Double-sided dark battery foil and preparation method thereof

A battery, double-sided technology, applied in the direction of battery pack parts, battery box/outer, battery box/cover material, etc., can solve the problems of low tensile strength, poor plate shape, low production efficiency, etc., to improve performance, The effect of high performance and surface quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

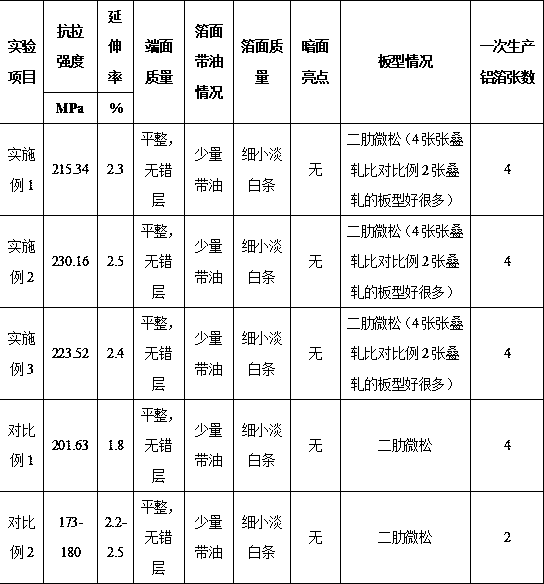

Examples

preparation example Construction

[0031] The preparation method of the double-sided dark battery foil comprises the following steps:

[0032] (1) Add the raw materials of the double-sided dark battery foil into the melting furnace for melting, and the melting preparation conditions are as follows: the melting temperature is 730-760°C to obtain the aluminum alloy melt;

[0033] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 7.0-7.5mm, and cool it to room temperature;

[0034] (3) When the cast-rolled billet is cold-rolled by a cold rolling mill to a thickness of 1.8-4.0mm, homogenization annealing treatment is performed: the annealing temperature is 550°C, and the holding time is 25h;

[0035] (4) After the homogenized annealed aluminum coil is cooled to room temperature, it is cold rolled to 0.9-1.9mm in separate passes;

[0036] (5) After the aluminum coils in step (4) are cold-rolled in separate passes, they are recoiled and trimm...

Embodiment 1

[0042]A double-sided dark battery foil, comprising the following raw materials in mass percentage: Si: 0.105%, Fe: 0.416%, Cu: 0.0333%, Mn: 0.0213%, Mg: 0.005%, Ti: 0.0206%, Al: 99.36% .

[0043] The preparation method of the double-sided dark battery foil comprises the following steps:

[0044] (1) Add the raw materials of the double-sided dark battery foil into the melting furnace for melting. The melting preparation conditions are as follows: the melting temperature is 750°C to obtain the aluminum alloy melt;

[0045] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 7.0mm, and cool it to room temperature;

[0046] (3) The cast-rolled billet is cold-rolled by cold-rolling mill to thicknesses of 3.3mm and 1.8mm, and homogenized annealing treatment is carried out: the annealing temperature is 550°C, and the holding time is 25h;

[0047] (4) After the homogenized annealed aluminum coil is cooled to ro...

Embodiment 2

[0053] A double-sided dark battery foil, comprising the following raw materials in mass percentage: Si: 0.127%, Fe: 0.419%, Cu: 0.0343%, Mn: 0.0214%, Mg: 0.005%, Ti: 0.0267%, Al: 99.33% .

[0054] The preparation method of the double-sided dark battery foil comprises the following steps:

[0055] (1) Add the raw materials of the double-sided dark battery foil into the melting furnace for melting. The melting preparation conditions are as follows: the melting temperature is 750°C to obtain the aluminum alloy melt;

[0056] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 7.5mm, and cool it to room temperature;

[0057] (3) The cast-rolled billet is cold-rolled to a thickness of 4.0 mm through the cold-rolling mill and then subjected to homogenization annealing treatment: the annealing temperature is 550°C, and the holding time is 25 hours;

[0058] (4) After the homogenized annealed aluminum coil is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com