Reliability analysis method of mechanical component structure

A technology of mechanical parts and analysis methods, applied in computer-aided design, instruments, geometric CAD, etc., can solve problems such as high reliability, not maximum stress, etc., to achieve the effect of simple form, important engineering value, easy to understand and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

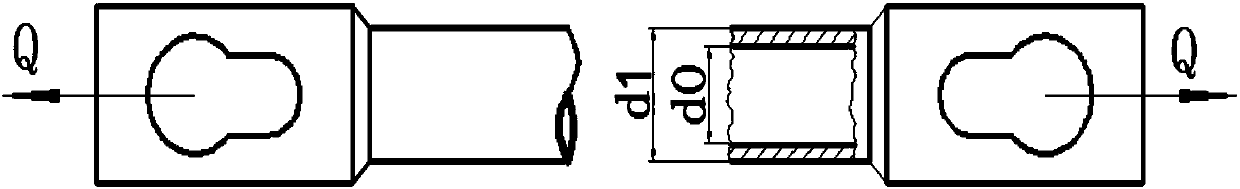

[0047] The mechanical part in this embodiment is a hollow circular tube tie rod with a symmetrical structure, and the parameters of the test piece are shown in Table 1, where Q is the load on the tie rod, d 1 The outer diameter of the section, d 0 is the inner diameter of the section, and r is the strength of the tie rod.

[0048] Table 1 Specimen parameters

[0049]

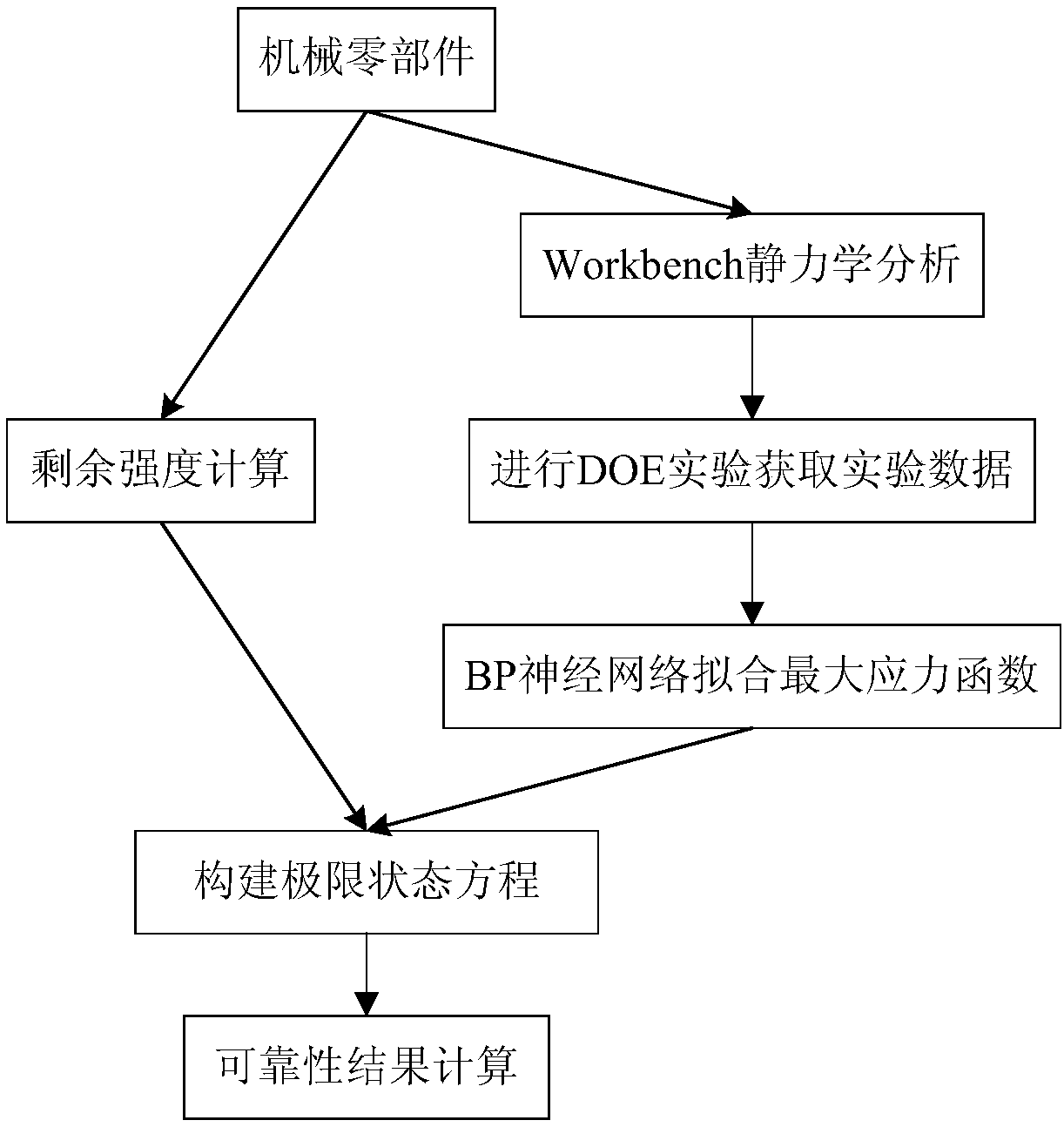

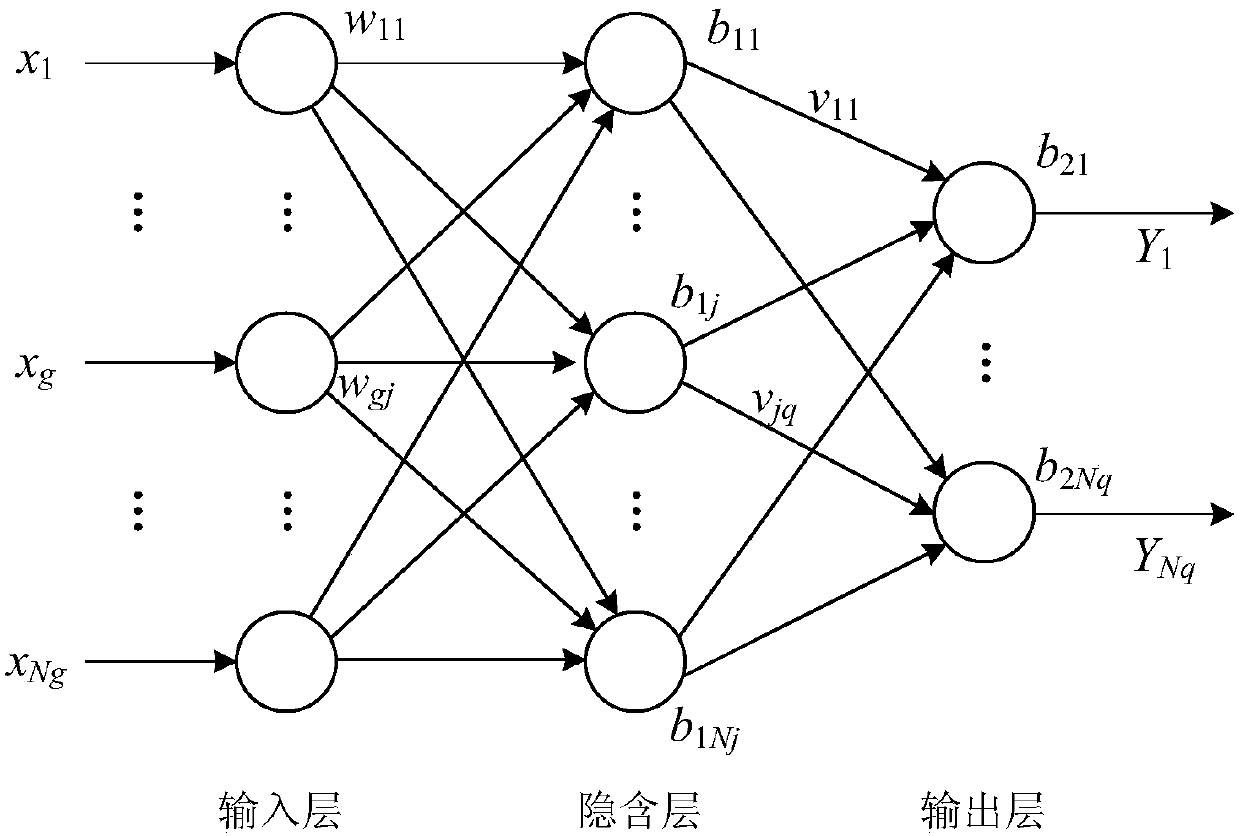

[0050]In order to make the reliability calculation results of mechanical parts under the stress-strength interference model more accurate or closer to reality, the method of this embodiment proposes to use the maximum stress of the static analysis results of AnsysWorkbench finite element software as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com