Preparation method of magnesium diboride superconducting thin film used for superconducting cables

A technology of superconducting thin film and magnesium diboride, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as small prospects, achieve high critical current density, increase density and grain boundary Connectivity, effect of prolonging annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

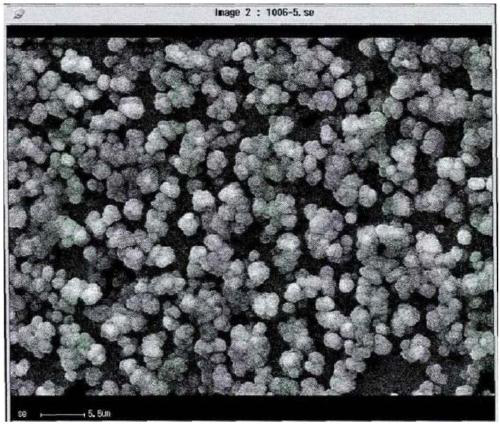

Image

Examples

Embodiment Construction

[0013] The preparation method of magnesium diboride superconducting thin film for superconducting cable comprises the following steps:

[0014] (1) Select the substrate substrate, the substrate is one or more of SiC, strontium titanate, sapphire, MgO, polysilicon, lanthanum aluminate and stainless steel.

[0015] (2) Clean the substrate substrate for 5 minutes, remove oil stains, dry it with nitrogen gas, and store it.

[0016] (3) Start the mechanical pump to draw a low vacuum in the deposition chamber, and then start the molecular pump to draw a high vacuum. when reaching 10 -5 After the vacuum degree of Pa, the substrate was heated at 10°C / min, and the mixed gas of argon and hydrogen was introduced. The volume ratio of argon and hydrogen was 4:1, so that the pressure in the deposition chamber was kept at 0.01Pa, and the holding time was 10-15 minutes. Introduce diborane with a concentration of 0.2%-0.5% into the deposition chamber, keep the air pressure at 1000-5000Pa, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com