Foamed ceramic prepared by using polishing mud as base material and preparation method thereof

A technology of foaming ceramics and polishing mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0025] The application itself includes a formula and a preparation method, but since the production method is based on the formula, the following clarification of the application is carried out from the perspective of the preparation method. The synthesis of the foamed ceramics of the present application includes the following steps:

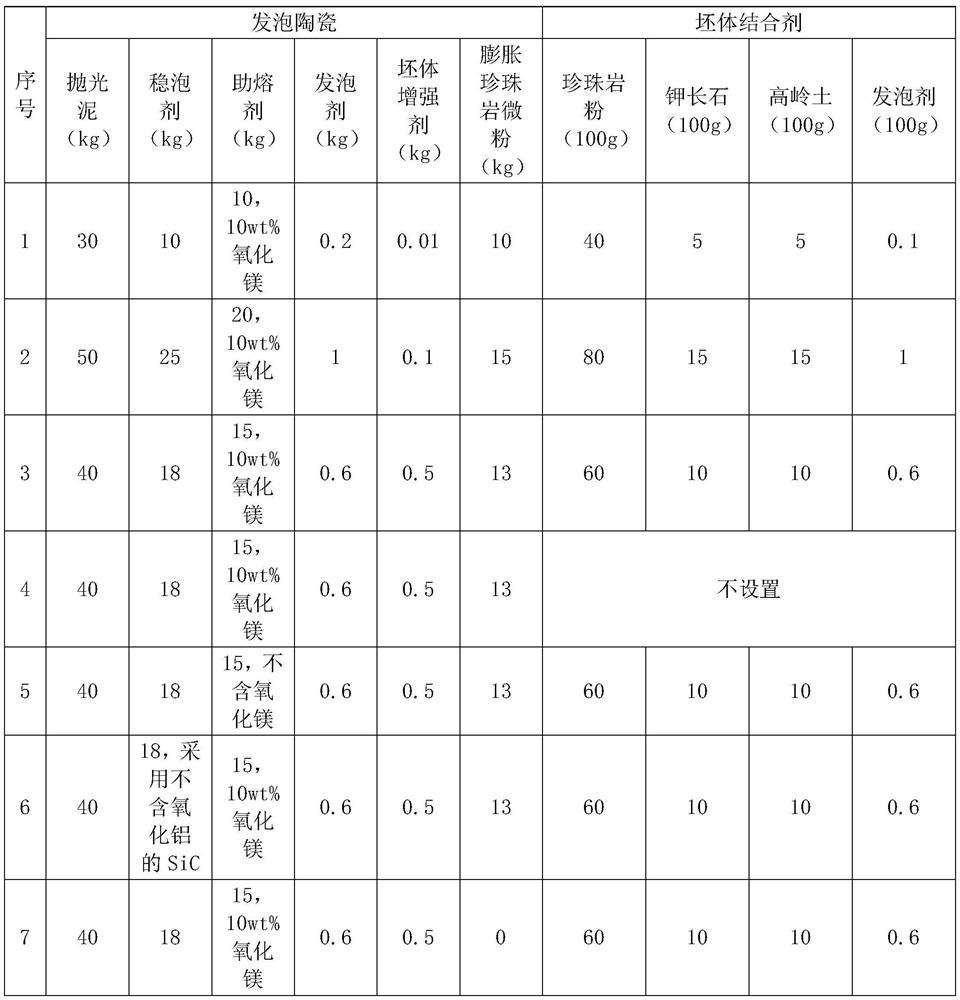

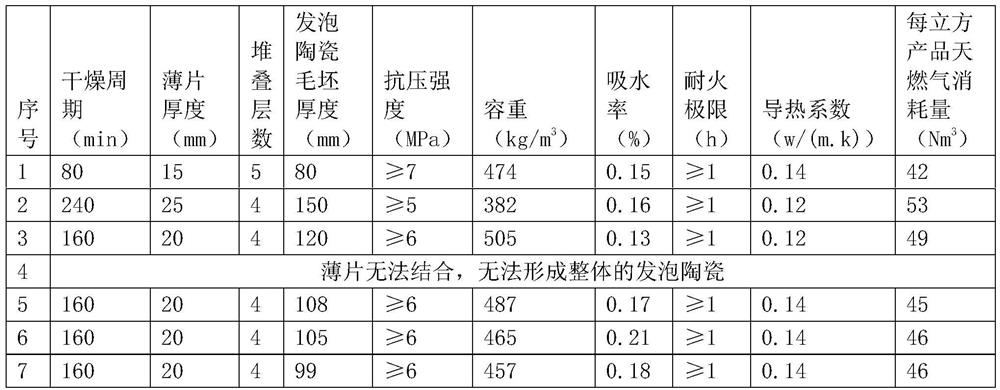

[0026] S1. Ingredients: Foam ceramic raw materials are as follows in parts by weight: polishing mud: 30-50 parts; expanded perlite micropowder: 10-25 parts; foam stabilizer: 10-20 parts; flux: 5-20 parts ; Foaming agent: 0.2-1 part, green body reinforcing agent: 0.01-0.1 part; green body binder takes the following raw materials in parts by weight: perlite powder: 40-80 parts; potassium feldspar: 5-15 parts; Kaolin: 5-15 parts; Foaming agent: 0.1-1 part;

[0027] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com