Thin-gauge high-grade silicon steel and production method thereof

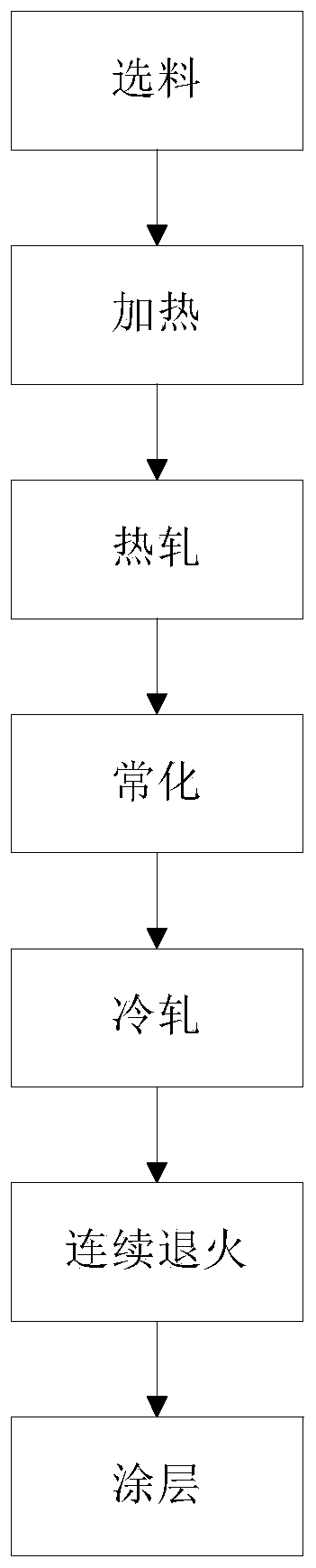

A manufacturing method and thin-gauge technology, which are applied to thin-gauge high-grade silicon steel and its manufacturing field to achieve the effects of improving machining accuracy, reducing transverse and longitudinal strength differences, and reducing annealing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The following mass percentages of raw materials are selected: C≤0.003%, Si=2.3%, Al=0.9%, Mn=0.35%, P≤0.02%, N≤0.003%, Ti≤0.003%, and iron in balance. After melting and casting, the billet is heated to 1180°C, hot rolled to 2.3mm, and the final rolling temperature is 880°C. The normalization temperature is 1000°C. After pickling, it is cold rolled to 0.30mm once. Carry out continuous annealing, the annealing temperature is 960°C, the annealing speed is 65m / min, and the tension in the furnace is 3MPa. After being out of the furnace, it is cooled to 700°C at a cooling rate of 15°C / s, and the steel strip is cooled to room temperature and then coated with an insulating coating. The difference between the transverse and longitudinal yield strength of the finished product is 5MPa.

Embodiment 2

[0050] The following mass percentages of raw materials are selected: C≤0.003%, Si=2.8%, Al=0.64%, Mn=0.23%, P≤0.02%, N≤0.003%, Ti≤0.003%, and the balance is Fe. After melting and casting, the billet is heated to 1180°C, hot rolled to 2.3mm, and the final rolling temperature is between 880°C. The normalization temperature is 860°C. After pickling, it is cold rolled to 0.30mm once. Carry out continuous annealing, the annealing temperature is 1000°C, the annealing speed is 85m / min, and the tension in the furnace is 2.5MPa. After being out of the furnace, it is cooled to 700°C at a cooling rate of 12°C / s, and the steel strip is cooled to room temperature and then coated with an insulating coating. The difference between the transverse and longitudinal yield strength of the finished product is 9MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com