Medicine bottle transfer system

A medicine bottle and rotating platform technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reducing circulation efficiency, increasing circulation costs, messy placement, etc., to reduce damage, reduce detection pressure, The effect of reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

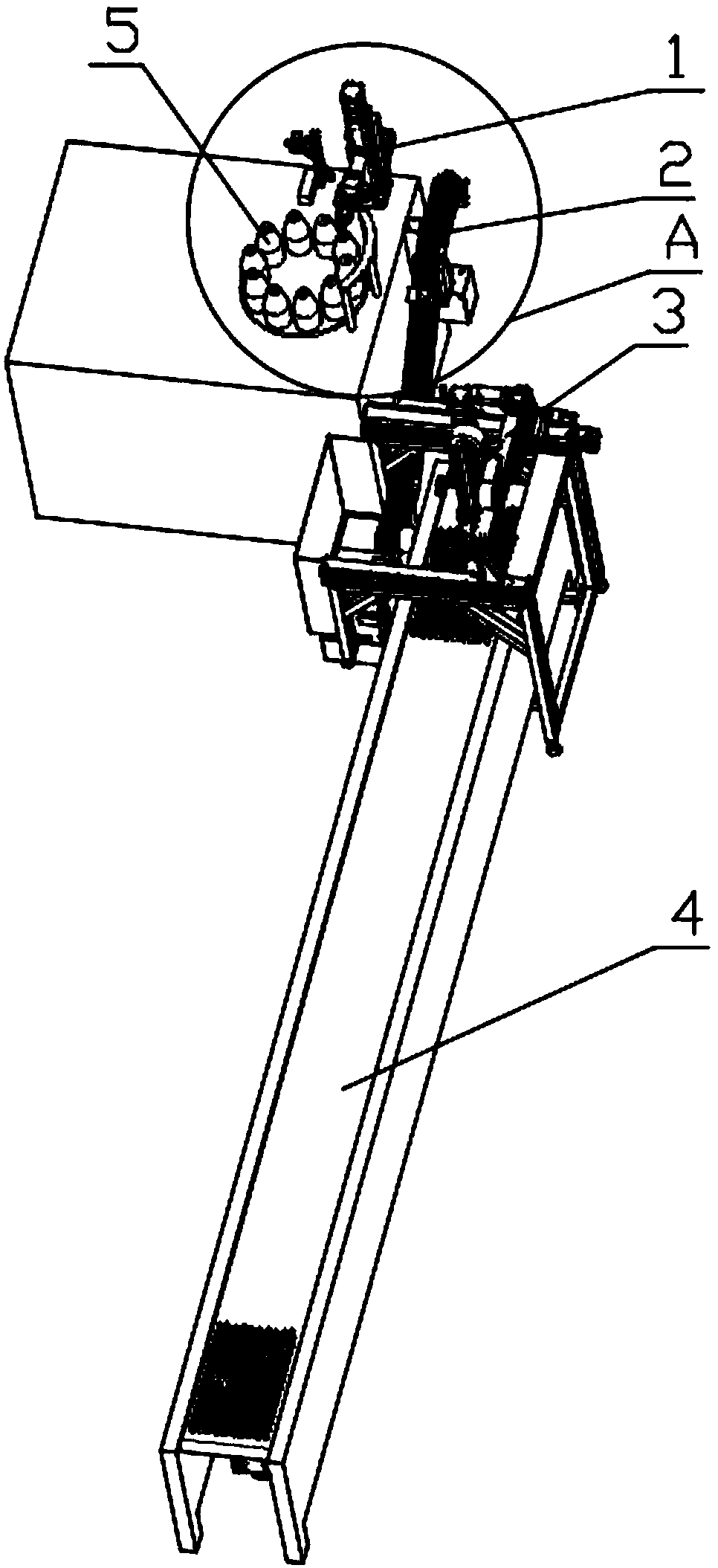

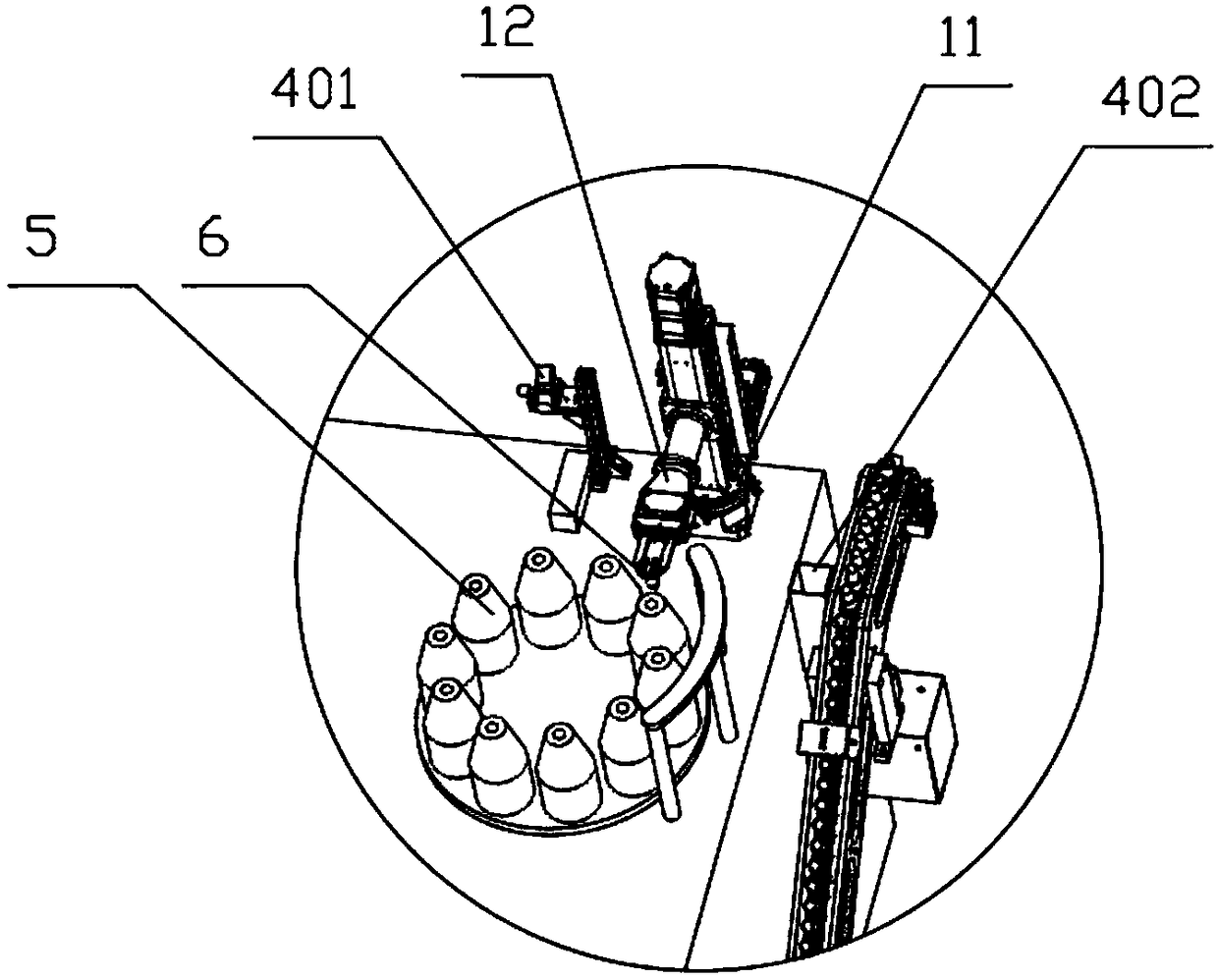

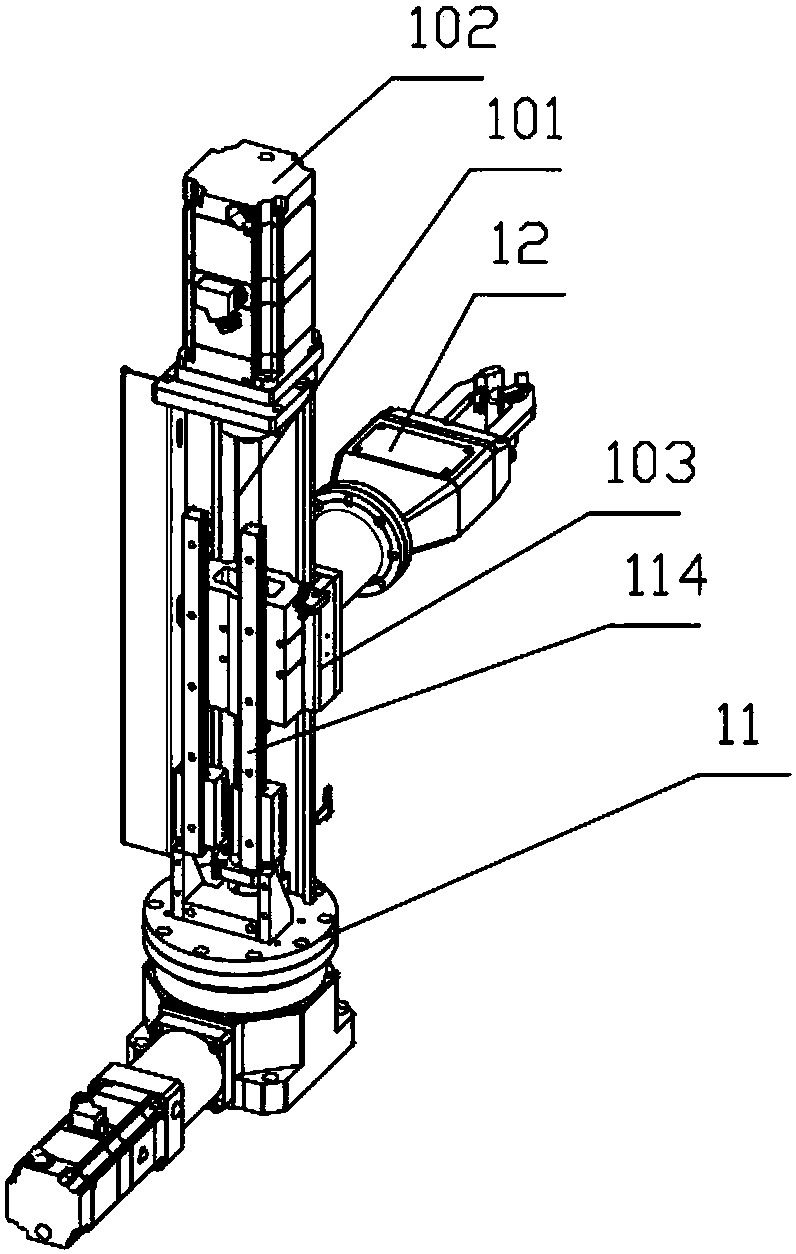

[0039] Such as figure 1 As shown, a drug bottle circulation system includes a first grabbing device 1 , a first conveying device 2 , and a second grabbing device 3 installed in sequence. The second conveying device 4 is arranged below the second grasping device 3, and the second conveying device 4 is a conveyor belt conveying device. Such as figure 2 As shown, a camera 401 is provided on one side of the first grabbing device 1 , and a waste bottle recovery port 402 is provided between the first grabbing device 1 and the first conveying device 2 . Both the first grasping device 1 and the camera 401 are connected to the control device, and the camera 401 is aimed at the station 5, which is the position where the medicine bottle 6 is put down from the bottle making machine. The camera 401 combined with the control device can detect the medicine bottle on each station 5. If the detection result is good, the first grasping device 1 places the medicine bottle 6 on the first conve...

Embodiment 2

[0049] Such as Figure 13 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1, except that the number of the first grabbing device 1 and the first conveying device 2 are both two, which are respectively arranged at the two ends of the second grabbing device 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com