Method for improving pure copper grain boundary corrosion resistance by increasing coherent twin grain boundary proportion

A technology of grain boundary corrosion and twin boundary, which is applied in the field of materials, can solve problems such as the inability to accurately measure the proportion of coherent twin boundary, and achieve the effect of prolonging the annealing time and improving the resistance of grain boundary corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

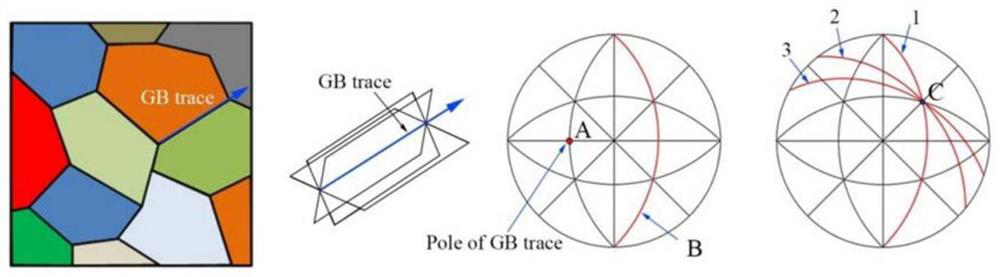

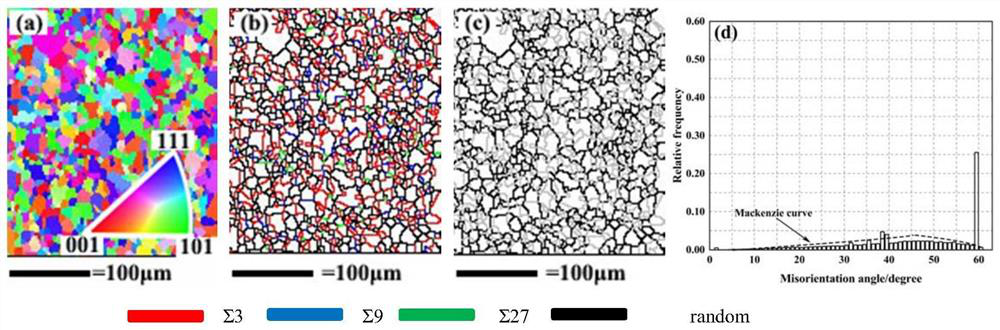

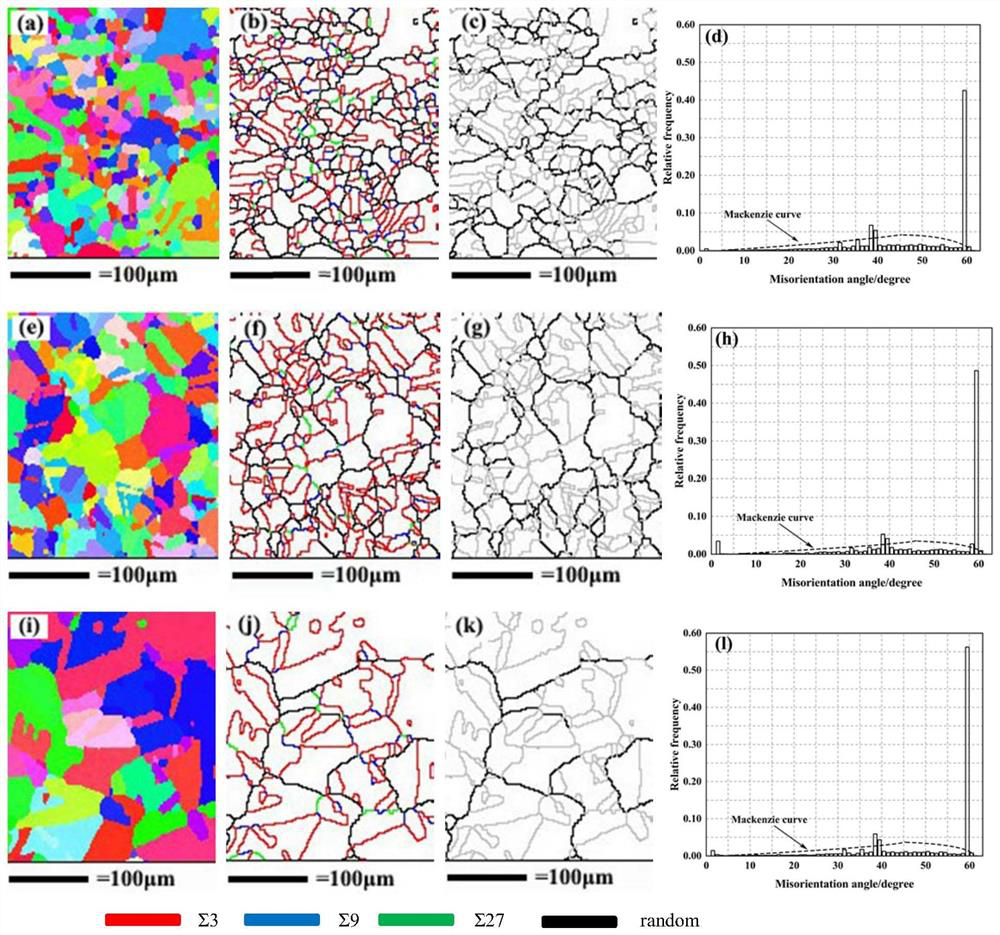

[0023] 1. Improve the corrosion resistance of pure copper grain boundaries by increasing the proportion of coherent twin boundaries

[0024] (1) In order to eliminate the influence of the initial state of the pure copper sample (possible texture and organization inhomogeneity) on the experiment, the sample needs to be subjected to a homogenization treatment, that is, repeated room temperature multidirectional forging and 600 ℃ recrystallization annealing to make the experiment The sample achieves tissue homogenization and obtains an ideal sample that can be used for subsequent experiments. A four-column universal hydraulic press is used for multi-directional forging. Before each round of multi-directional forging, the oxide layer on the surface of the sample should be ground off with sandpaper to expose the metallic color of Cu, which is purple-red. The samples were forged from three directions of x, y, and z with a hydraulic press, and the compression amount was 50% each tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com