Quick-drying polyurethane adhesive with single component and no solvent and preparation method thereof

A solvent-free polyurethane, quick-drying technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc. Insufficient and other problems, to achieve the effect of fast curing speed, good operability and reducing curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

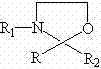

Method used

Image

Examples

Embodiment 1

[0034] Add 270kg of polyoxypropylene castor oil polyol into the reaction kettle, stir and raise the temperature to 115°C, turn on the vacuum pump, and dehydrate under reflux for 2h. Then cool down to 67°C, fill with nitrogen protection, add 250kg of diphenylmethane diisocyanate to react for 4 hours, add 8.6kg of bisoxazolidine to the system, keep stirring at 50°C for 0.5h, and then add 0.23kg of dilauric acid Dibutyltin, heat preservation and stirring at 50°C for 0.5h, and finally measure the content of -NCO groups in the system. When the percentage content of -NCO groups decreases to about 2.5%, cool down and store in airtight, that is, one-component quick-drying Type solvent-free polyurethane adhesive.

[0035] After testing, the NCO content of this product is 2.1%, the curing time is 35min, and the viscosity is 4750mPa.s / 25℃.

Embodiment 2

[0037] Add 216kg of polyoxypropylene castor oil polyol into the reaction kettle, stir and raise the temperature to 110°C, turn on the vacuum pump, and dehydrate under reflux for 1.5h. After that, the temperature was lowered to 65°C, filled with nitrogen protection, and 250kg of diphenylmethane diisocyanate was added to react for 3.5h, then 0.11kg of triethylenetetramine was added to the system, kept stirring at 50°C for 0.5h, and 7.7kg of isoxane was added For oxazolidine, heat and stir at 50°C for 0.5h, and finally measure the content of -NCO groups in the system. When the percentage content of -NCO groups decreases to about 3%, cool down and store in airtight to obtain a single-component fast Dry solvent-free polyurethane adhesive.

[0038] After testing, the NCO content of this product is 2.4%, the curing time is 35min, and the viscosity is 3950mPa.s / 25℃.

Embodiment 3

[0040]Add 181 kg of polyoxypropylene castor oil polyol into the reaction kettle, stir and heat up to 110° C., turn on the vacuum pump, and dehydrate under reflux for 1 hour. After that, the temperature was lowered to 67°C, filled with nitrogen protection, 250kg of diphenylmethane diisocyanate was added to react for 3 hours, and then 7.3kg of (S)-(-)-4-tert-butyl-2-oxazolidinone was added to the system, Stir at 50°C for 0.5h, then add 0.2kg of dibutyltin dilaurate and 0.11kg of triethylenetetramine, keep stirring at 50°C for 0.5h, and finally measure the content of -NCO groups in the system. When -NCO When the percentage content of the base is reduced to about 3.5%, the temperature is lowered, and airtight storage is performed to obtain a one-component quick-drying solvent-free polyurethane adhesive.

[0041] After testing, the NCO content of this product is 3.4%, the curing time is 40min, and the viscosity is 3525mPa.s / 25℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com