Carbon elimination process for non-oriented silicon steel production

A technology of oriented silicon steel and decarburization, applied in the field of improvement of silicon steel production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

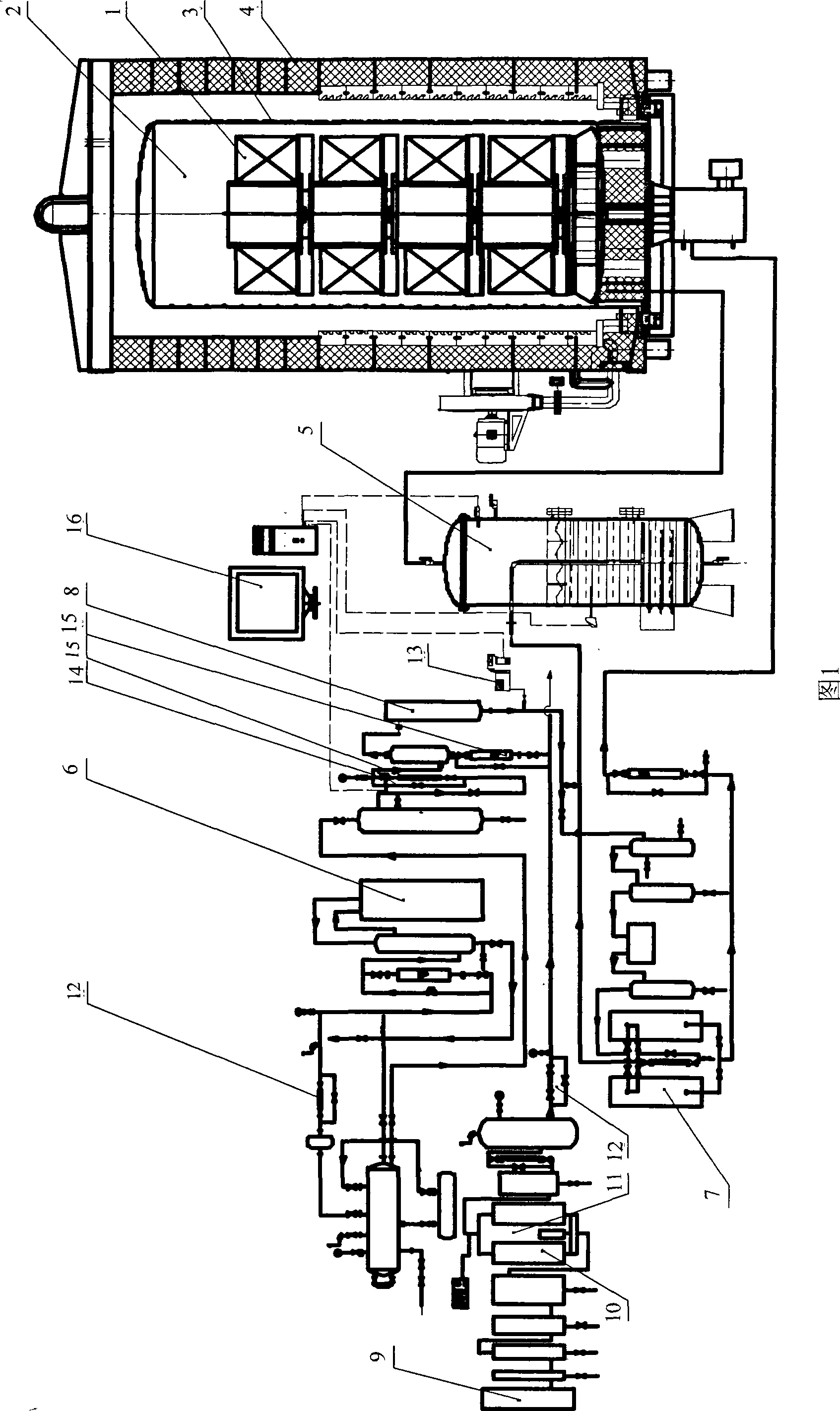

[0008] It can be seen from the figure that first, the silicon steel coils (1) cold-rolled at room temperature are uncoiled, and then they are stacked in a bell annealing furnace (2), and then a thick-walled and high-temperature-resistant stainless steel inner cover (3) is used. Cover the silicon steel coil (1), then buckle the improved heating mantle (4) outside the inner cover (3), fill the inner cover (3) with nitrogen to carry out "catch-up" treatment, that is, replace the air with nitrogen, according to The process requires heating the silicon steel coil (1) to 800-850°C under different atmospheres in several stages and keeping the temperature constant. Carbon diffuses to the surface at high temperature and reacts chemically with water vapor. In the bell-type annealing furnace (2), because the flow direction of the gas in the furnace is toward the bottom of the hearth, it is easy to discharge the carbon monoxide gas and water formed by the decarburization reaction together,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com