Method for growing CdS film or CdS nano-structure on CdTe film

A nanostructure and thin film technology, applied in the field of solar cells, can solve the problems that have not been reported, and achieve the effect of increasing the utilization rate, simple equipment, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

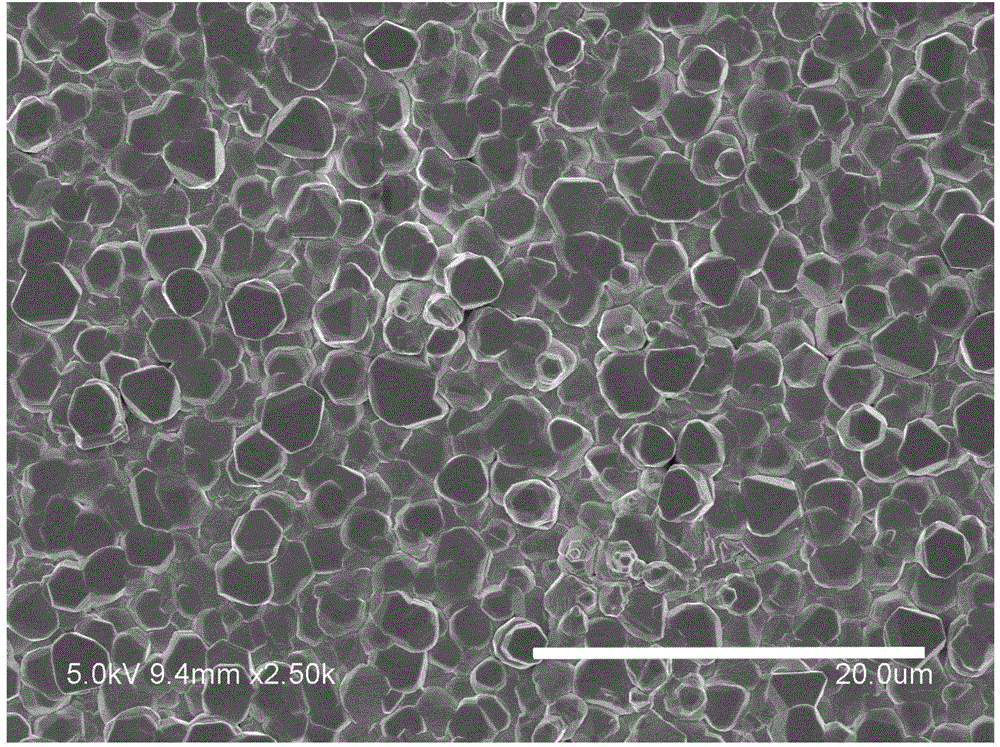

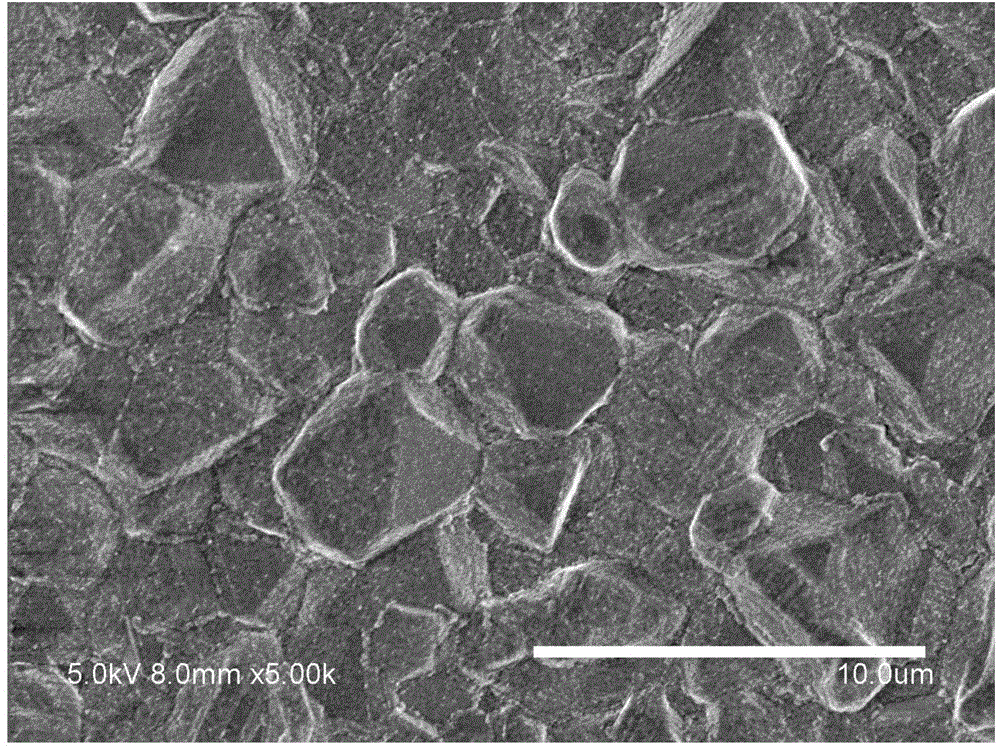

Image

Examples

Embodiment

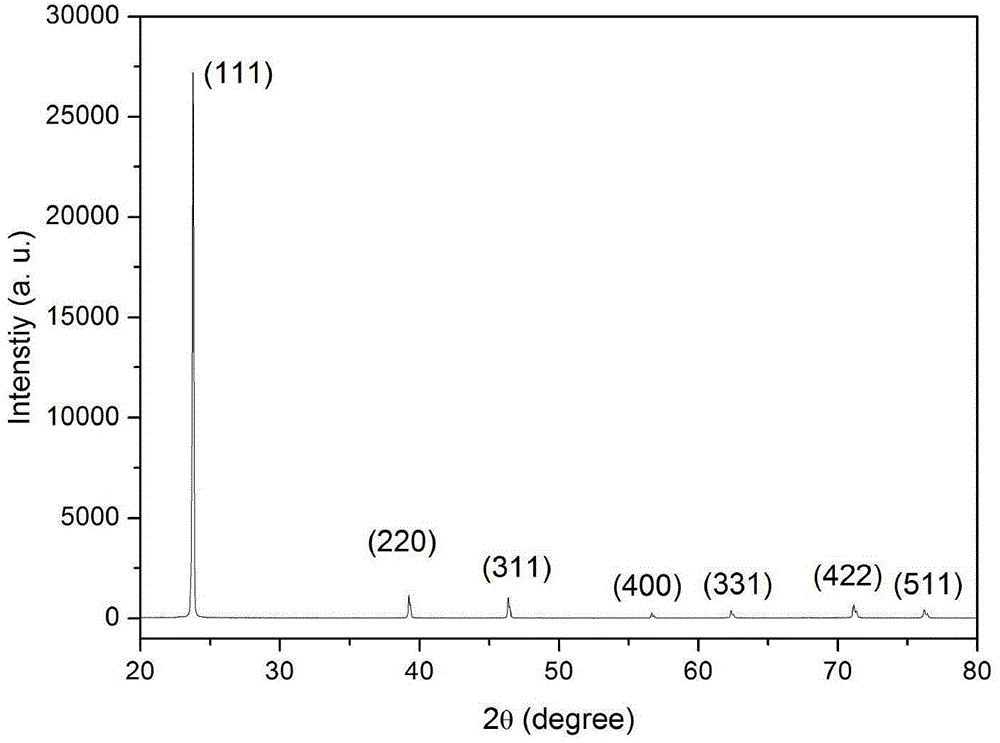

[0041] The above-mentioned prepared CdTe film is packed into a quartz tube, put into a sintering furnace, and sealed, and the quartz tube is evacuated with a vacuum pump. When the air pressure is reduced to 1Pa, the pumping is stopped, and after the hydrogen sulfide gas is introduced into the quartz tube, Seal; the sintering furnace is heated to 420°C at 10°C / min, and starts to cool down naturally after 60 minutes of heat preservation. After the temperature drops to room temperature, the film is taken out to obtain a finished product. like Figure 8 It can be seen from the figure that the phase structure of CdS is also formed after annealing in static hydrogen sulfide gas.

[0042] Example 4

[0043] The above-mentioned prepared CdTe film is packed into a quartz tube, put into a sintering furnace, and sealed, then feed 100 sccm of nitrogen to flush the quartz tube for 5 min, to get rid of the air in the quartz tube; then feed the mixed gas of nitrogen and hydrogen sulfide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com