Cage type furnace convection plate

A convection plate and bell furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of small loss of steel coils, large loss of steel coils, and large difference in hardness of steel coils, so as to reduce temperature difference and increase The effect of uniformity and hydrogen flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation of the present invention will be described below through the examples and accompanying drawings, but the convection plate of the bell-type furnace is not limited to the following examples.

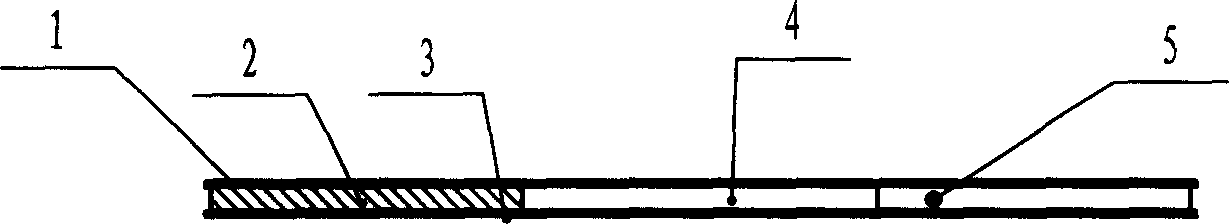

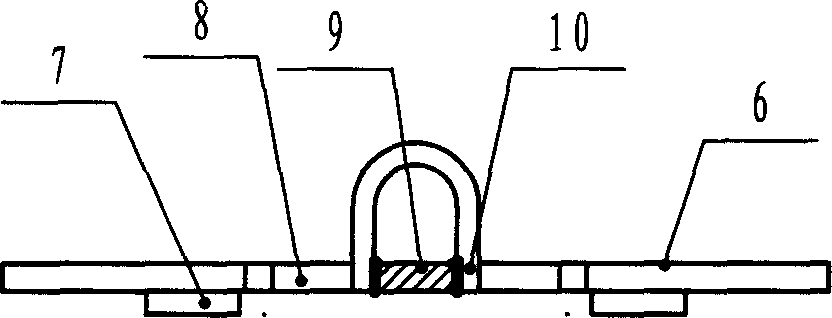

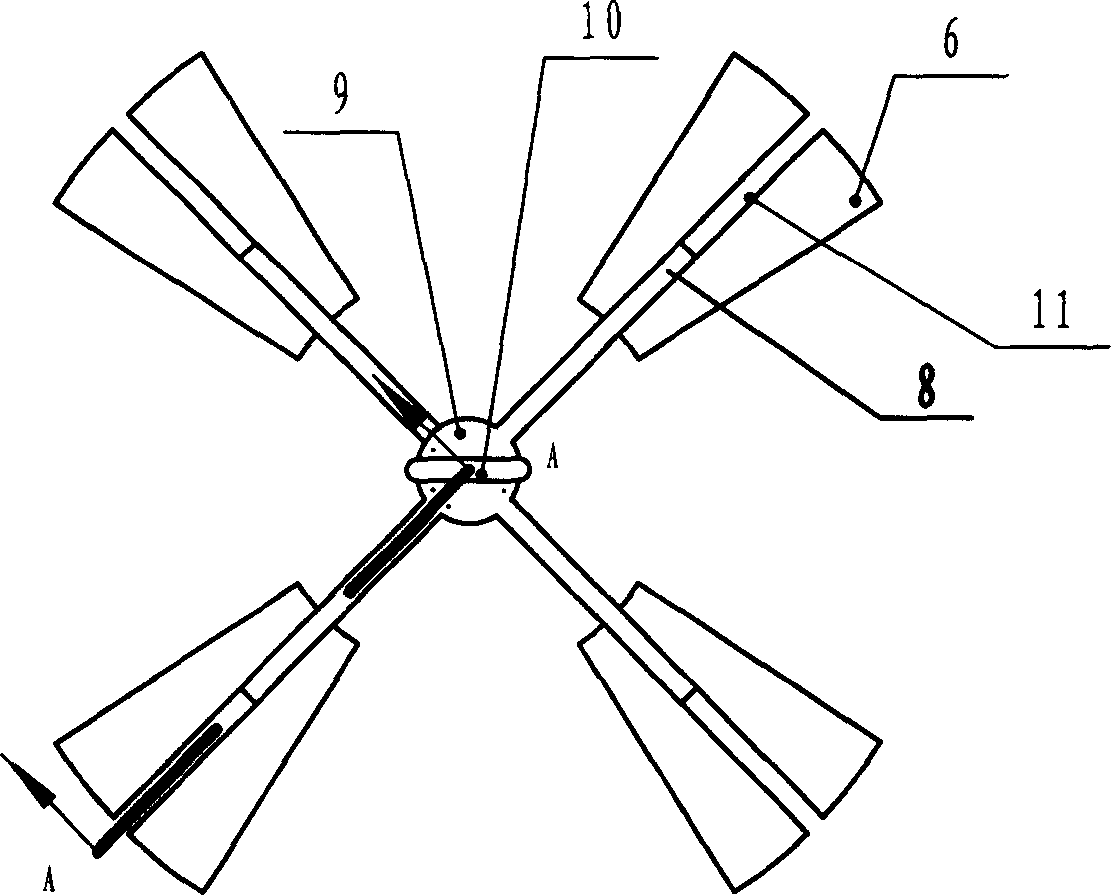

[0039] figure 2 and image 3 The bell furnace convection plate described includes a partition and a connecting piece, and the partition and the connecting piece are welded as a whole. U-shaped suspension ring 10 is welded together; Said connector is four connecting rods 8 that form a cross shape with circular connecting plate 9 as a whole, and a strip fan-shaped dividing plate 6 is welded on the both sides of every connecting rod 8, Form interval 11 between two adjacent elongated fan-shaped partitions 6, below the middle part of each elongated fan-shaped plate 6, be welded strip backing plate 7, see Figure 4 , Figure 5 . The length of the strip backing plate 7 is 1 / 3-1 / 2 of the strip fan-shaped partition 6. The distance from the outer end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com