Silicon carbide crystal annealing process

An annealing process, silicon carbide technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as crystal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

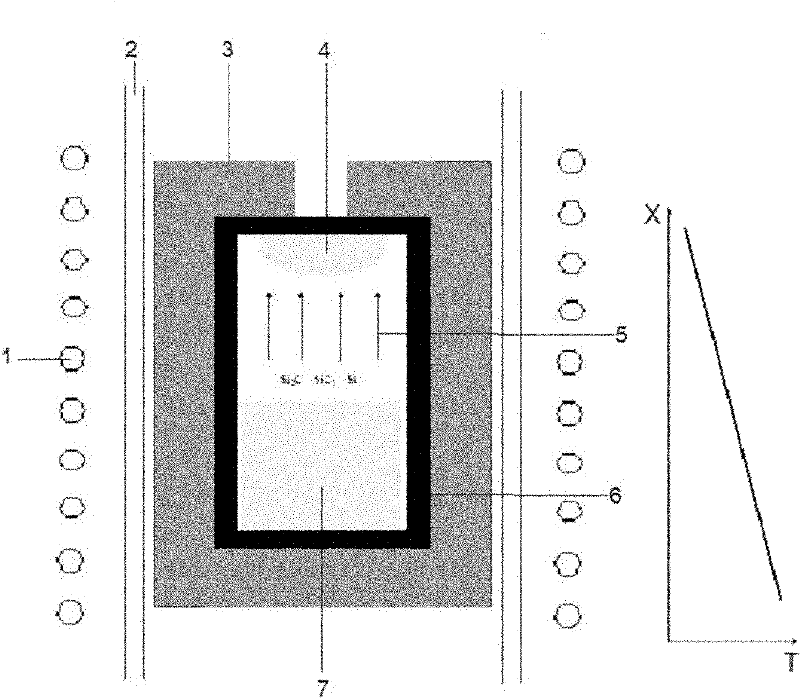

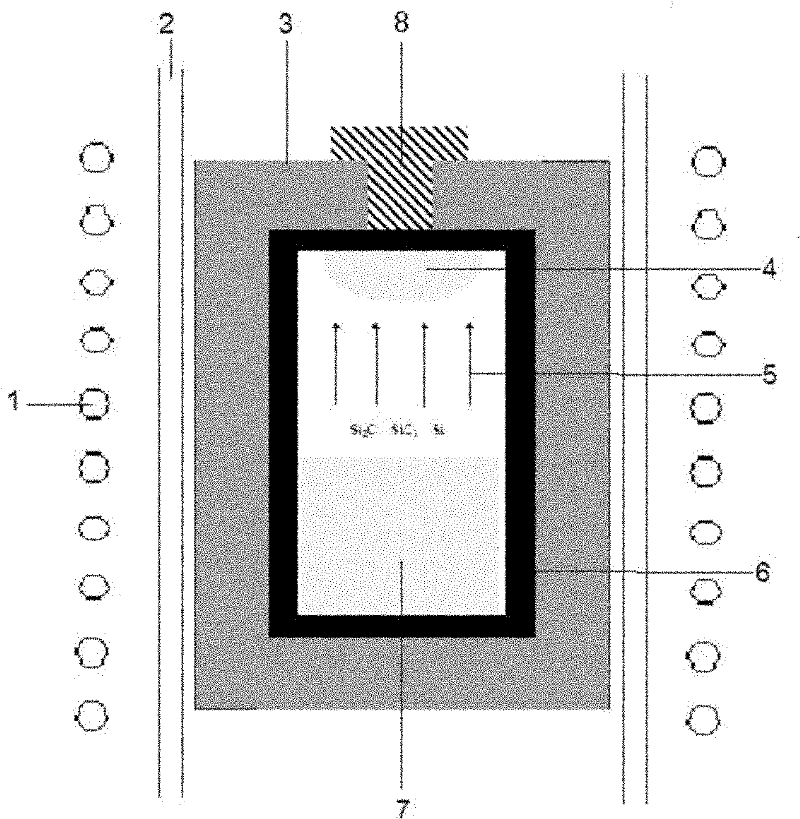

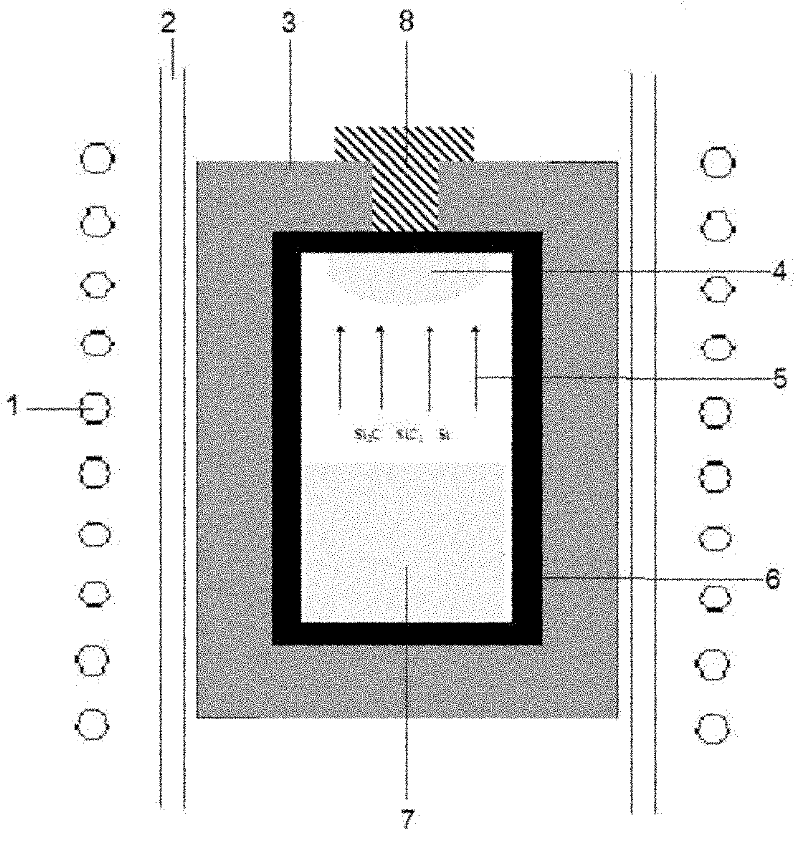

Image

Examples

Embodiment 1

[0028] The designed insulation layer ensures that the placement of the insulation layer at the annealing temperature can reduce the crystal temperature gradient from about 20°C / cm to below 5°C / cm. After the growth of the 2-inch 6H semi-insulating silicon carbide crystal is completed, the insulation layer is placed in the heat dissipation hole with a mechanical device. The whole process takes 2 hours and the temperature is raised. It also takes 2 hours to raise the temperature to 2300 ° C. After placing The insulation layer and the increase of the crystal temperature increase the argon pressure in the growth chamber at the same time, and the pressure is raised from 2 kPa to 20 thousand Pa in 2 hours. When the temperature is constant for 20 hours, it takes 22 hours to cool down from 2300°C to 100°C at a speed of 100°C / h, and then turn off the power directly.

Embodiment 2

[0030]The designed insulation layer ensures that the placement of the insulation layer at the annealing temperature can reduce the crystal temperature gradient from about 25°C / cm to below 5°C / cm. After the growth of the 3-inch 4H conductive silicon carbide crystal is completed, the thermal insulation layer is placed in the heat dissipation hole with a mechanical device. The whole process takes 3 hours, and the temperature is raised. It also takes 3 hours to raise the temperature to 2300°C. layer and increase the crystal temperature while increasing the argon pressure in the growth chamber, and the pressure was raised from 2 kPa to 30,000 Pa in 3 hours. When the temperature is constant for 30 hours, it takes 22 hours to cool down from 2300°C to 100°C at a speed of 100°C / h, and then turn off the power directly.

Embodiment 3

[0032] The designed insulation layer ensures that the placement of the insulation layer at the annealing temperature can reduce the crystal temperature gradient from about 30°C / cm to below 5°C / cm. After the growth of the 4-inch 4H conductive silicon carbide crystal is completed, the insulation layer is placed in the heat dissipation hole with a mechanical device. The whole process takes 4 hours, and the temperature is raised. It also takes 4 hours to raise the temperature to 2400°C. layer and increase the crystal temperature while increasing the argon pressure in the growth chamber, and the pressure was increased from 2 kPa to 40,000 Pa in 4 hours. When the temperature is constant for 30 hours, it takes 23 hours to cool down from 2400°C to 100°C at a speed of 100°C / h, and then turn off the power directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com