A method for producing grain-oriented pure iron by secondary annealing

A technology of secondary annealing and grain orientation, applied in heat treatment equipment, manufacturing tools, heat treatment process control, etc., can solve the problems of poor purification effect, achieve the effect of improving magnetic induction intensity and increasing annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

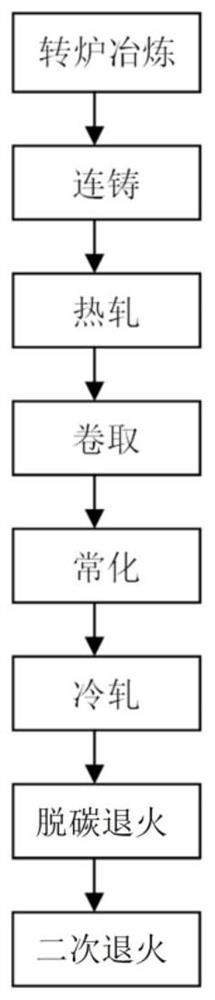

Method used

Image

Examples

Embodiment 1

[0046] combine figure 2 As shown, in this embodiment, the chemical composition mass percentage of grain-oriented pure iron is: C=0.04%, Si=0.10%, Mn=0.10%, S=0.005%, Als=0.015%, N=0.007%, The rest are unavoidable impurities and Fe. The specific production steps are as follows:

[0047] 1) Converter smelting: The tapping temperature of the converter is 1600°C. Then, the converter smelting molten steel is refined by using the molten steel vacuum circulation degassing method, and the composition of the molten steel is adjusted after refining to obtain the refined molten steel. Among them, the refining start temperature is 1590°C, and the refining end temperature is 1545°C;

[0048] 2) Continuous casting: Protective casting of molten steel by blowing argon through long nozzles to obtain continuous casting slabs; wherein the cooling method of natural cooling is adopted for die casting. It is worth noting that the thickness of the slab is 155mm.

[0049] 3) Soaking: put the sl...

Embodiment 2

[0062] The content of this embodiment is basically the same as that of Example 1. The difference is that the content of this embodiment is basically the same as that of Example 1. The difference is that the mass percentage of the chemical composition of grain-oriented pure iron in this embodiment is: C= 0.02%, Si=0.10%, Mn=0.10%, S=0.005%, Als=0.007%, N=0.007%, and the rest are unavoidable impurities and Fe. The process parameters of production are the same as in Example 1, and the magnetic properties of the obtained grain-oriented pure iron are measured, and the result is: B 800 =1.928T,B 10000 =2.125T.

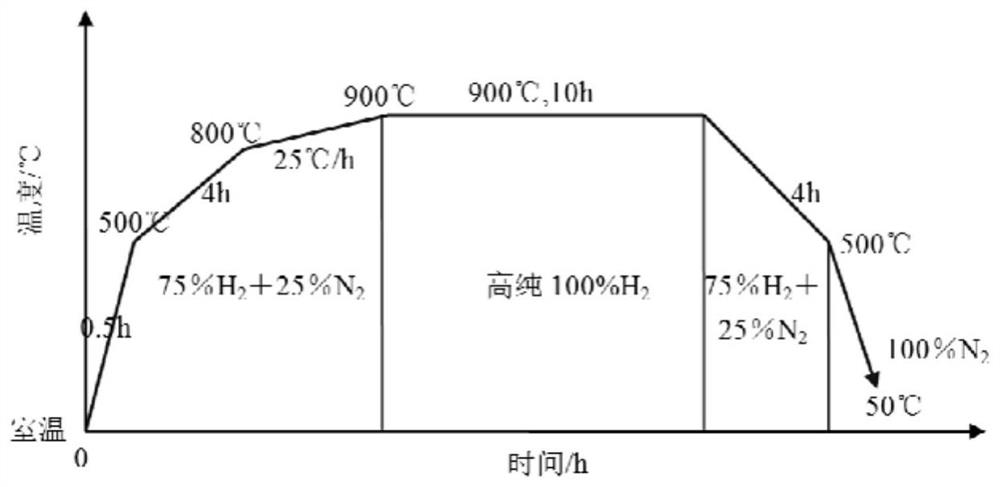

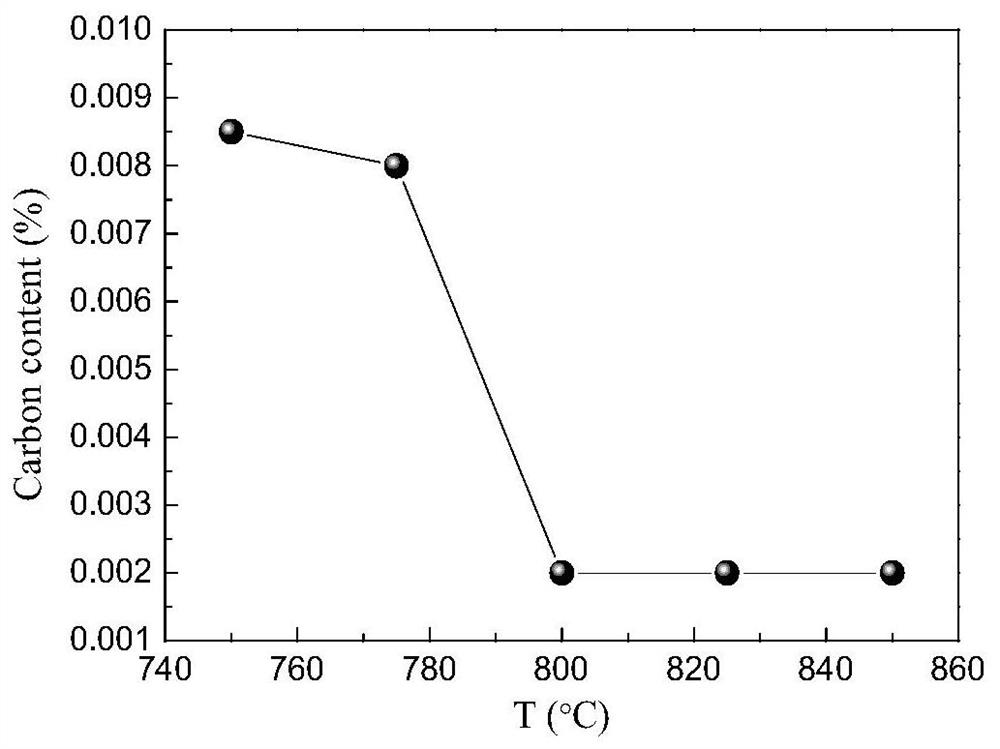

[0063] It can be seen from the above examples and comparative examples that the magnetic induction of grain-oriented pure iron is further improved by performing secondary annealing on the slab and by cooperating with other process steps. It should be noted that only when the high temperature purification section temperature T 高净 The best effect can be achieved when the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com