Aluminum alloy cable strap material and production method thereof

A production method and aluminum alloy technology, applied in the field of aluminum alloy materials, can solve the problems of long production cycle, unsatisfactory quality of aluminum alloy plates, high energy consumption, etc., and achieve the effects of simplified production process, easy promotion, and increased annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of aluminum alloy cable belt and production method thereof

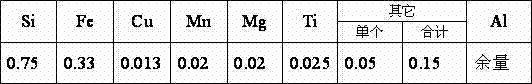

[0029] 1. Product ingredients

[0030]

[0031] 2. Production method

[0032] (1) Melting Add scraps and remelted aluminum ingots that meet the above requirements into the flame reverberatory furnace, heat to melt and stir thoroughly, stirring for 15 minutes each time, and stirring again at intervals of 20 minutes to prevent local overheating of the melt, and then carry out slag removal ;Take samples when the temperature is adjusted to 750±5°C. When sampling, pay attention to stirring the melt thoroughly to ensure uniform composition. According to the results of pre-furnace analysis, adjustments are made in the melting furnace according to the proportion of alloy components. The additives added during adjustment, such as Fe agent, Al-Si ingots, etc., must meet the requirements of national standards. When the melt temperature is measured, the thermocouple thermometer should be placed i...

Embodiment 2

[0042] Embodiment 2, production method are the same as embodiment 1, and difference is:

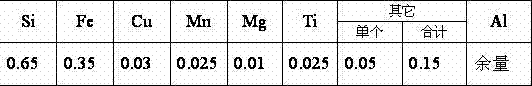

[0043] 1. Product ingredients

[0044]

[0045] 2, production method, difference with embodiment 1 is:

[0046] During continuous casting and rolling, the aluminum alloy melt is cast and rolled into a 7.0mm strip; the roll gap is 5.5mm, the length of the casting and rolling area is 50mm, the temperature of the front box is 700°C, the casting speed is 850mm / min, and the roughness of the casting roll is 0.85 μm;

[0047]The work roll crown is 0.07mm, the roughness is 0.35μm, and the rolling oil temperature is 40°C during cold rolling; the work roll crown is 0.05mm, the roughness is 0.3μm, and the rolling oil temperature is 50°C during foil rolling. ℃, the rolling speed is 430m / min; during annealing, it is kept at 390℃ for 9h, and then the furnace temperature is lowered to 370℃, and kept at 9h to obtain the finished product.

[0048] Finished performance indicators: tensile strength 96...

Embodiment 3

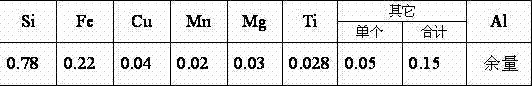

[0049] Embodiment 3, production method are the same as embodiment 1, and difference is the composition of product:

[0050]

[0051] During continuous casting and rolling, the aluminum alloy melt is cast and rolled into a 6.5mm strip; the roll gap is 5.3mm, the length of the casting and rolling area is 52mm, the temperature of the front box is 710°C, the casting speed is 950mm / min, and the roughness of the casting roll is 0.9 μm;

[0052] During cold rolling, the crown of the work roll is 0.05mm, the roughness is 0.35±0.03μm, and the temperature of the rolling oil is 42°C; The oil temperature is 52°C, and the rolling speed is 400m / min; during annealing, the temperature is kept at 400°C for 10 hours, and then the furnace temperature is lowered to 350°C, and the temperature is kept for 10 hours to obtain the finished product.

[0053] Finished performance indicators: tensile strength 93MPa, elongation 25.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com