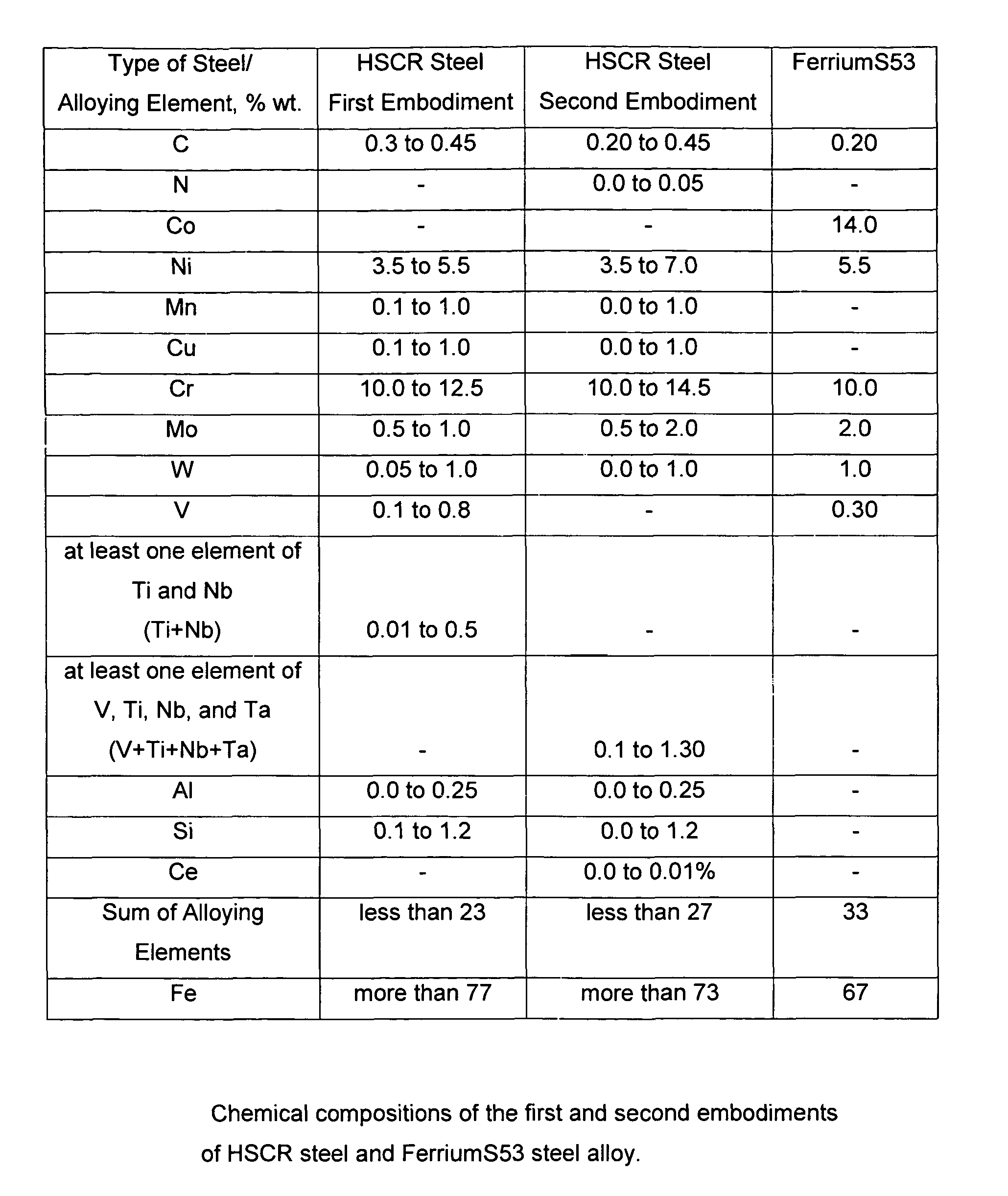

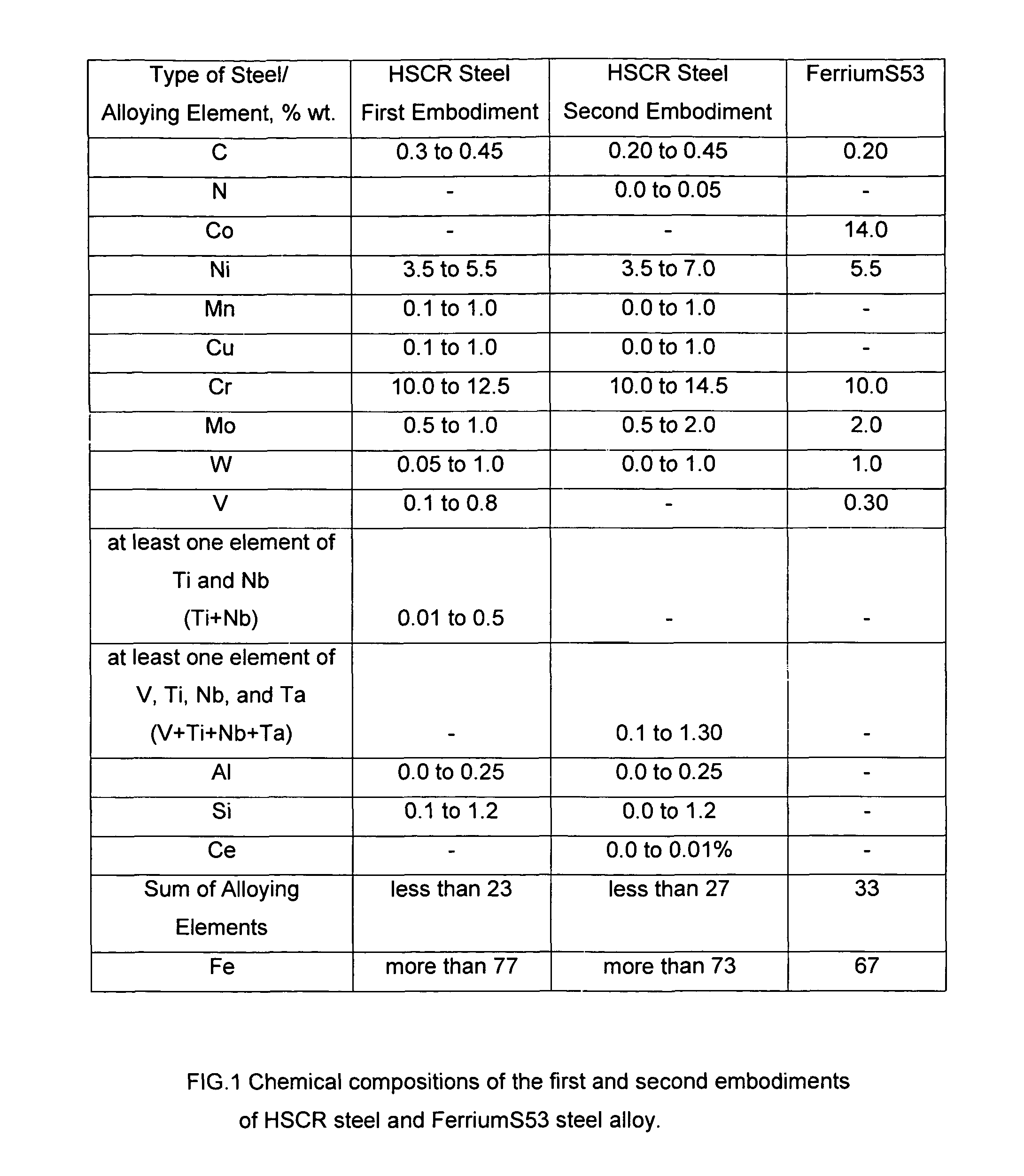

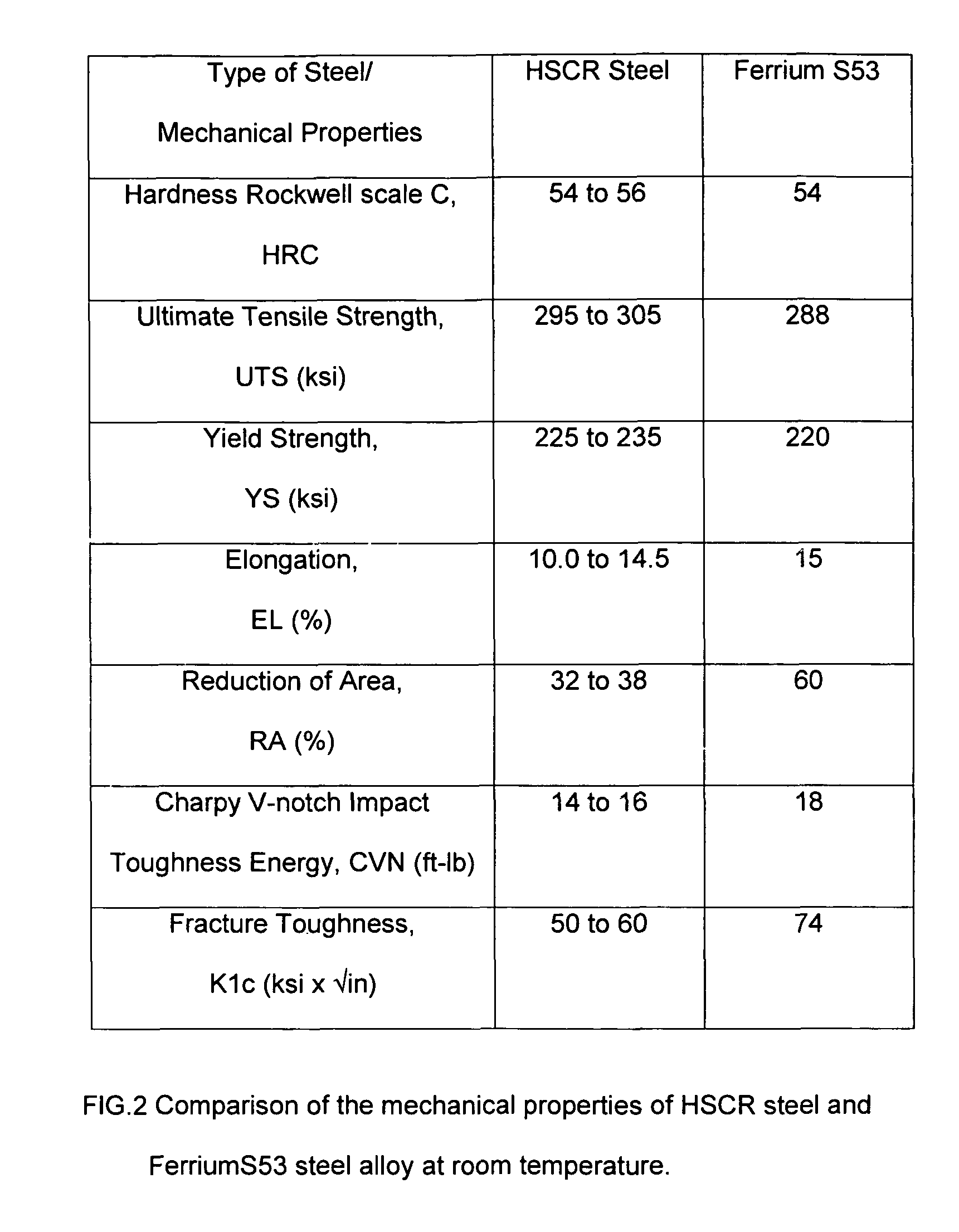

High strength corrosion resistant steel

ActiveUS8361247B2High strengthImprove corrosion resistanceFurnace typesHeat treatment furnacesSalt spray testAircraft landing

A quenched and tempered high strength, corrosion resistant steel suitable for aircraft landing gears and structures, having a unique combination of mechanical and corrosion resistant properties: ultimate tensile strength of 295 to 305 ksi, yield strength of 225 to 235 ksi; elongation of 12 to 13.5%, reduction of area of 34 to 36%, Charpy v-notch impact toughness energy of about 14 to 16 ft-lb, fracture toughness of 55 to 60 ksiVin, and corrosion resistance in salt spray test.

Owner:VARTANOV GREGORY

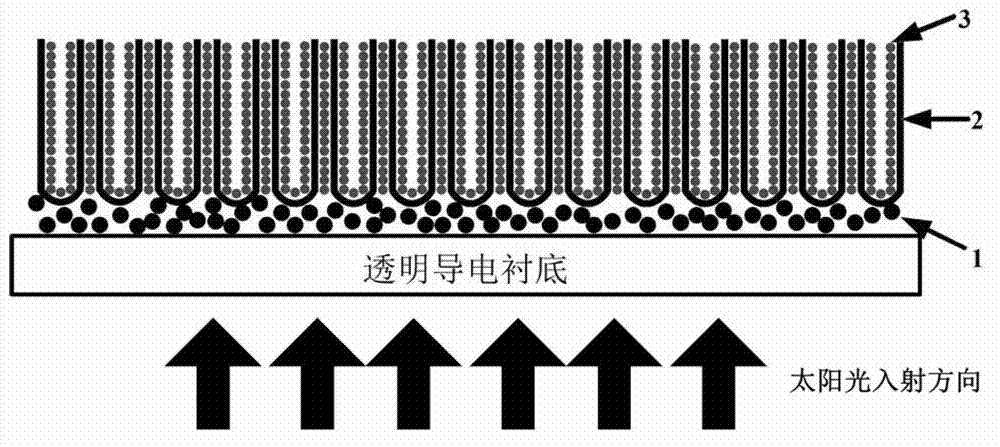

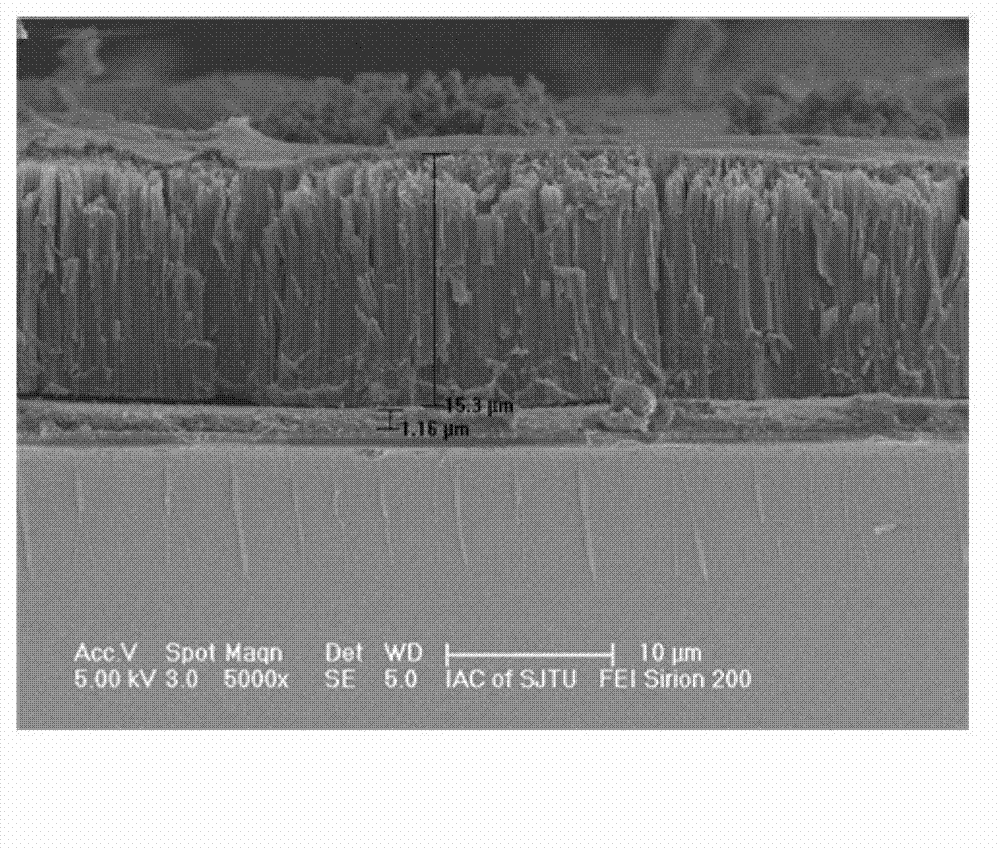

Method for preparing transparent electrode based on titanium dioxide nanotubes

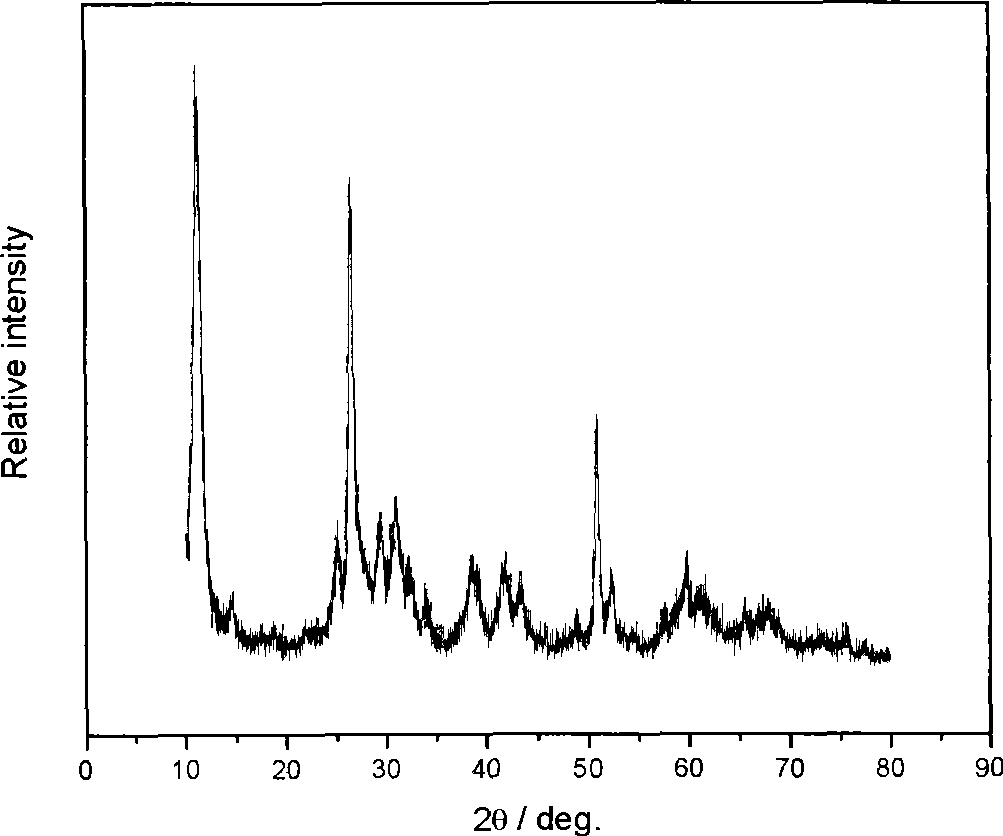

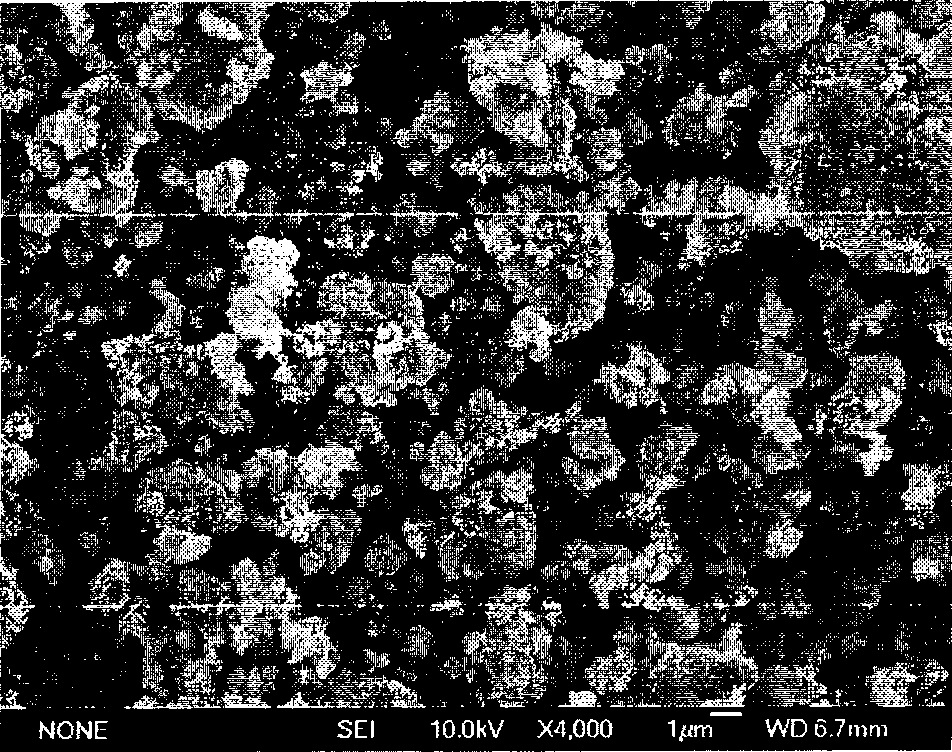

ActiveCN102881455AQuality improvementClosely connectedLight-sensitive devicesCapacitor electrodesCrystallinityNanotube

The invention discloses a method for preparing a transparent electrode based on titanium dioxide nanotubes. The method comprises the following steps of: peeling titanium dioxide nanotube films in different thicknesses off a titanium metal base by using an anodic reoxidation method to improve the quality and crystallinity of the titanium dioxide nanotube films; and adhering the titanium dioxide nanotube films to different transparent conductive substrates to form a single-layer or multi-layer transparent electrode based on the titanium dioxide nanotubes. The quality and the crystallinity are high, the method for preparing the single-layer or multi-layer transparent electrode based on the titanium dioxide nanotubes has the characteristics of simplicity, reliability and high flexibility, and the titanium dioxide nanotubes are easily applied to different fields such as dye-sensitized solar cells.

Owner:SHANGHAI JIAO TONG UNIV

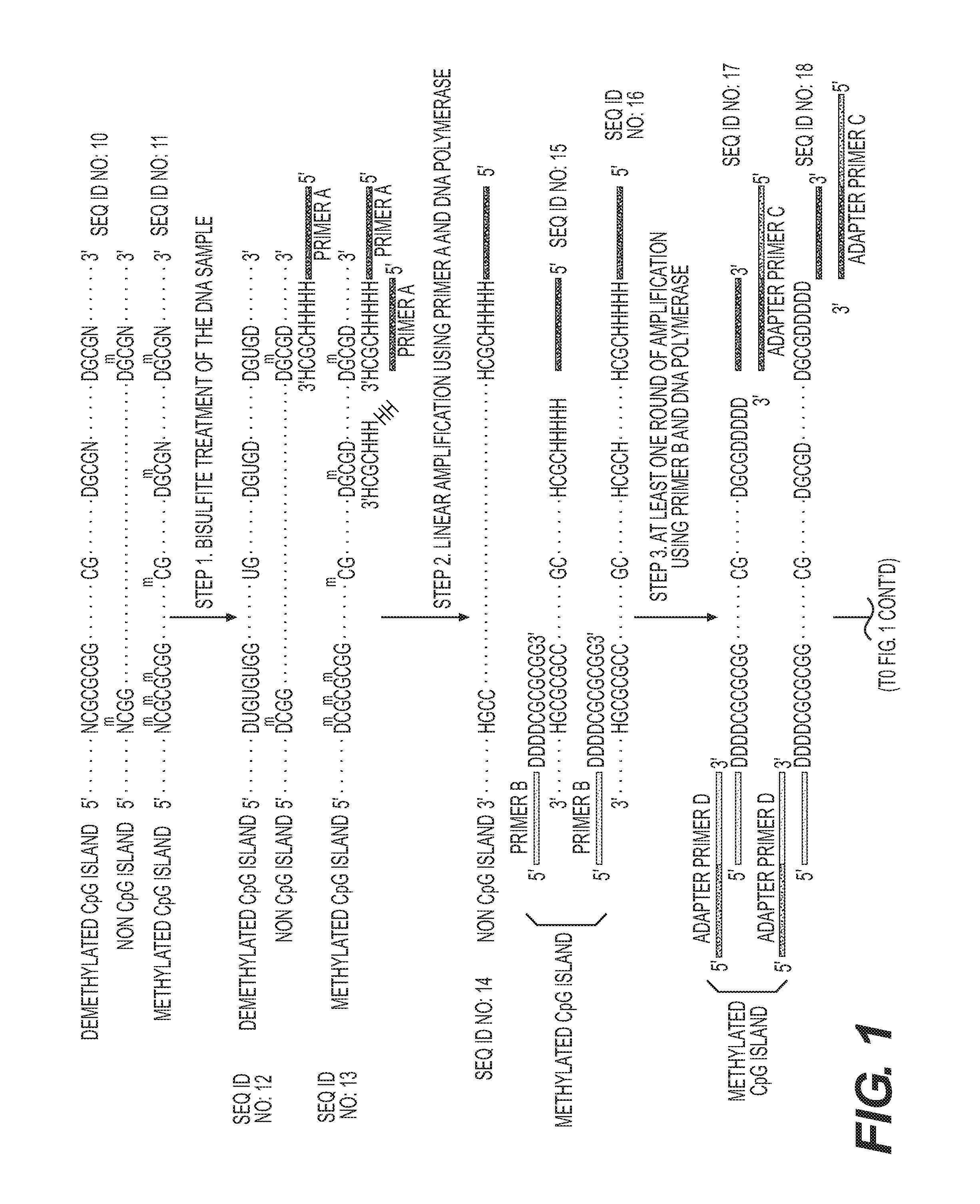

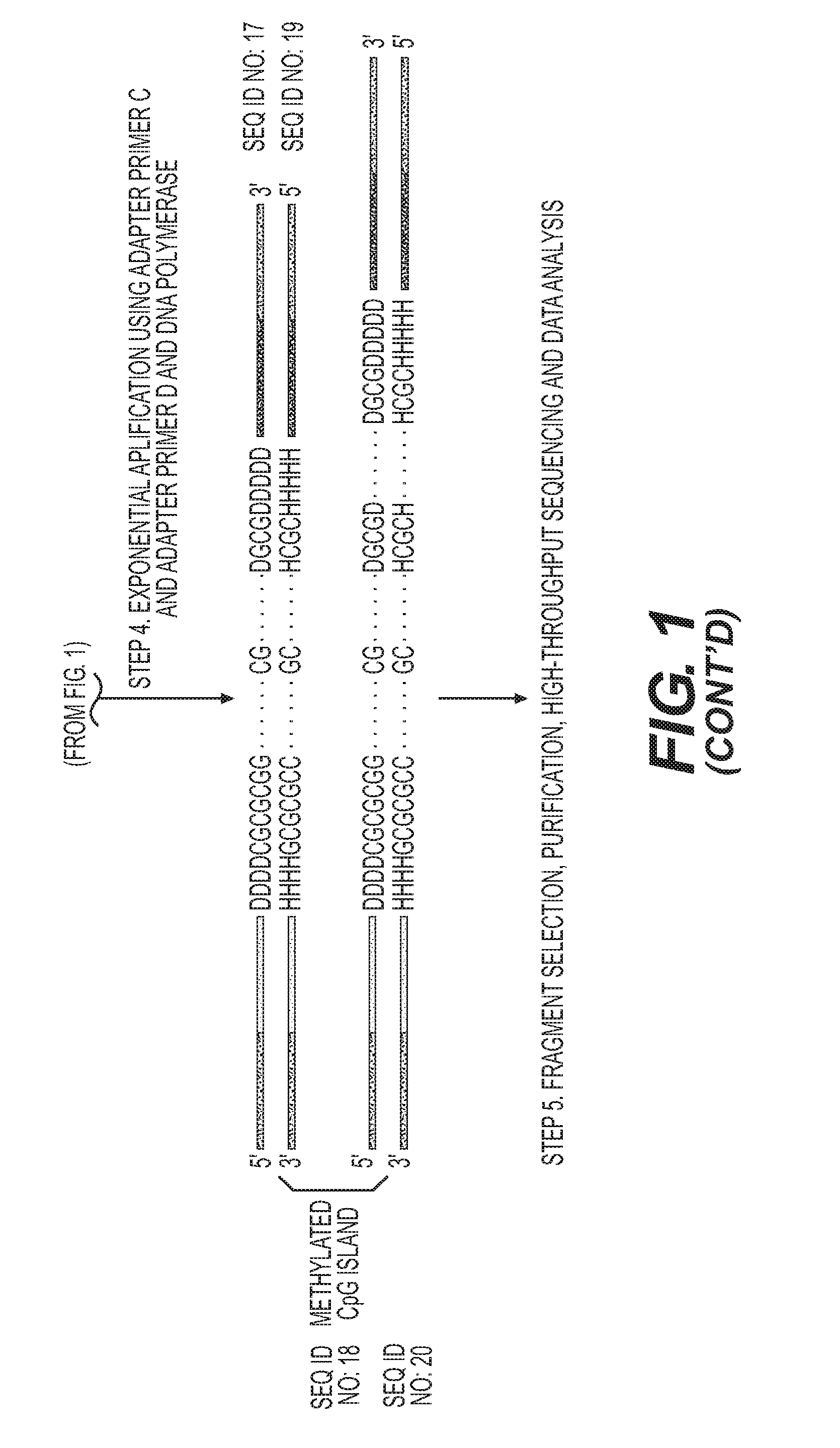

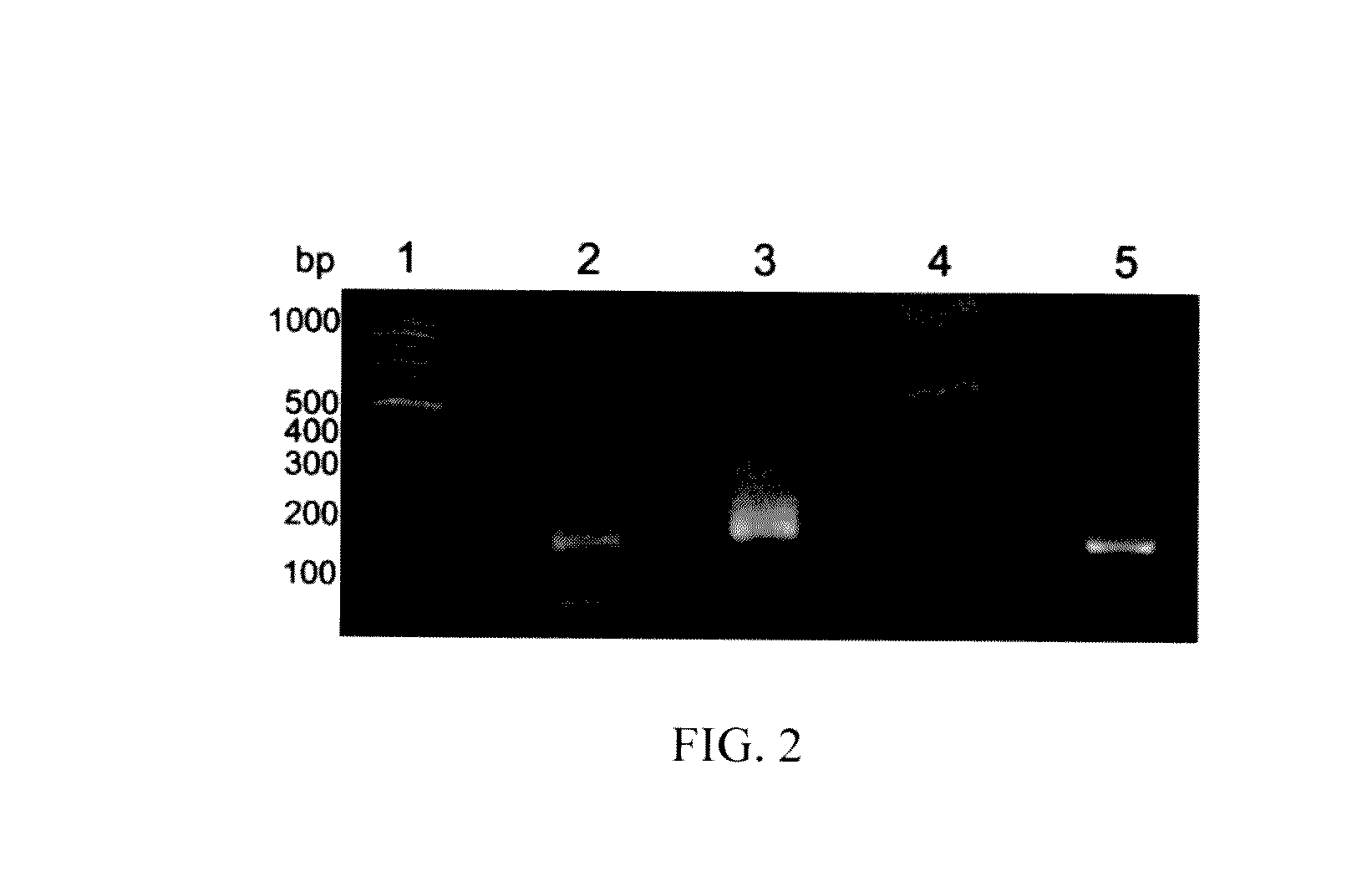

High-throughput sequencing detection method for methylated cpg islands

ActiveUS20160298183A1Efficient enrichmentCost-effectiveMicrobiological testing/measurementDna polymerasenA-DNA

A high-throughput sequencing method for detecting methylated CpG islands includes: processing a DNA sample by using a modifier, and converting cytosine in the DNA sample into uracil, and keeping 5′methylcytosine unchanged; amplifying the obtained segment by using a primer A and DNA polymerase, to obtain a segment having one end being capable of anchoring a junction primer C; amplifying the obtained segment by using a primer B and DNA polymerase, to obtain a segment gathering methylated CpG islands and having two ends being capable of separately anchoring junction primers C and D; amplifying the obtained segment at a PCR exponent by using the junction primers C and D and the DNA polymerase, to obtain the amplified product; and separating and purifying the amplified product, to form a high-throughput sequencing library and perform computer sequencing, and data analysis.

Owner:PEKING UNIV

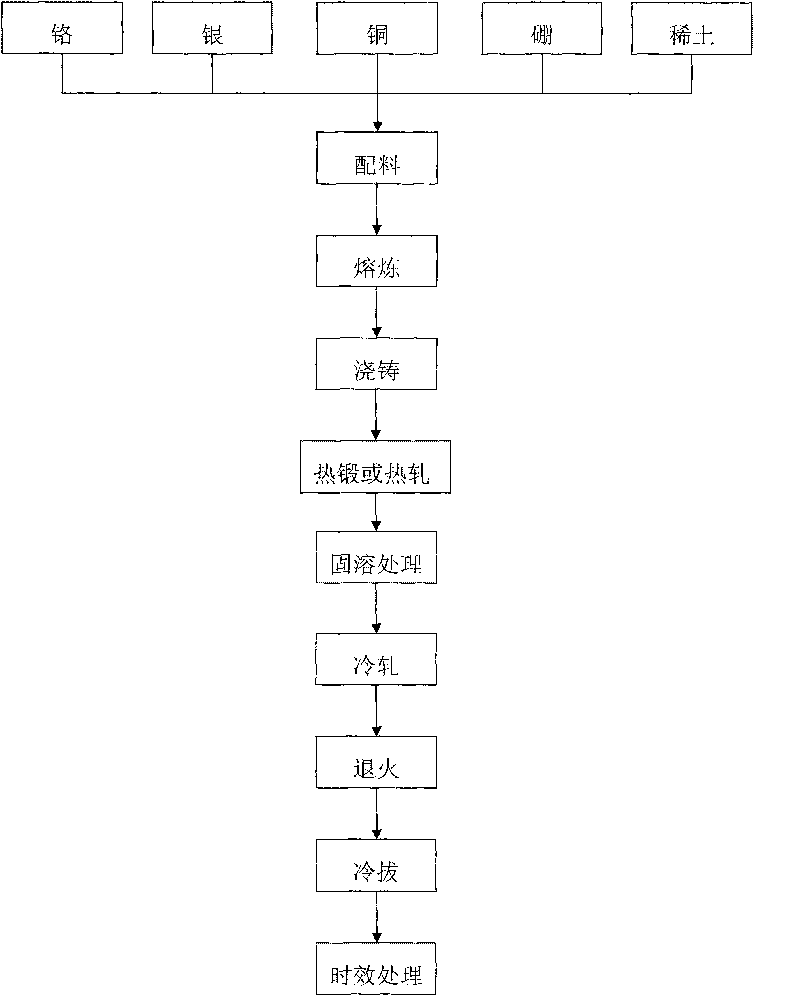

Cu-Cr in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Cr in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Cr and trace Ag and B, rare earth or rare earth compounds to prepare the high performance copper alloy in-situ composite through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing industrial application in the aspects such as electrician switches, contact materials, resistance electrodes, rotor conductors of large electrical high speed turbine generators, overhead conductors of electric cars and electric trains, lead frames of very large scale integrated circuits and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

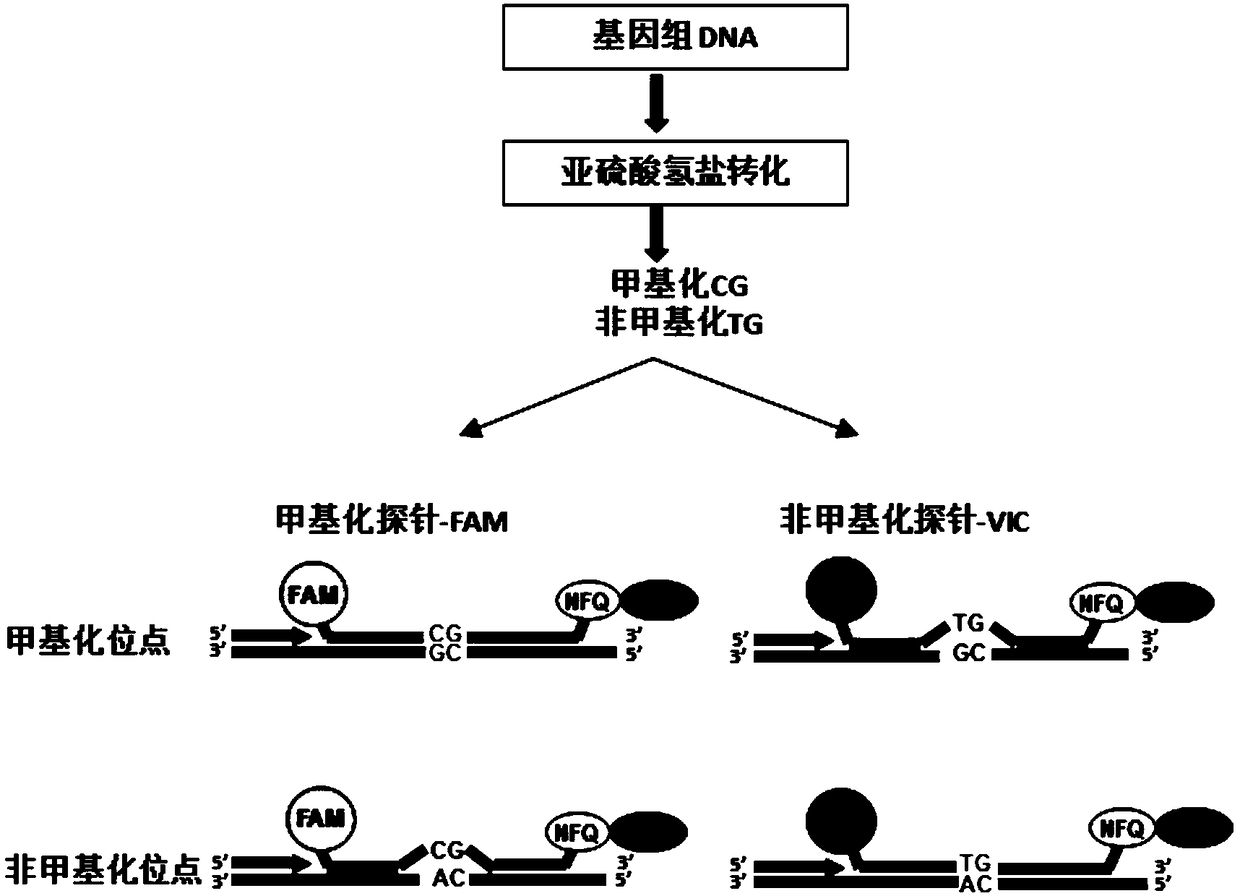

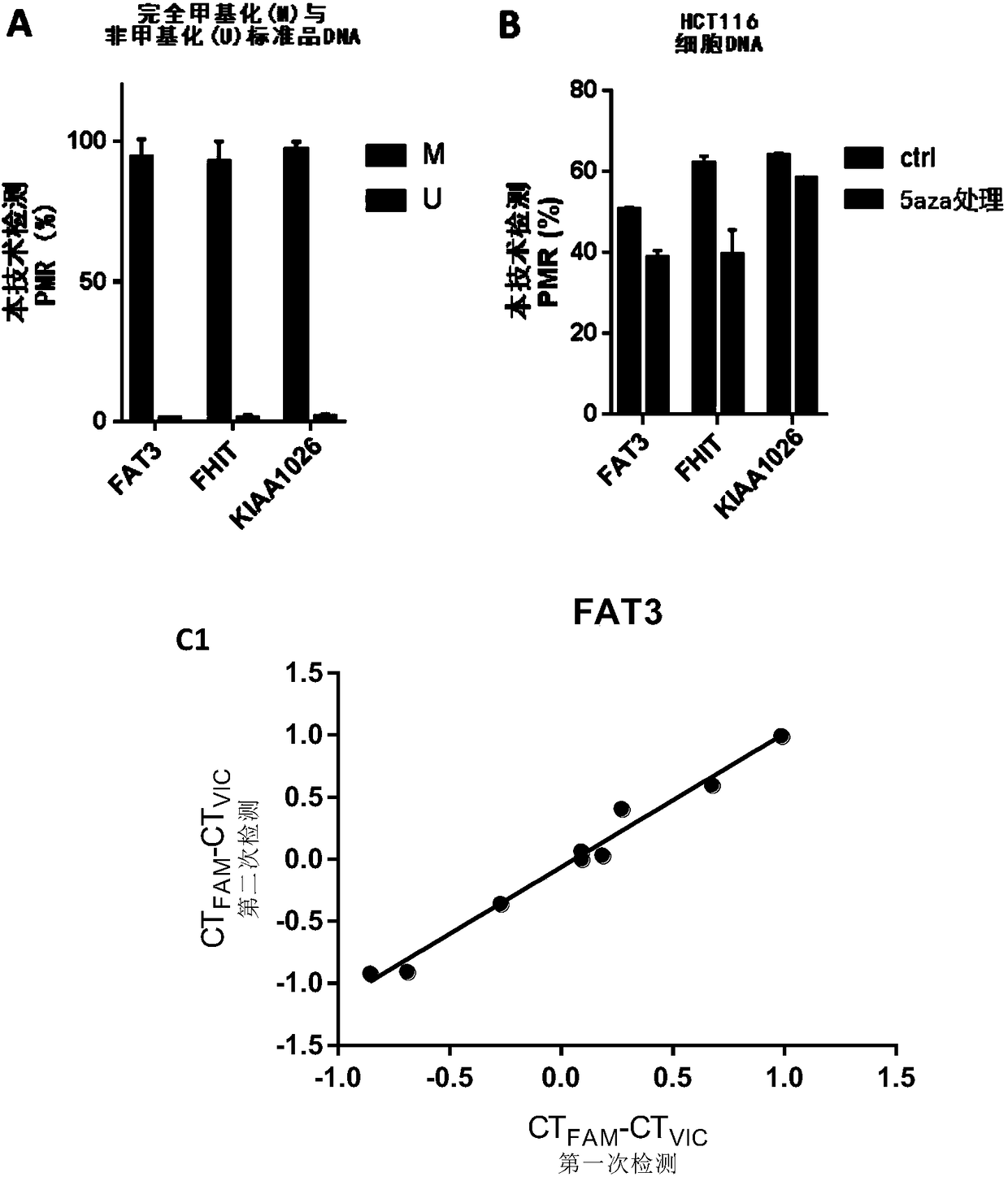

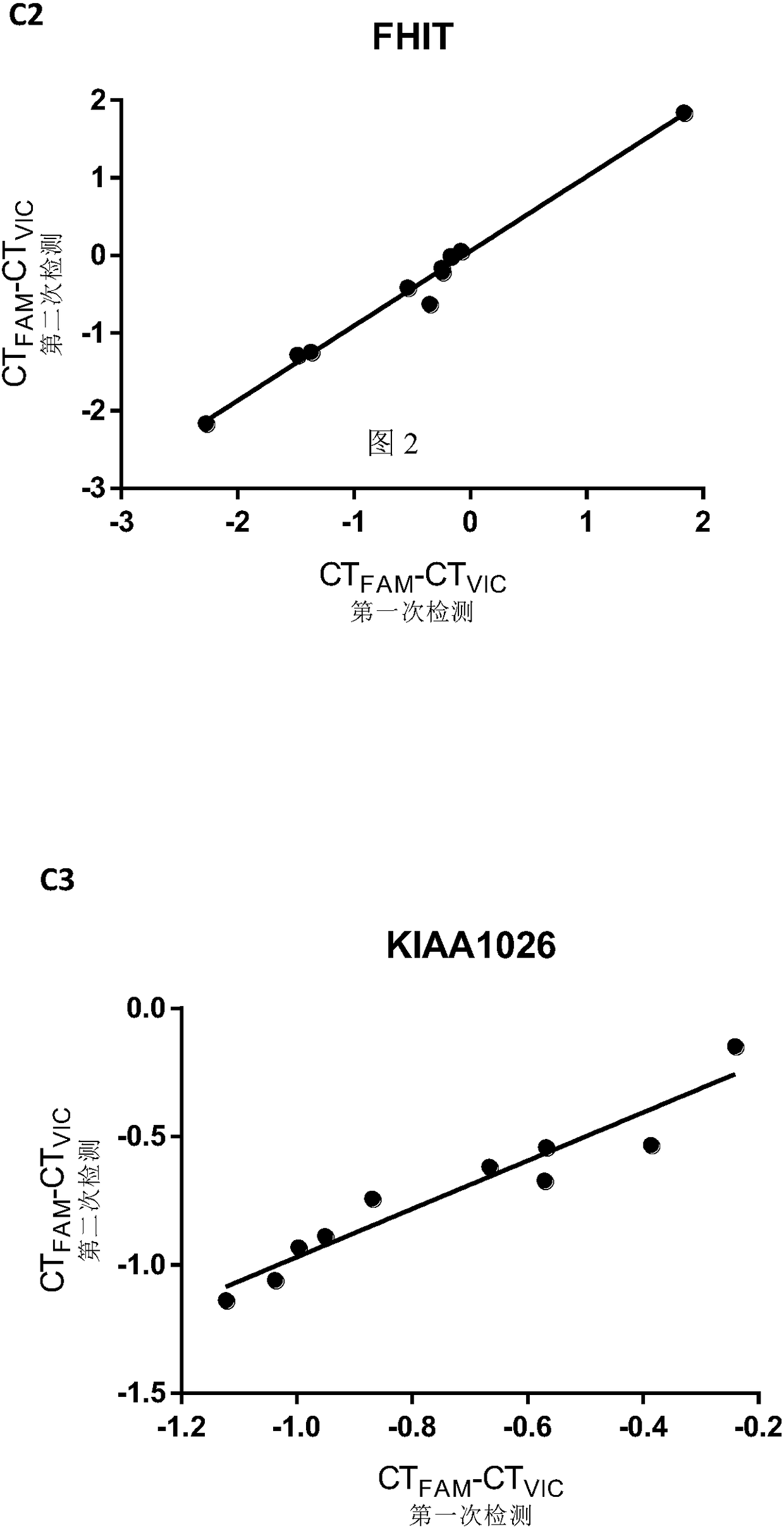

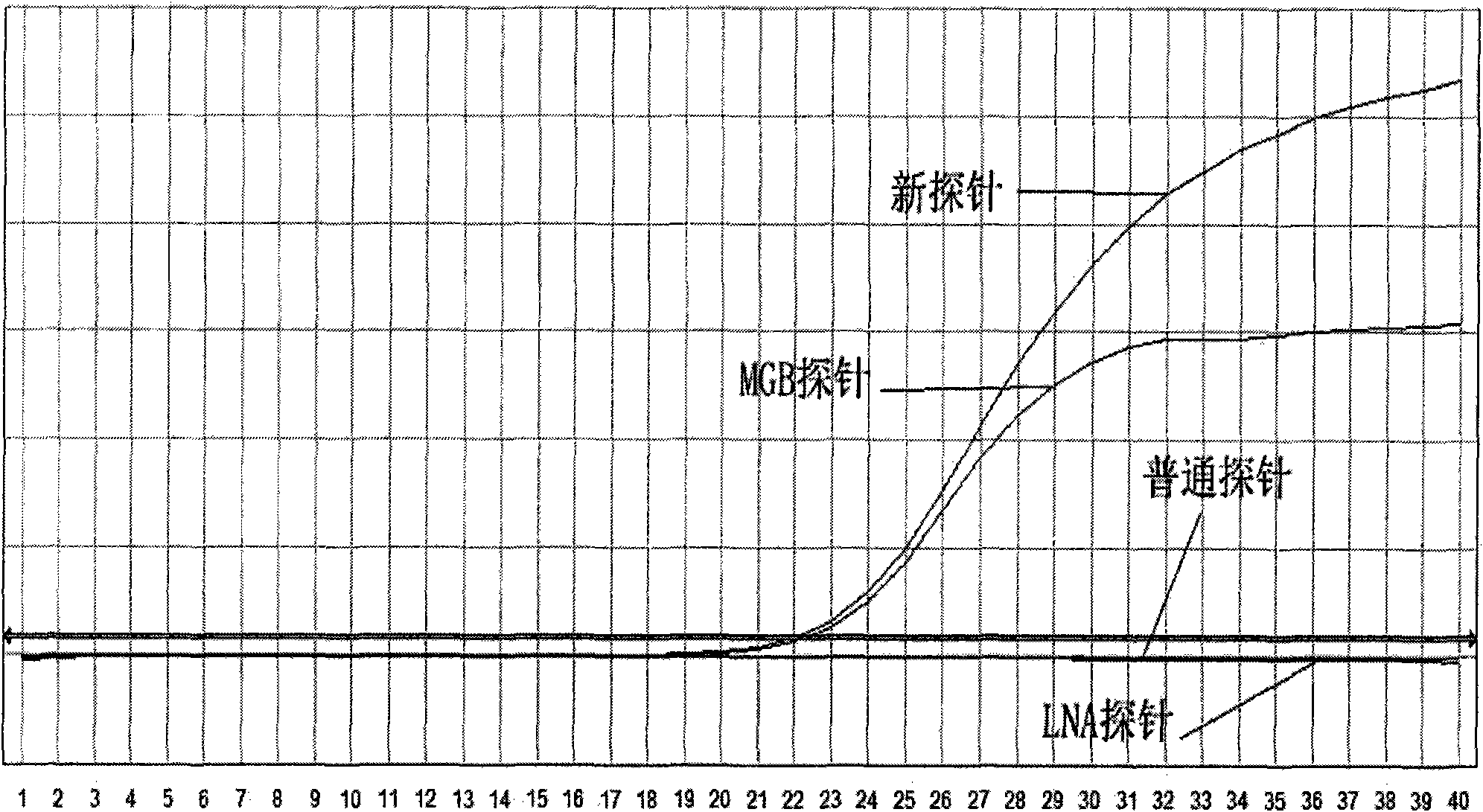

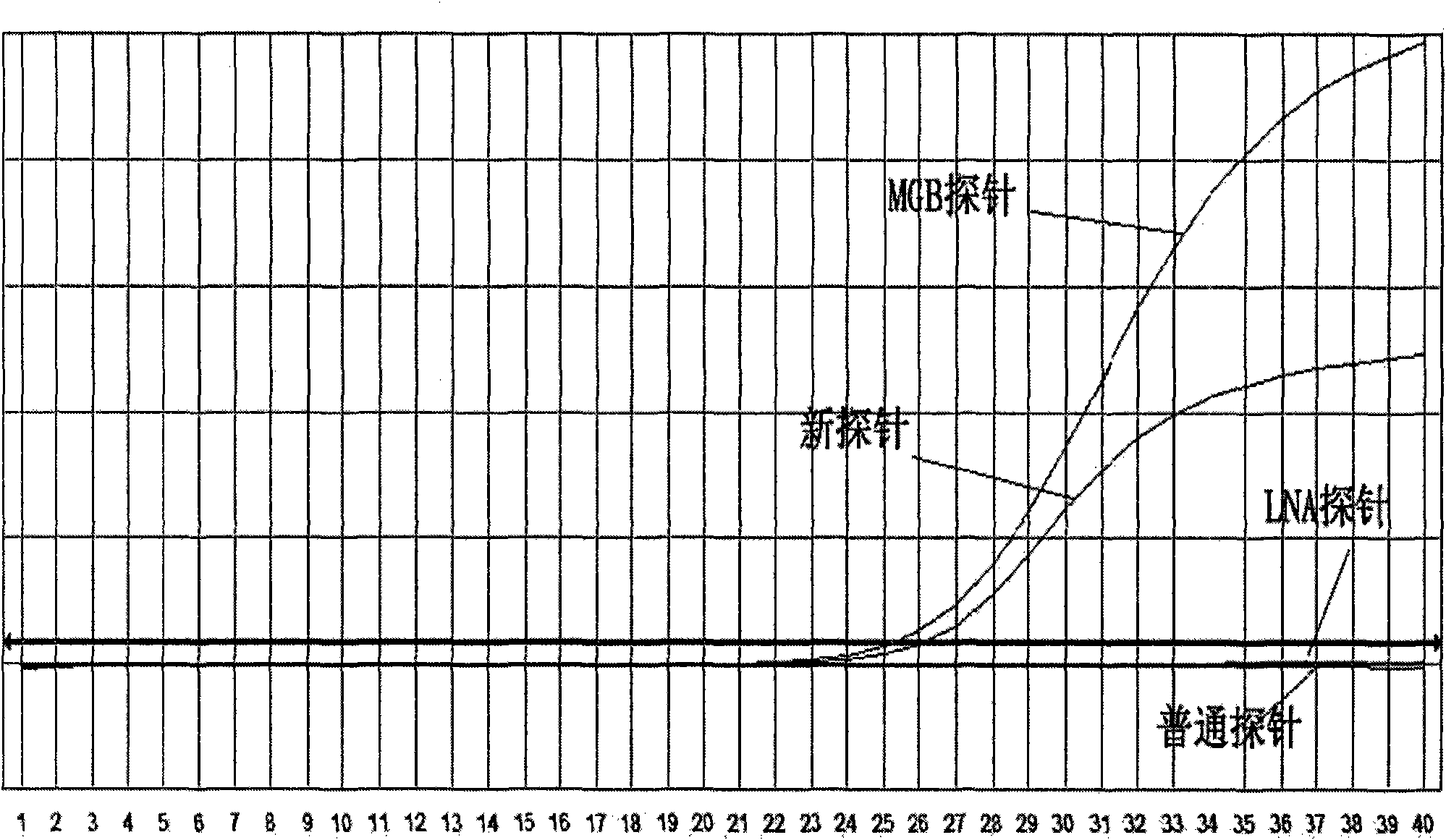

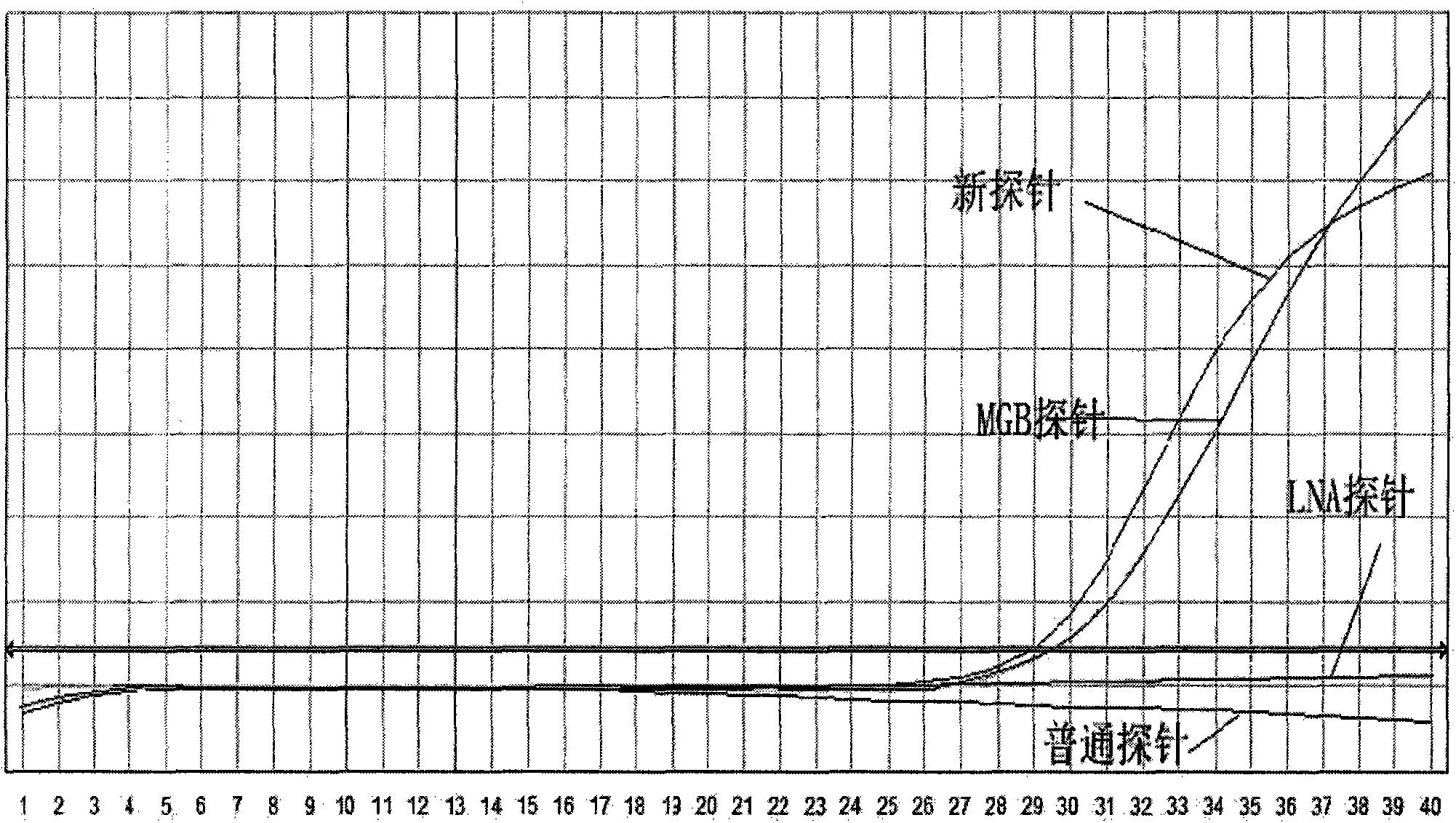

Detection kit and method for DNA methylation

InactiveCN109385464AEfficient detectionRaise the annealing temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsCpG siteOpen sea

The invention relates to a detection kit and method for DNA methylation, especially to a detection kit and method for DNA methylation without CpG sites at flanking sequences. The kit and method employa Taqman probe binding to a minor groove binder (MGB) and can determine the methylation of both a CpG island (CGI) and isolated CpG sites in CpG open sea and the like without CpG at two flanking sequences. The kit and method provided by the invention are specific and sensitive, simple to operate, and does not require a control reaction or a fully-methylated standard DNA substance as a reference,thereby overcoming defects resulting from the control reaction and the fully-methylated standard DNA substance. In addition, the kit and method have higher repeatability and accuracy than the existingMethyLight technology.

Owner:THE SIXTH AFFILIATED HOSPITAL OF SUN YAT SEN UNIV +1

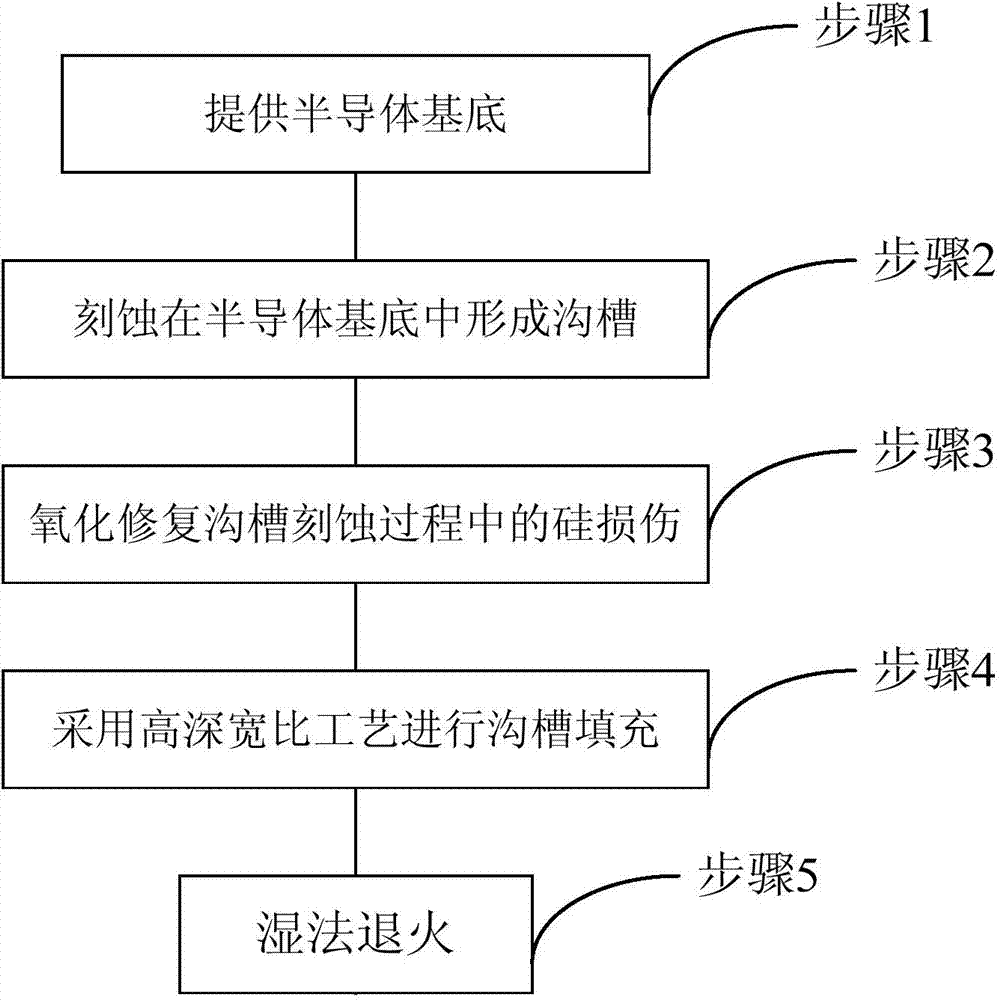

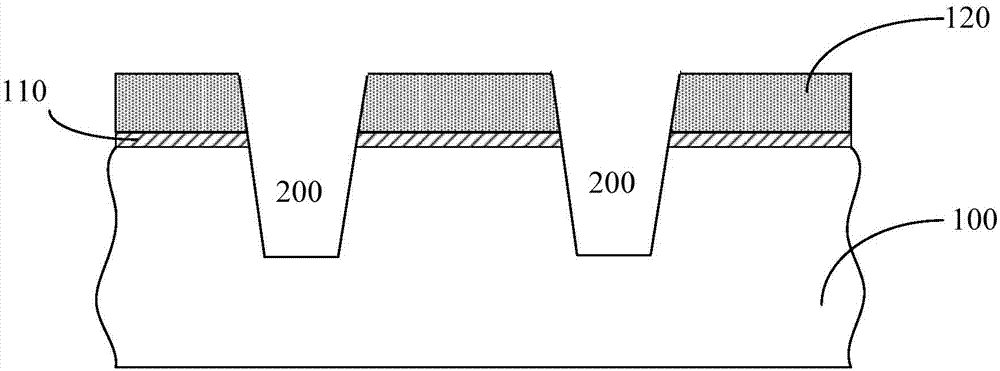

Preparation method of STI (shallow trench isolation) structure

InactiveCN103531523AFully filledStop the spreadSemiconductor/solid-state device manufacturingWater vaporOxygen

The invention relates to the technical field of semiconductors and discloses a preparation method of an STI structure. The preparation method comprises the steps as follows: providing a semiconductor substrate covered with a silicon dioxide layer on the surface; forming a trench in the semiconductor substrate by etching; forming a silicon dioxide film covering the surface of the trench by oxidizing the bottom and side walls of the trench; forming a linear silicon nitride layer on the structure surface of the trench; forming a linear silicon dioxide layer on the surface of the linear silicon nitride layer; depositing a silicon dioxide filling layer and filling the trench; and annealing. Compared with the prior art, the preparation method has the advantages that the compact and stable silicon dioxide layer is introduced, so that the diffusion of water vapor or oxygen molecules can be stopped, and the silicon loss caused by high-temperature wet annealing is effectively prevented; and meanwhile, the annealing temperature can also be increased due to introduction of the silicon nitride layer, so that filling gaps in a high aspect ratio process can be improved, and the high-quality STI structure can be obtained.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

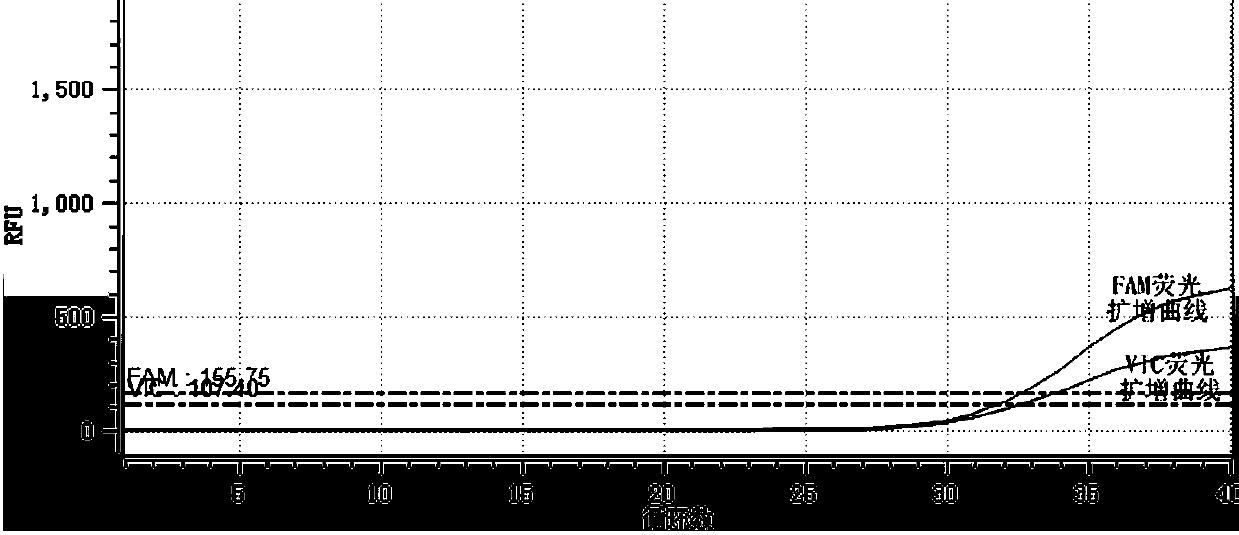

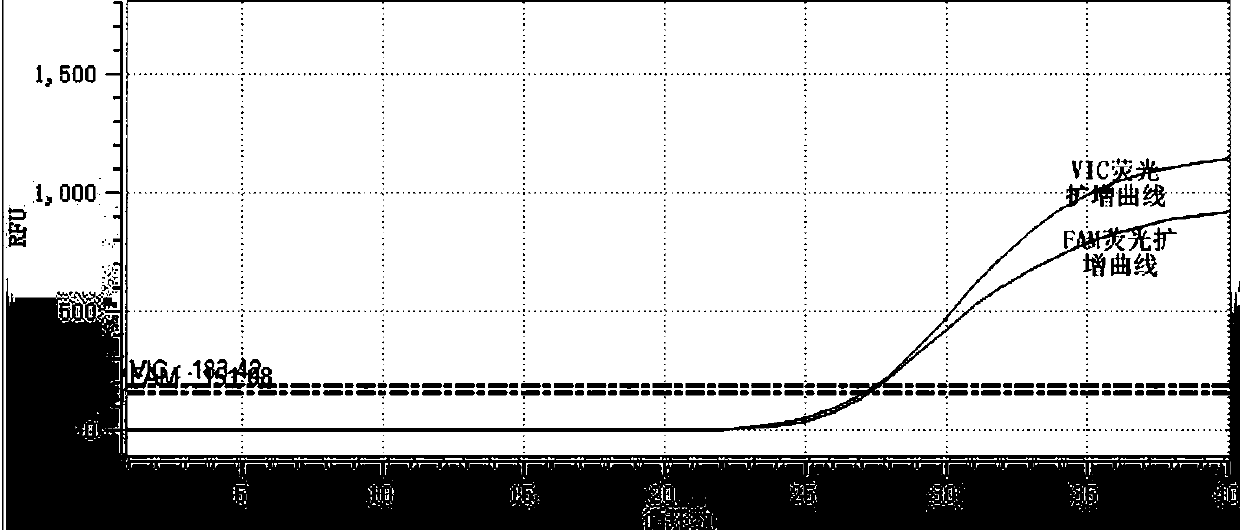

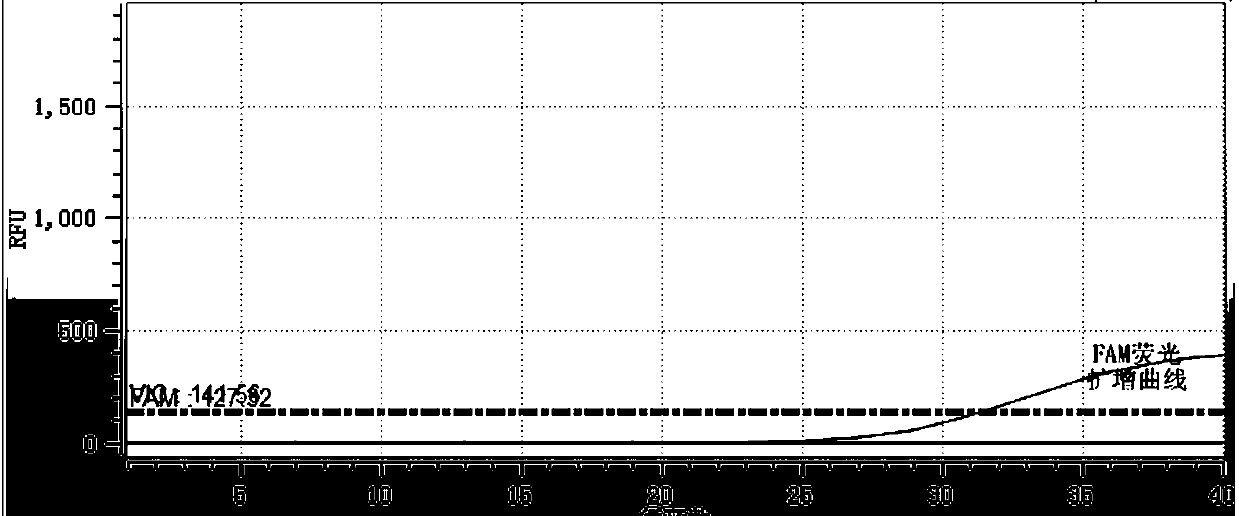

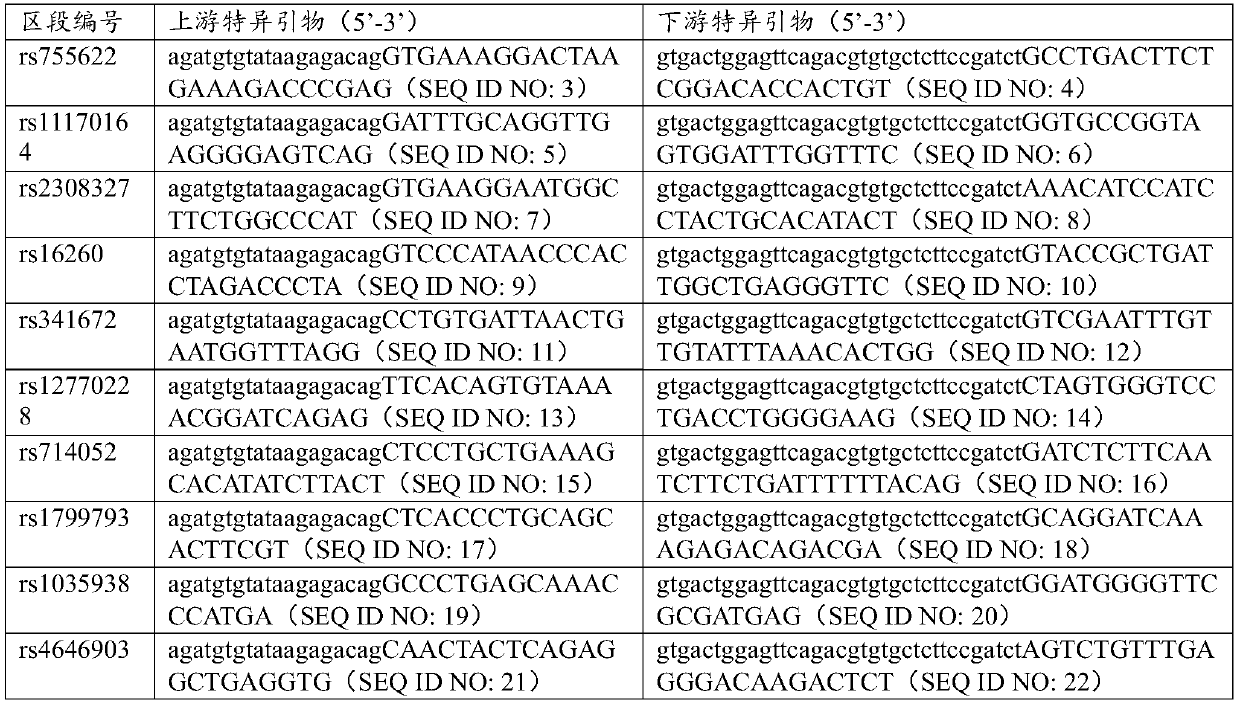

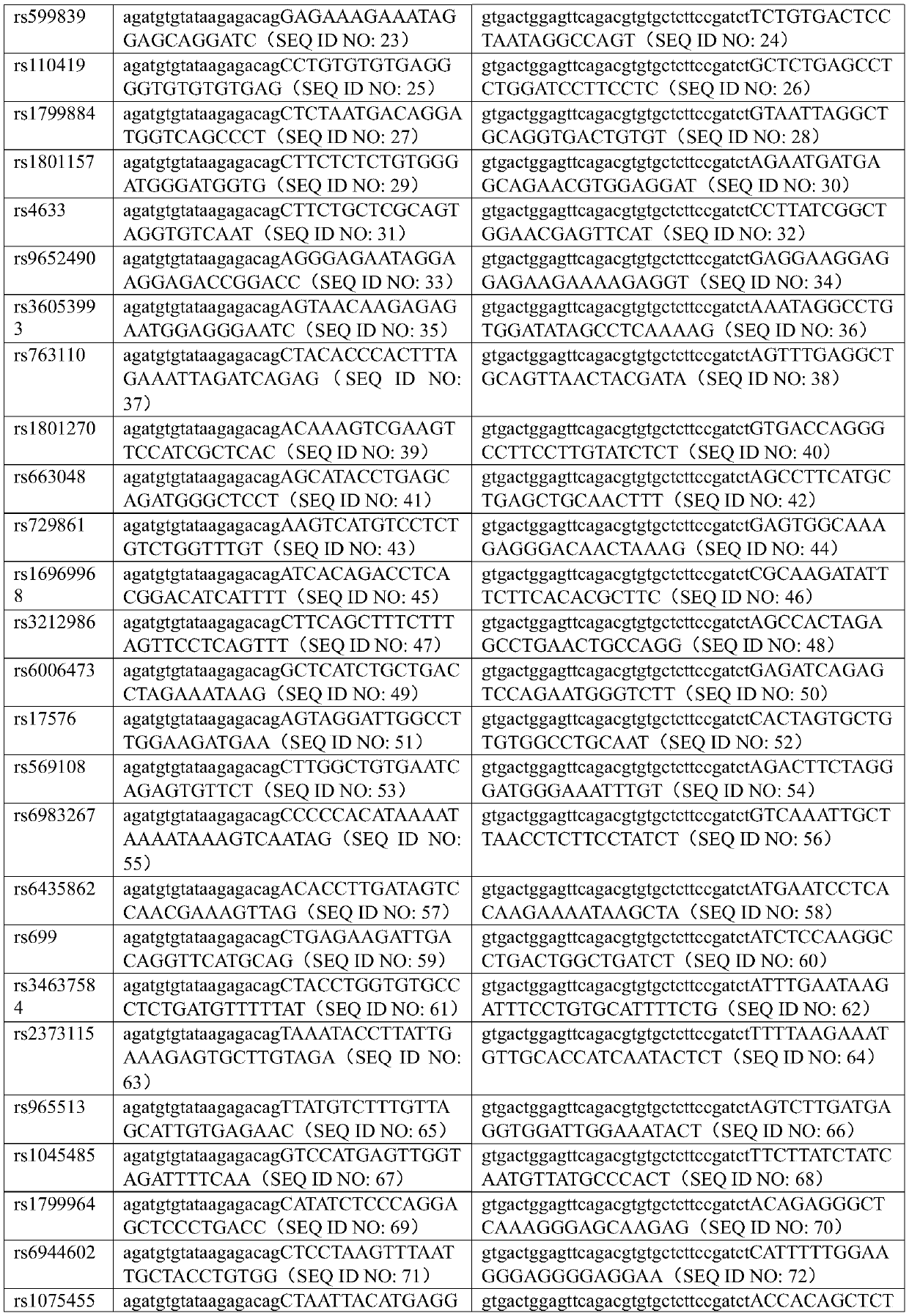

Kit for detecting CYP3A4 and CYP3A5 polymorphic sites and method thereof

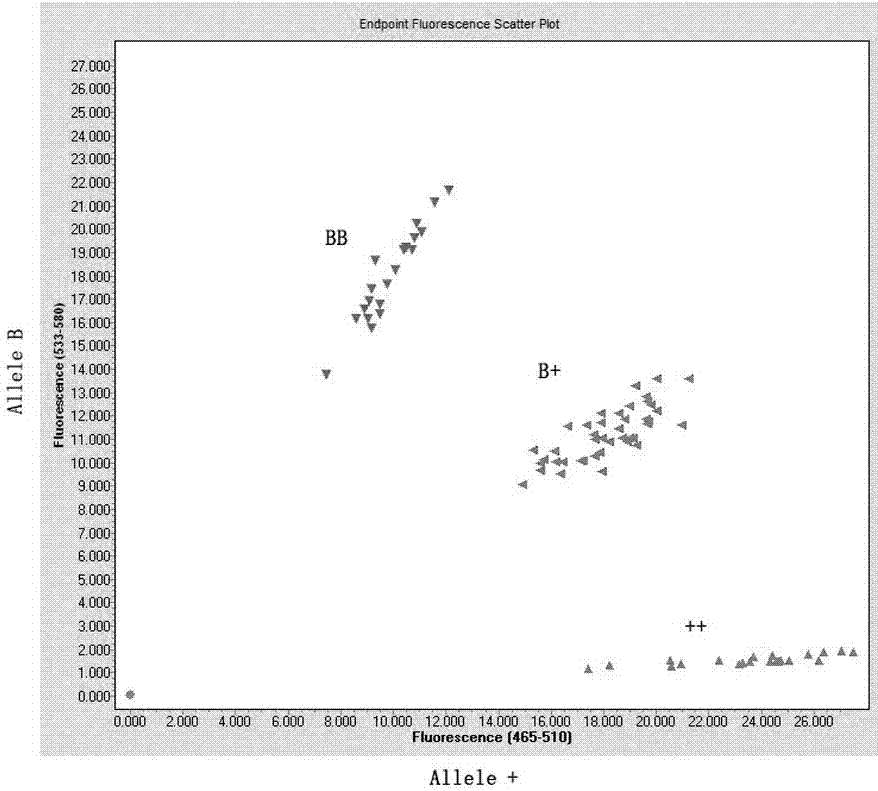

ActiveCN108410961AIncrease the Tm valueRaise the annealing temperatureMicrobiological testing/measurementDNA/RNA fragmentationFluorescenceRepeatability

The invention discloses a kit for detecting CYP3A4 and CYP3A5 polymorphic sites and a method thereof. The kit comprises specificity upstream and downstream primer sequences of CYP3A4*1G shown in sequences 1-4 in a sequence table, specificity TaqMan-MGB bi-fluorescence probe sequences of CYP3A4*1G shown in sequences 5-8, specificity upstream and downstream primer sequences of CYP3A5*3 shown in sequences 9-12 and specificity TaqMan-MGB bi-fluorescence probe sequences of CYP3A5*3 shown in sequences 13-16. The kit has the advantages that the specificity is high, pollution is prevented, the sensitivity is high, the detection speed is high, result analysis is simple, and the accuracy is high; the kit can judge the metabolism capacity of to-be-detected objects to fentanyl medicine by detecting polymorphic sites of CYP3A4 and CYP3A5 genes, the using amount of medicine such as fentanyl can be more accurately and effectively guided accordingly, and the kit has the actual clinical application value. The kit is applied to clinical diagnosis, the fit degree between the kit and the prior art is higher, the cost is low, and repeatability is high.

Owner:浙江鼎创医疗科技有限公司

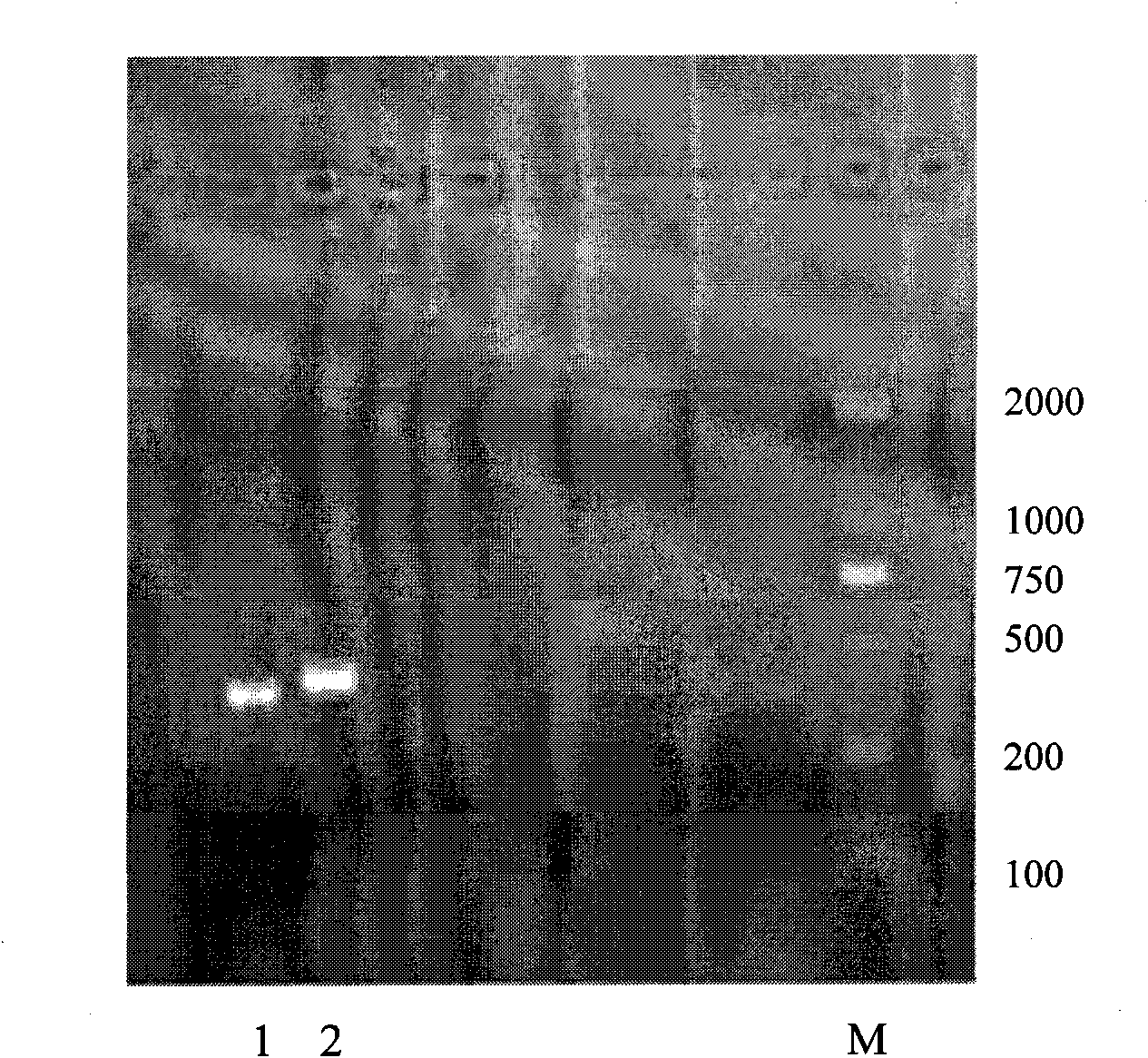

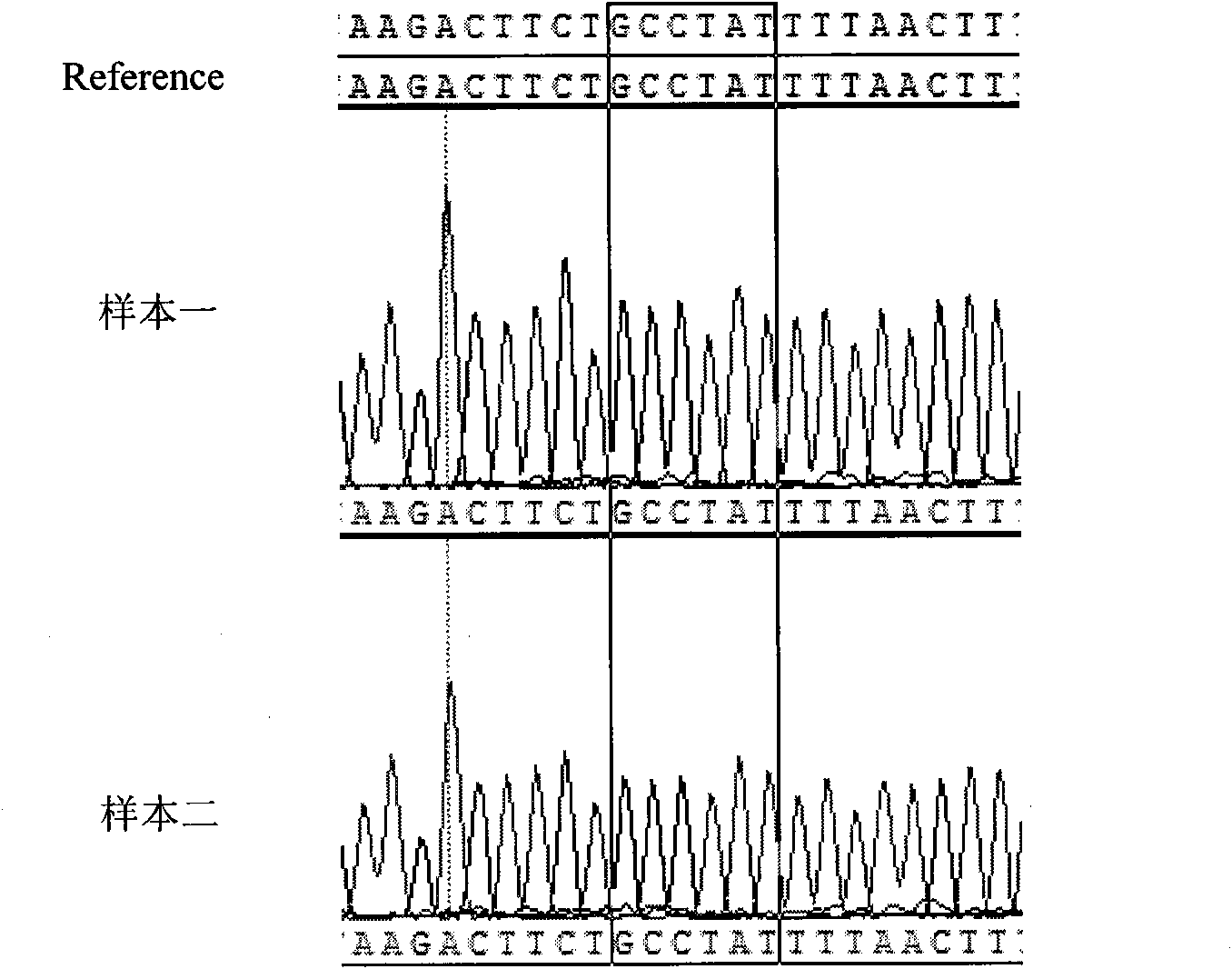

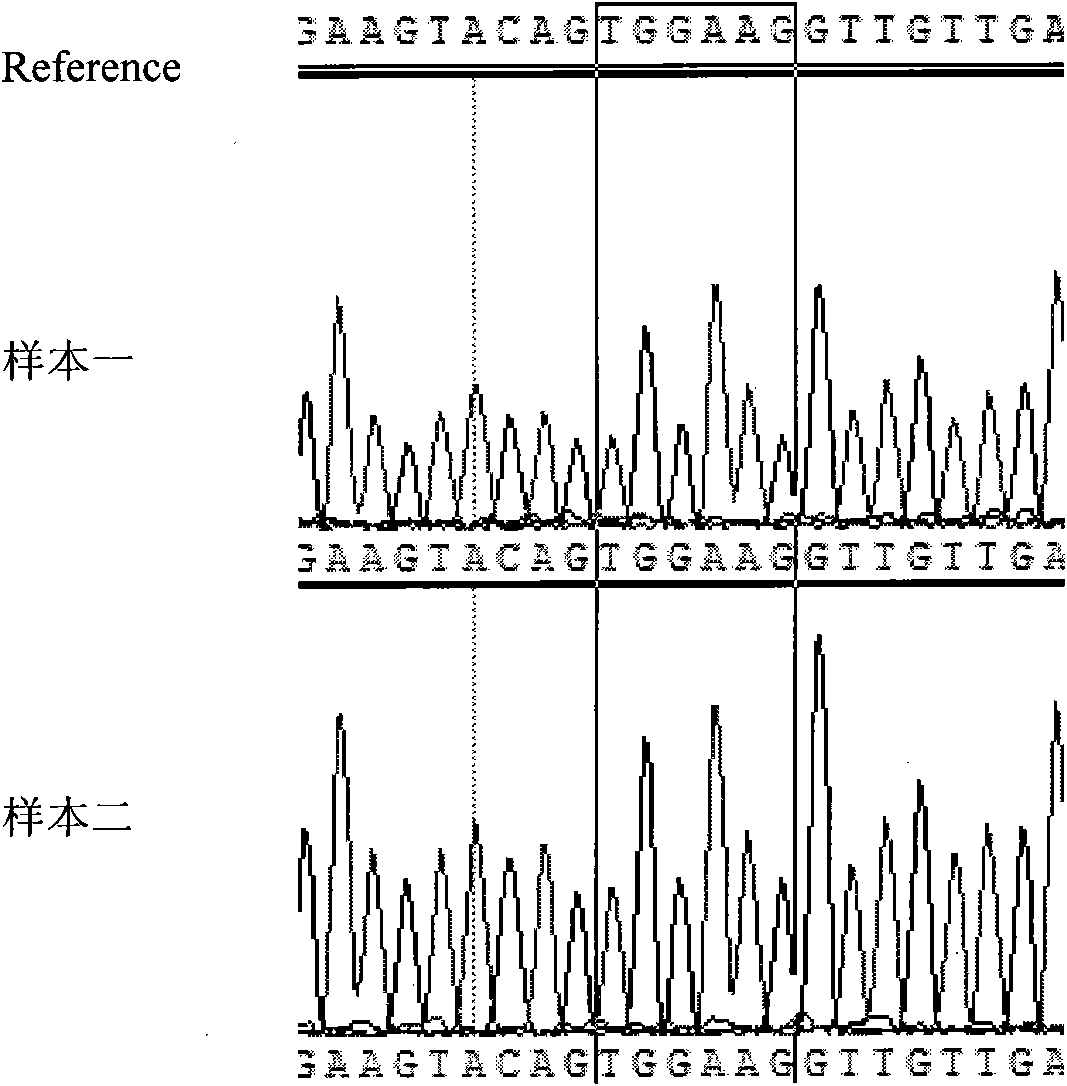

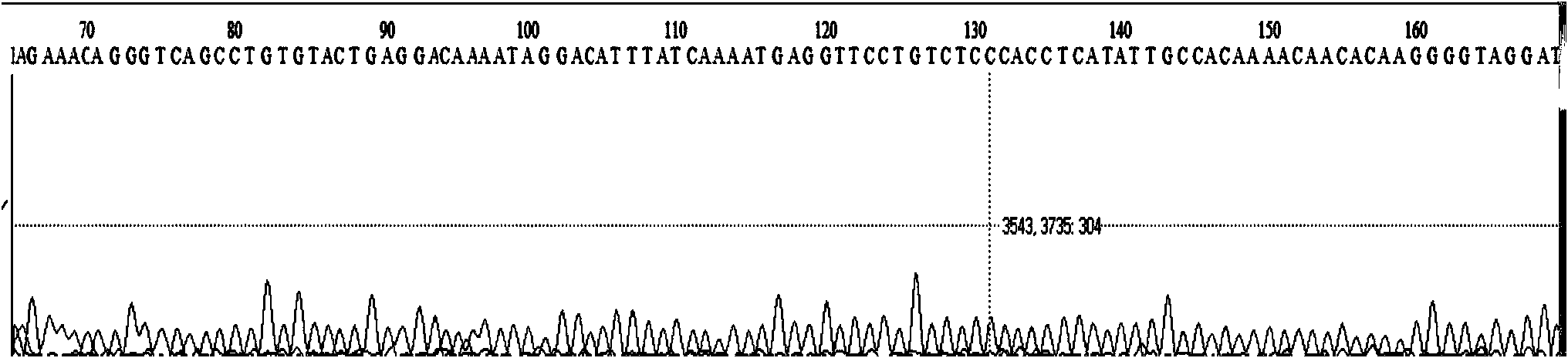

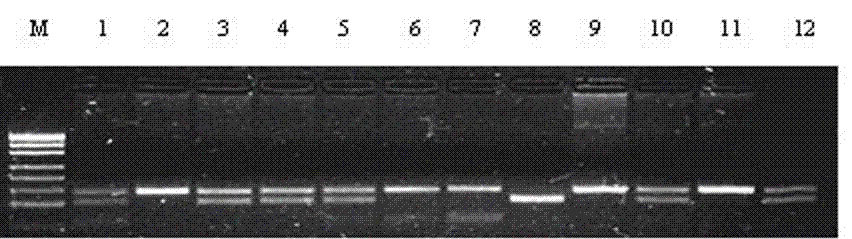

Primer used for detecting c-kit gene mutation and application thereof

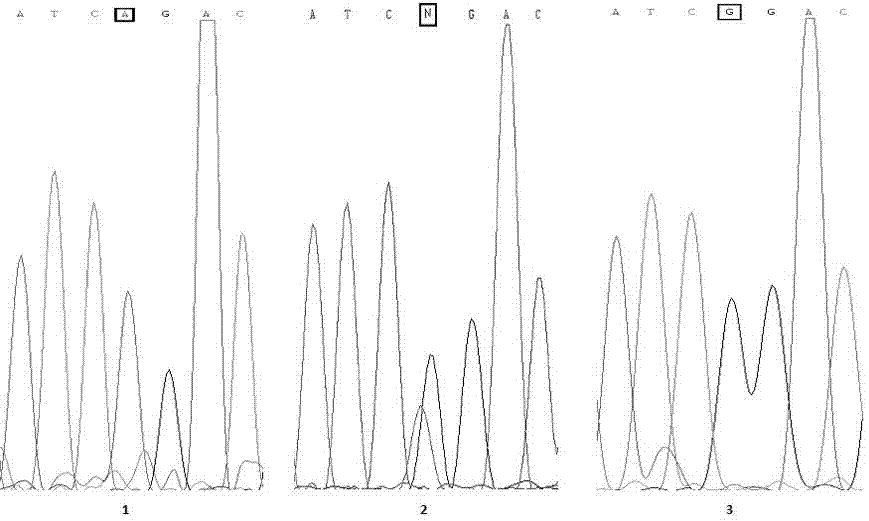

InactiveCN102061333AHigh reference significanceRaise the annealing temperatureMicrobiological testing/measurementDNA/RNA fragmentationTumor therapyA-DNA

The invention relates to the technical field of molecule detection for guiding tumor therapy and in particular discloses a primer used for detecting mutation of exons 9 and 11 of a c-kit gene and application thereof to the identification of the sensitivity of a tumor patient to imatinib (gleevec) medicaments. First, a DNA is extracted from a tumor tissue or a blood sample of a patient; secondly, a target fragment is amplified by the designed primer; and finally, the mutation locuses of the kit exons 9 and 11 are detected by sequencing the target segment so as to guide the therapy on the tumor patient.

Owner:SHANGHAI BIOTECAN PHARMA

Pressure sensor forming method

ActiveCN104155035AFully annealedReduce internal stressDecorative surface effectsForce measurementLaser processingSemiconductor

A pressure sensor forming method includes the steps that a semiconductor substrate is provided; a bottom electrode layer is formed on the semiconductor substrate; a sacrificial layer is formed on the semiconductor substrate, and the bottom electrode layer is covered with the sacrificial layer; a top electrode layer is formed, and the top face and the side faces of the sacrificial layer and part of the semiconductor substrate are covered with the top electrode layer; the top electrode layer is processed through laser annealing; after the laser processing, an opening penetrating through the top electrode layer in the thickness direction is formed in the top electrode layer, and the sacrificial layer is exposed out of the opening; the sacrificial layer is removed through the opening. Through the pressure sensor forming method, the performance of a formed pressure sensor can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Multiple PCR method for improving amplification specificity and uniformity

ActiveCN110592200AImprove efficiencyQuality improvementMicrobiological testing/measurementAgainst vector-borne diseasesNucleic acid detectionDNA fragmentation

The invention belongs to the technical field of nucleic acid detection, and particularly relates to a multiple PCR method for improving amplification specificity and uniformity. The method comprises the steps as follows: extracting genome DNA from a sample; performing fragmentation and purification on the extracted genome DNA; carrying out a PCR amplification reaction by multiple specific primer pairs with the purified genome DNA as a template, wherein in the PCR amplification reaction, differential temperatures from low to high are used for annealing. The fragmentation and purification treatment is performed on DNA, the template and primers can be bond quickly, and the use rate of the primers is increased. Firstly, in a lower annealing temperature mode, amplification primers are fully bond to template DNA, the annealing temperature is increased gradually, and the binding specificity of all primers is improved; and amplification specificity and uniformity of the multiple PCR are remarkably improved.

Owner:GENETALKS BIO TECH CHANGSHA CO LTD

Co-modified nucleic acid segment of locked nucleic acid and minor groove conjugation

ActiveCN101659952AStrong specificityBig choiceSugar derivativesMicrobiological testing/measurementMinor grooveNucleic acid sequencing

The invention relates to a marking method of oligonucleotide and discloses a co-modified nucleic acid segment of a locked nucleic acid (LNA) and a minor groove binding agent (MGB), namely, both the LNA and the MGB are marked on the same oligonucleotide chain. The invention enables that the capacity of identifying nucleotide sequence mutation and SNP of the oligonucleotide is enhanced by applying the combined modification of the MGB and the LNA.

Owner:SHANGHAI ZJ BIO TECH

Production method of cold-rolled annealed low-carbon steel strip with low cost and high stamping forming performance

The invention discloses a production method of a cold-rolled annealed low-carbon steel strip with low cost and high stamping forming performance. The production method includes the procedures of smelting, continuous casting, hot rolling, cold rolling and continuous annealing. In the hot rolling procedure, the heating temperature of a hot-rolled plate blank is 1,050-1,200 DEG C, the heating time is70-200 min, the hot rolling finish rolling temperature is 810-850 DEG C, and the coiling temperature is 710-750 DEG C. In the cold rolling procedure, the cold rolling rolling speed is controlled at 800-1,200 m / min. The content of the solid solution C in steel is controlled by controlling hot rolling process parameters, it is promoted that {111} recrystallized grains fully grow by controlling thecold rolling and annealing temperatures, and the stamping forming performance is improved. No high-cost alloys such as niobium and titanium are added into used chemical components, it is not needed toincrease the cold rolling reduction rate or increase the annealing temperature, and the production method has the beneficial effects that the cost is low, and production is easy to control.

Owner:TANGSHAN IRON & STEEL GROUP +1

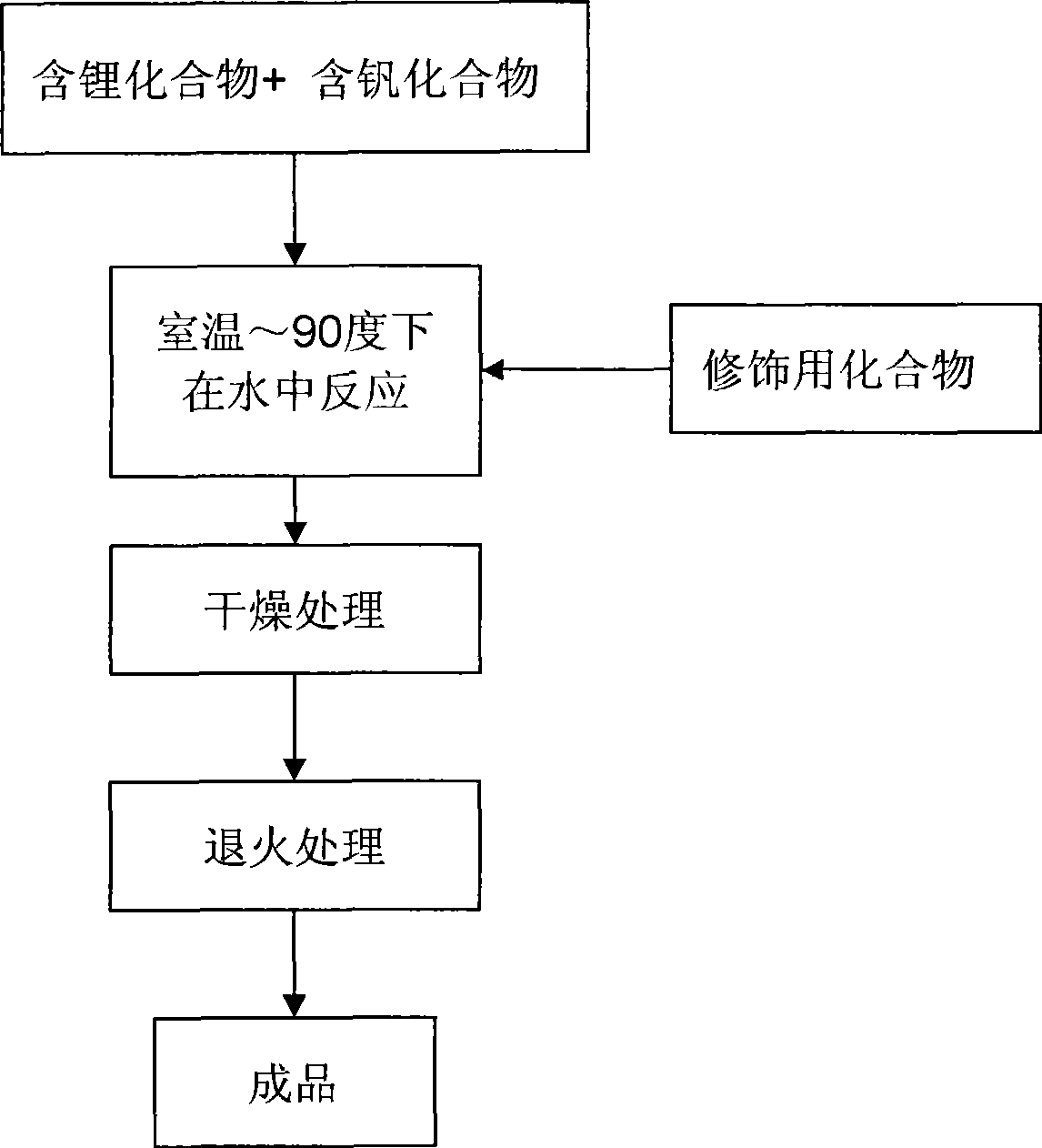

Low temperature synthesizing method of long life lithium vanadate

InactiveCN101503213AComposition is easy to controlSolve the problem that the stoichiometric ratio cannot be accurately controlledElectrode manufacturing processesVanadium compoundsVanadium CompoundsRoom temperature

The invention discloses a low temperature synthetic method for lithium vanadate with long service life, which comprises the following steps: firstly, reacting a lithium compound and a vanadium compound in water for 0.5 to 10 h at the temperature of room temperature to 90 DEG C according to the molar ratio (0.9 to 1.1) of a lithium ion and a vanadium ion, wherein the weight ratio of the water and a solid mixture is (1 to 10):1; secondly, drying the product prepared in the step 1 at the temperature of room temperature to 120 DEG C, wherein the drying time is 1 to 24h; and thirdly, annealing for 0.5 to 5h at the temperature of 100 to 400 DEG C. The invention has the advantages of accurate composition, long cycle life, controllable electrochemical performance, easy adulteration, cladding and other decorations, simple preparation method and low flow energy consumption.

Owner:TIANJIN B&M SCI & TECH

Semi-random primer based on PCR walking technology, and kit thereof

ActiveCN103397028AEasy to operateImprove amplification specificityMicrobiological testing/measurementDNA/RNA fragmentationMicrobiology

The present invention discloses a semi-random primer based on a PCR walking technology, a kit and a method for performing PCR walking by using the kit. The sequence of the semi-random primer is represented by the SEQ ID NO.7 in the sequence list. The kit comprises the semi-random primer. The method is similar to the ordinary two-primer PCR, at most requires two PCR cycles to obtain a target sequence, and has characteristics of simple, rapid and efficient operation. According to the method, an annealing temperature of the whole PCR cycle process is increased, amplification specificity is increased, the used experimental materials are not limited, and the kit can be used by microorganism samples, animal samples and plant samples. The method can be used in experiments so as to simplify operations, shorten an experiment time, improve experiment efficiency, reduce experiment cost, and provide broad application prospects.

Owner:BRIGHT DAIRY & FOOD

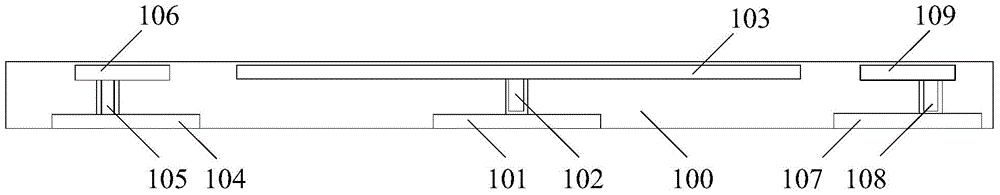

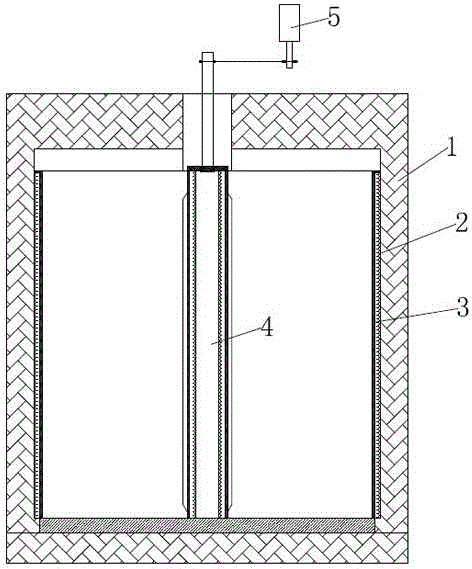

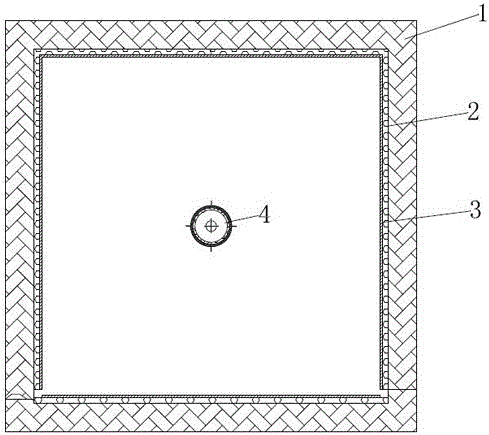

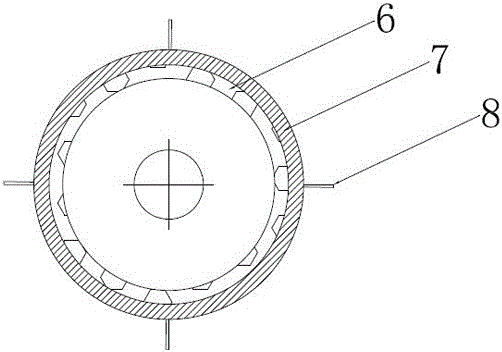

Box type annealing furnace with high uniformity and annealing method thereof

InactiveCN106116127ALow temperature solutionImprove the uniformity of the temperature fieldField uniformitySquare Shape

The invention discloses a box type annealing furnace with high uniformity and an annealing method thereof, belongs to the technical field of heat treatment of optical materials, and is used for mainly solving the problem of poor annealing uniformity in a conventional annealing technology. The box type annealing furnace is mainly characterized in that the box type annealing furnace is a cubic box type annealing furnace having a square horizontal cross section; a hearth of the box type annealing furnace is provided with heating elements along the walls at the periphery, and the heating elements are externally provided with heat conduction plates; the middle part of the hearth of the box type annealing furnace is provided with a three-dimensional heating column, the heating column is fixed on a rotary shaft passing through the top of the box type annealing furnace, and the rotary shaft is connected with a transmission device outside the furnace. The temperature field uniformity of the annealing furnace is greatly improved, products can have the temperature rapidly kept consistent with the temperature field during heating and cooling, and the temperatures of the center and the surface of the products more tend to be consistent. The products annealed by using the device and the method have good individual uniformity, and the whole furnace products are highly consistent, and thus the device and the method are suitable for annealing of products of high-end optical devices.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Single transistor charge transfer random access memory

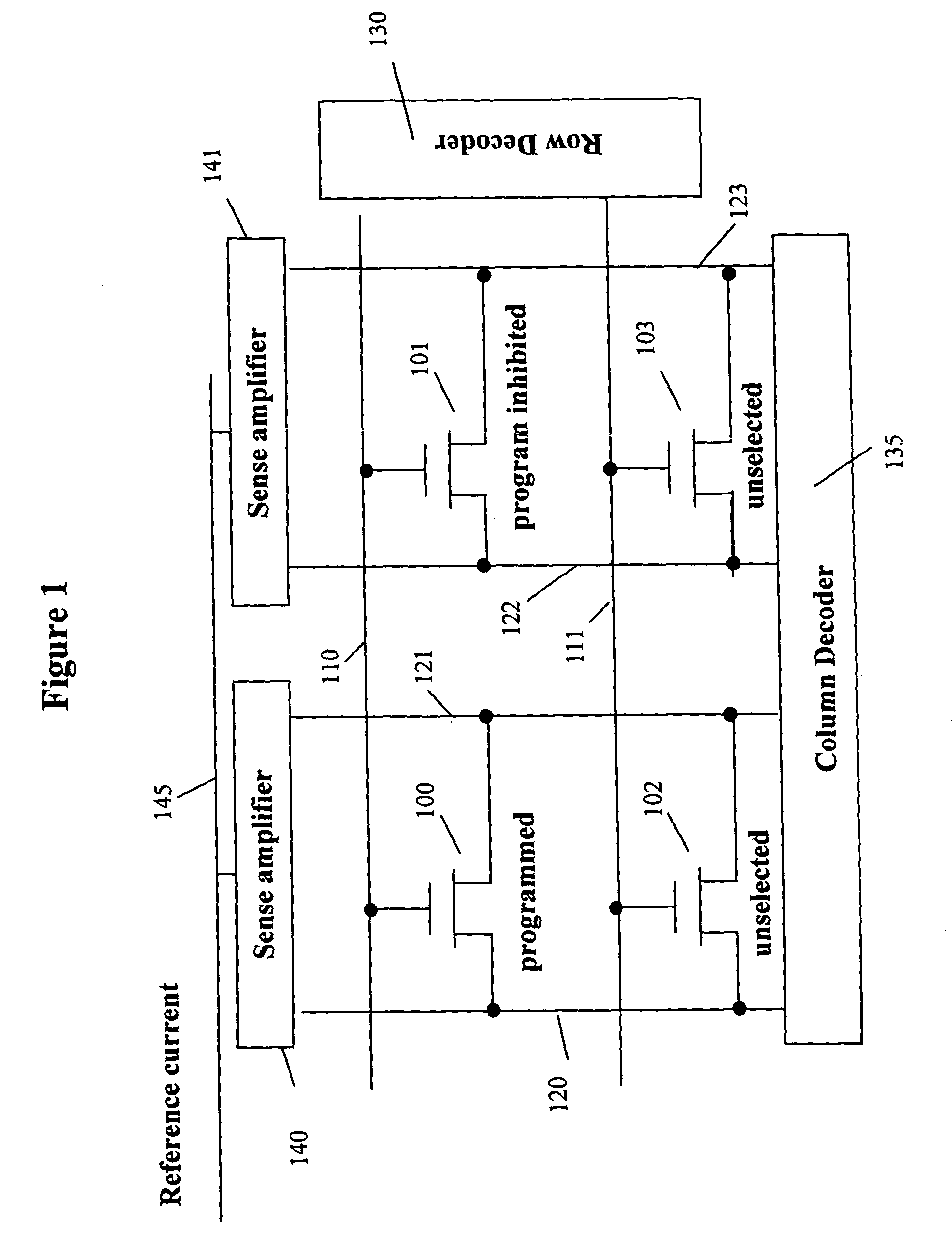

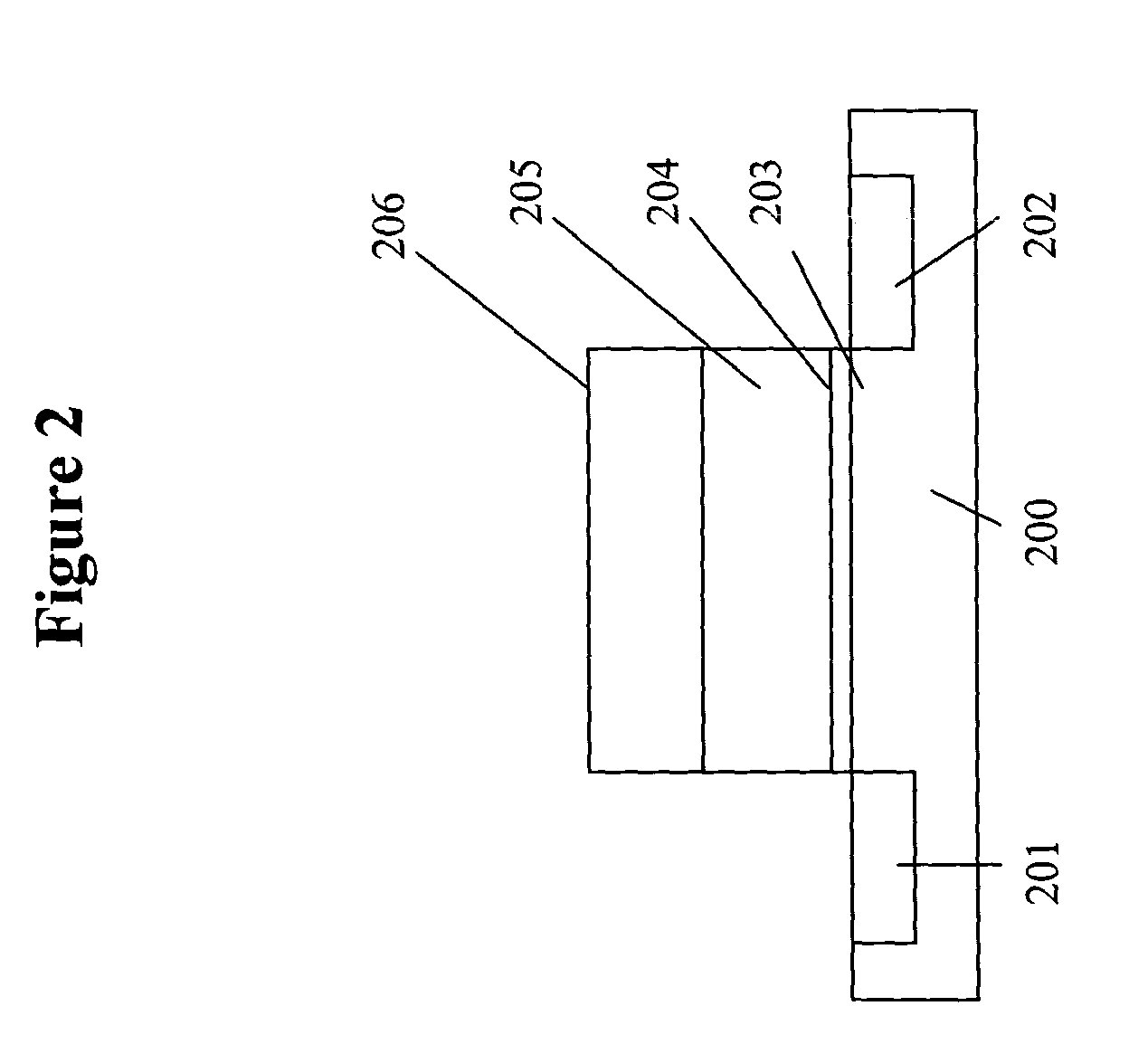

InactiveUS7973348B1Low enduranceHigh programming voltageSemiconductor/solid-state device manufacturingDigital storagePhysicsLower threshold

A nonvolatile semiconductor memory device is described where each memory cell is composed of a single field effect transistor with a dual gate dielectric comprising a dielectric interfacial layer in contact with a silicon substrate and a ferroelectric layer in between the interfacial layer and the gate electrode. To program (write) the cell the ferroelectric layer is polarized in one of two directions, the ferroelectric polarization creating a large electric field in the interfacial layer. This electric field causes electrons or holes to be transported across the interfacial layer and be trapped in the ferroelectric layer establishing a high (erased) or low (programmed) threshold voltage depending on the direction of the ferroelectric polarization representing the two logic states. To read the memory cell a voltage is applied to the drain of the selected transistor and depending on whether a high or low threshold state was programmed into the cell a low or high current is sensed.

Owner:DALTON DAVID I +1

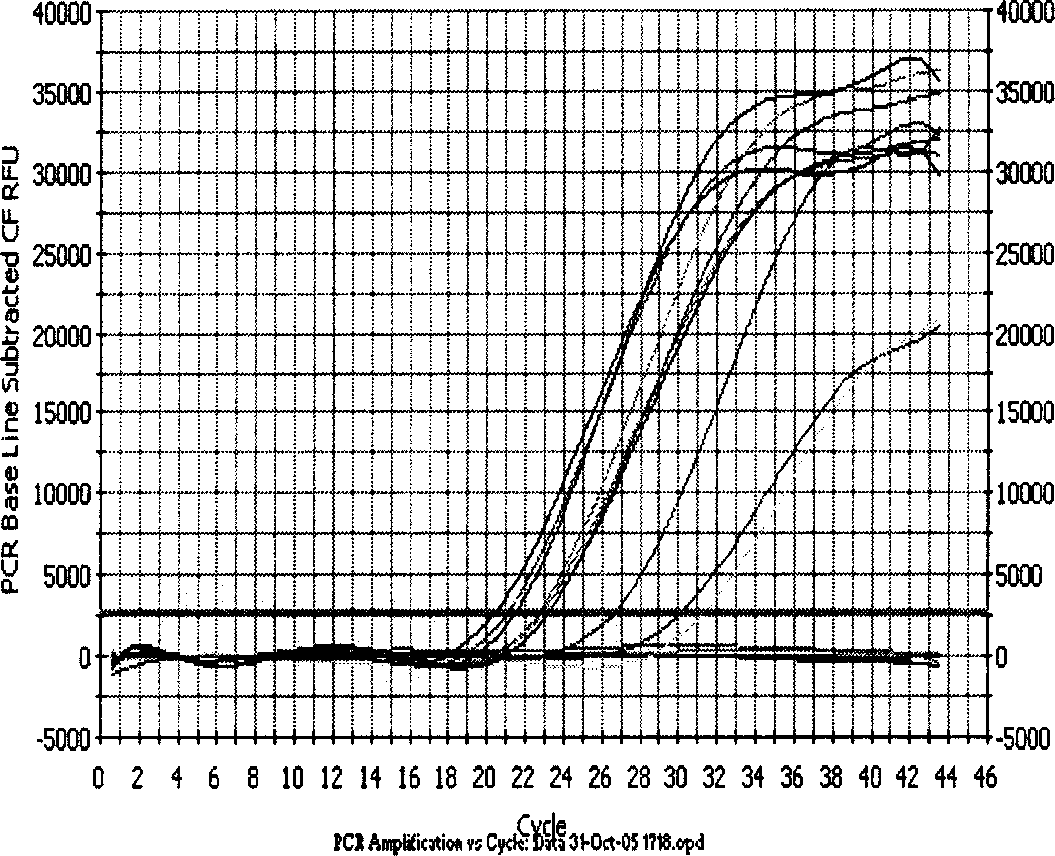

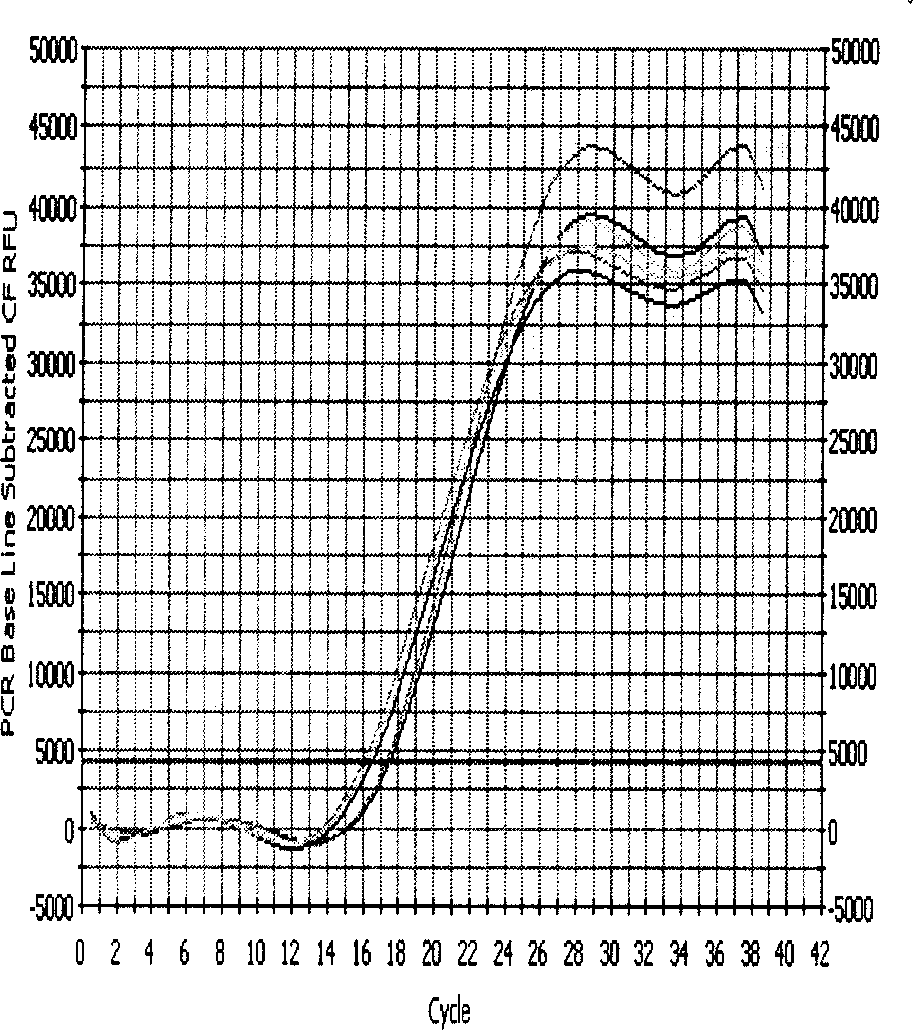

Quantitative fluorescent PCR inspection for hepatitis-B virus drug-tolerant gene mutation

ActiveCN1896278ARaise the annealing temperatureTroubleshooting Nonspecific Amplification ProblemsMicrobiological testing/measurementFluorescence/phosphorescenceLamivudine resistanceGene mutation

The present invention relates to the real-time quantitative PCR assay for the Lamivudine resistance mutation of hepatitis b virus. The mutations related with Lamivudine resistance locate in the rtL180M and rtM204V / I mutations of DNA polymerase. This method utilizes the character that the primer cannot elongate correctly during the PCR process with mismatches in the 3'-end, designs the mutation site in the 3'-end of the real-time quantitative PCR primer, chooses proper primer concentrations and Touch-down PCR process, and couples the melting point curve of PCR product containing SyBrGreen I. The existence of mutation in the Lamivudine site can be determined with the real-time quantitative PCR signals and the melting point curve. This invention can detect the DNA mutations in the clinical hepatitis b virus specimens rapidly and accurately, and is also suitable for the detection of other gene mutations.

Owner:SHANDONG MEDICAL BIO TECH RES CENT

Double-sided dark battery foil and preparation method thereof

ActiveCN109402456AEasy to useQuality improvementJackets/cases materialsMetal rolling arrangementsRoom temperatureRaw material

The invention discloses double-sided dark battery foil and a preparation method thereof. The double-sided dark battery foil is prepared from the following component raw materials: Si, Fe, Cu, Mn, Mg,Ti and Al. The preparation method of the double-sided dark battery foil comprises the following steps: (1) the raw materials are added into a smelting furnace to be smelted, and molten liquid is obtained; (2) the molten liquid is input into a cast-rolling machine to be cast-rolled into a blank; (3) the cast-rolled blank is cold-rolled by a cold-rolling machine, and homogenizing annealing treatmentis conducted; and (4) after an aluminum coil subjected to homogenizing annealing is cooled to the room temperature, cold rolling in passes is conducted; (5) rerolling and edge cutting are conducted;(6) intermediate annealing treatment is conducted; (7) the aluminum coil subjected to intermediate annealing treatment is cold-rolled; and (8) the cold-rolled aluminum coil is rerolled, then foil rolling is conducted, and thus the double-sided dark battery foil is prepared. Aluminum powder on the dark side of the double-sided dark battery foil produced by the invention is effectively controlled,corrugated edges are avoided, the using performance and surface quality of a finished product are high, and the double-sided dark battery foil can be applied to most batteries.

Owner:GUANGXI BAISE XINGHE ALUMINUM

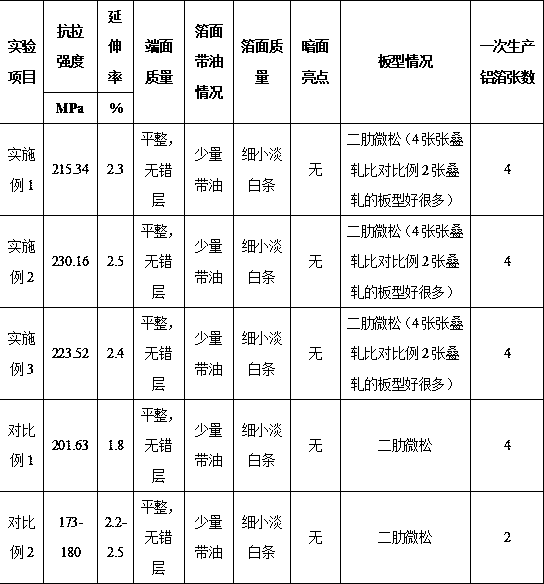

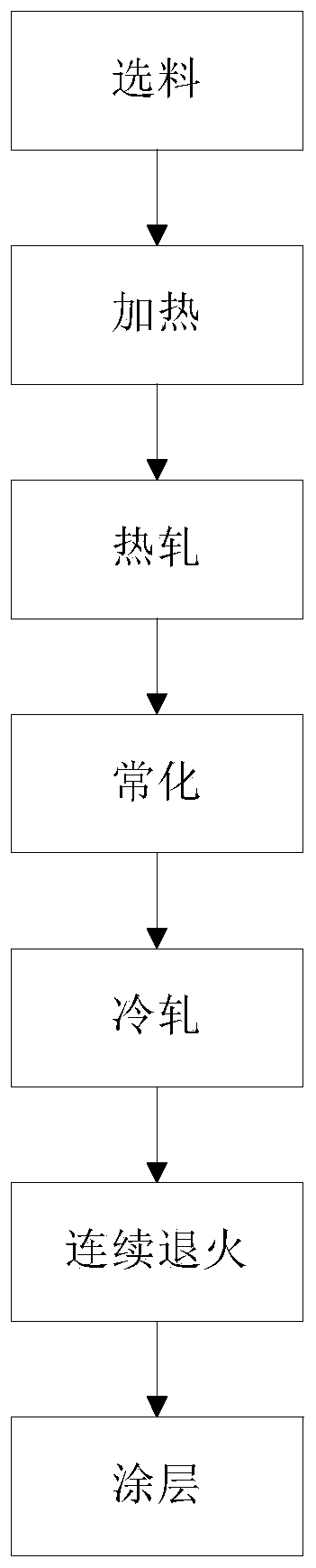

Thin-gauge high-grade silicon steel and production method thereof

InactiveCN110423877AReduce horizontal and vertical strength differenceMeet processing needsChemical compositionRoom temperature

The invention discloses thin-gauge high-grade silicon steel and a production method thereof. The method comprises the following steps that materials are selected, specifically, the selected raw materials comprise the following chemical components in percentage by mass: less than or equal to 0.003% of C, 2.0-3.0% of Si, greater than or equal to 0.5% of Al, 0.10-0.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.003% of N, less than or equal to 0.003% of Ti, and the balance Fe, wherein Si+Al is less than or equal to 3.5%; heating is carried out, specifically, the raw materials are smelted and cast into a blank, and then the cast blank is heated; hot rolling is carried out, specifically, the cast blank is hot-rolled into a silicon steel strip with the thickness of 2.3 mm;normalizing is carried out, specifically, normalizing treatment is carried out on the hot-rolled silicon steel strip; cold rolling is carried out, specifically, the silicon steel strip subjected to normalizing treatment is cold-rolled into a thin-gauge steel strip with the thickness of 0.3 mm; continuous annealing is carried out, specifically, continuous annealing is carried out on the cold-rolledthin-gauge steel strip, wherein the annealing temperature is 950-1100 DEG C, the tension in a furnace is within 2-4 MPa, and after discharging is carried out, the thin-gauge steel strip is cooled to700 DEG C at a cooling speed of less than or equal to 20 DEG C / s; and coating is carried out, specifically, the thin-gauge steel strip is coated with an insulating layer after being cooled to room temperature. According to the thin-specification high-grade silicon steel and the manufacturing method thereof, the annealing tension and the cooling speed are reduced, so that the transverse longitudinal strength difference of the thin-specification high-grade silicon steel is effectively reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Kit and method for detecting A746G mutation of sheep BMPR-IB gene by using Taqman-MGB probe

ActiveCN107338287AIncrease the Tm valueRaise the annealing temperatureMicrobiological testing/measurementDNA/RNA fragmentationPositive controlGenomic DNA

The invention belongs to the field of biotechnology, and in particular relates to a kit and method for detecting the A746G mutation of a sheep BMPR-IB gene by using a Taqman-MGB probe. The kit mainly comprises three tubes of positive control samples, a DNA extraction solution I, a DNA extraction solution II, a 2 * Light Cycler 480 probes master reaction buffer solution, BMF and BMR primers, BPA and BPG probes and ddH2O. The Method includes the steps of rapidly extracting genomic DNA, conducting real-time fluorescent quantitative PCR amplification on the genomic DNA by using the primers, and performing gene interpretation. The kit and method for detecting the A746G mutation of the sheep BMPR-IB gene by using the Taqman-MGB probe has the advantages of being simple to operate, fast in detection and high in accuracy, and can judge types without subsequent analysis of PCR products; besides, the whole reaction process is performed in a closed tube, so that cross-contamination is reduced.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com