Foamed ceramic and high-strength foamed cement composite board and preparation method thereof

A technology of foamed ceramic boards and foamed cement boards, which is applied in the production of ceramic products, ceramic materials, clay products, etc., can solve the problems of high production costs of foamed ceramics, shorten annealing time, reduce specific gravity, reduce The effect of small foam expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

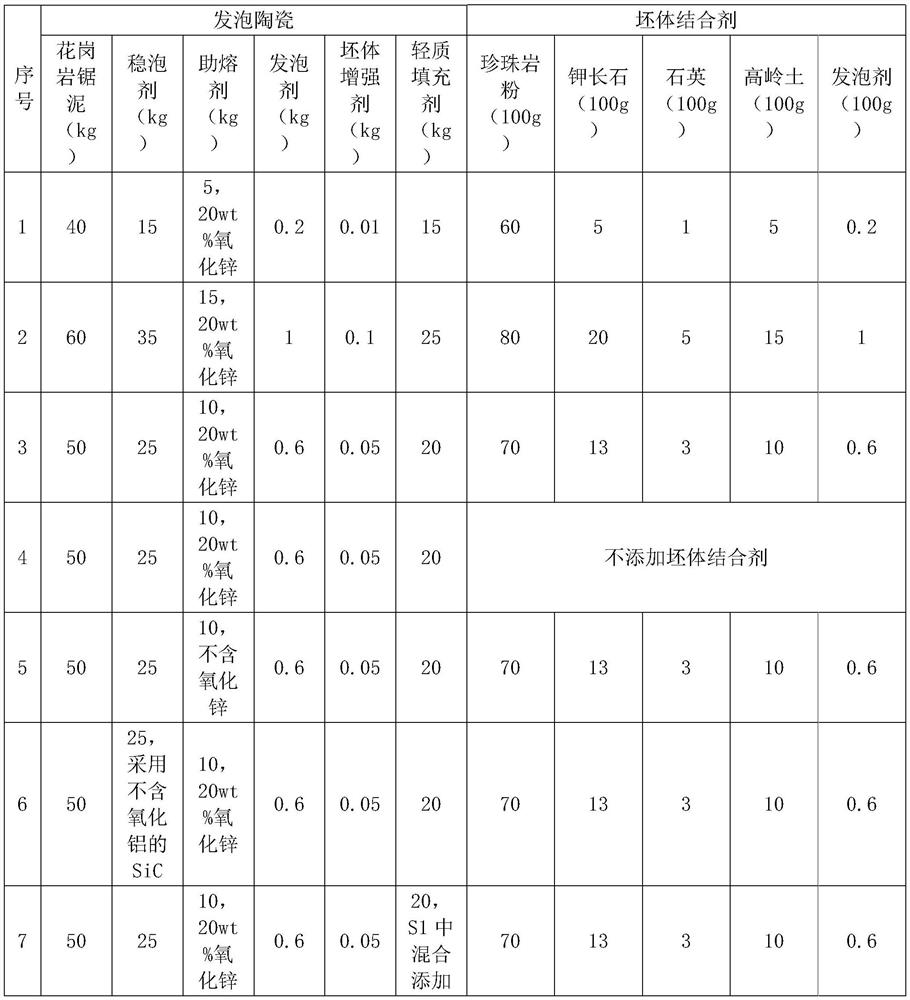

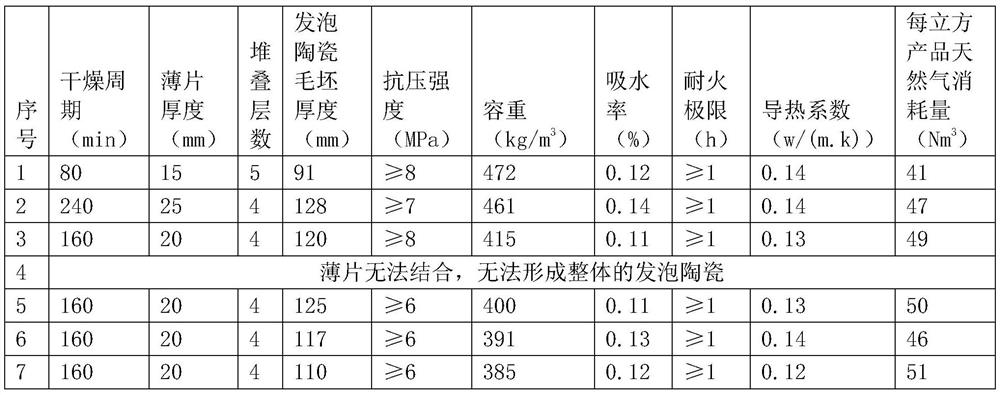

[0057] In order to clearly illustrate the technical characteristics of the present solution, the present application will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

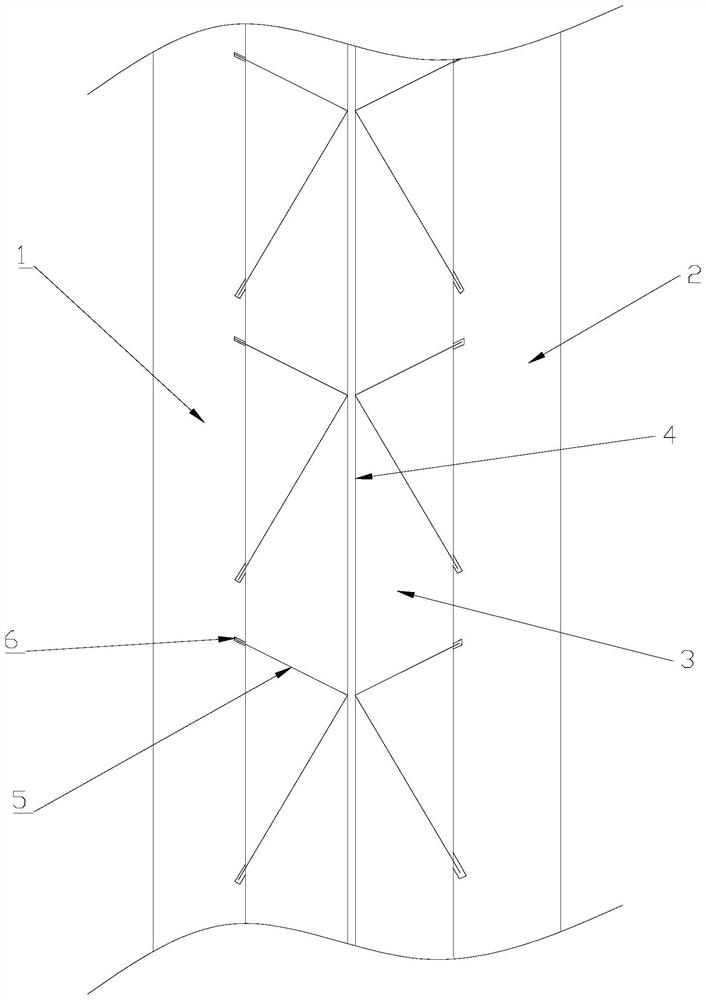

[0058] In the first embodiment, as in figure 1 As shown, a composite plate of foamed ceramics and high-strength foamed cement comprises a first foamed ceramic plate 1 and a second foamed ceramic plate 2, between the second foamed ceramic plate 2 and the second foamed ceramic plate 2 Foamed cement boards 3 are arranged between them, and structural reinforcements 4 are arranged inside the foamed cement boards 3 . The structural reinforcement is a steel mesh; the steel mesh is hung with a number of L-shaped hooking parts 5, and a number of reinforcing fibers are arranged on the L-shaped hooking parts 5. The L-shaped hooking part 5 is arranged in contact with the first foamed ceramic plate 1 or the second foamed ceramic plate 2, and the L-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com