Forging method for R6-grade mooring chain riveting swivel

A mooring chain and riveting technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as cracking, achieve the effect of prolonging the annealing time, ensuring plasticity, and eliminating the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

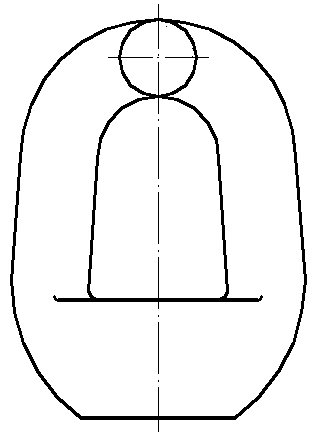

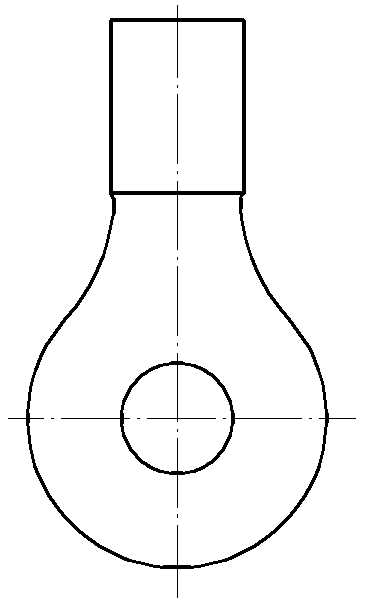

[0022] A forging method for a riveted swivel, the swivel includes a swivel body and a swivel ring bolt, characterized in that it includes the following steps: 1) blanking: ensure that the surface of the blanked piece is smooth, and remove the edges and corners of the saw edge; 2) riveting the swivel Ring body billet: put the raw material round steel into the flame furnace to heat; use the air hammer to upset and stretch the heated round steel to make a blank of close size, then gas cut the inner hole (the size of the hole is smaller than the forming size), forging There should be no interlayers, cracks, grooves and other defects that reduce product performance; 3) Forming of riveted swivel body: check the forming mold before forming, the forming cavity should have a smooth surface, and there should be no cracks, grooves and lowering Other defects in product performance; then the bent blank is heated to 1200~1260°C and formed by forging with a forming die, and the final forging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com