Rolling ball type peristaltic pump with gear-like structure

A technology of ball-type and peristaltic pumps, which is applied to variable-capacity pump components, pumps with flexible working elements, pumps, etc., can solve problems affecting the service life of pump tubes, waste of energy and materials, and excessive stretching of pump tubes. Achieve light weight, save energy and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

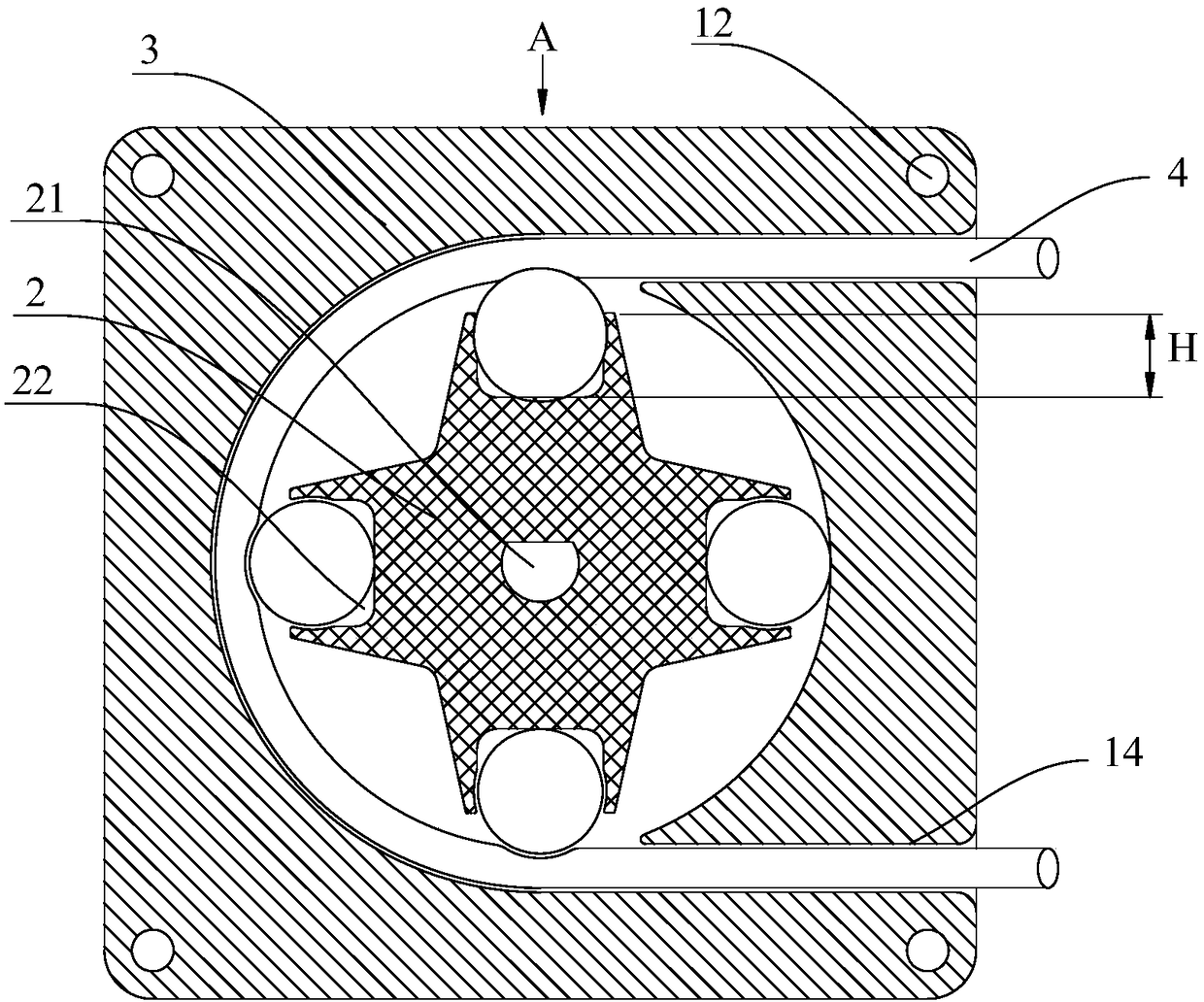

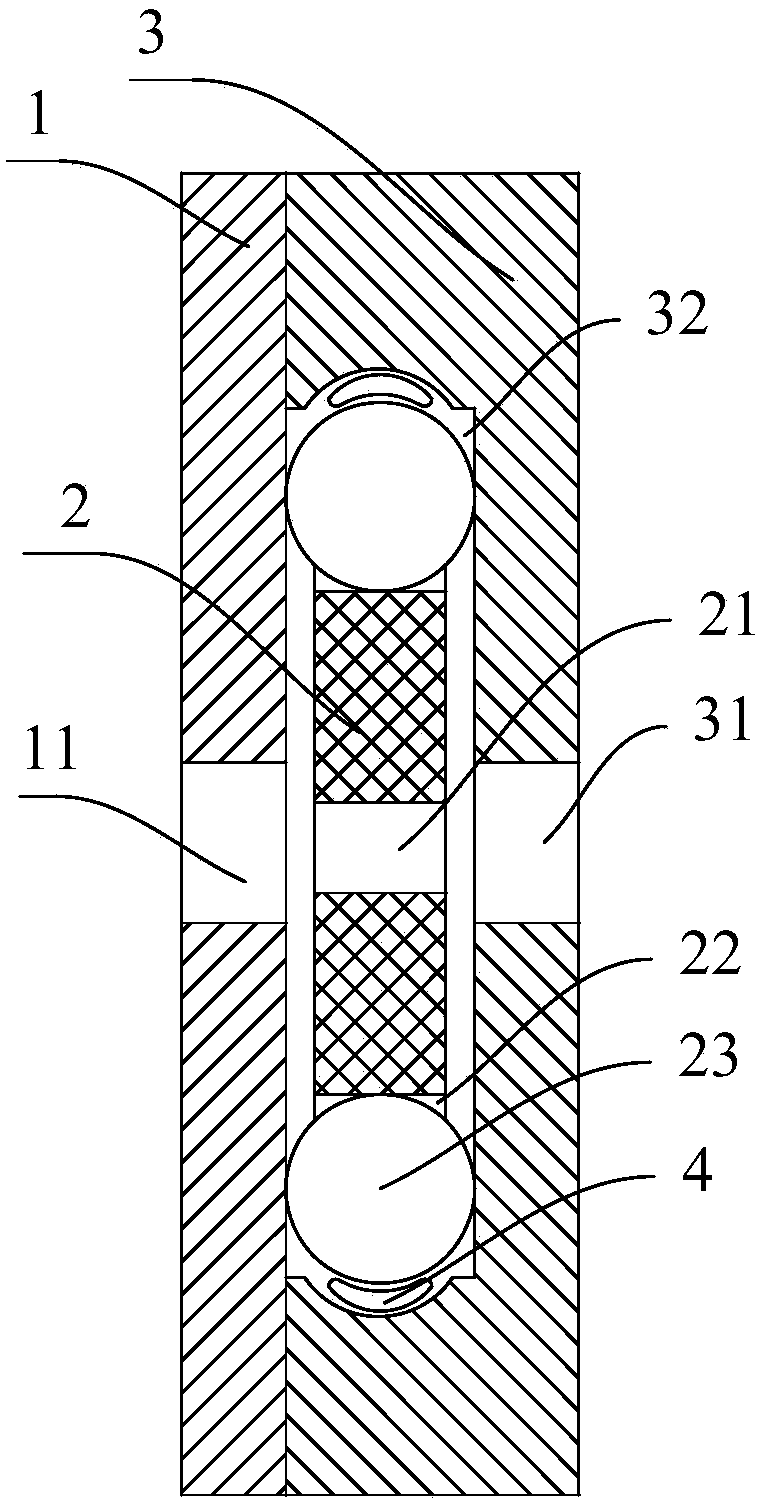

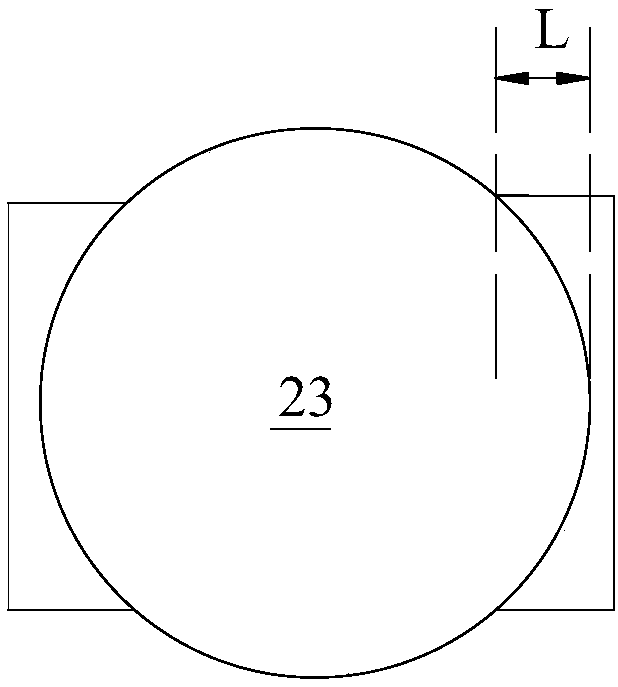

[0027] combine figure 1 , 2 The ball-type peristaltic pump with tooth-like structure shown includes a base 1, a rotating member 2 and an upper cover 3. The center of the base 1 is provided with a central hole 11, and the surrounding is provided with a fixing hole 12; the center of the upper cover 3 is provided with a central hole 31, and the surrounding is provided with a fixing hole 12, and the lower end surface is provided with a rotating part holding hole 32; Inside the rotating member holding hole 32 , the center of the rotating member 2 is provided with a rotating shaft mounting hole 21 . The central hole 11 of the base 1, the central hole 31 on the loam cake 3 and the rotating shaft installation hole 21 are concentric.

[0028] The center of the rotating part 2 is provided with a transmission shaft installation hole 21, and the rotating part 2 is connected and fixed with the rotating shaft of similar power devices such as motors and hydraulic motors through the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com