Patents

Literature

90results about How to "Meet the actual requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gear profile modification method based on vibration reliability and genetic algorithm

InactiveCN102314534AImprove transmission error reliabilityEliminate shockSpecial data processing applicationsGear systemGenetic algorithm

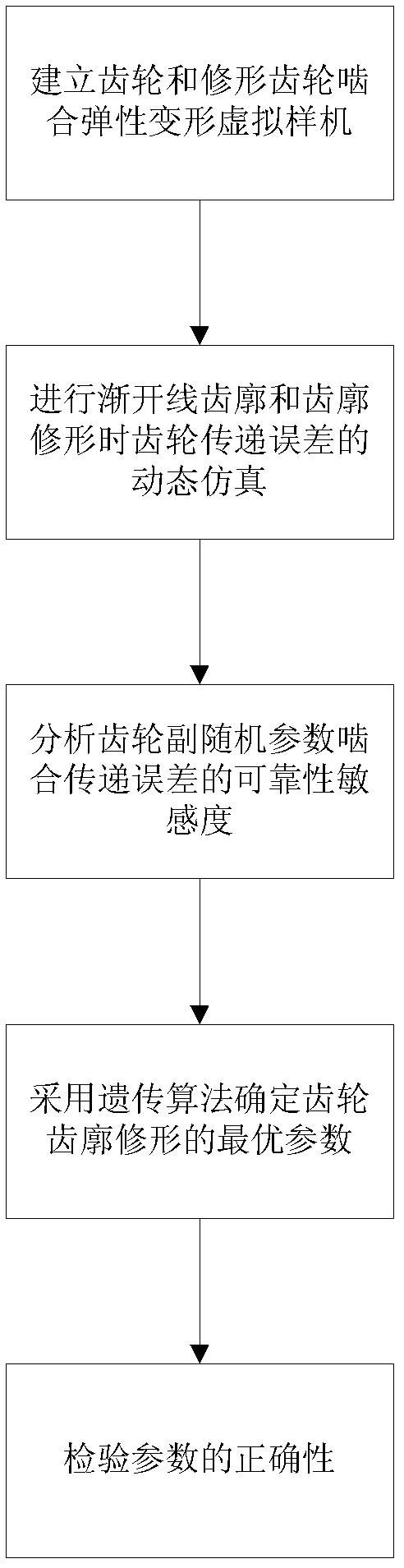

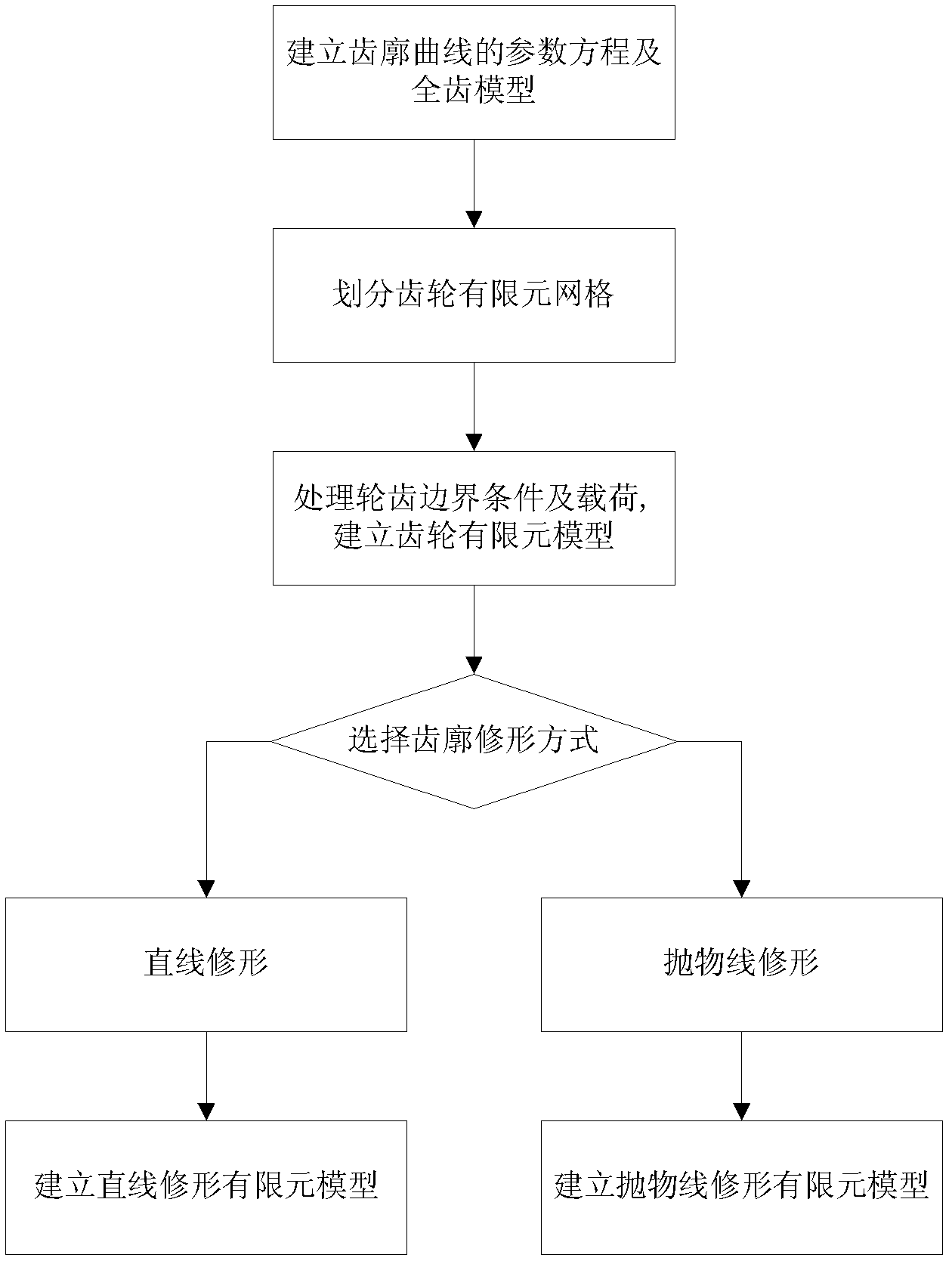

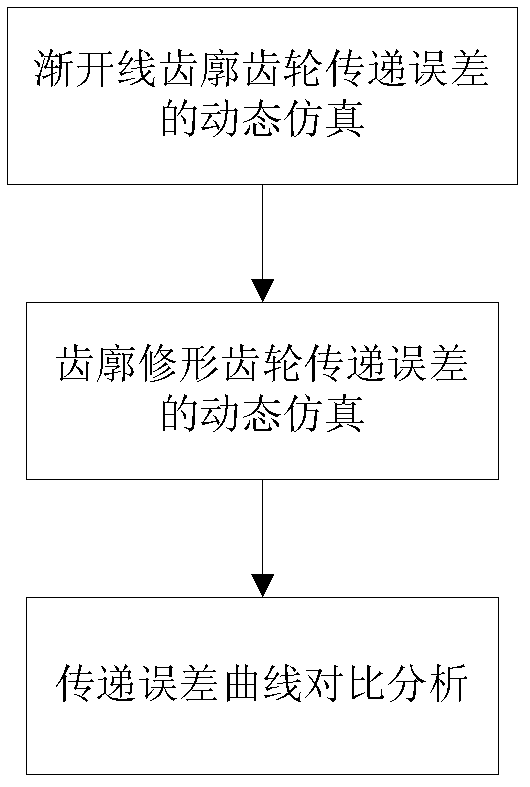

The invention discloses a gear profile modification method based on vibration reliability and a genetic algorithm, belonging to the technical field of reliability designs. The gear profile modification method can not only reduce meshing impact due to elastic deformation and manufacturing errors, but also reduce the meshing excitation of a gear so that a gear system has smooth transmission, the vibration and the noises are reduced, and the reliability and service life of the gear system can be improved. The gear profile modification method comprises the following steps of: (1), establishing an elastic modification virtual prototype for meshing between a gear and a modifying gear; (2) carrying out dynamic simulation on gear transmission errors in the process of an involute profile and the profile modification; (3) analyzing the reliability sensitivity of the transmission errors at the time of gear pair random parameter meshing; (4) determining optimal parameters of the gear profile modification by utilizing the genetic algorithm; and (5) verifying the correctness of the parameters.

Owner:NORTHEASTERN UNIV LIAONING +1

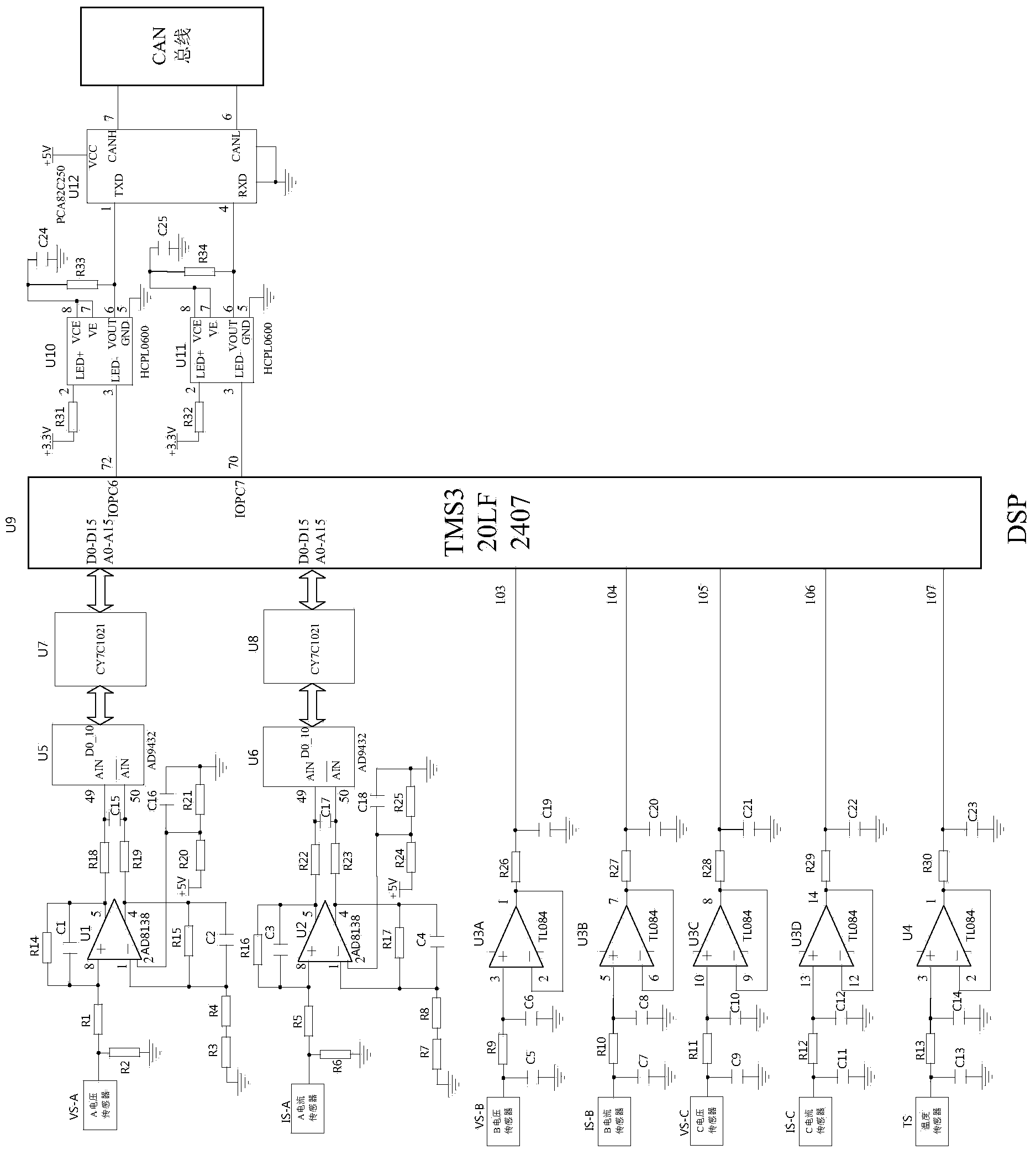

Ground testing system suitable for power source controller of stratospheric airship

ActiveCN104375502AImplement performance testingImplement functional testingElectric testing/monitoringTest efficiencyPower controller

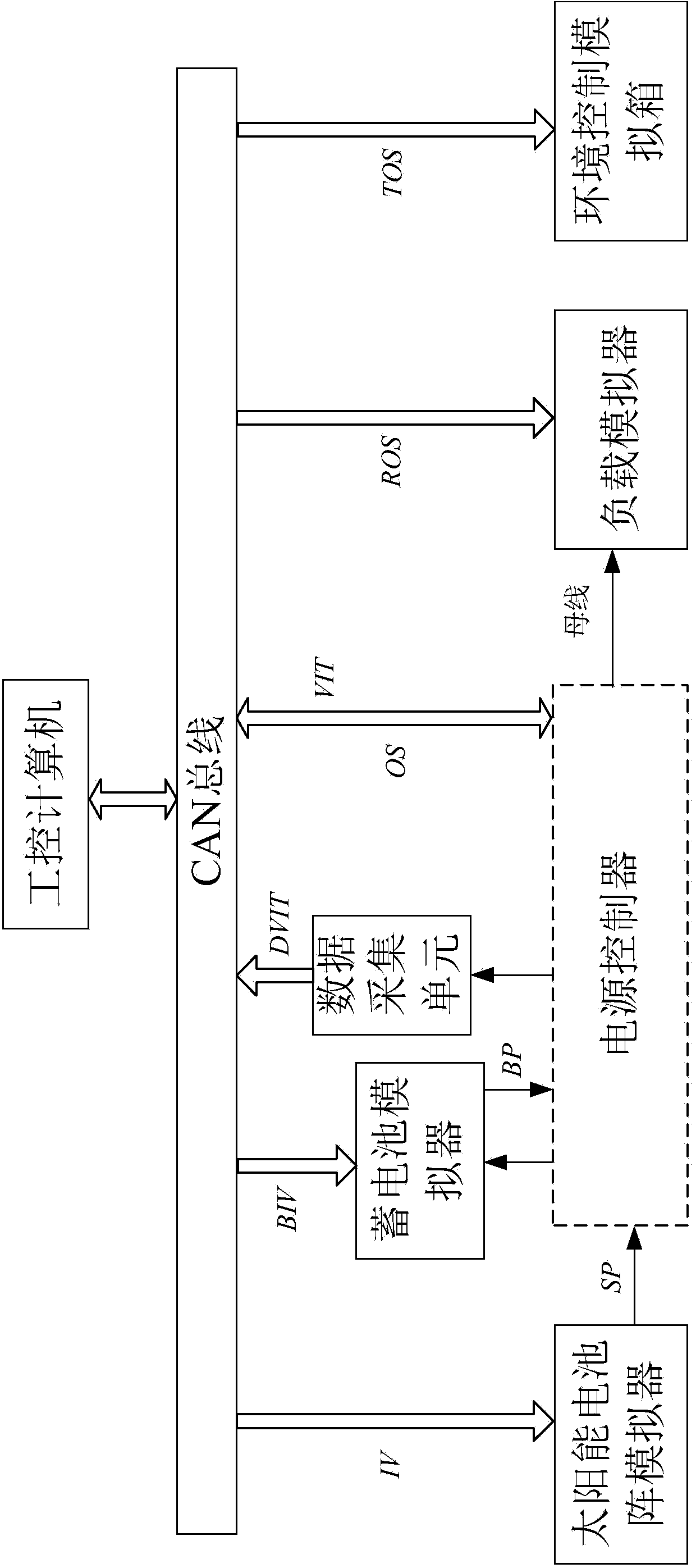

The invention discloses a ground testing system suitable for a power source controller of a stratospheric airship. The ground testing system is applied to the development and test processes of the power source controller of the stratospheric airship. The ground testing system is composed of an industrial personal computer, a CAN bus, a data collecting unit, a solar battery array simulator, a storage battery simulator, a load simulator and an environment control simulation box. The CAN bus is adopted for communicating with the power source controller of the stratospheric airship, and combined with the industrial control computer and the data collecting unit, and testing on the function and the performance of the power source controller is finished under signals issued by the industrial control computer. The designed ground testing system reduces the testing cost and improves the testing efficiency.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

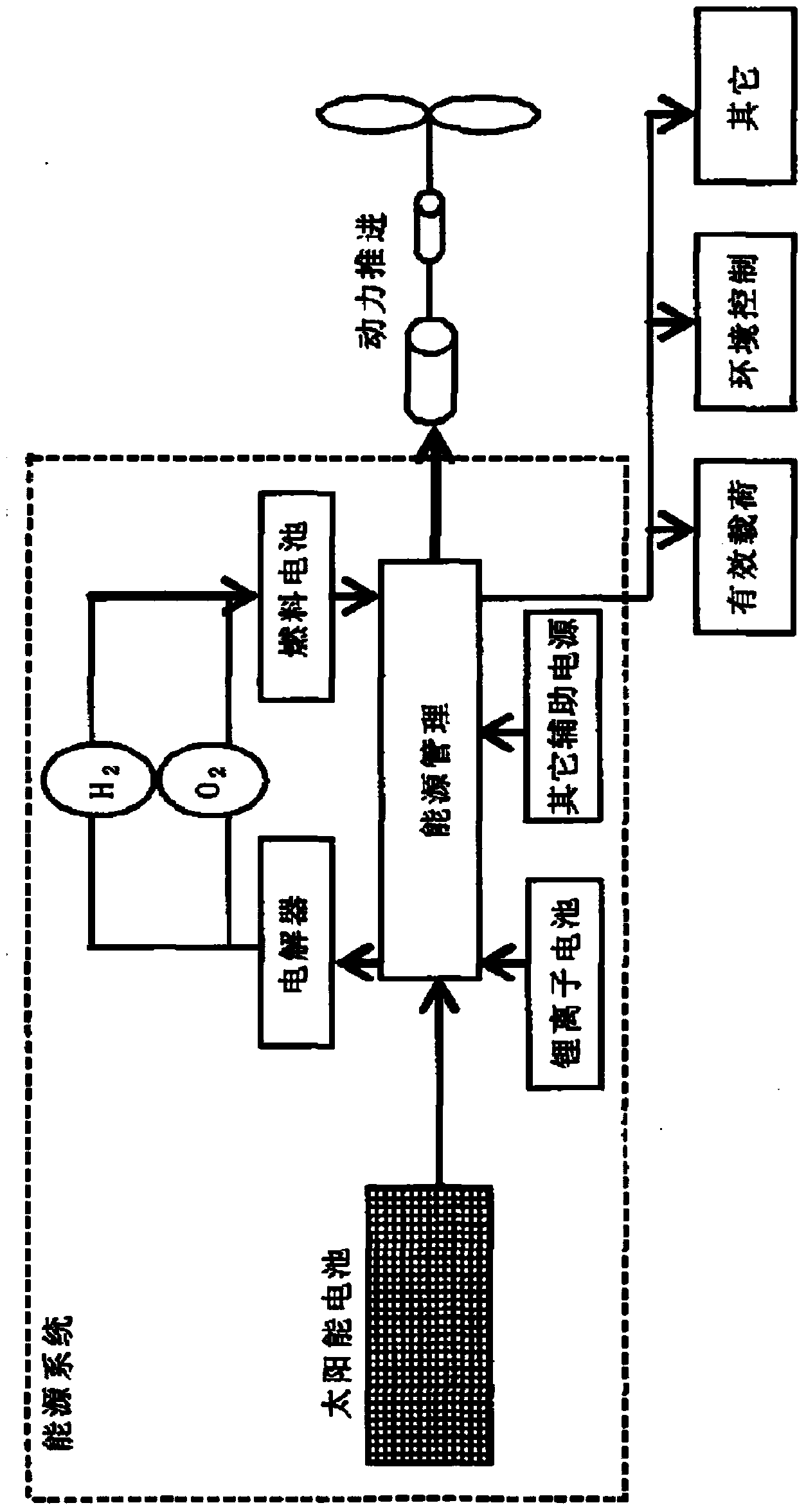

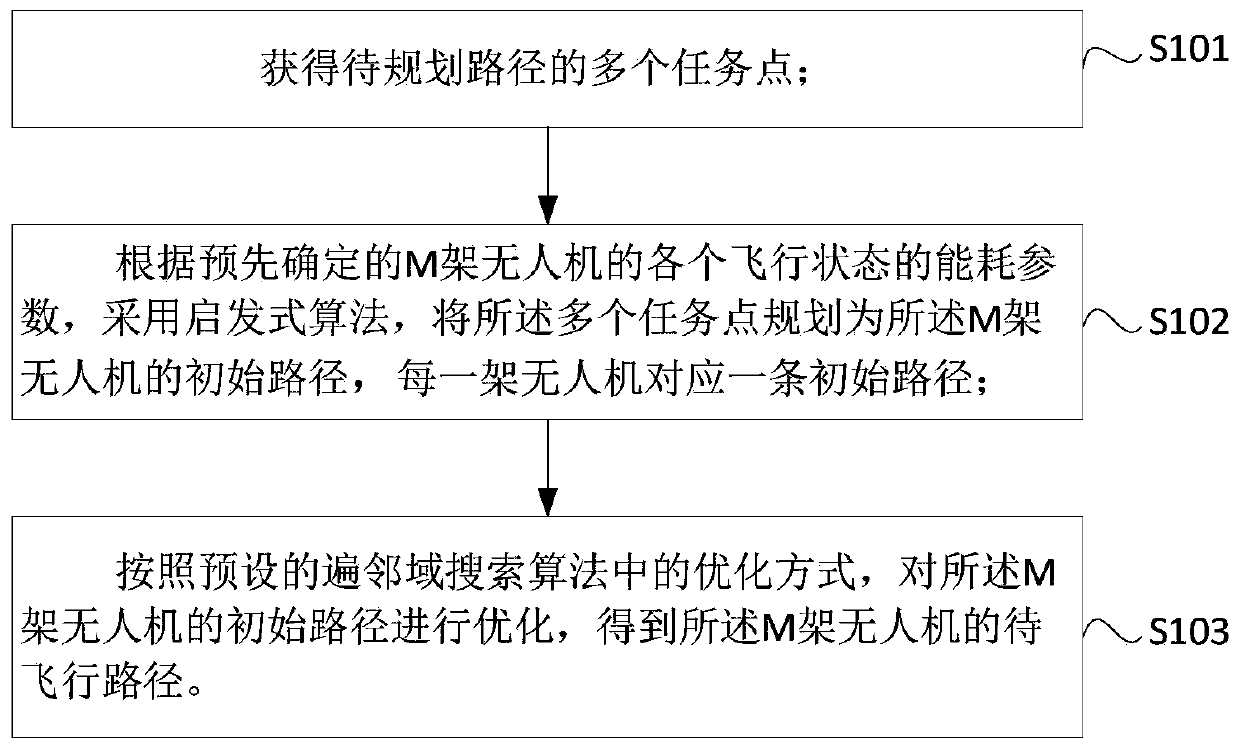

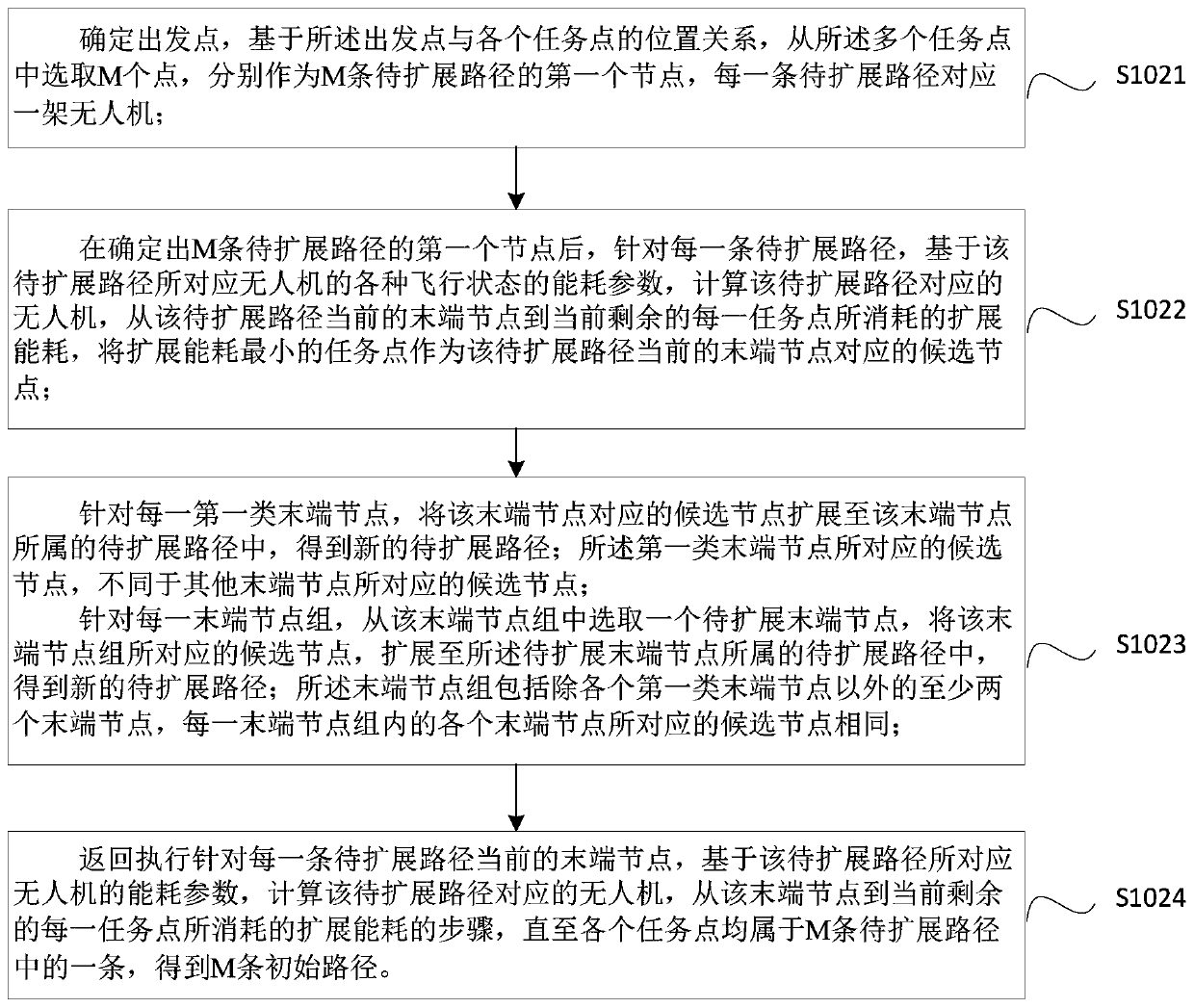

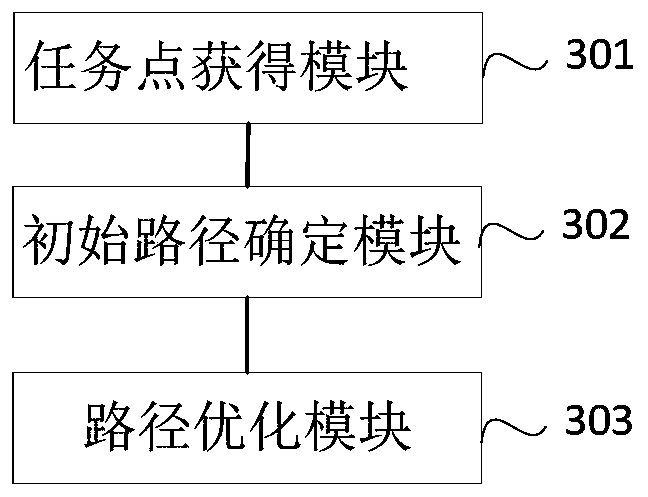

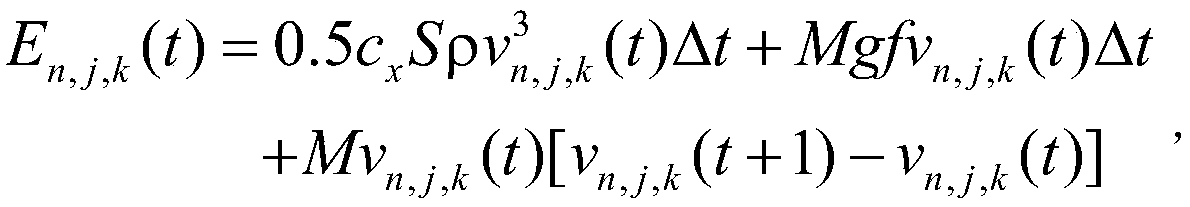

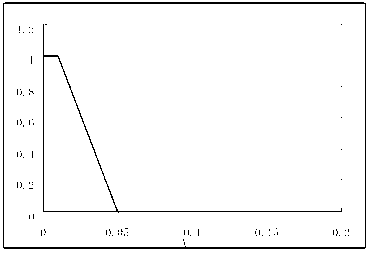

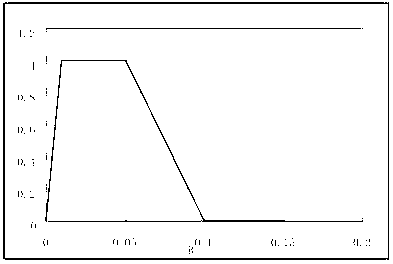

Multi-UAV mission planning method based on minimization of maximum energy consumption and device

ActiveCN109933089AMeet the actual requirementsReduce energy consumptionPosition/course control in three dimensionsNeighborhood searchSimulation

The embodiment of the invention provides a multi-UAV mission planning method based on minimization of maximum energy consumption and device. The method comprises steps: multiple mission points are acquired; the multiple mission points are planned to an initial path; and the initial path is optimized according to an optimization manner in a preset traversing neighborhood search algorithm to obtainflight paths of M UAVs. The step of planning the multiple mission points to an initial path comprises sub steps: a starting point is determined and M points are selected from the multiple mission points to serve as first nodes of M to-be-expanded paths; after the first nodes of the M to-be-expanded paths are determined, in view of a tail-end node of each to-be-expanded path, the expansion energy consumption is calculated, and a mission point with the minimum expansion energy consumption is used as a candidate node; and the expansion energy consumption of the rest to-be-expanded paths is returned to be calculated until each mission point belongs to one of the M to-be-expanded paths, and M initial paths are obtained. Through the scheme of the invention, the flight path of multiple UAVs working together can be further effectively adjusted.

Owner:BEIJING UNIV OF POSTS & TELECOMM

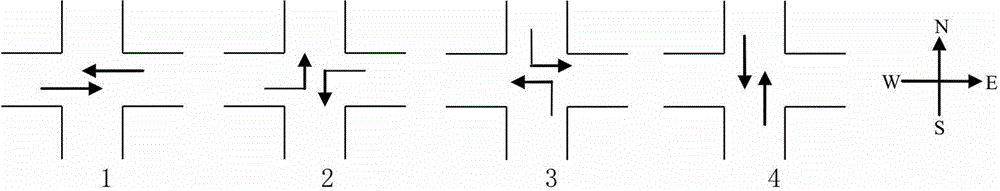

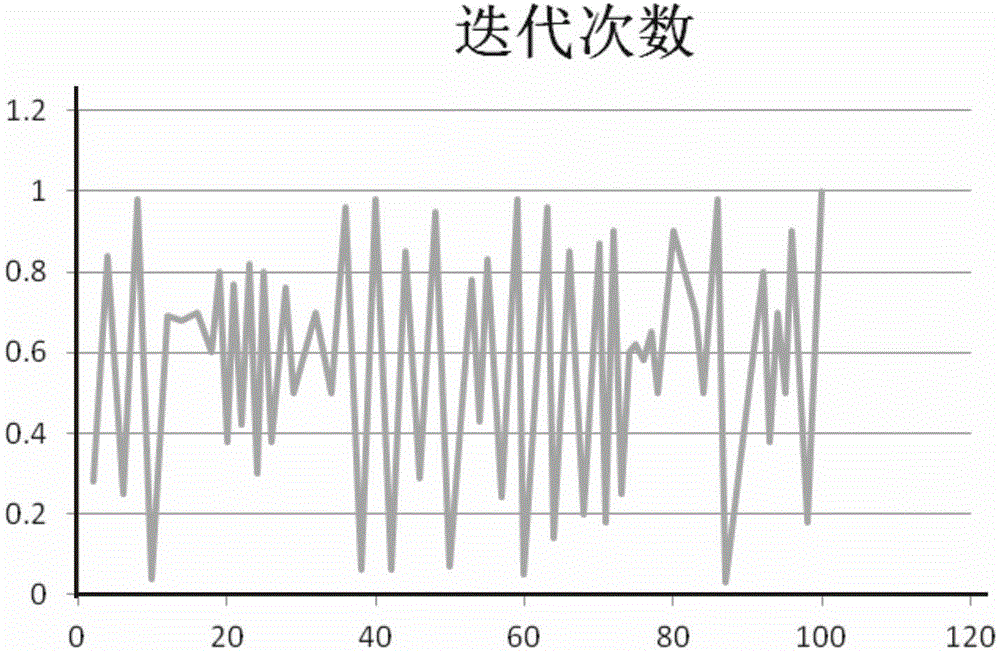

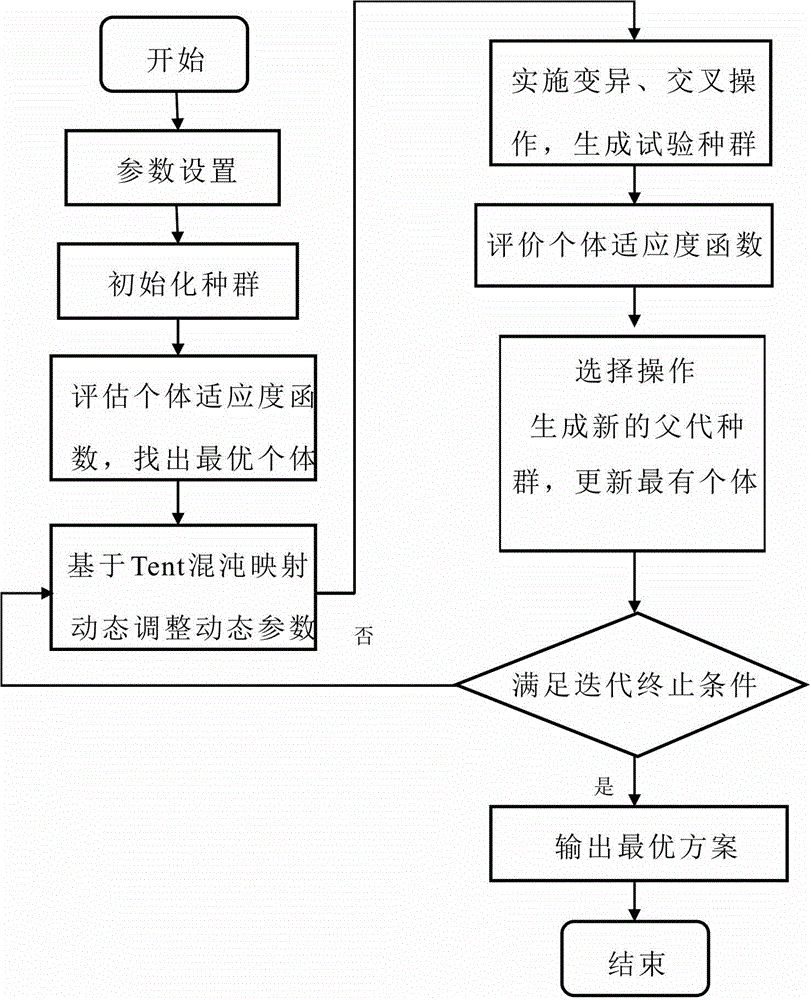

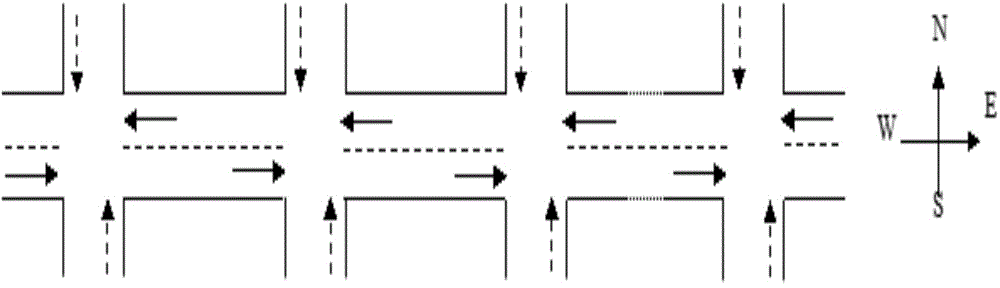

Traffic control method of intersections containing mixed traffic flows

InactiveCN104021685AMeet the actual requirementsReach parkingControlling traffic signalsSimulationTraffic flow

The invention relates to a traffic control method of intersections containing mixed traffic flows, belonging to the technical field of intelligent transportation. The method comprises the following steps: (1) establishing an intersection transportation control model containing mixed traffic flows; (2) solving the established intersection transportation control model containing the mixed traffic flows by using a chaos differential evolution algorithm. The method has the beneficial effects that the constraints of the mixed traffic flows are taken into account, and then, the traffic conditions of the intersections are more accurately reflected, so that a signal coordination scheme developed based on the traffic conditions is more reliable; minimum vehicle delay, minimum stop number and maximum pass capacity are targeted, so that the effectiveness of traffic coordination control is improved to the maximum. The traffic control method of the intersections containing the mixed traffic flows, based on the chaos differential evolution algorithm, disclosed by the invention, has the advantage that the problems of high dimensionality, nonlinearity and multiple constraints of the intersections can be excellently solved.

Owner:GUANGDONG UNIV OF TECH

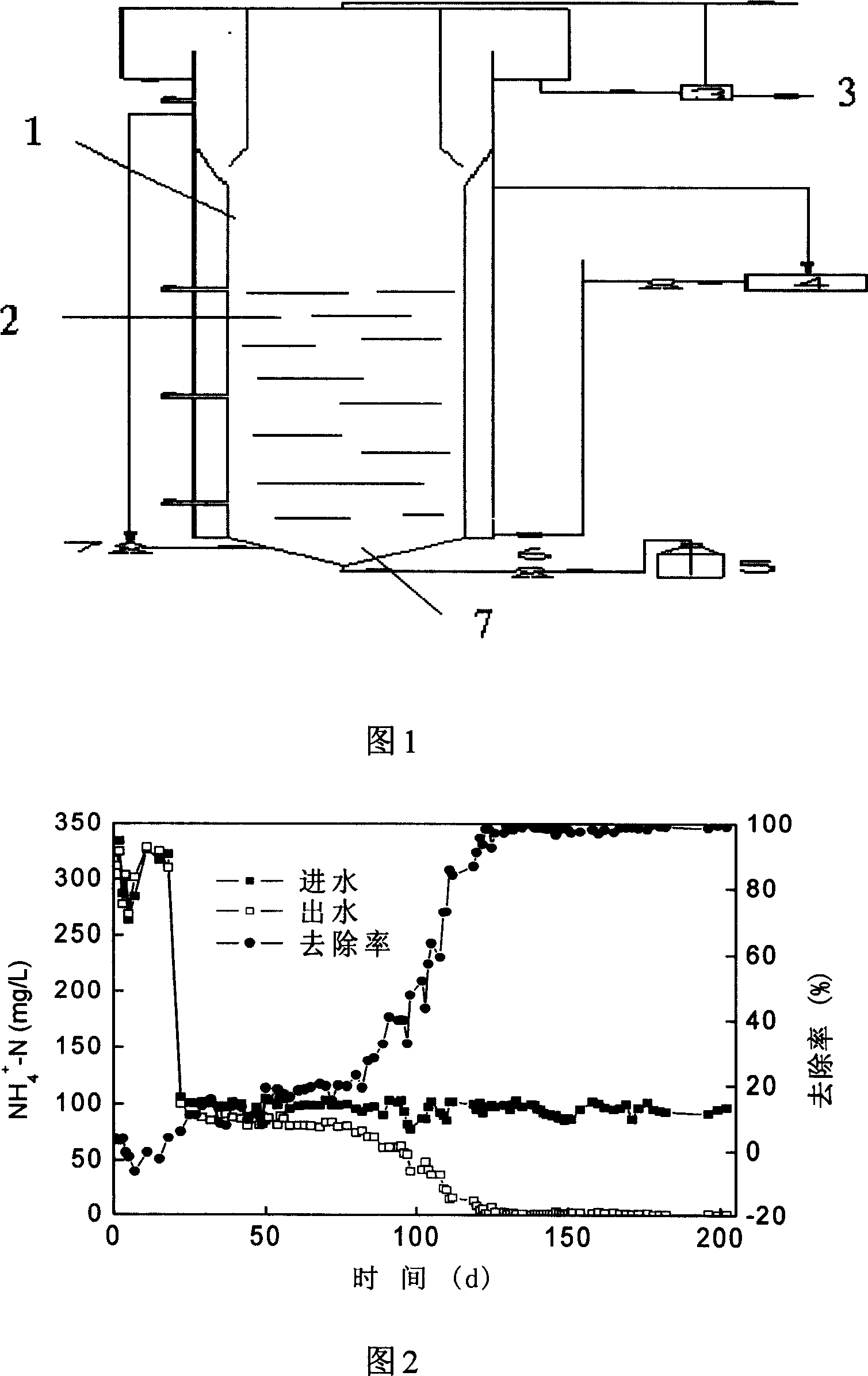

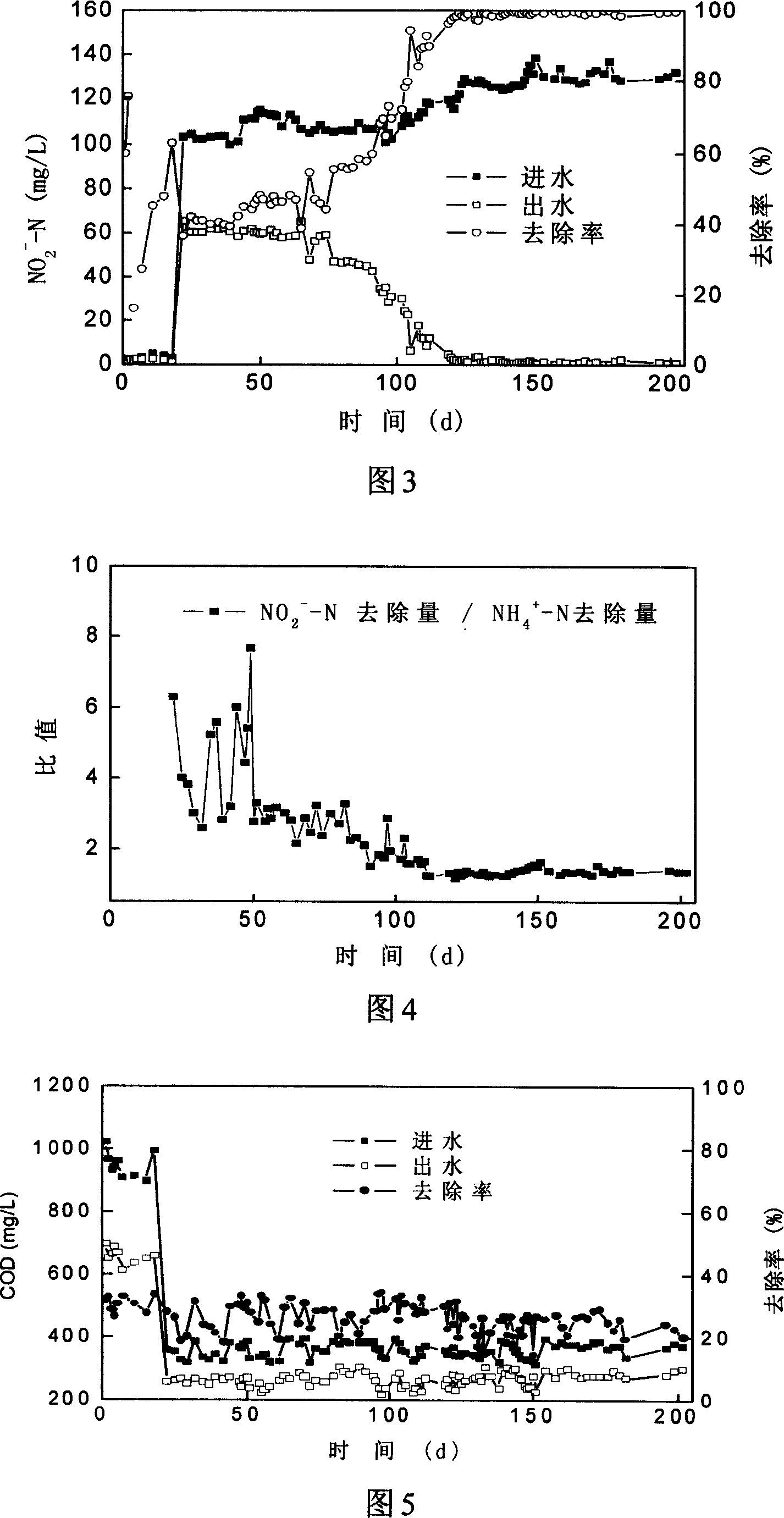

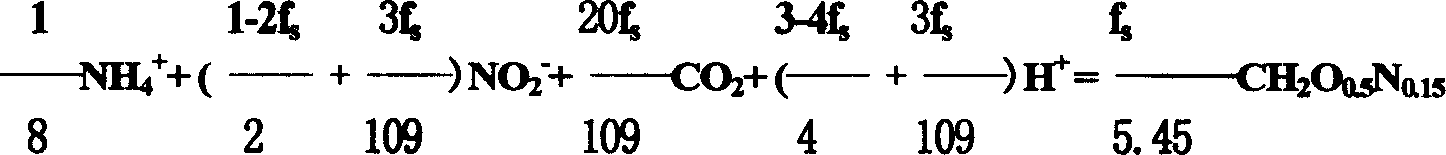

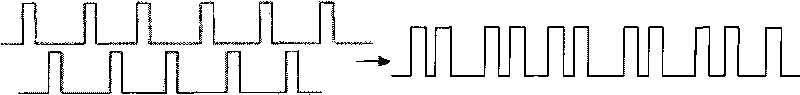

Anerobic ammoxidation and denitrification synergistic denitrification method for garbage leachate

InactiveCN101007684AMeet the actual requirementsAchieve synergyTreatment with aerobic and anaerobic processesActivated sludgeAmmonia-oxidizing bacteria

The invention discloses a method of garbage percolation water anaerobic ammoxidation and denitrifying synergic denitrify, which comprises the following steps: mixing garbage waste-water with COD, NH4+,NO2- and NO3- and nitrated nitrogenous water; leading organic wastewater into activated sludge and garbage percolation water; enriching anaerobic ammonia-oxidizing bacteria and denitrifying bacteria on the tamed anaerobic sludge bed; removing COD, ammonia nitrogen and nitrated nitrogen synchronously through cooperating knife-bar of anaerobic ammonia-oxidizing bacteria and denitrifying bacteria; controlling temperature of waste-water under 26-36 deg.c. The invention realizes denitrifying reaction, which removes partial COD effectively.

Owner:SOUTH CHINA UNIV OF TECH

Method for generating random frequency pulse and method for controlling acceleration and deceleration of stepper motor

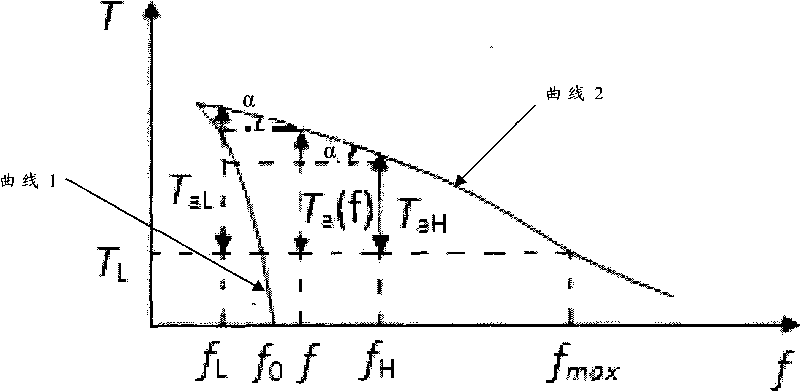

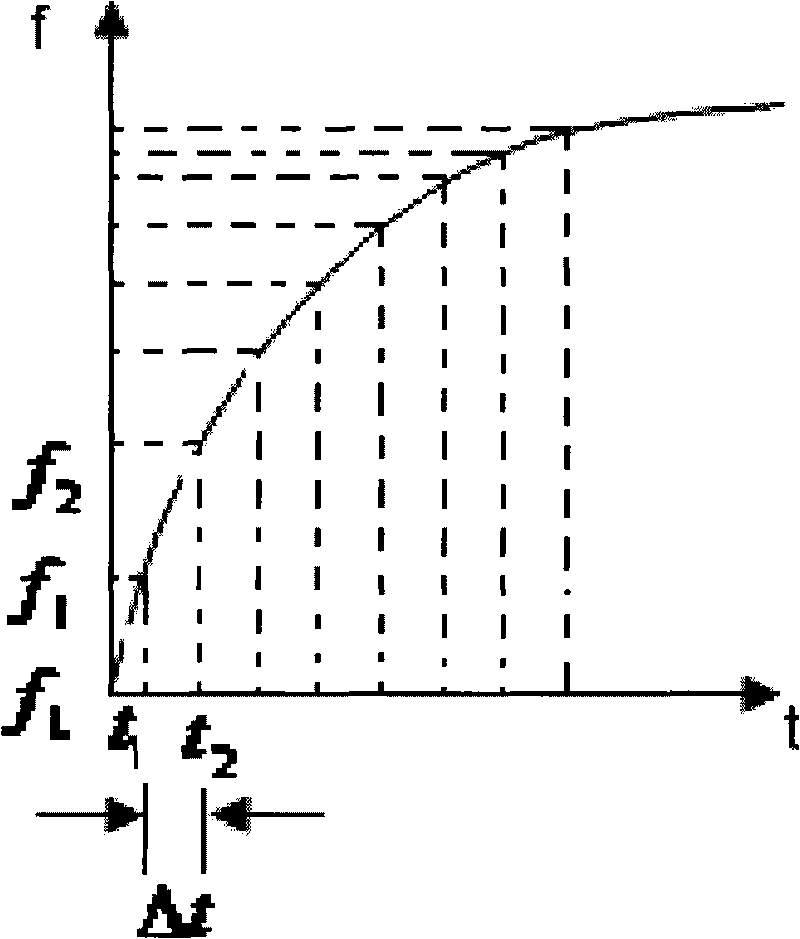

InactiveCN101710814APrevent overshootMeet the actual requirementsDynamo-electric converter controlClock rateCrossover frequency

The invention discloses a method for generating random frequency pulse and a method for controlling acceleration and deceleration of a stepper motor, comprising the following steps of: firstly, counting by using a clock control counter provided from an external part ; secondly, demultiplying a clock frequency provided by the external part by using different counting bits, and outputting pulse signals with different demultiplying frequencies through each counting bit; and then extracting the pulse signals with one or several demultiplying frequencies to carry out a combination according to actual needs to generate the pulse signals of the needed frequency. The invention overcomes the defect that the traditional method only can generate pulse signals with integer frequency demultiplication value, thereby satisfying the actual requirement on precision. The invention is used for the field of stepper motor control, at the same time, the generated pulse value is combined with an actual frequency time curve graph of the stepper motor during the acceleration and the deceleration, so that the pulse value on each time point is more coincided with the actual running track and the phenomenon that the lost-step and the overshoot of the stepper motor occur at the starting and the braking phases can be avoided.

Owner:青岛朗讯科技通讯设备有限公司

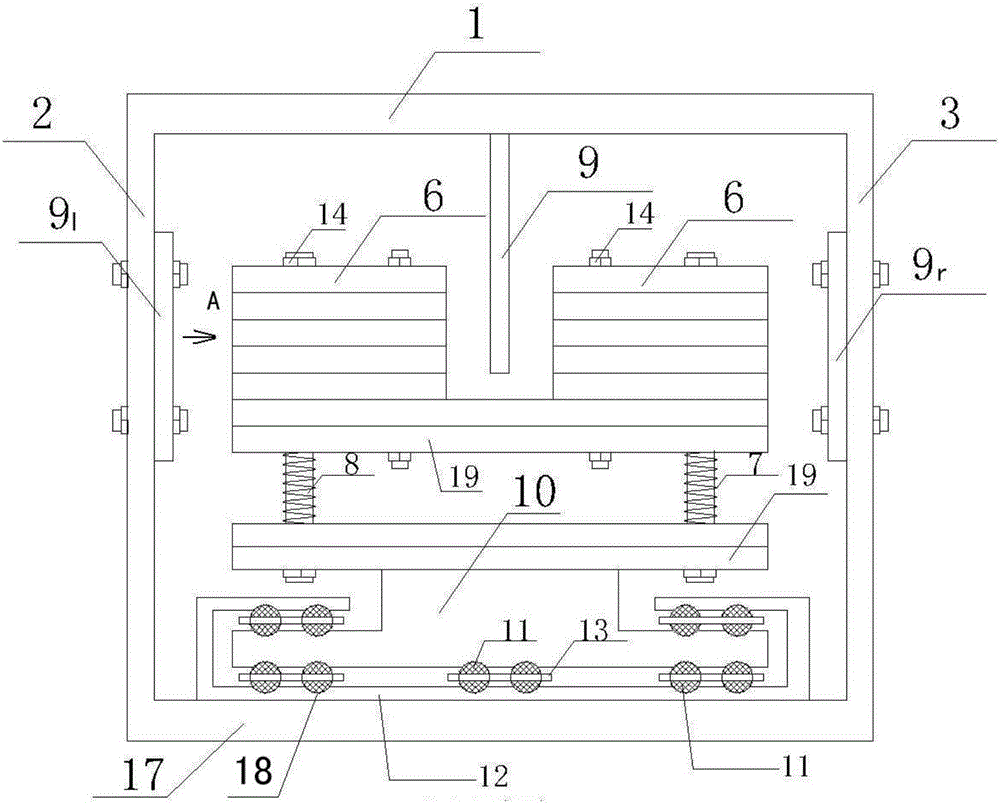

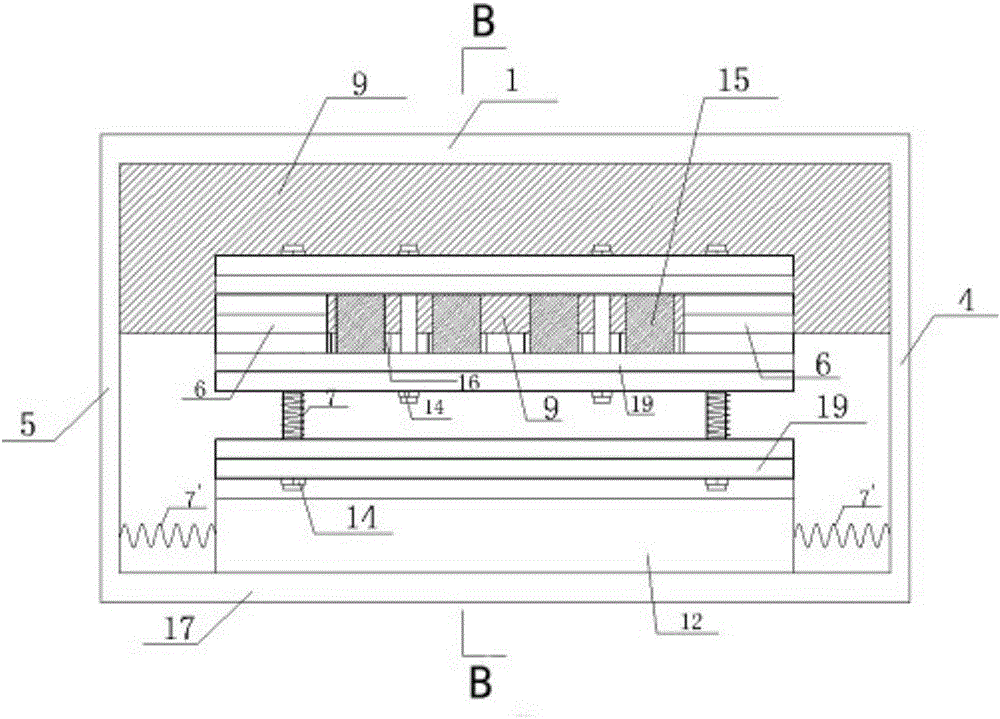

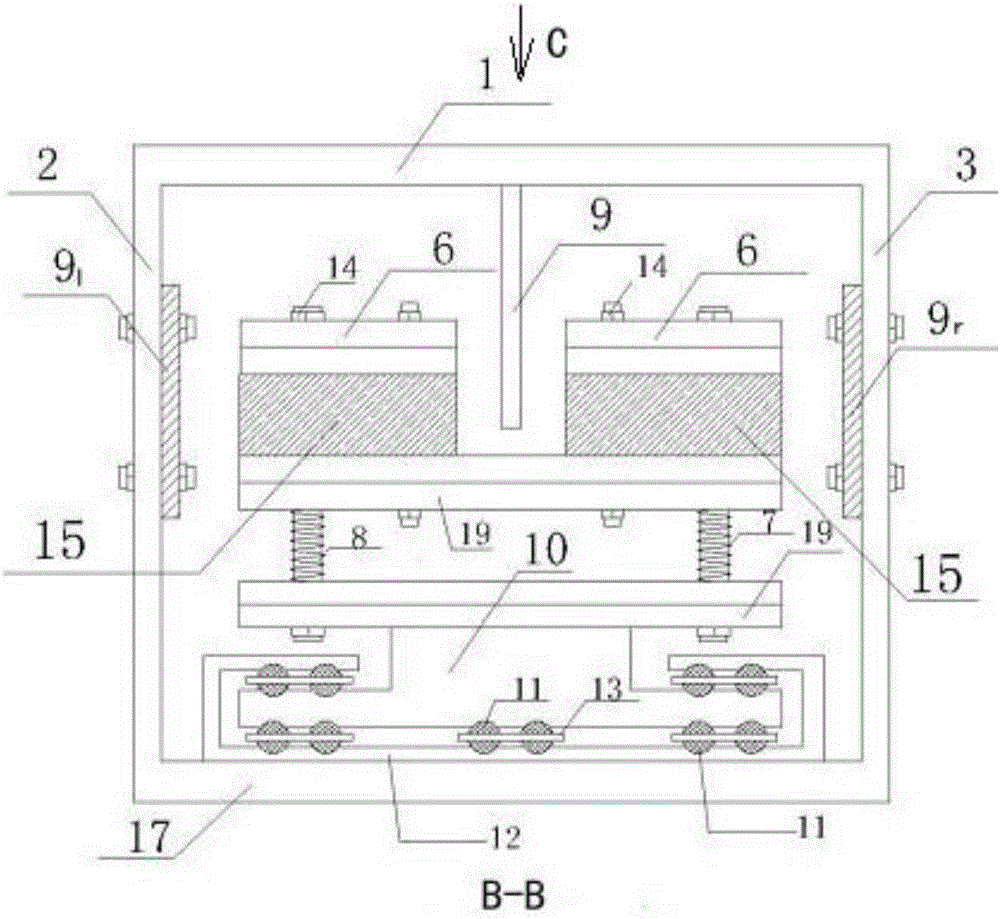

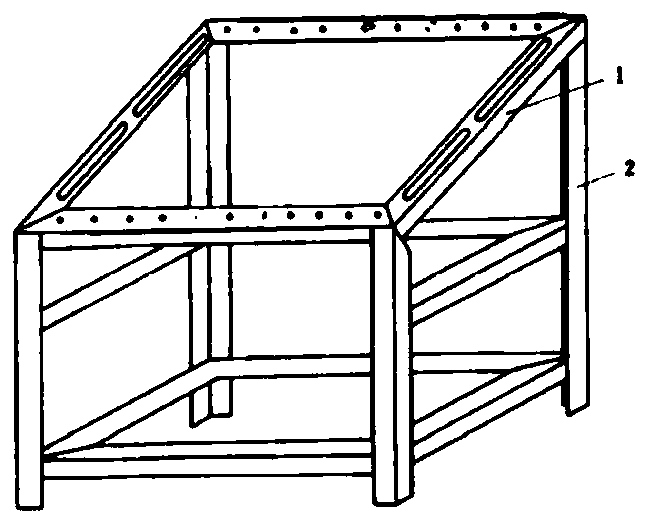

Bidirectional TMD control device and parameter determination method

InactiveCN106368488ASolve the problem of vibration controlTo achieve the purpose of two-way controlProtective buildings/sheltersShock proofingSheet steelSteel ball

The invention discloses a bidirectional TMD control device and a parameter determination method. Four steel plates are vertically arranged on a bottom plate which is horizontally disposed, a first steel plate is parallel to the bottom plate, mass blocks (6) are installed on a steel plate (19) through guide rods, and the guide rods are sleeved with vertical springs. The lower portion of a base is embedded in a rail groove of a rail assembly (12) through steel balls and steel ball clamping slots; a copper plate (9) is installed at the middle portion of the first steel plate, a left copper plate (91) and a right copper plate (9r) are installed on the portions, corresponding to the mass blocks, of the second steel plate and the third steel plate respectively, permanent magnets are installed in clamping slots, and the two ends of transversal springs (7') are connected with the fourth steel plate and the base respectively; the two ends of another pair of transversal springs (7') are connected with the fifth steel plate (5) and the base (10) respectively. The parameter determination method comprises the following steps: optimizing the TMD vertical parameter and the TMD horizontal parameter which are obtained by calculation in finite element software to obtain an optimal solution; then determining the final parameter of a TMD.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

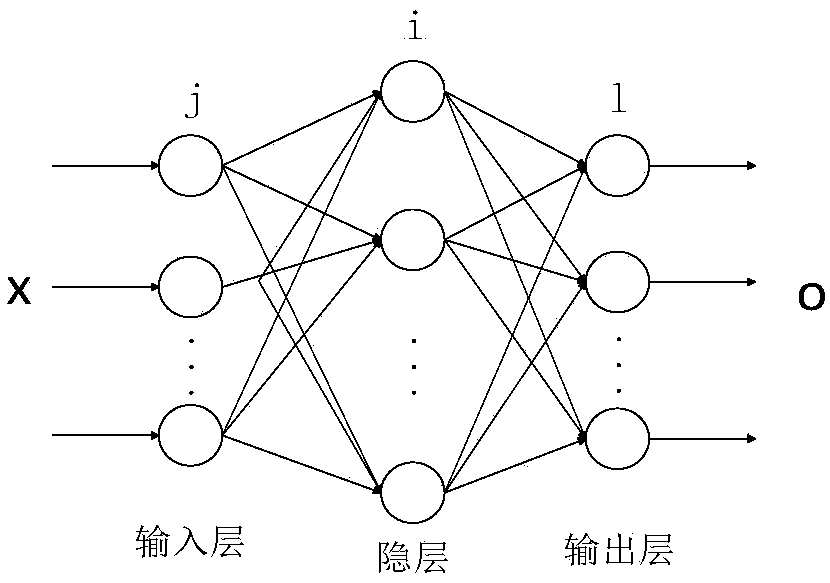

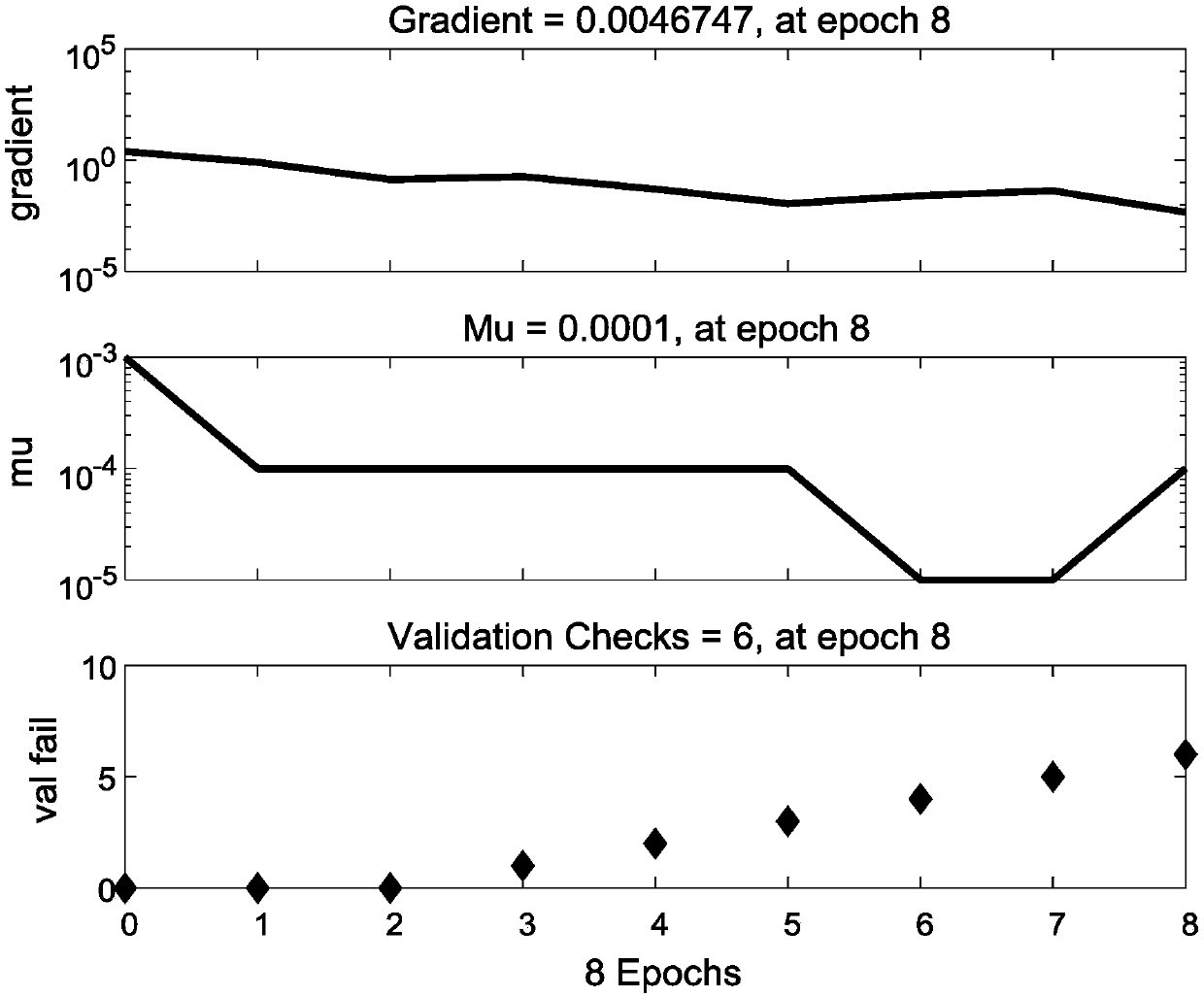

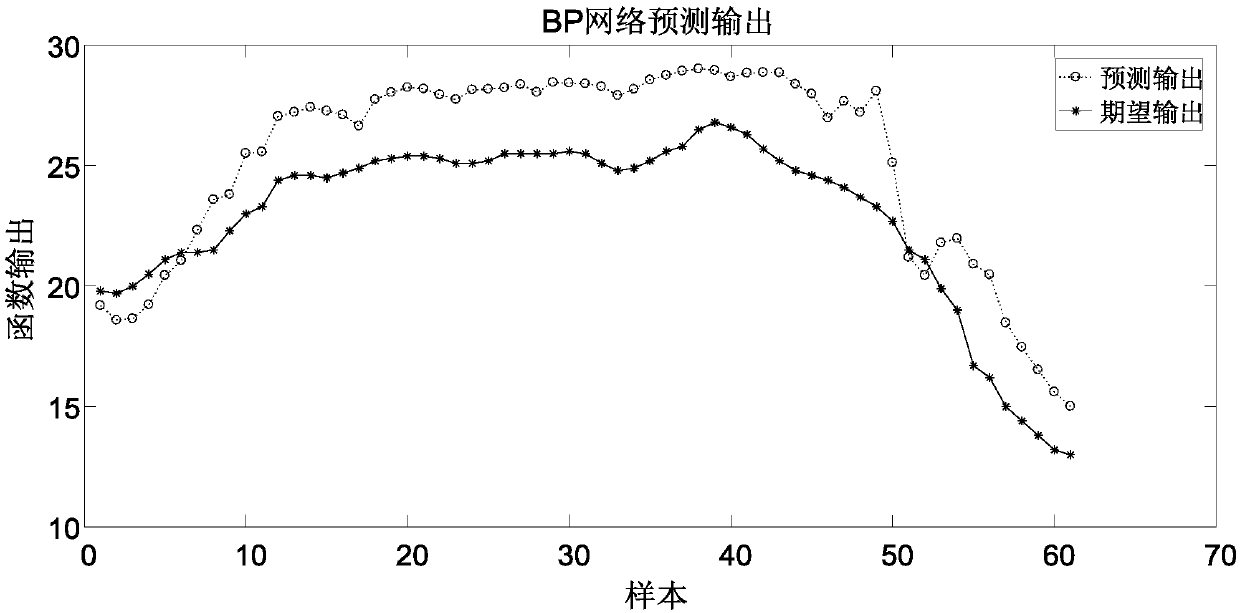

Genetic BP neural network-based solar greenhouse temperature prediction method

InactiveCN107909149AImprove the simulation effectMeet the actual requirementsNeural learning methodsPredictive methodsGenetic algorithm

The invention discloses a genetic BP neural network-based solar greenhouse temperature prediction method. According to the method, on the basis of analysis on main factors affecting the microclimate environment of a greenhouse, with the temperature and light in the greenhouse and the difference of temperature inside and outside the greenhouse adopted as model input, a BP neural network-based greenhouse temperature prediction model is constructed; and the BP neural network algorithm is improved by using the genetic algorithm to optimize the weight and threshold of the network, and therefore, agenetic BP neural network-based greenhouse temperature prediction model is constructed. A simulation result shows that the prediction effect of the genetic algorithm optimized BP neural network has fewer errors and higher prediction than the prediction effect of the BP neural network, and can realize effective prediction of the temperature of the solar greenhouse.

Owner:NORTHWEST A & F UNIV

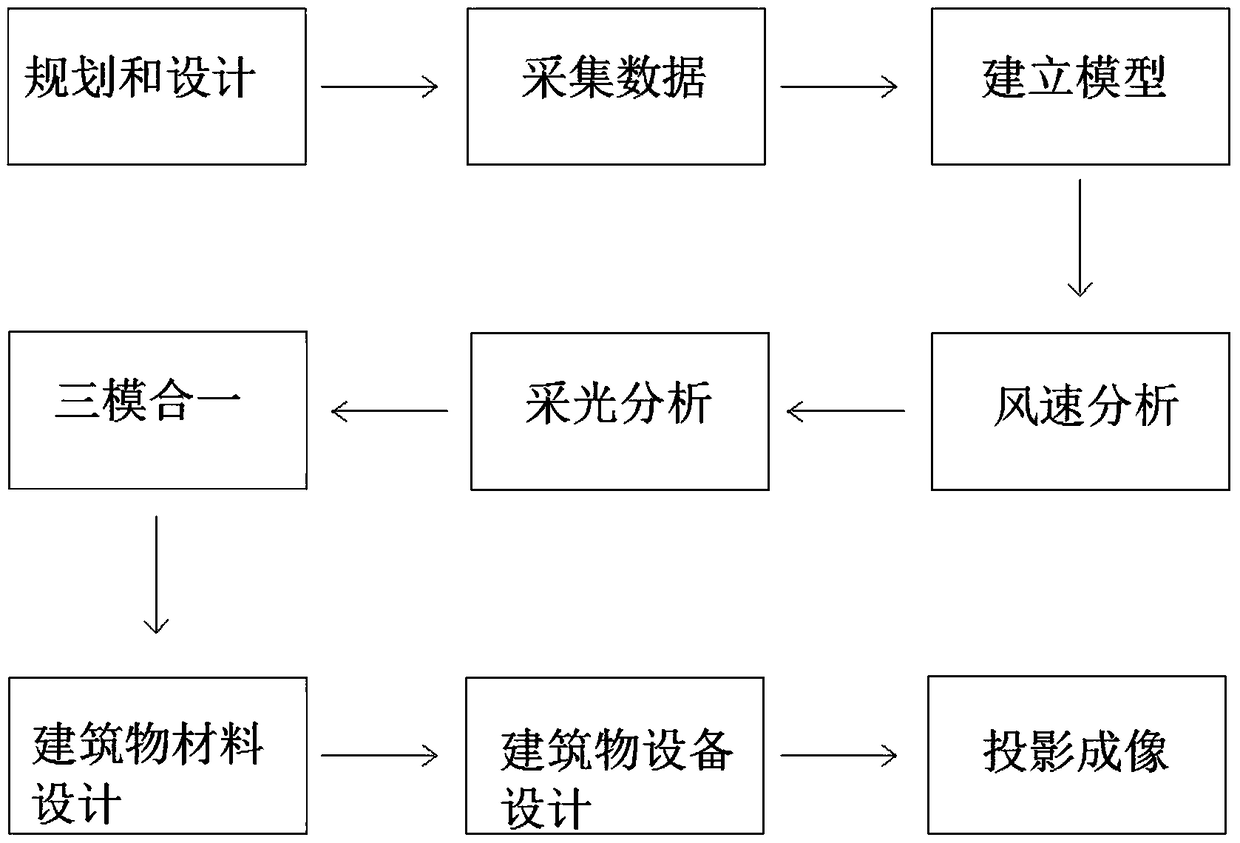

Green building design method based on BIM technology

InactiveCN109446583AComprehensive collectionMeet the actual requirementsGeometric CADSpecial data processing applicationsLight energyEngineering

The invention discloses a green building design method based on a BIM technology, comprising the following steps of planning and designing, collecting data, establishing model, analyzing wind speed and daylighting, carrying out the three-in-one operation, designing the building material and building equipment, and carrying out the projection imaging. By collecting the information of the selected area, such as the basic conditions, the geomorphology, geological hydrology, climatic conditions, the growth of animals and plants, even the traditional lifestyle messages, the information collectionis better, the architectural design is made better accord with the actual situation in the selected area and is not separated from the reality, and in conjunction with various means to model, such asborrowing scene, combing scenes, separating scenes and adding scenes, the internal and external environments cooperate better to avoid the disadvantage of the scheme. After collecting wind energy andlight energy data, the wind energy and light energy are applied to the actual building model through BIM technology, and the best location of the building is obtained, which is convenient to collect wind energy and light energy, and the energy-saving concept is integrated into the model.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

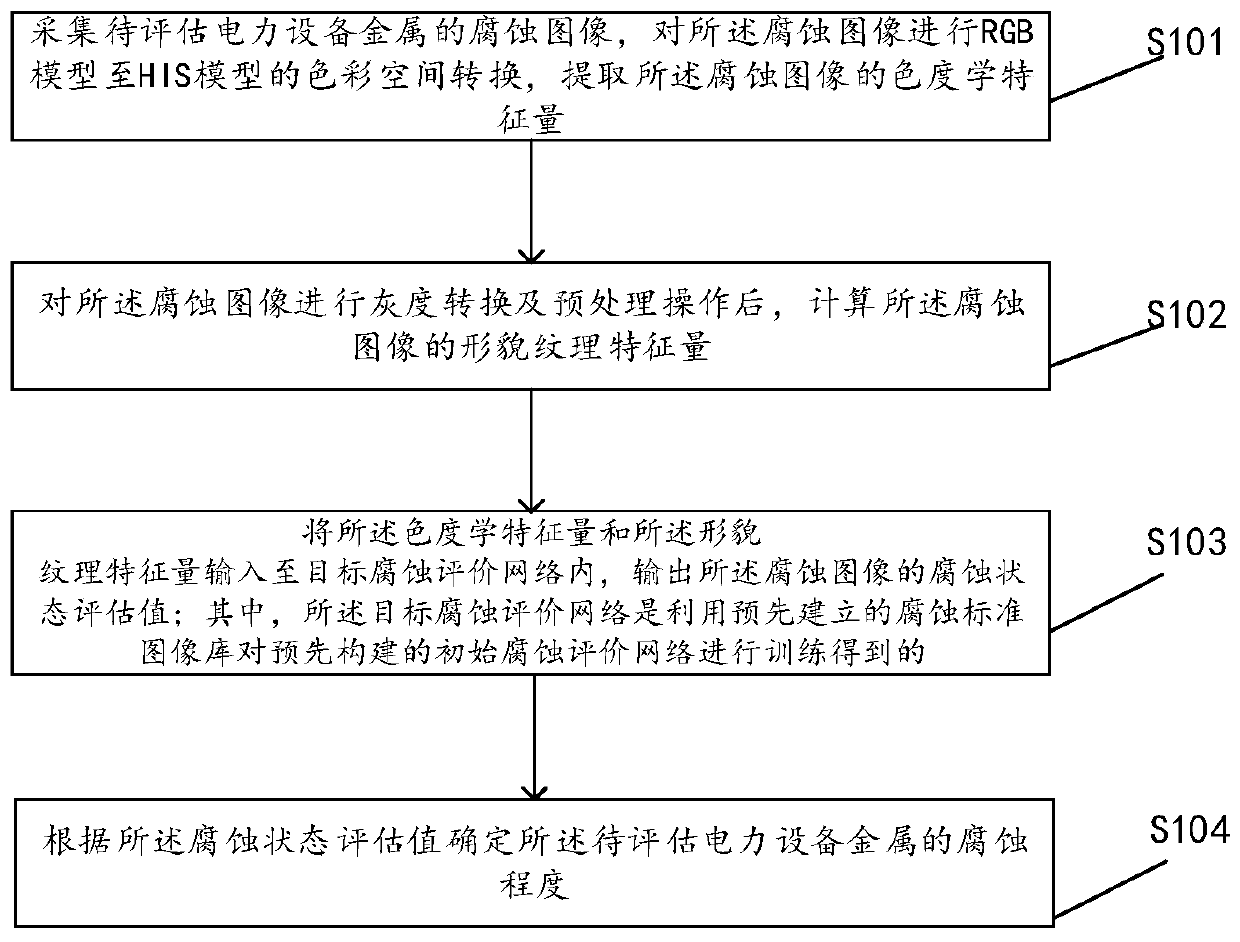

Evaluation method, device and equipment for metal corrosion state

PendingCN110009632AEasy to operateImprove detection efficiencyImage enhancementImage analysisPower equipmentPre treatment

The invention discloses an evaluation method, device and equipment for a metal corrosion state, and the method comprises the steps: collecting a corrosion image of to-be-assessed power equipment metal, carrying out the color space conversion from an RGB model to an HIS model of the corrosion image, and extracting the colorimetry characteristic quantity of the corrosion image; after carrying out gray scale conversion and preprocessing operation on the corrosion image, calculating the morphology and texture characteristic quantity of the corrosion image; inputting the chromaticity characteristicquantity and the morphology texture characteristic quantity into a target corrosion evaluation network, and outputting a corrosion state evaluation value of the corrosion image; and determining the corrosion degree of the power equipment metal to be evaluated according to the corrosion state evaluation value. According to the method, the device and the equipment provided by the invention, the metal corrosion state evaluation efficiency is improved.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +3

Bait feeding system based on body lengths of shrimps

InactiveCN105052804AAdjustment scienceReasonable adjustmentClimate change adaptationPisciculture and aquariaShrimpZoology

The invention relates to the field of shrimp cultivation technology, in particular to a bait feeding system based on body lengths of shrimps. The system is used for precisely adjusting feeding quantity according to the change of body lengths of shrimps during shrimp cultivation processes, and comprises a data storage module, a data update module, a shrimp body length obtaining module, a data analysis module and a bait feeding control module. The shrimp body length obtaining module is used for detecting body lengths of shrimps in cultivation water in real time. The data analysis module is used for comparing length body data, which is acquired in real time, of shrimps, with the length body and weight data, which are stored in the data storage module, of the same kind of shrimps, and calculating the total feeding quantity of bait. The bait feeding control module is used for controlling feeding quantity of the shrimps and executing feeding. The bait feeding system is capable of properly automatically feeding bait according to different species of shrimps, so rest bait in the cultivation water is reduced, micro-particles are reduced, numbers of filtering processing for the cultivation water are reduced, production cost is reduced and electric power and human resources are saved.

Owner:QINGDAO AGRI UNIV +1

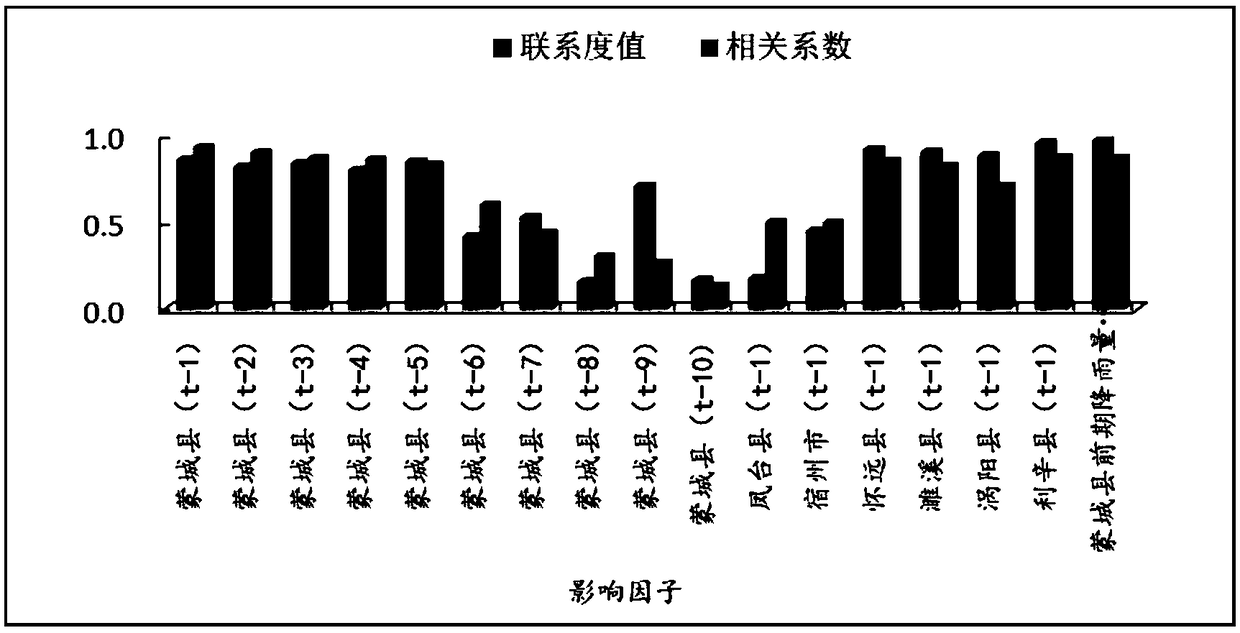

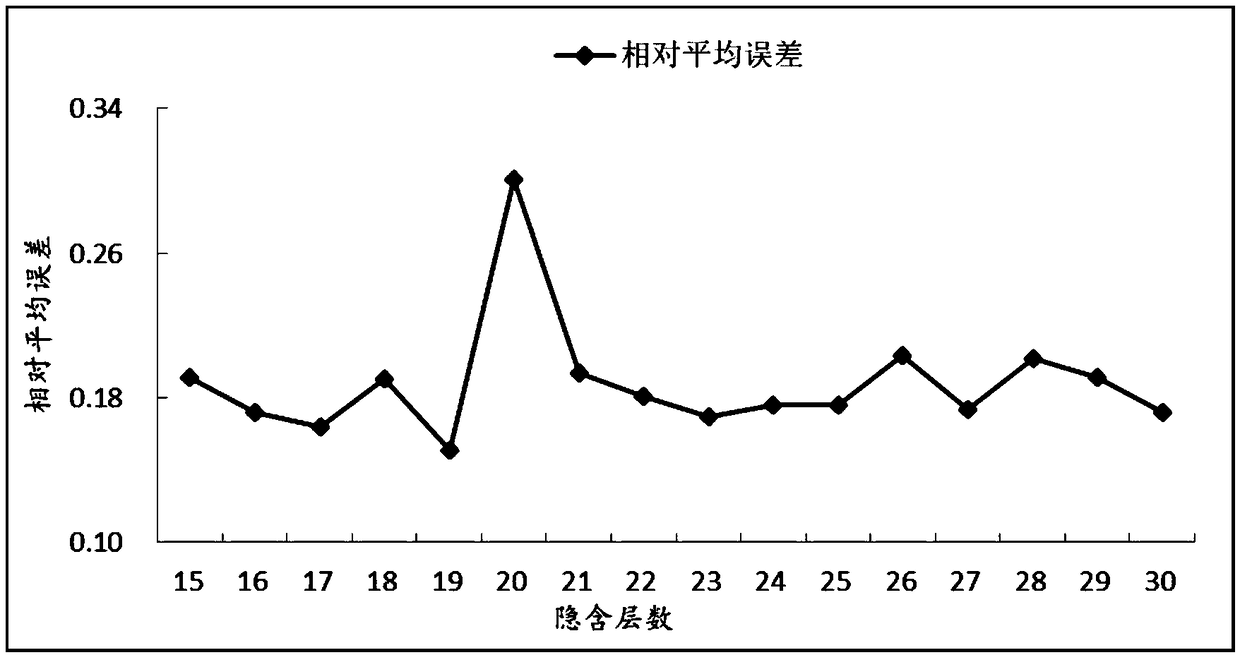

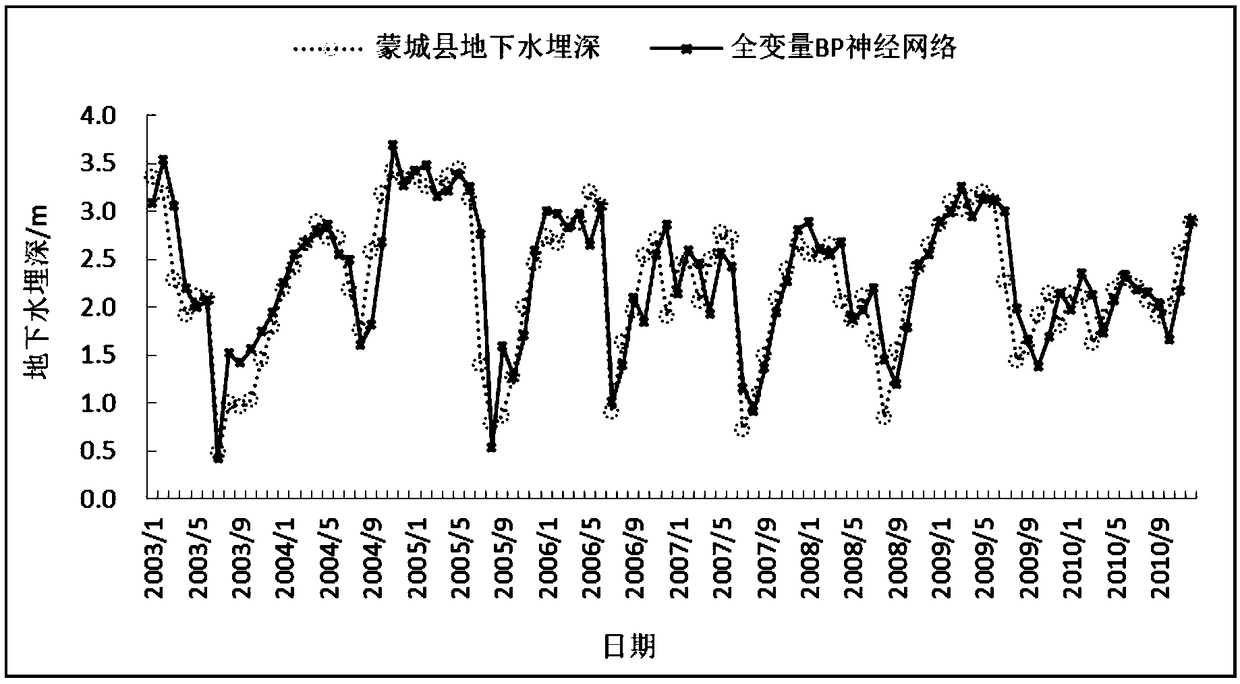

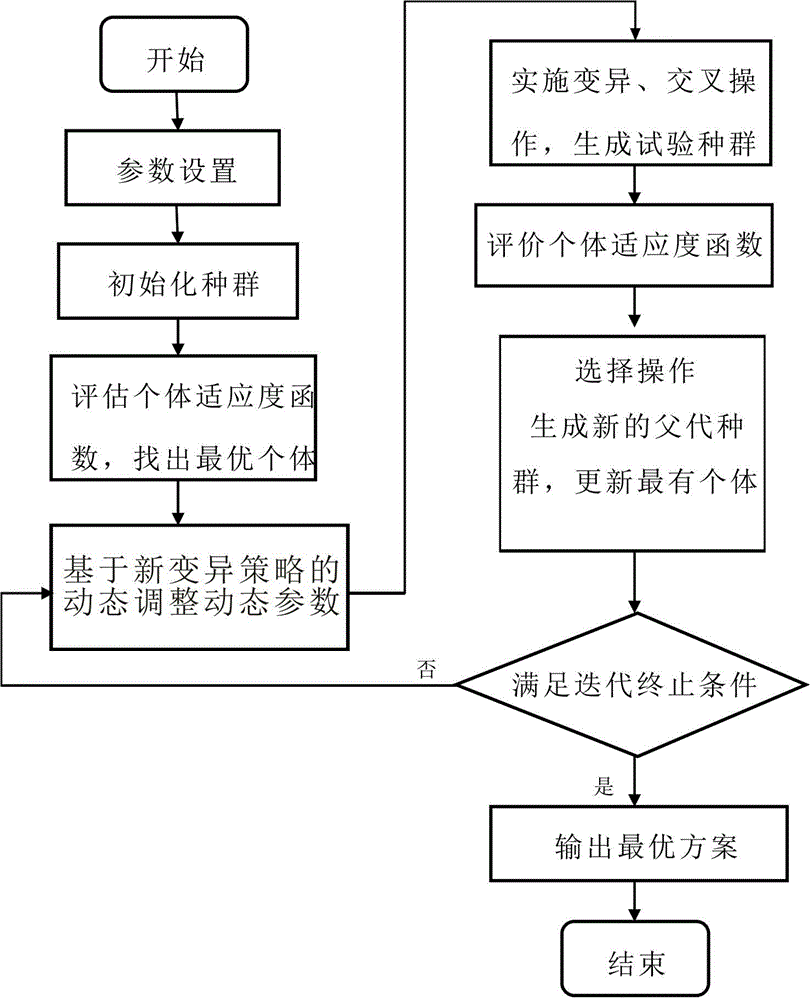

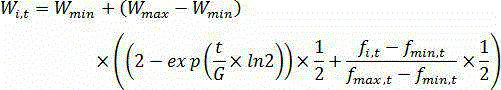

A method for optimizing groundwater depth of BP neural network based on genetic algorithm

InactiveCN109409568AImprove relevanceImprove forecast accuracyForecastingNeural learning methodsAlgorithmPredictive methods

A method for optimizing groundwater depth of BP neural network based on genetic algorithm includes collecting data, analyzing and screening independent variable by set pair, and taking samples corresponding to said target independent variable; the output result of BP neural network is obtained by setting BP neural network; setting initial parameters of genetic algorithm; individual selection operation: In the old population, the preset probability is used to select the individual to produce the next generation. The selection principle is as follows: selecting according to the fitness value ofthe individual from large to small; crossover: the generation of new individuals through the crossover of chromosomes; mutation: An individual selected from a population to mutate a segment of a chromosome to produce a new individual; the fitness is calculated and compared with the original population when the number of evolution reached the upper limit. The chromosome corresponding to the fitnessoptimal solution is the threshold value and weight value corresponding to BP neural network. The application of the embodiment of the invention can improve the accuracy of the groundwater burial depth.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Traffic coordination control method of multiple intersections

InactiveCN104021686ASolve high-dimensionalSolve nonlinear problemsControlling traffic signalsHigh dimensionalitySimulation

The invention relates to a traffic coordination control method of multiple intersections, belonging to the technical field of intelligent transportation. The method comprises the following steps: (1) establishing an intersection transportation control model containing mixed traffic flows; (2) solving the established intersection transportation control model containing the mixed traffic flows by using a chaos differential evolution algorithm. The method has the beneficial effects that the constraints of the mixed traffic flows are taken into account, and then, the traffic conditions of the intersections are more accurately reflected, so that a signal coordination scheme developed based on the traffic conditions is more reliable; minimum vehicle delay, minimum stop number and maximum pass capacity are targeted, so that the effectiveness of traffic coordination control is improved to the maximum. The traffic control method of the intersections containing the mixed traffic flows, based on the chaos differential evolution algorithm, disclosed by the invention, has the advantage that the problems of high dimensionality, nonlinearity and multiple constraints of the intersections can be excellently solved.

Owner:GUANGDONG UNIV OF TECH

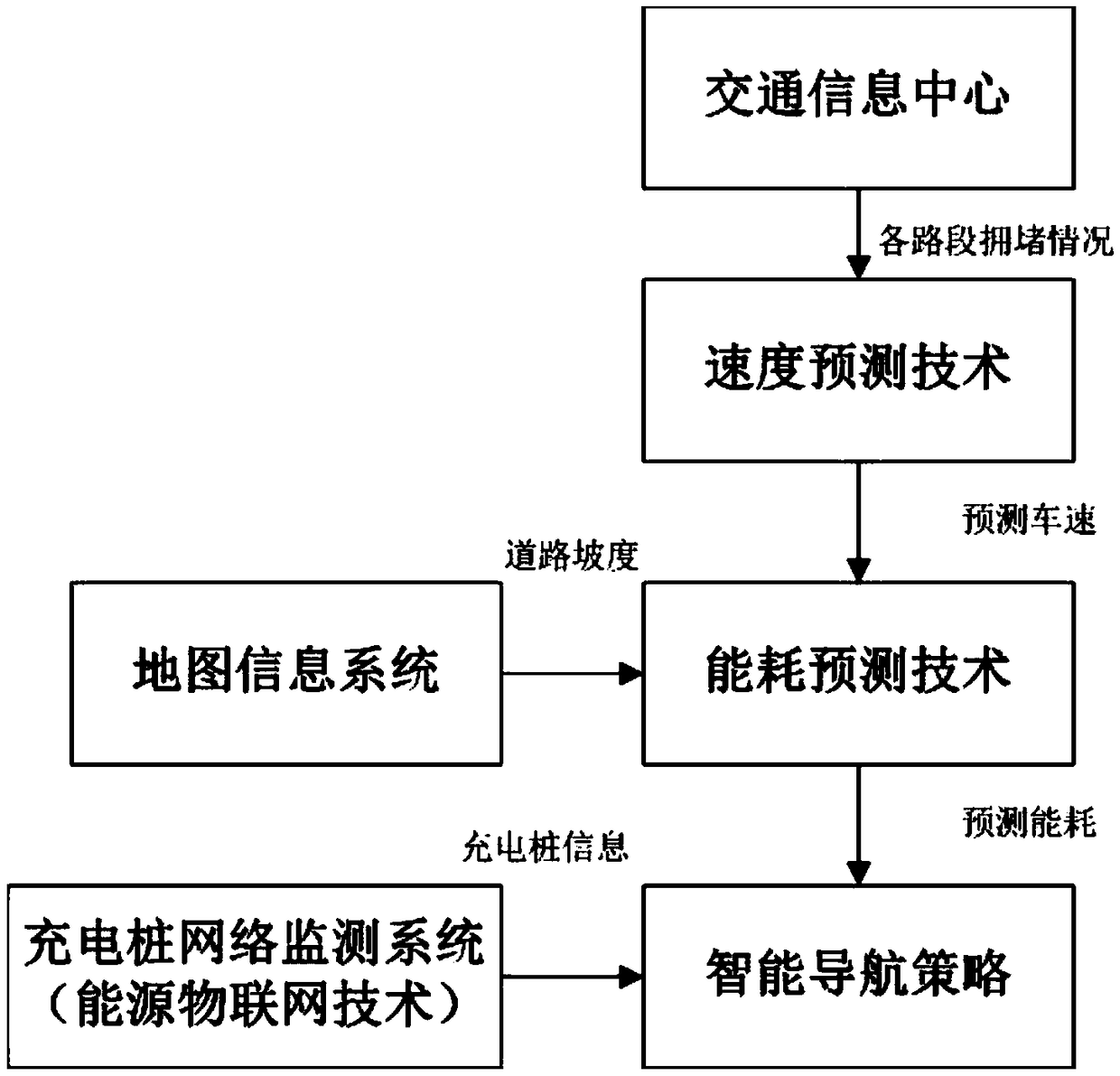

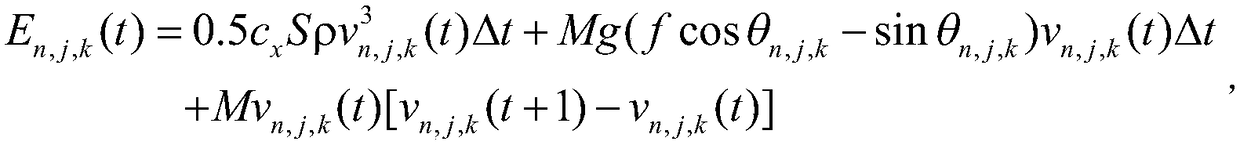

Charging navigation method of electric vehicle charging navigation system

ActiveCN108981732AFully consider the cruising rangeAvoid situations where you can't reach your destinationInstruments for road network navigationMinimum timeEngineering

The invention discloses a charging navigation method of an electric vehicle charging navigation system. The charging navigation method comprises a shortest time navigation mode, a minimal cost navigation mode and an integrated navigation mode. A user can choose any navigation mode according to the own navigation needs. The charging navigation method fully considers the characteristic of the shortdriving mileage of an electric vehicle limited by the battery capacity, and is relatively close to the actual situation that a charging pile needs to be found for charging the electric vehicle in thecase of insufficient electric quantity of the electric vehicle; the cruising ability of the remaining electric quantity serves as the precondition of navigation, and thus, the condition that the destination is not reached before the electric quantity is used up is avoided; meanwhile, the different navigation requirements of an electric vehicle owner under different conditions are considered; and by setting up three different strategy modes in combination with the information of the charging pile, the decision of the optimal target charging pile is finally made, and the optimal path is planned.

Owner:HANGZHOU ZHONGHENG ELECTRIC CO LTD +1

Comprehensive detection and judgment system and method for quality of cast tin-lead solder product

ActiveCN103267834AResolve detectionMeet the actual requirementsTesting metalsChemical compositionComputer science

The invention discloses a comprehensive detection and judgment system and method for quality of a cast tin-lead solder product. The system comprises an authority identification module, a detection data input module, a membership grade module, a quality grade identifying module, a quality grade judging matrix module, a product quality first-grade judging module and a quality grade output module. The method comprises the following steps of: detecting chemical components, weight and appearance of the tin-lead solder product, establishing membership functions of various grades of the cast tin-lead solder product, calculating the membership degree to obtain a judging matrix, and subsequently carrying out primary judgment and secondary judgment in sequence. The system and the method are simple and reliable, and have the characteristics that the identification is accurate and the judgment efficiency is high; and the defect that comprehensive judgment cannot be realized in the prior art is overcome.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

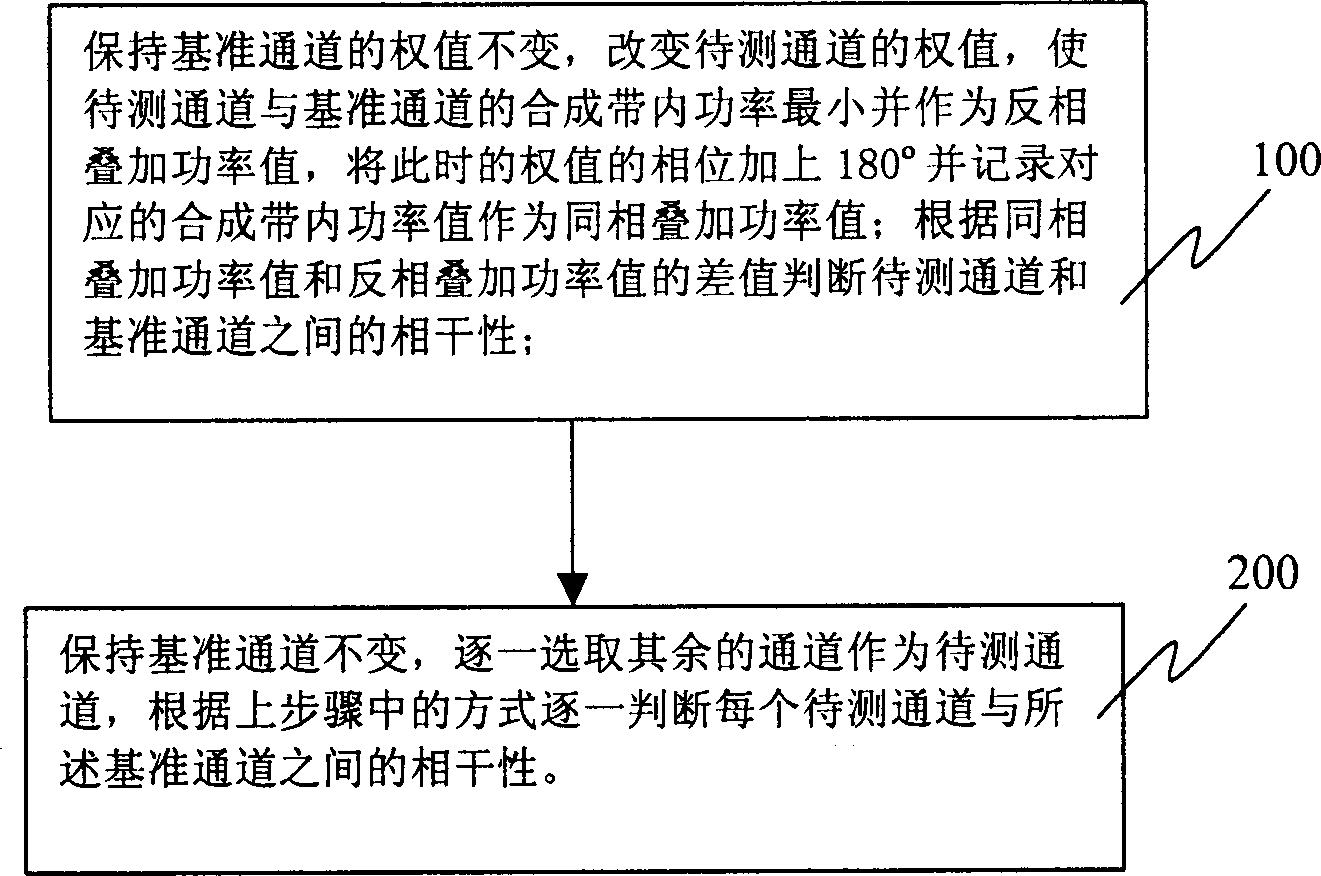

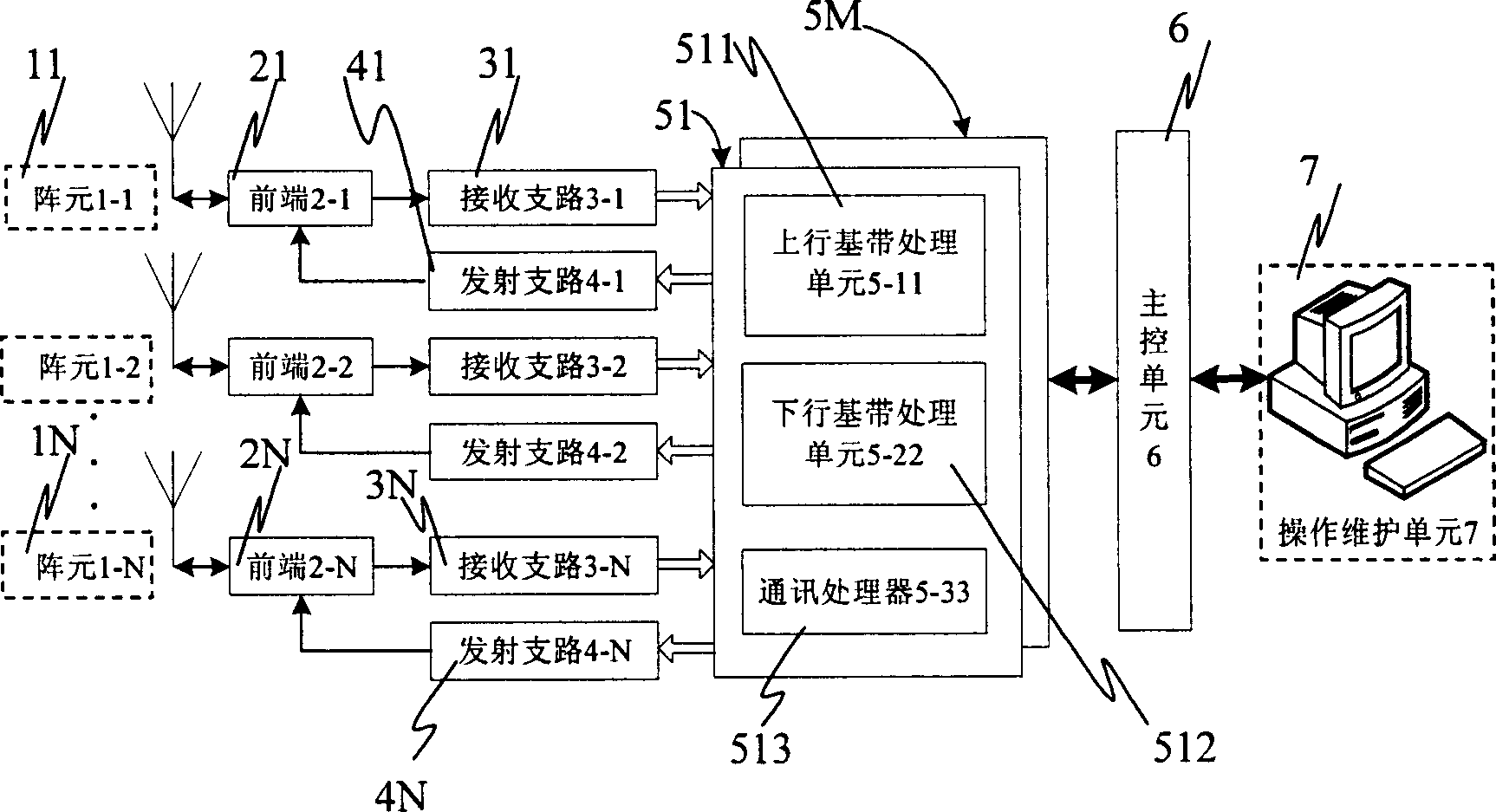

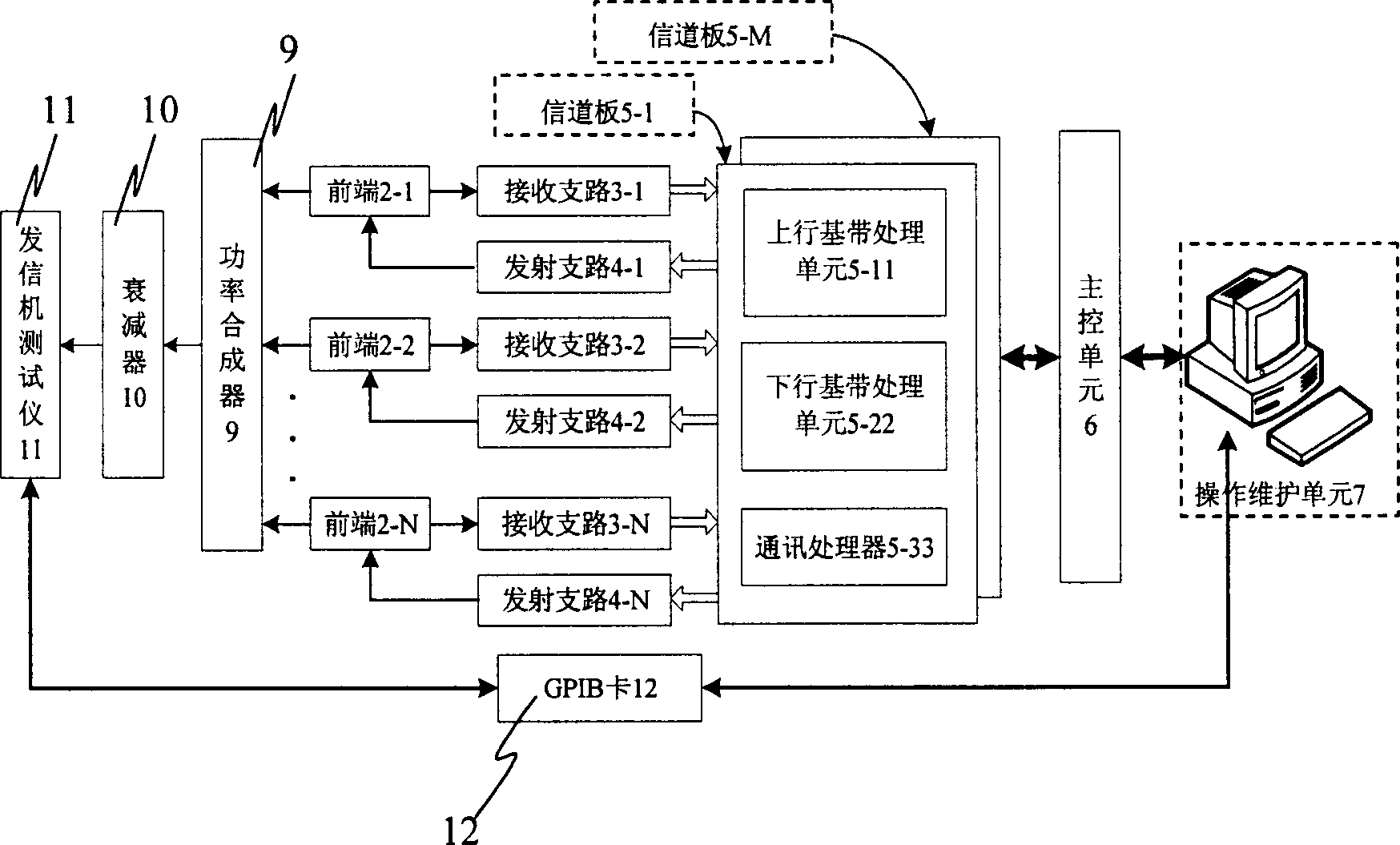

Channel coherence detection method for intelligent antenna base station

Being in use for testing multiple up going channels or multiple down going channels of base station, the method includes uses one channel as standard channel, another channel as channel to be tested, and closes up other channels; keeping weight value of standard channel unchanged, and changing weight value of channel to be tested to make synthetic power in-band minimum, which is as value of first power; adding 180 degrees to or subtracting 180 degrees from the weight value and recording the synthetic power in-band as value of second power at this point; determining coherence between channel to be tested and standard channel based on different value between second and first values of power; keeping standard channel unchanged, and selecting the rest of channels one by one as channel to be tested; determining the said coherence from one channel to another. The invention solves issue of that there is no dedicated instrument to measure coherence between channels.

Owner:晋江市高新技术开发办公室

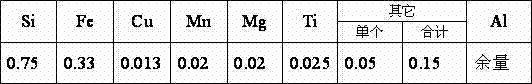

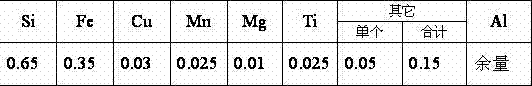

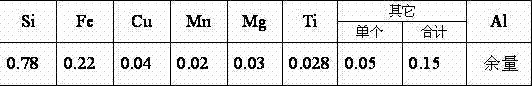

Aluminum alloy cable strap material and production method thereof

InactiveCN102191414ALow tensile strengthHigh tensile strengthSingle bars/rods/wires/strips conductorsProcess efficiency improvementSocial benefitsUltimate tensile strength

The invention relates to an aluminum alloy cable strap material and a production method thereof. The aluminum alloy cable strap comprises the following components in percentage by weight: 0.60 to 0.80 percent of Si, 0.20 to 0.40 percent of Fe, less than or equal to 0.05 percent of Cu, less than or equal to 0.03 percent of Mn, less than or equal to 0.03 percent of Mg, 0.02 to 0.03 percent of Ti and the balance of Al and inevitable impurities. The production method comprises the following steps of: smelting, refining in a standing furnace, refining crystalline grains, online degassing, filtering, continuous casting rolling, cold rolling, foil rolling, slitting and annealing. The tensile strength of the aluminum alloy cable strap is 90 to 105MPa and the percentage elongation is more than or equal to 23 percent. When the aluminum alloy cable strap is compared with the traditional product, the tensile strength is reduced, the percentage elongation is improved and requirements of clients are met to a greater extent. The production process is simplified; annealing for one time is required in the production process; and the product with low tensile strength and high percentage elongation can be obtained without adding any process in the subsequent processing process. By the method, the production cost can be saved, and the production efficiency and the yield are improved. The method is easy to popularize and has obvious economic and social benefits.

Owner:河南顺源宇祥铝业科技有限公司

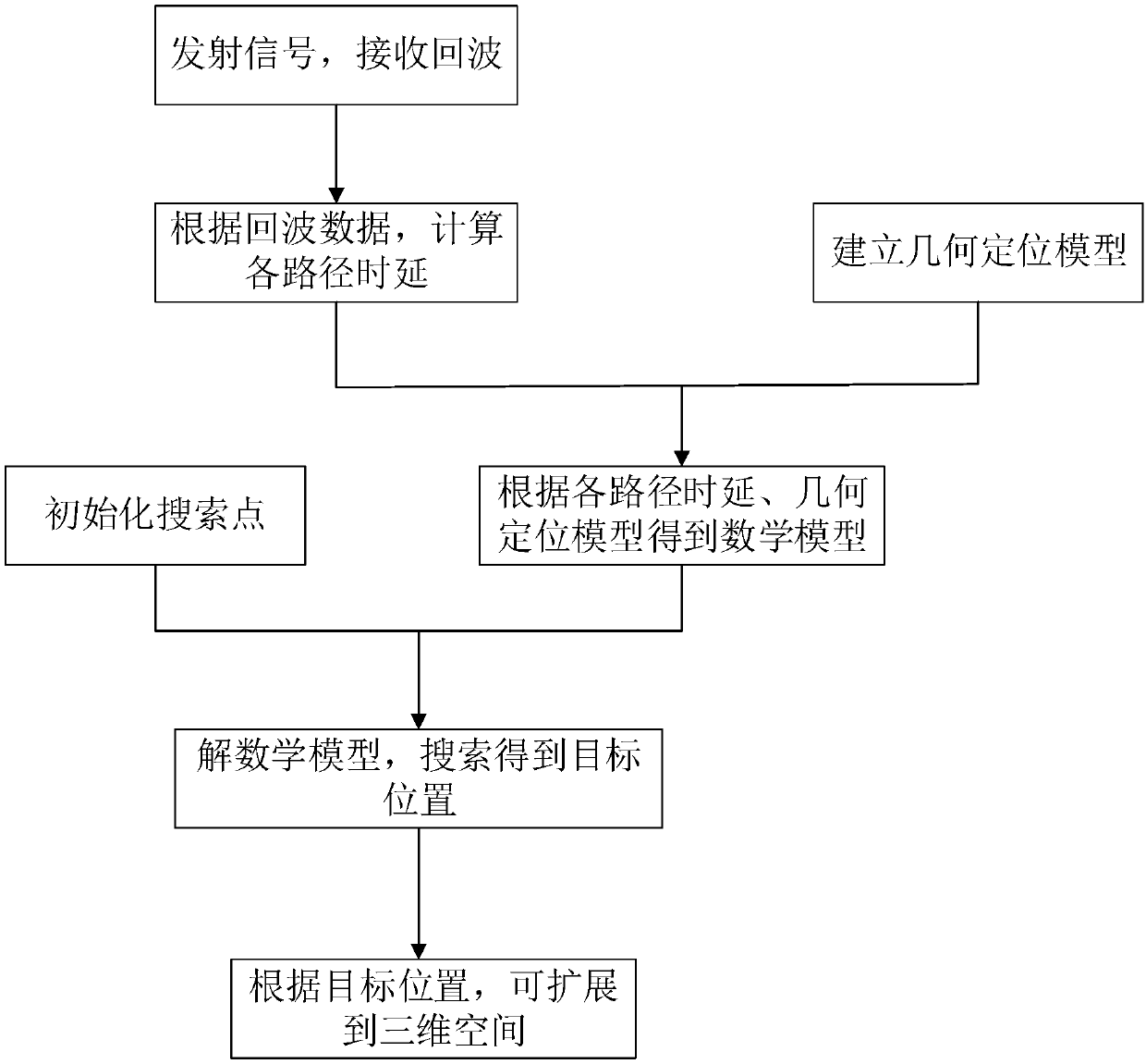

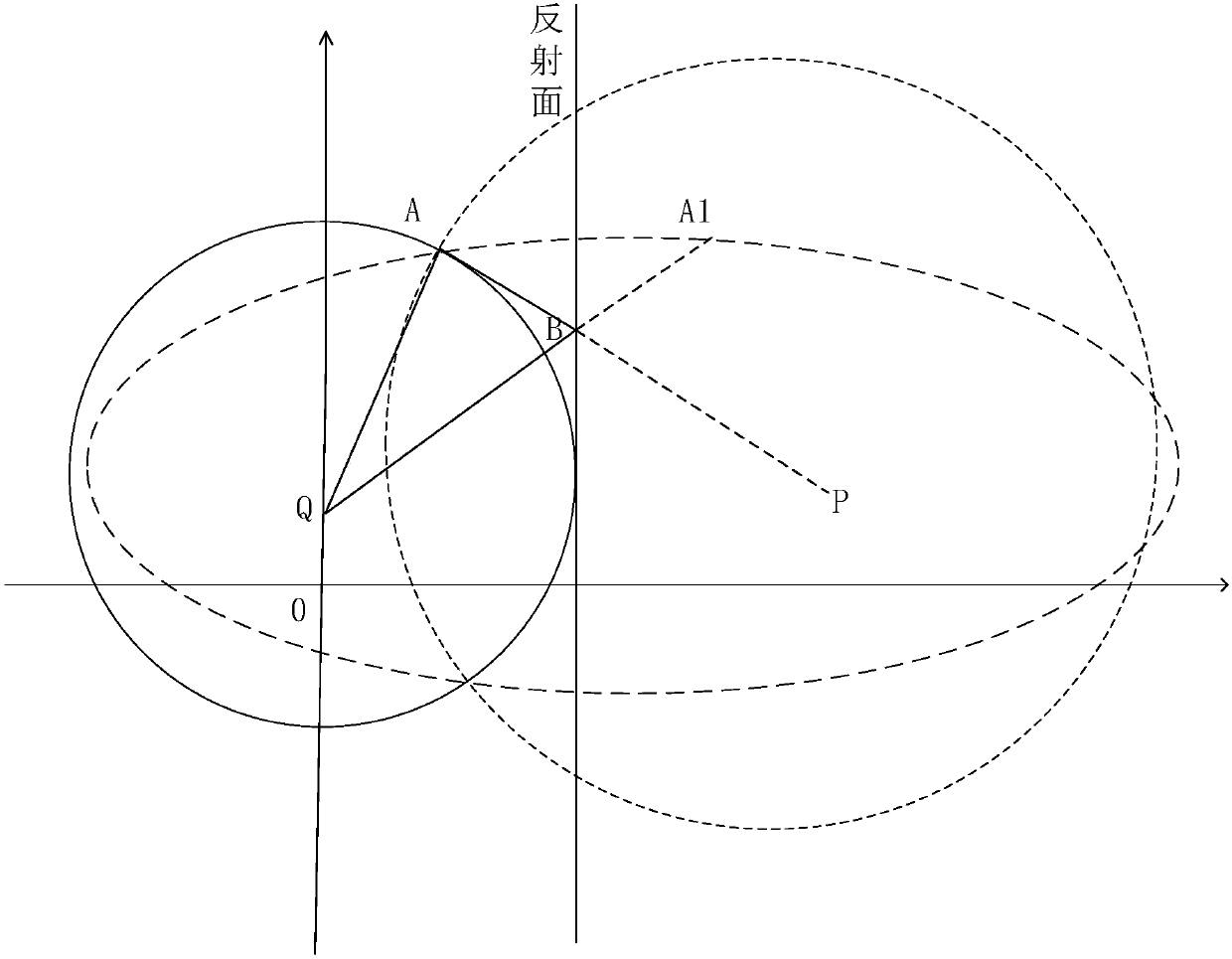

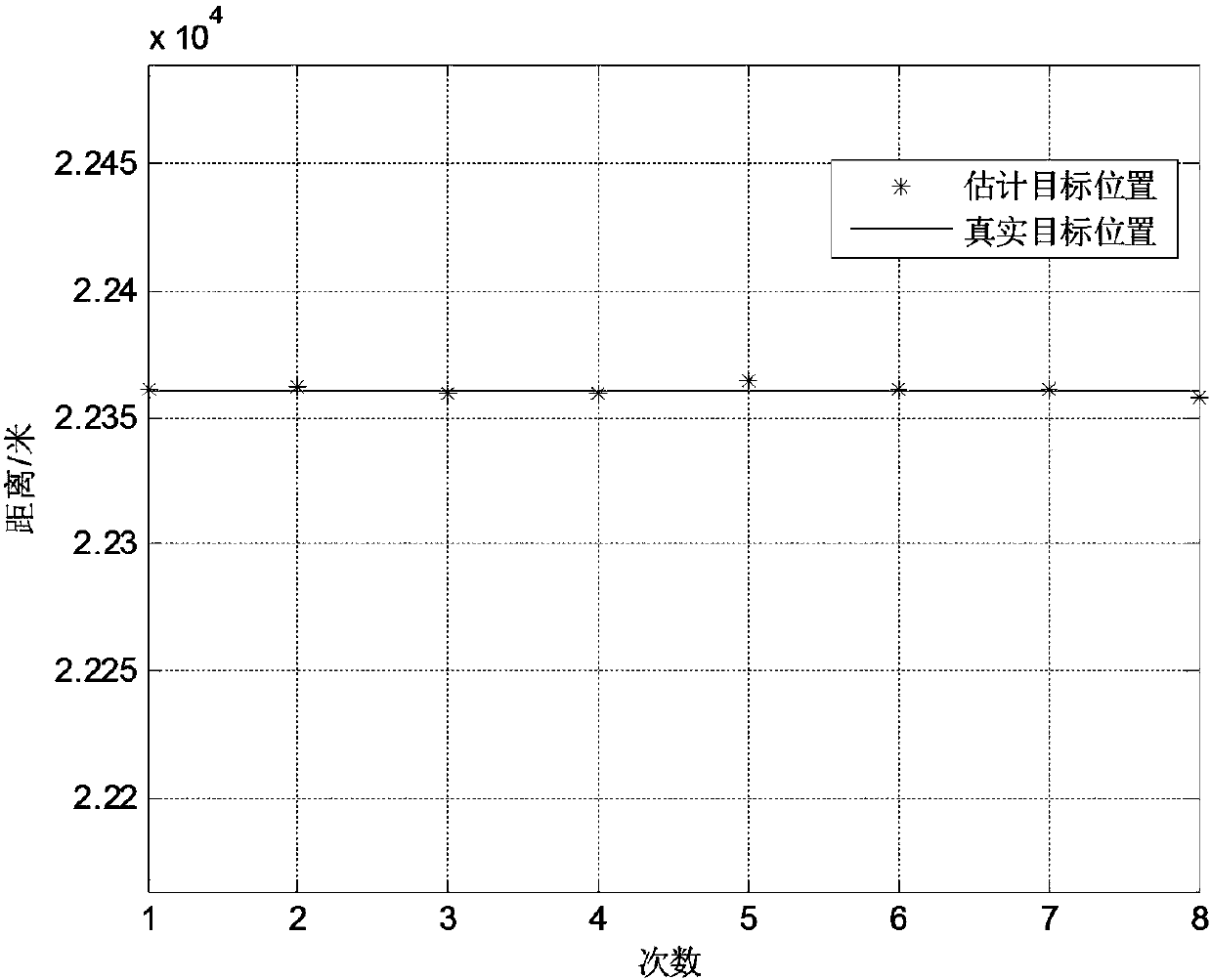

Radar target locating method based on multipath utilization

ActiveCN107918115AThe detection position is accurateAccurate measurementWave based measurement systemsRadarData treatment

The invention discloses a radar target locating method based on multipath utilization, and mainly aims at solving the problem that a radar point target cannot be located accurately in the multipath environment in the prior art. The method is realized by the steps that 1) an emission signal is generated to obtain echo data; 2) the echo data is processed to obtain time of arrival (TOA) of differentpaths; 3) a geometric location model of a radar target is obtained; 4) the obtained TOA of different paths are substituted into the established geometric location model; 5) an initial searching pointis initialized; 6) the geometric location model and the initial searching point are input to a searching function lsqnonlin, and the searching function lsqnonlin is used to obtain an accurate target position by searching; and 7) the target position obtained by searching is expanded to a 3D space. According to the method, multipath information can be utilized effectively, the established geometriclocation model is simple, the cost is lower, the location precision is improved, and the method can be used to locate low-altitude point targets.

Owner:XIDIAN UNIV

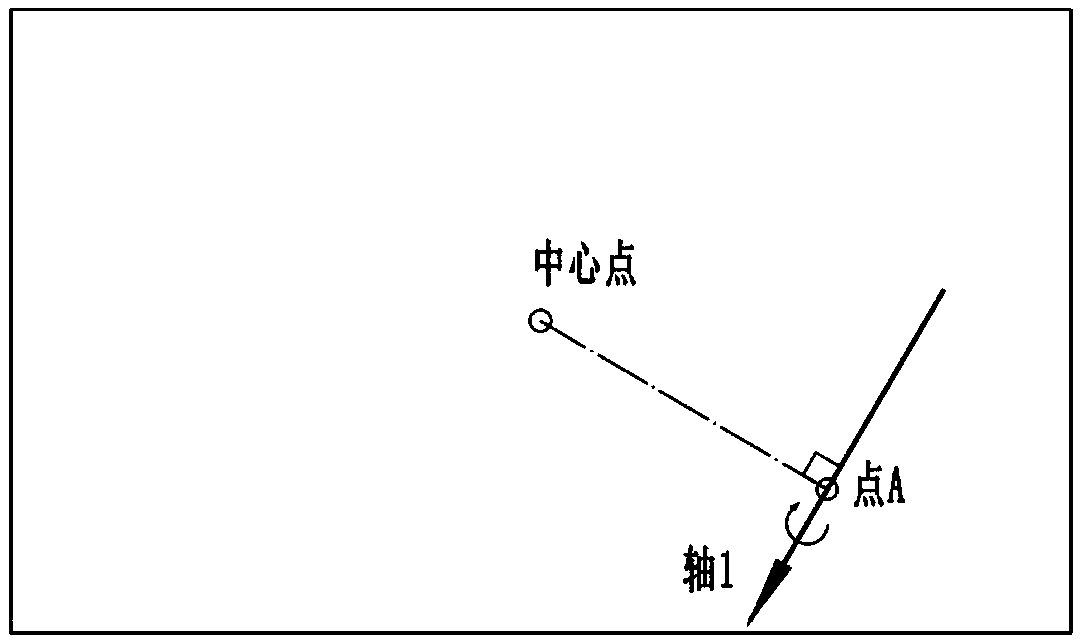

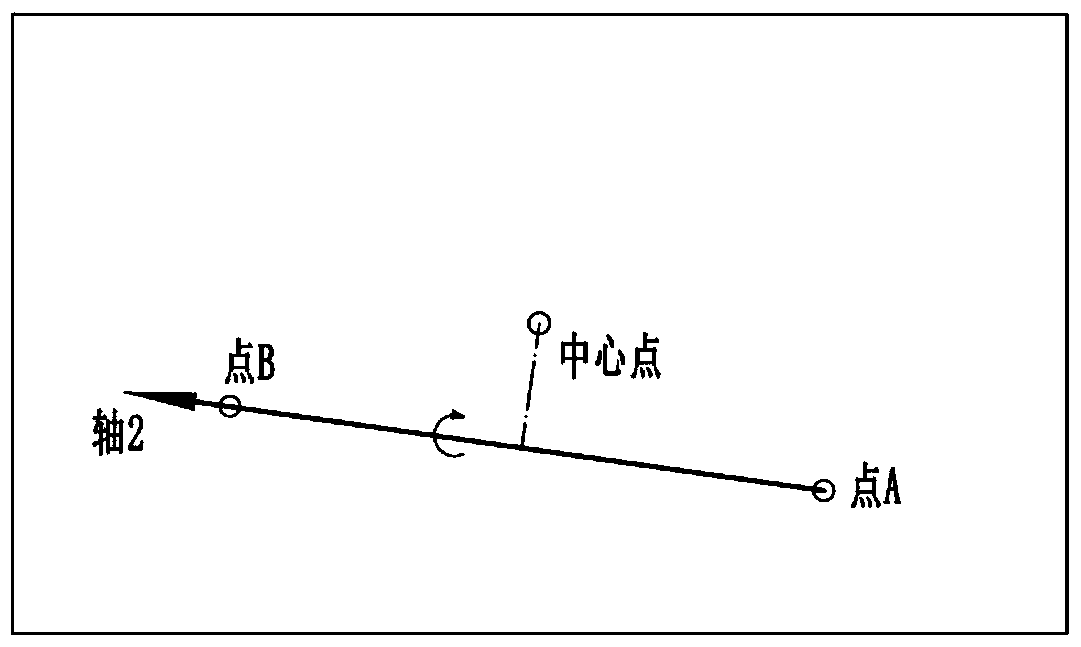

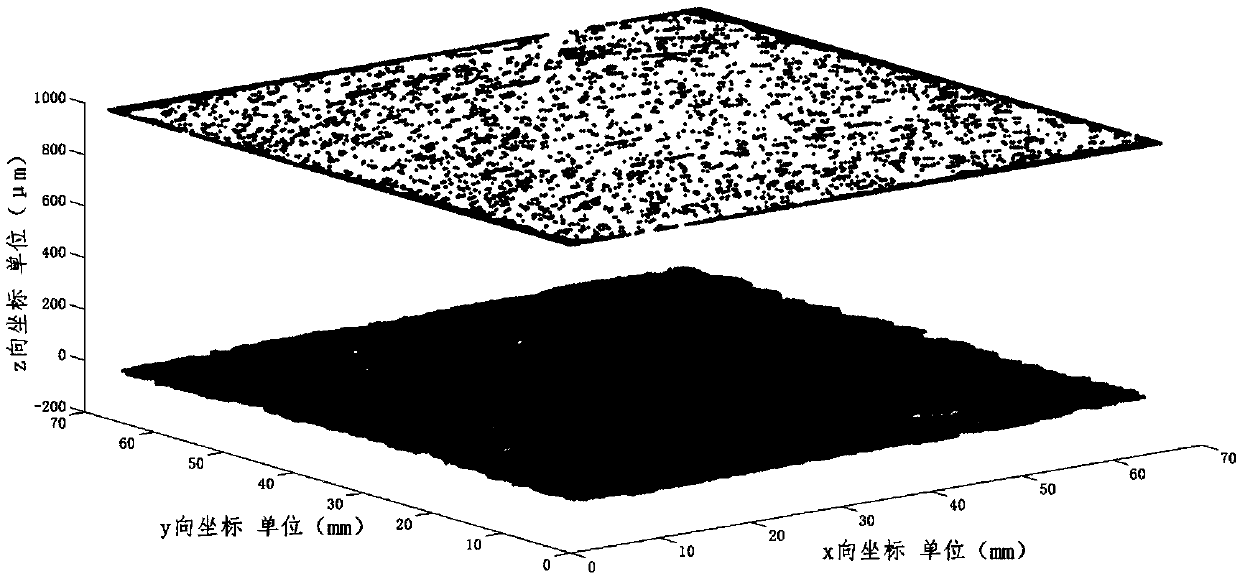

A method for determining the spatial posture of assembly contact based on measured surface topography

ActiveCN109101761AThe initial contact setup complies withImprove accuracyDesign optimisation/simulationSpecial data processing applicationsMultiscale decompositionElement model

The invention provides a method for determining the spatial posture of the assembly contact based on the measured surface topography, which starts with the point cloud processing technology and the assembly stacking technology, and decomposes the measured joint surface topography data in multiple scales. The topographic features of the high frequency part which has little influence on the assemblyposture are filtered, and the noise generated in the measurement process of the joint surface is removed. The method comprises steps: determining a plane according to the three points, finding out the three points that the upper and lower surfaces contact first when assembling, and judging the three points in turn. The normal vector of the plane determined by three points is used to represent thespatial posture of the assembly of the upper and lower parts. According to the spatial attitude, the assembly model is constructed. Therefore, the accuracy of contact analysis is improved to a certain extent. The method of the invention makes the initial contact setting in the finite element model of the assembly more conform to the actual requirements, and improves the accuracy of the assembly simulation analysis.

Owner:DALIAN UNIV OF TECH

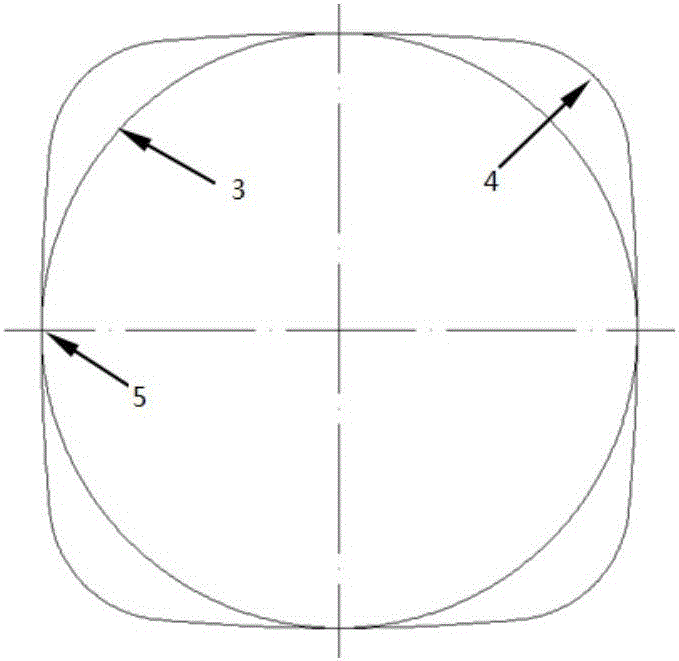

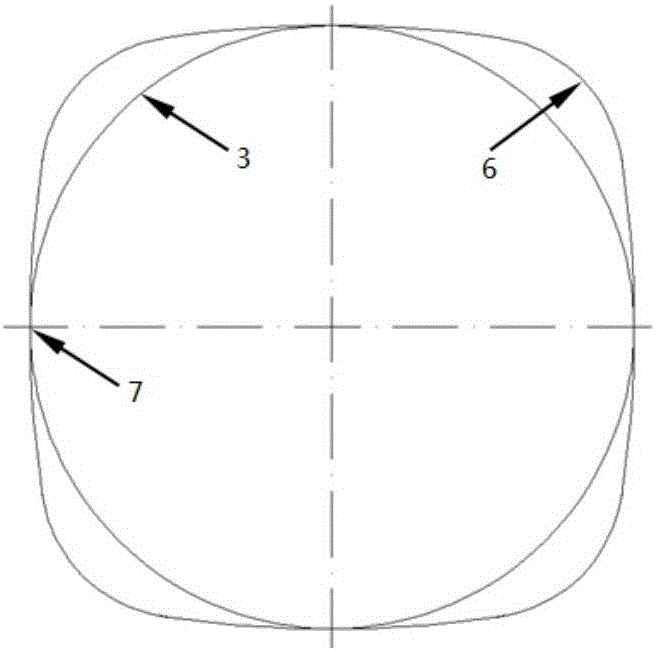

Engineering discrete variable based two-variable multi-circular arc special-shaped hole balance design method and model

ActiveCN105046000AQuality improvementSmall scaleSpecial data processing applicationsCircular discAviation

The present invention discloses an engineering discrete variable based two-variable multi-circular arc special-shaped hole balance design method and model. The method comprises: firstly, establishing a standard alternative pool for each design variable according to arc radius standard series defined by international standards, to store arc radius standard values; secondly, performing rounding on original continuous variables by using a self-defined conversion function; thirdly, performing control on design space of discrete variable combination by using a boundary verification module, and performing deletion on cross-boundary parameters; and finally, performing optimization iteration, and before optimization, performing sequential numbering on discrete design points by size. In the optimization iteration, when a new design point is selected, a new design point number is selected through number calculation, and then a new design point is determined according to a mapping relationship between the numbers of the discrete design points and actual design points. According to the method, the two-variable special-shaped hole profile design radius meets an industrial manufacturing standard, and the design of a connecting unit of a high-pressure turbine plate of an aircraft engine meets an equal-strength principle, thereby improving design efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

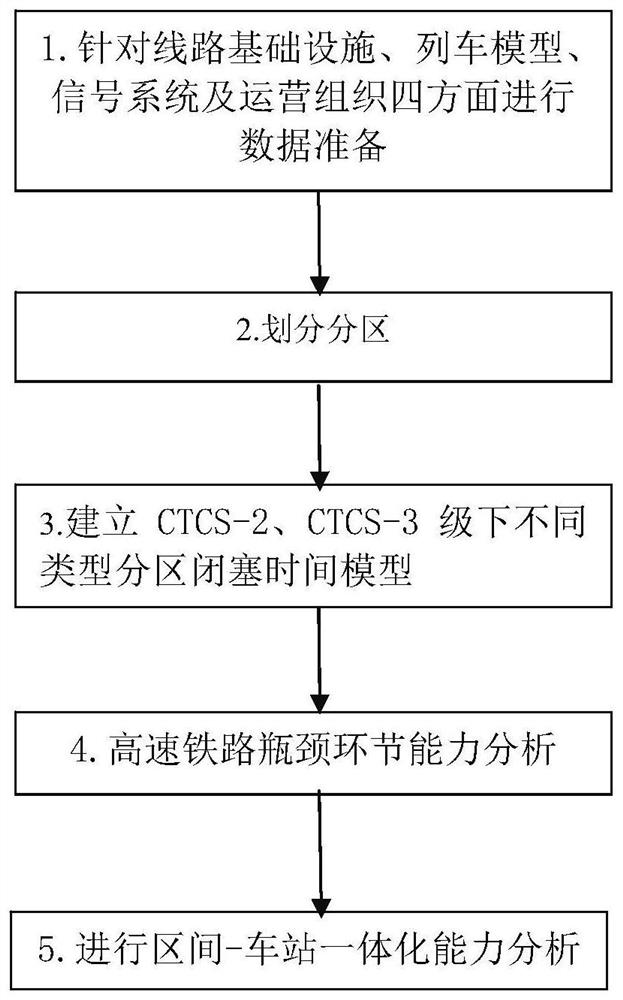

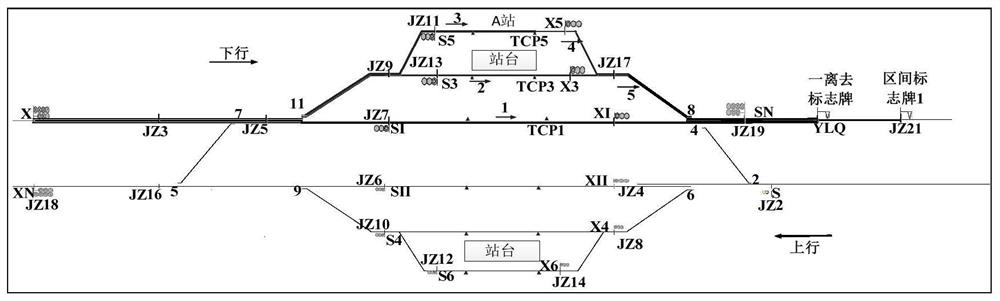

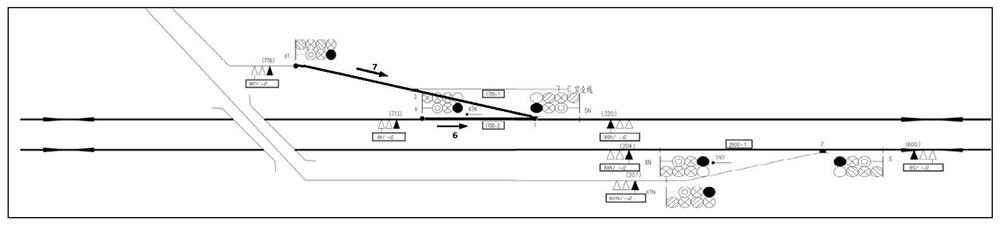

Capability analysis method suitable for high-speed railway

ActiveCN111915221AEnriching Theory of Capability ComputingOvercome limitationsResourcesData preparationReal-time computing

The invention relates to a capability analysis method suitable for a high-speed railway. The method specifically comprises the following steps: A, preparing data in four aspects of line infrastructure, a train model, a signal system and operation organization parameters; B, according to different access types, dividing partition divisions, specifically, dividing the partitions into five types including a train receiving partition, a train departure partition, a station track partition, an interval partition and a line place partition; C, establishing different types of partition block time models under CTCS2 level and CTCS3 level based on the signal system workflow and in combination with different operation scenes; D, analyzing the capacity of a bottleneck link in operation of the high-speed railway, namely analyzing the capacity of the convergence line where the bottleneck possibly occurs from two indexes, namely the worst train interval and the worst average minimum train interval,of a station; and E, carrying out capability analysis on the section station integration to obtain a most unfavorable section station integration operation plan.

Owner:BEIJING JIAOTONG UNIV

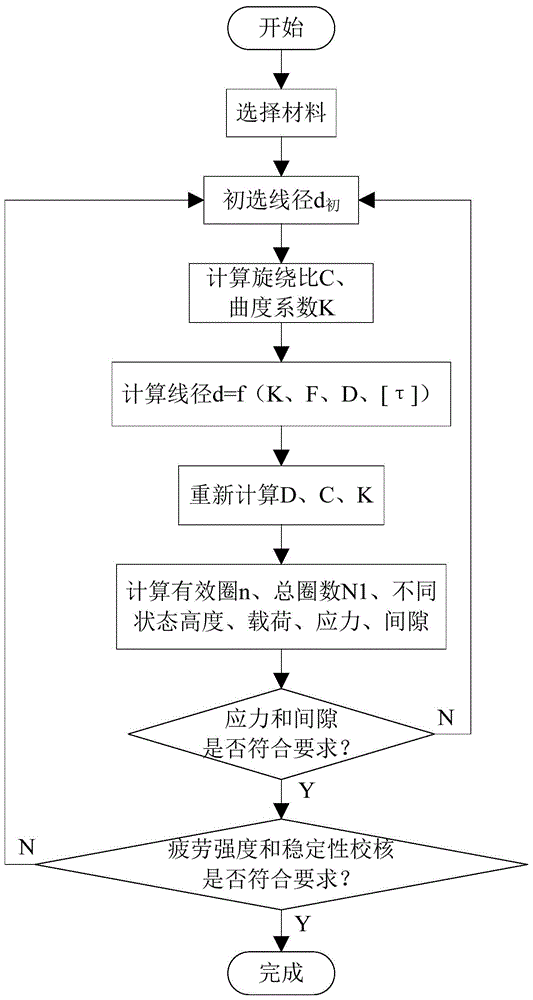

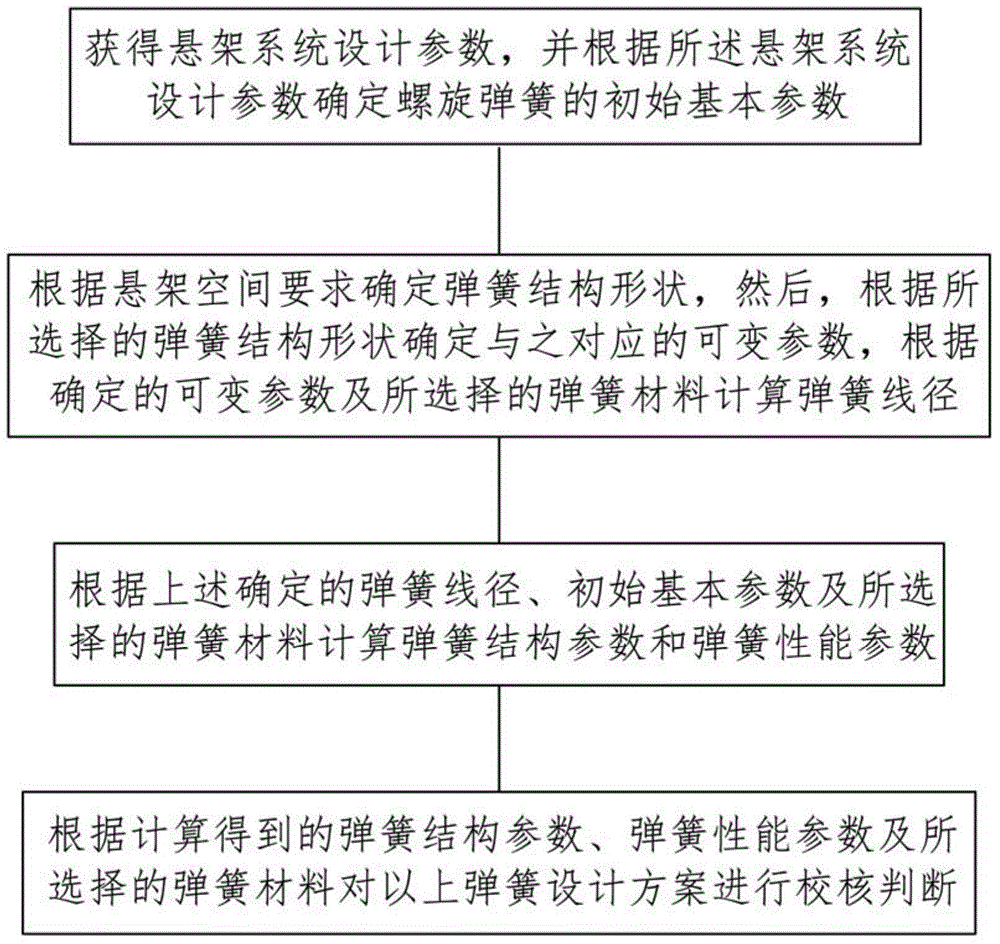

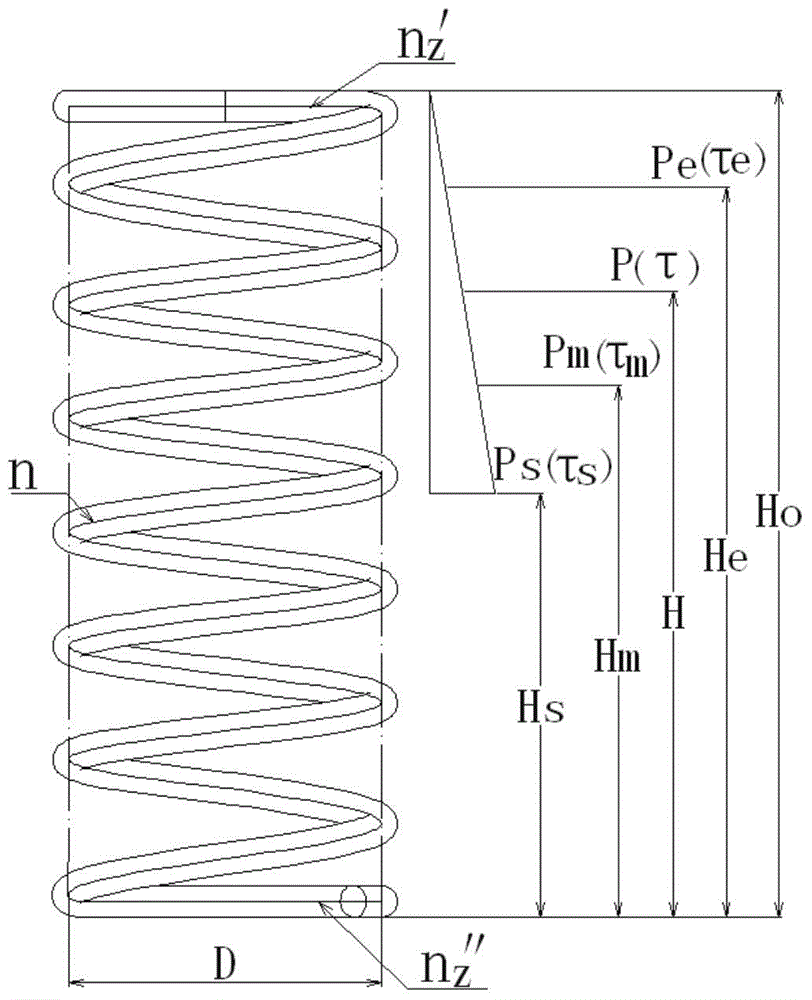

Method for designing spiral spring of automotive suspension

The invention provides a method for designing a spiral spring of an automotive suspension. The method comprises the following steps of acquiring a designing parameter of a suspension system; determining an initial basic parameter of the spiral spring according to the designing parameter of the suspension system; determining the structural shape of the spring according to requirements on space of the suspension; determining a variable parameter corresponding to the spring according to the selected structural shape of the spring; calculating a spring wire diameter according to the determined variable parameter and a selected spring material; calculating a spring structure parameter and a spring performance parameter according to the spring wire diameter, the initial basic parameter and the selected spring material; and checking and judging a spring designing scheme according to the spring structure parameter, the spring performance parameter and the selected spring material. According to the method for designing the spiral spring of the automotive suspension, the spring wire diameter can be calculated directly; when springs with different structural shapes are designed, the variable parameters on calculation of the wire diameters are correspondingly changed, and the corresponding spring structure parameters and corresponding spring performance parameters can be calculated accurately.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

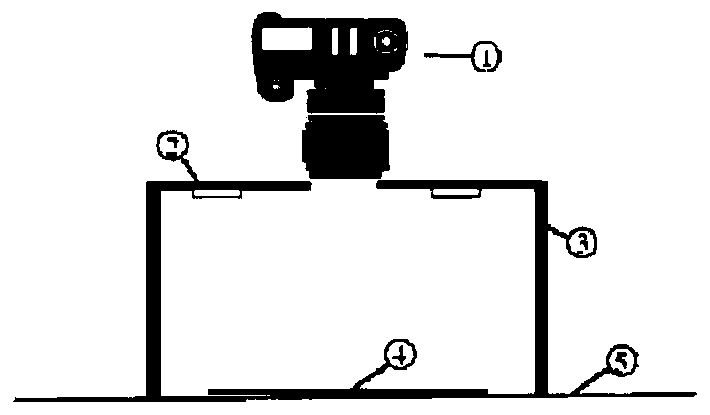

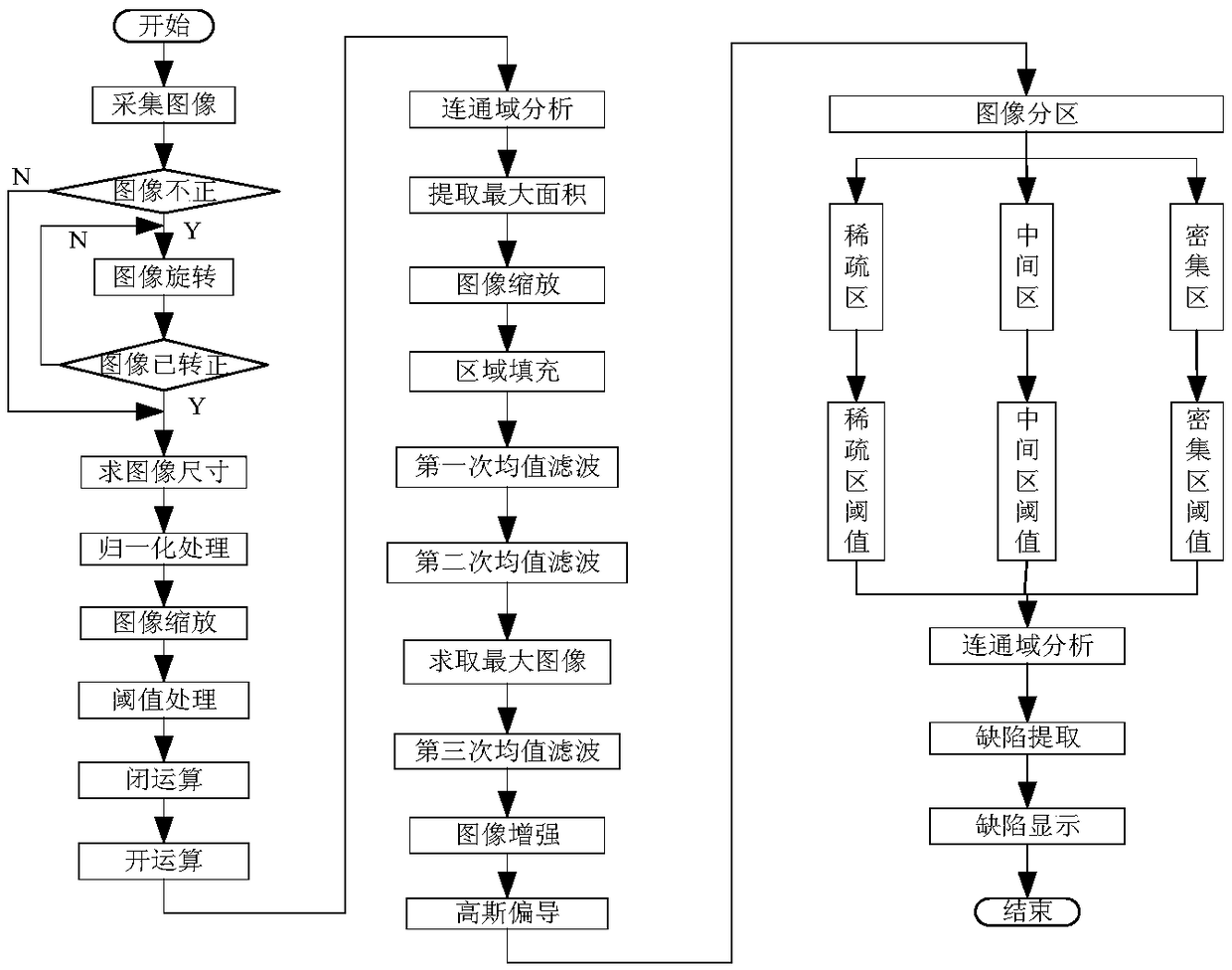

A method for detecting white dot defect of light guide plate

ActiveCN109272525AAccurate judgmentImprove detection accuracyImage enhancementImage analysisLight guideWhite point

A method for detecting white point defect of light guide plate. A light guide plate is partitioned according to the density of light point, different parameters are adopted for different area processing algorithm, and adjustment parameters such as area and eccentricity are set, so that white point defect required by manufacturer can be detected automatically and the adaptability is strong. The invention not only can detect the sparse area in the light guide plate, but also can accurately judge the small white dots in the dense area, and the detection accuracy is high. The algorithm of the invention can detect different types of light guide plates, and has good stability and wide application range. The invention has the advantages of simple algorithm, high efficiency, short processing timeof the light guide plate image, and conforms to the actual requirements of enterprises. In addition, the invention can realize full automatic detection only by properly adjusting a few parameters, andis convenient to operate and maintain.

Owner:HANGZHOU HUICUI INTELLIGENT TECH CO LTD

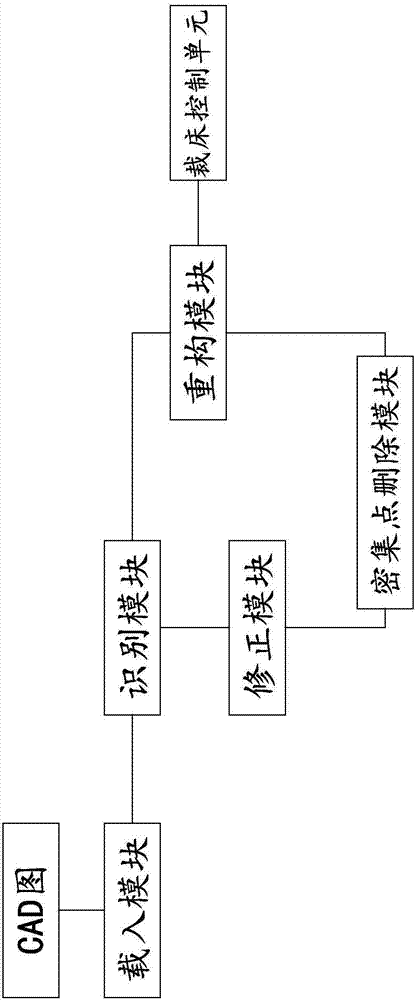

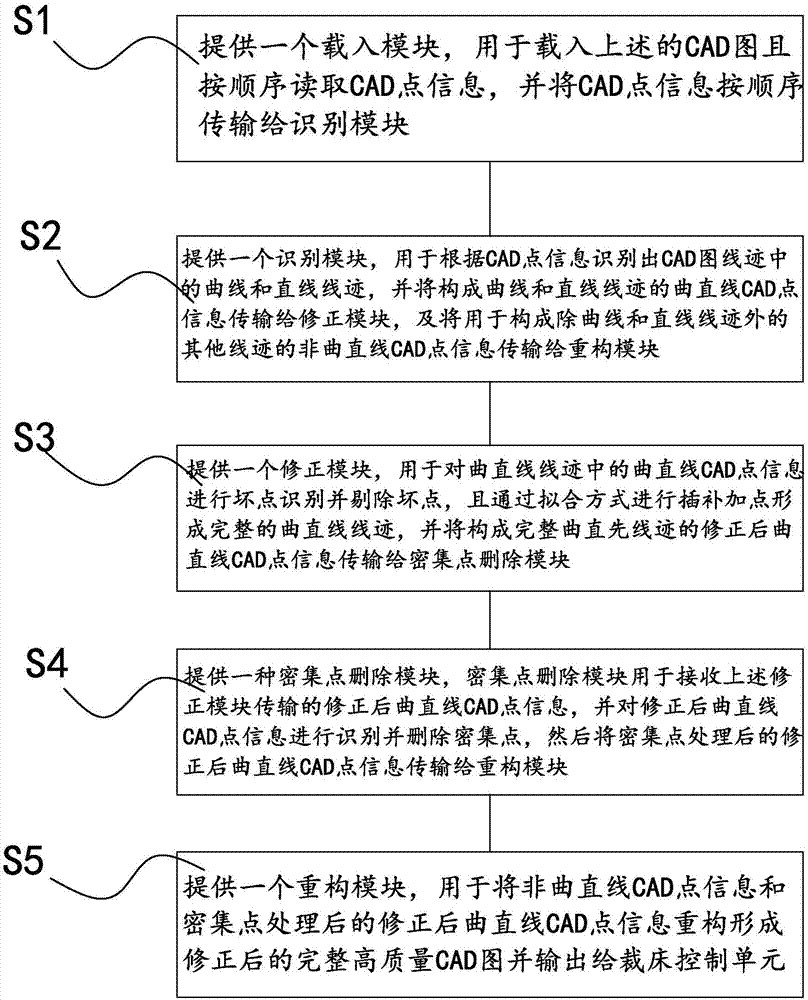

CAD graph intelligent correction system and method

ActiveCN107194885AQuality improvementReduce crop qualityImage enhancementDrawing from basic elementsEngineeringCorrection system

The invention provides a CAD graph intelligent correction system and method, belongs to the technical field of computers, and solves the problem of influence on an output result due to low quality of an existing CAD graph. The CAD graph intelligent correction system comprises a CAD graph with coordinate information and size information; a line trace on the CAD graph is formed by arranging a plurality of CAD points; each CAD point contains CAD point information; the correction system comprises a loading module, an identification module, a correction module and a reconstruction module. The CAD graph intelligent correction system has the advantages that an original CAD graph is intelligently corrected, and a high-quality CAD graph meeting the requirements is reconstructed, so that a high-quality output result is ensured.

Owner:BULLMER ELECTROMECHANICAL TECH

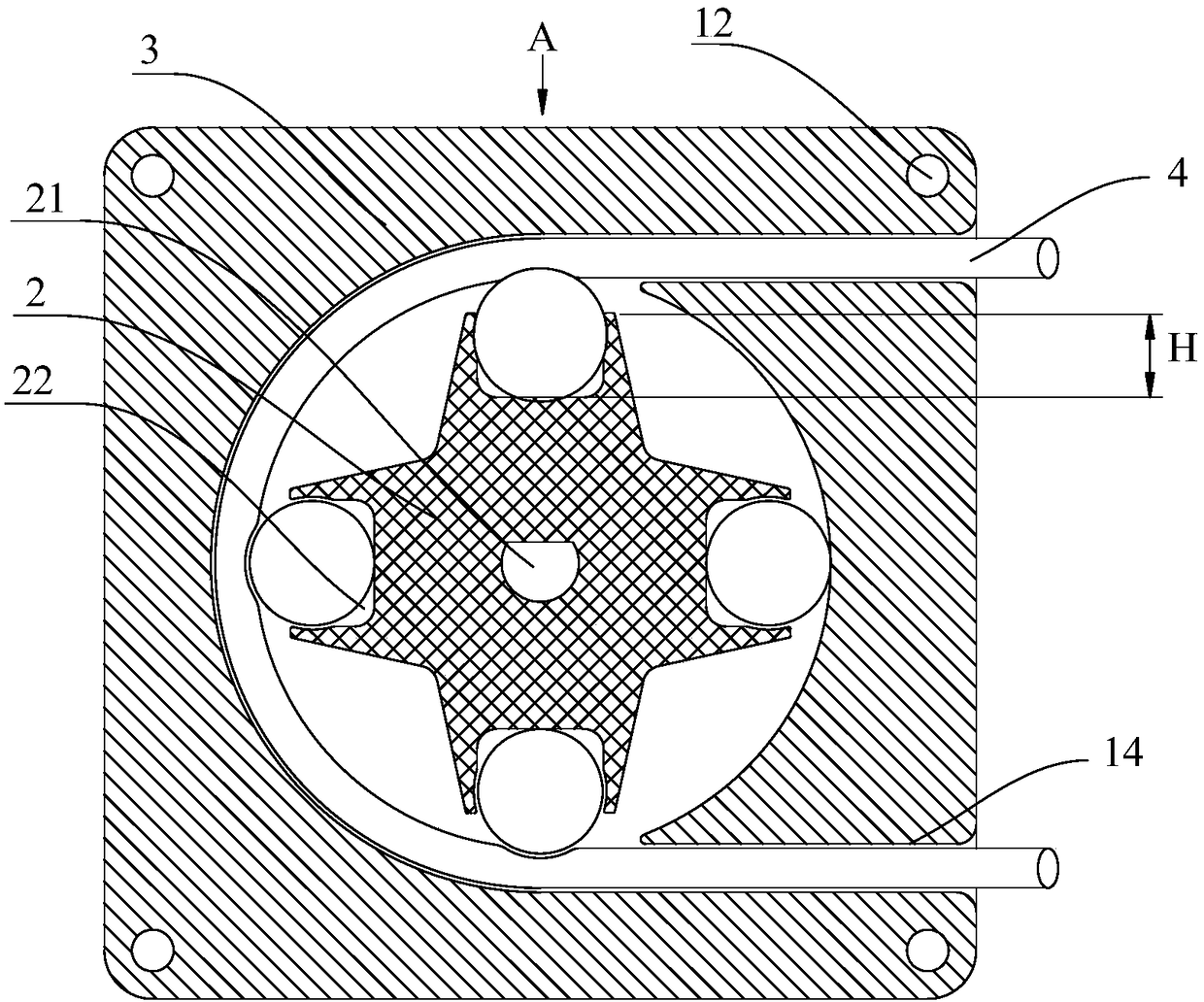

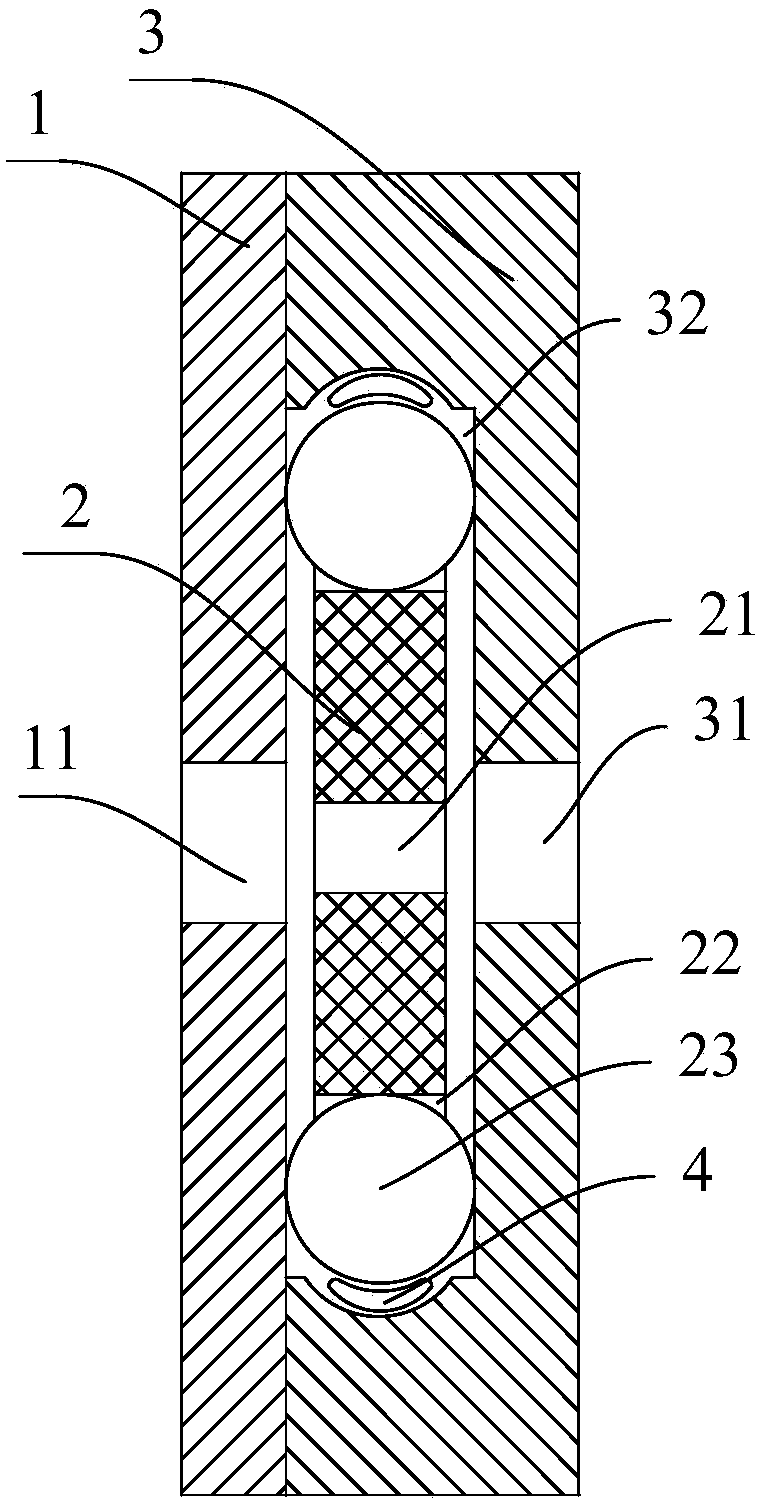

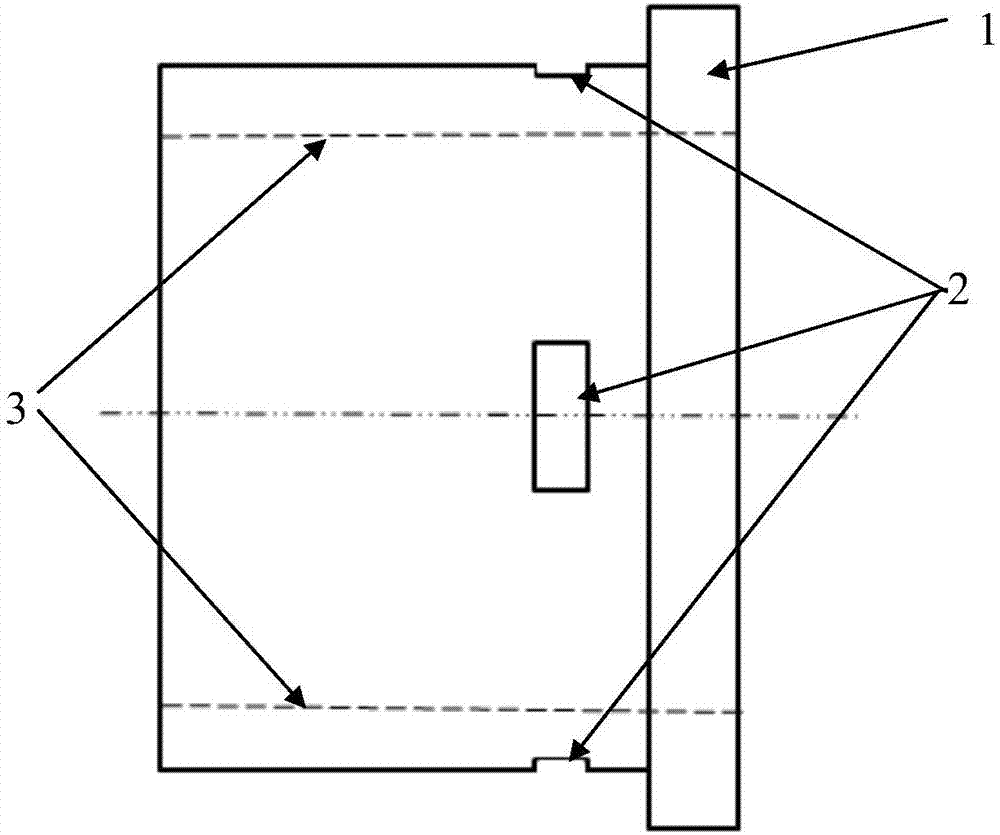

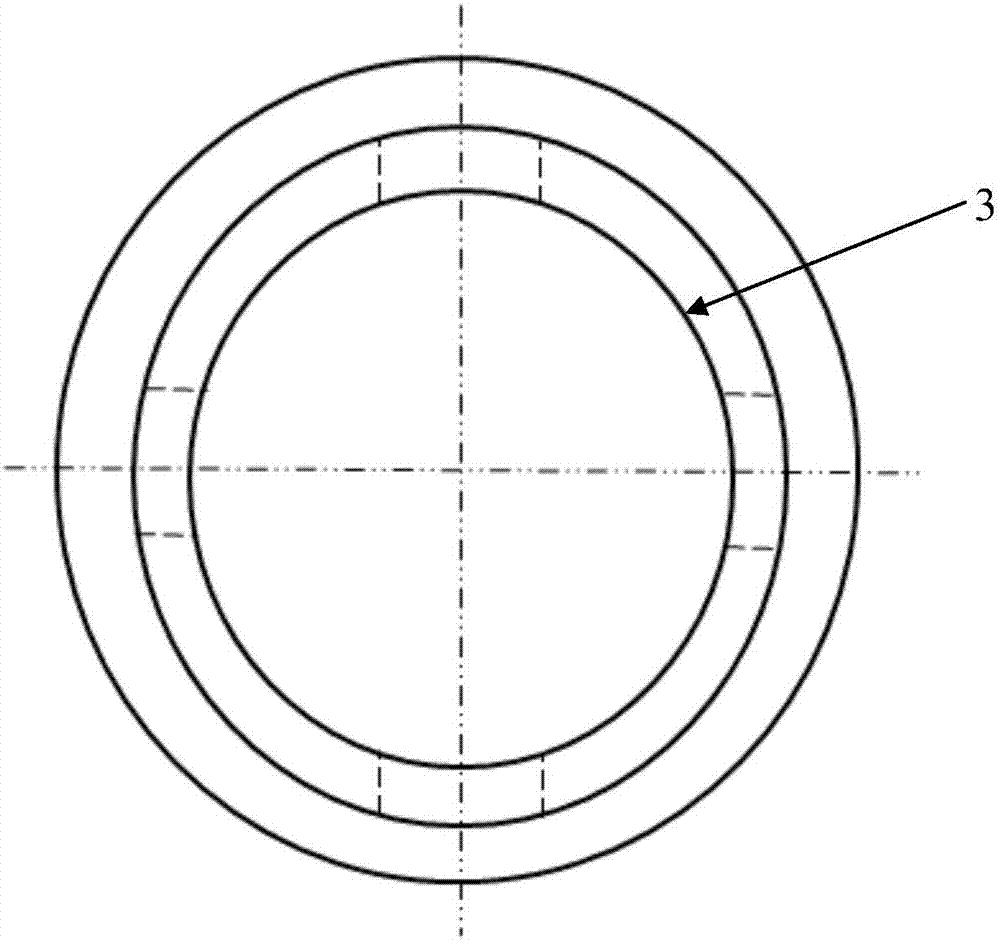

Rolling ball type peristaltic pump with gear-like structure

PendingCN108278194AReduce wearReduce frictionPositive displacement pump componentsFlexible member pumpsPeristaltic pumpEngineering

The invention relates to a peristaltic pump, in particular to a rolling ball type peristaltic pump with a gear-like structure, and aims to provide a peristaltic pump which is low in energy consumption, stable in flow speed, simple and compact in structure and easy to integrate. According to the technical scheme adopted by the invention, the peristaltic pump comprises a base, a rotating piece and an upper cover. The rotating piece is in a gear shape; rolling ball accommodating grooves are formed in gear ends; and rolling balls are arranged in the rolling ball accommodating grooves. A centre hole is formed in the centre of the upper cover; fixing holes are formed in the periphery of the upper cover; and a rotating piece retaining hole is formed in the lower end surface of the upper cover. Apump pipe guide hole is formed in the upper cover; and a pump pipe extends out of the base from the pump pipe guide hole. According to the rolling ball type peristaltic pump with the gear-like structure, rolling posts are replaced by rolling balls to serve as an extruding part, so that the friction with the pump pipe is reduced, the energy consumption is reduced and the wear to the pump pipe is also reduced; used materials are reduced to a certain degree through the rotating piece of a gear structure, so that the rolling ball type peristaltic pump with the gear-like structure has the characteristics of small volume and light weight; tooth number of the gear-shaped rotating piece can be increased or decreased according to actual situations so as to meet actual requirements to the maximum extent.

Owner:四川君汇科技有限公司

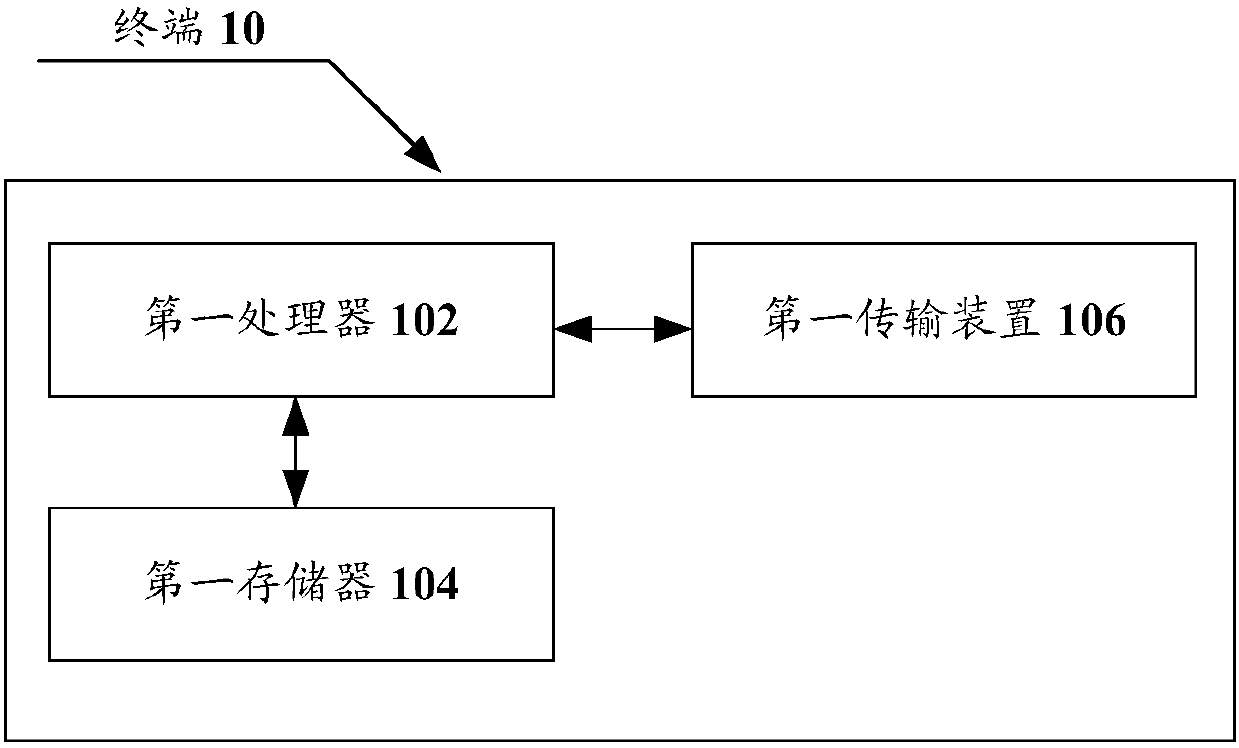

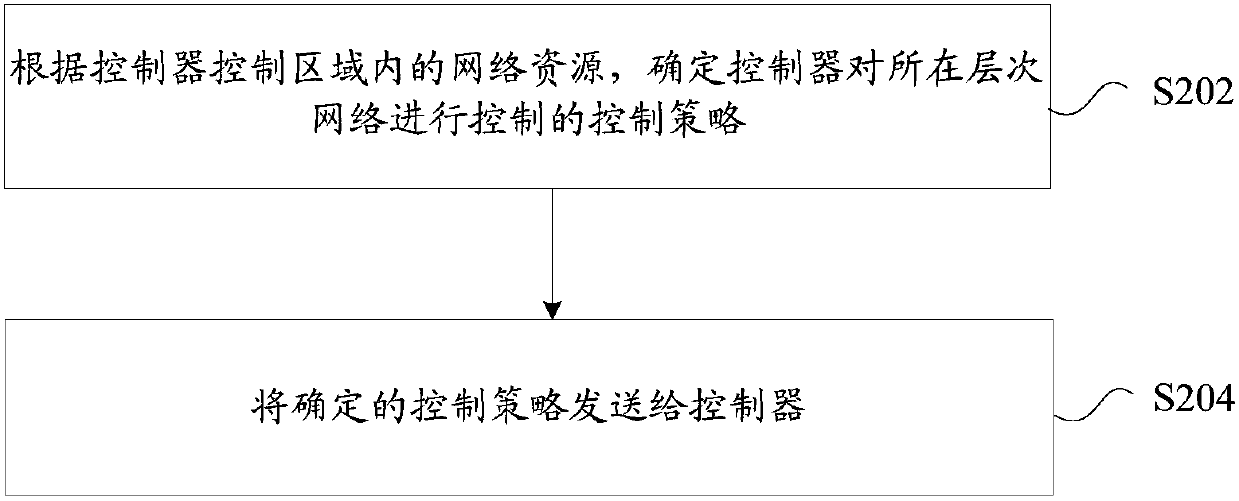

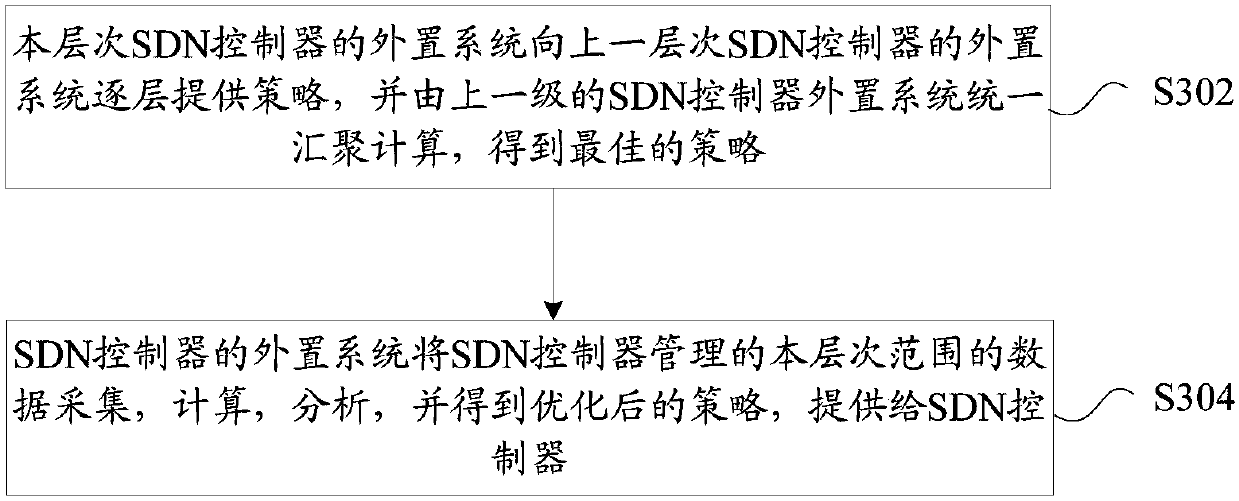

Strategy sending and receiving method and device, and controller

ActiveCN107645400AReduce the impact of operating efficiencyImprove operational efficiencyData switching networksControl areaComputer science

The present invention provides a strategy sending and receiving method and device, and a controller. The sending method comprises: determining a control strategy of a controller controlling a hierarchical network where the controller is located according to a network resource in a control area of the controller; and sending the determined control strategy to the controller. According to the invention, the problem is solved that a controller is low in operation efficiency in the prior art, and an effect of improvement of the operation efficiency of the controller is achieved.

Owner:ZTE CORP

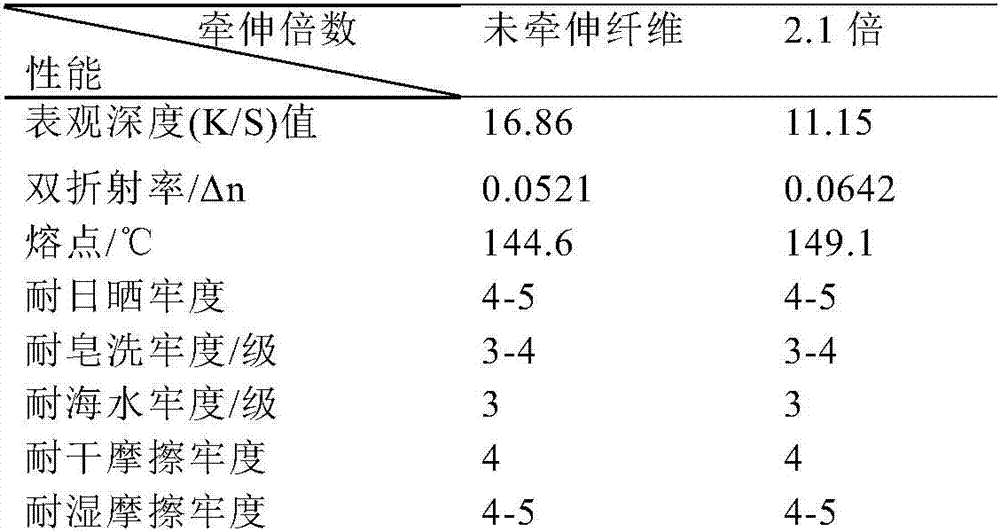

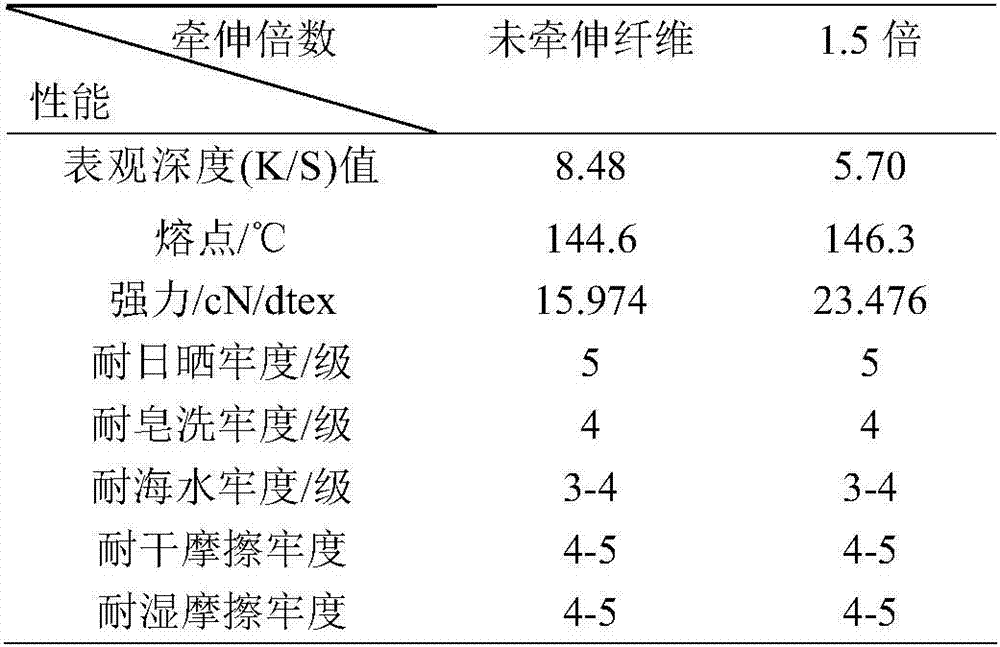

Colored ultra-high molecular weight polyethylene fibers and preparation method thereof

The invention relates to colored ultra-high molecular weight polyethylene fibers and a preparation method thereof. The preparation method comprises the following steps: (1) preparing dyeing liquor in an ultrasonic way, wherein the amount of a dispersing agent accounts for 0.05-0.5% of the mass of the dyeing liquor, the amount of a dye accounts for 0.5-10% of the mass of the fibers, the bath ratio is 1 to (10 to 100), and the dye is selected from highly hydrophobic azo disperse dyes or anthraquinone disperse dyes which have dipole moments of less than 5.0 Debye; (2) putting the dyeing liquor and ultra-high molecular weight polyethylene extract fibers into a dyeing machine, wherein the dyeing temperature is 90-120 DEG C, the dyeing time is 15-150min, and the pH value of the dyeing liquor is 4-9; carrying out reductive cleaning and drying on the dyed extract fibers; (3) carrying out stretch orientation on the dried ultra-high molecular weight polyethylene colored extract fibers to obtain the finished product of the ultra-high molecular weight polyethylene fibers. The method provided by the invention is simple and convenient as well as easy to control; the prepared colored ultra-high molecular weight polyethylene fibers have high apparent depth, color fastness and strong retention rate.

Owner:BEIJING INST OF CLOTHING TECH

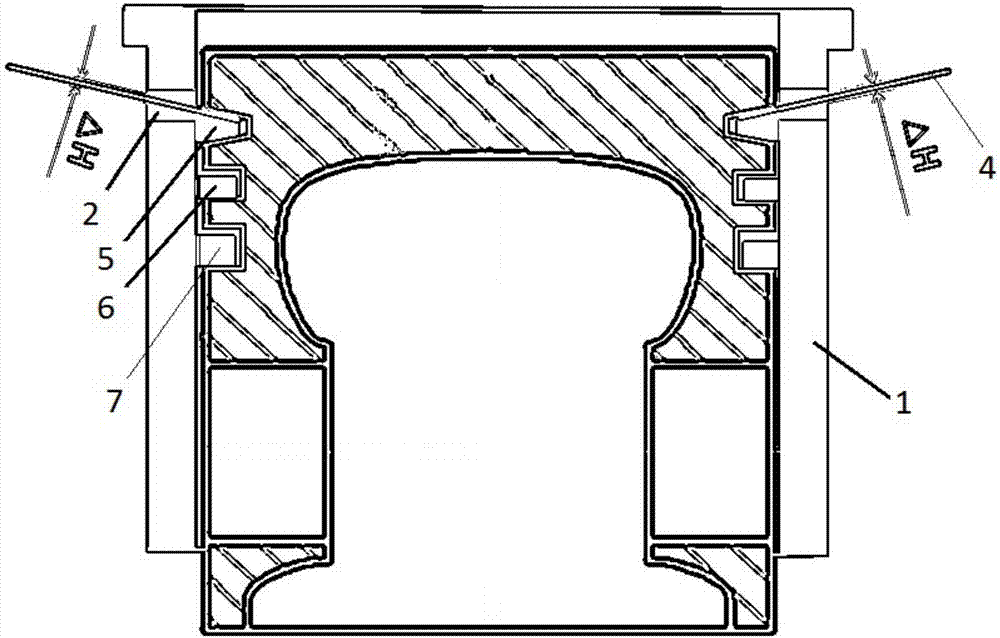

Detection device for detecting side clearance of piston ring

InactiveCN107883845AMeet the actual requirementsEasy to operatePiston ringsMechanical clearance measurementsPiston ringEngineering

The invention discloses a detection device for detecting the side clearance of a piston ring. The device comprises a sleeve. The inner diameter of the sleeve is consistent with the inner diameter of an air cylinder sleeve with a to-be-detected piston ring. Four detection windows are evenly arranged on the circumferential wall of the sleeve at equal intervals. The detection windows are used for feeler gauges to stretch into. Two feeler gauges are respectively used for penetrating through the detection windows to be inserted into the side clearance of the piston ring. By means of the detection device, whether the side clearance of the piston ring is qualified or not can be detected through judging whether the feeler gauges are matched with the side clearance of the piston ring or not. The detection device can rapidly and accurately detect whether the side clearance of the piston ring of an engine is qualified or not.

Owner:GUANGXI YUCHAI MASCH CO LTD

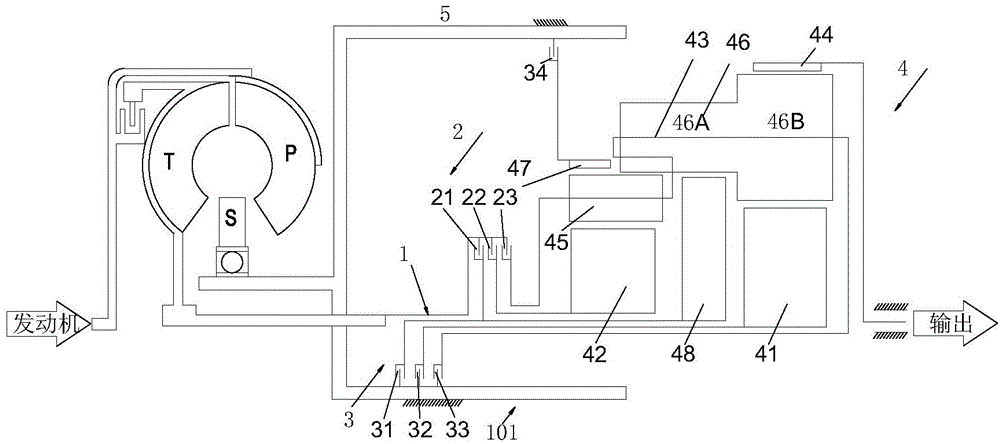

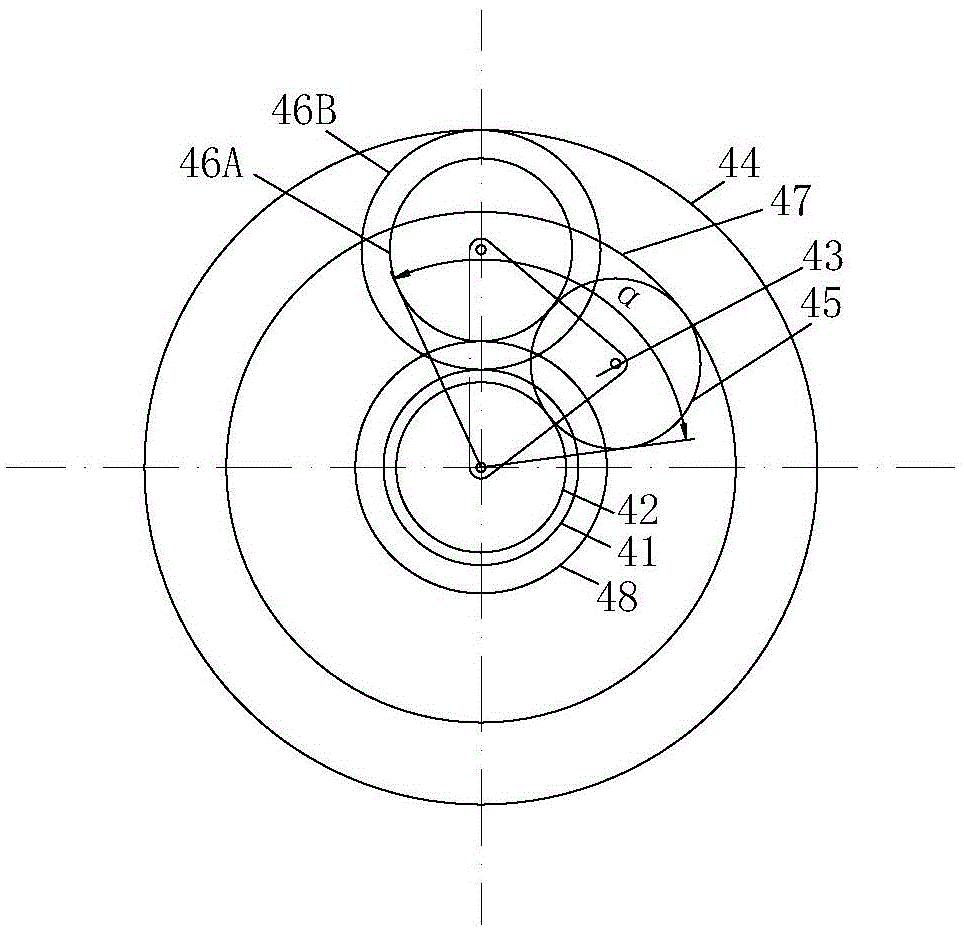

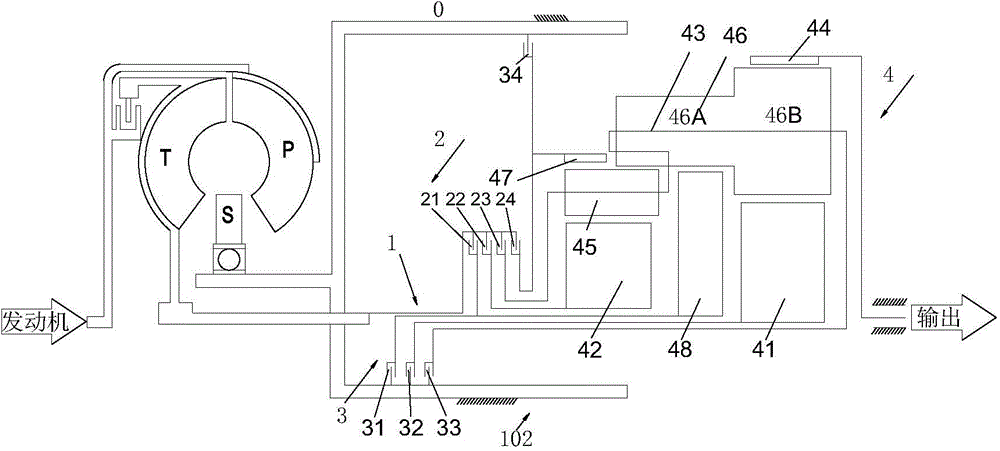

Eight-gear automobile automatic transmission

ActiveCN104964006AFew mechanical partsEasy to controlToothed gearingsTransmission elementsClutch controlAutomatic transmission

The invention belongs to the technical field of automatic transmissions and particularly relates to an eight-gear automobile automatic transmission. The transmission solves the technical problems that in the prior art, adjacent planetary gears interfere with one other, an obtained transmission ratio depends on a presumed transmission ratio, and the limitation of the transmission ratio of a system is large. The transmission comprises a box, a power input shaft, three clutches, four brakes and a planetary gear system. The planetary gear system comprises a first sun gear, a second sun gear, a third sun gear, a first gear ring, a second gear ring, a first planetary gear with a step, a first planetary gear without a step and a planetary frame. The second sun gear, the third sun gear and the planetary frame are controlled by the first clutch, the second clutch and the third clutch respectively. The second sun gear, the first sun gear, the planetary frame and the second gear ring are controlled by the first brake, the second brake, the third brake and the fourth brake respectively. The transmission is easy to control, transmission efficiency of all gears is high, and the adjacent planetary gears do not interfere with one other.

Owner:朗道科教设备(肇庆)有限公司

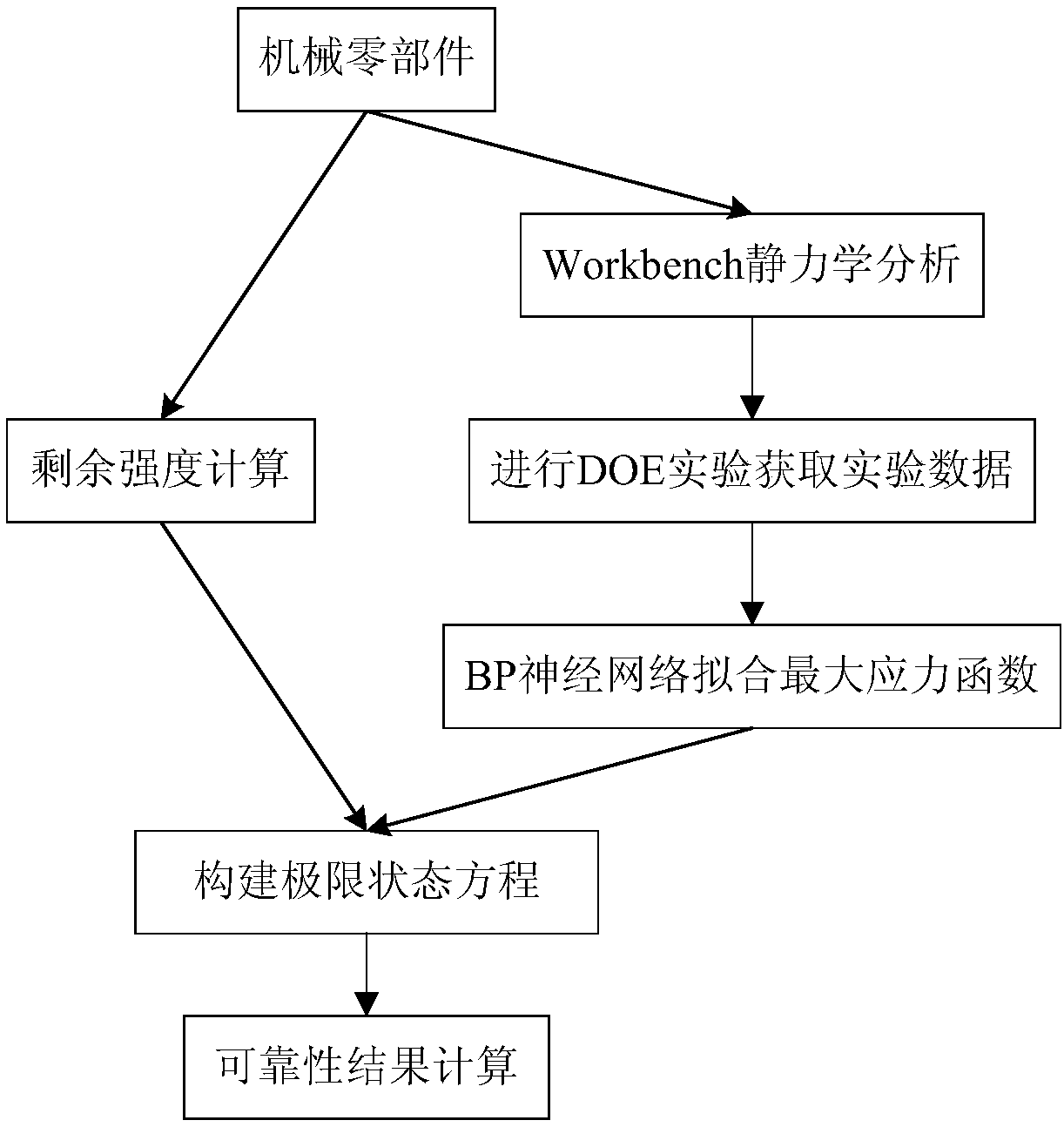

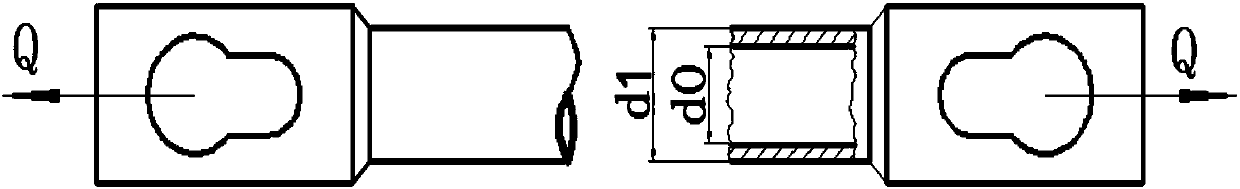

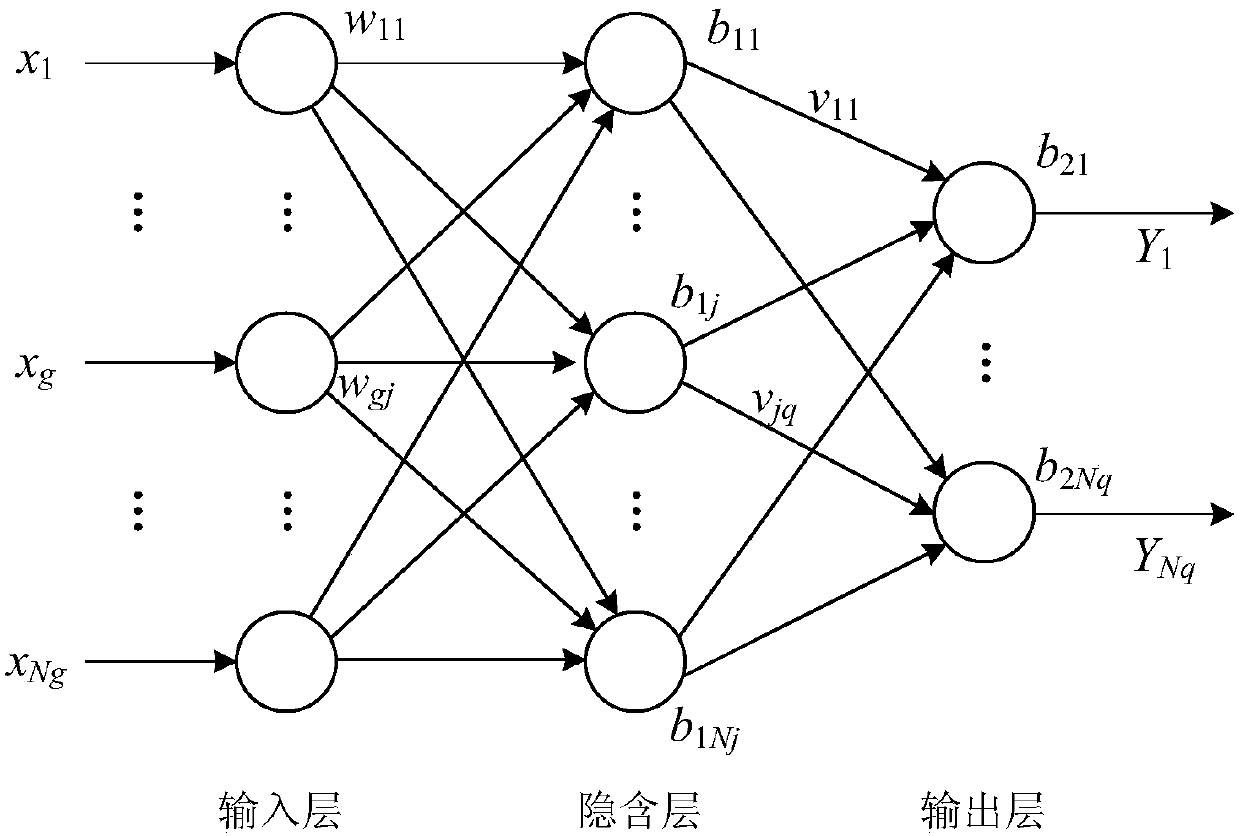

Reliability analysis method of mechanical component structure

InactiveCN108491627AWell formedEasy to understandGeometric CADDesign optimisation/simulationStatic timing analysisStructure analysis

The invention provides a reliability analysis method of a mechanical component structure, and relates to the technical field of mechanical component structure analysis. According to the method, firstly, statics analysis is carried out on mechanical components through AsysWorkbench, then Six Sigma Analysis is utilized to carry out DOE to obtain sufficient experiment data, a BP neural network is utilized to fit a maximum stress function, finally, a limit state equation of intensity degradation is constructed on the basis of Schaff's residual intensity theory, and reliability analysis and calculation are carried out to obtain a reliability analysis result of a mechanical component. According to the reliability analysis method of the mechanical component structure provided by the invention, anoperation process is simple, and reliability of calculation more accords with actual needs. The method has very high engineering practice feasibility and effectiveness.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com