Double-sided dark battery foil and preparation method thereof

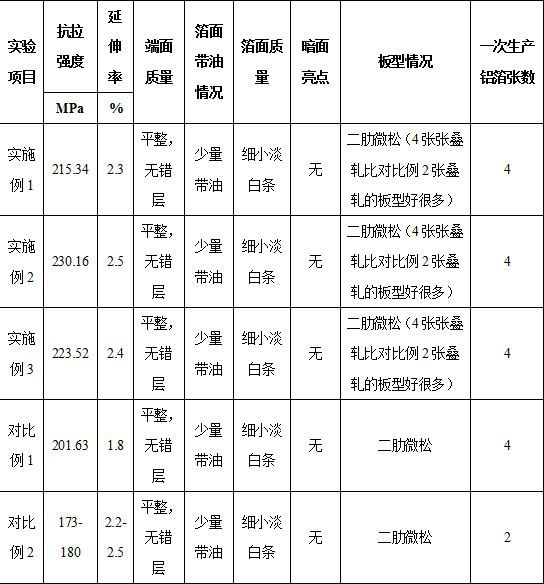

A battery and double-sided technology, which is applied to battery pack components, battery boxes/covers, battery box/cover materials, etc., can solve the problems of poor plate shape, low tensile strength, low production efficiency, etc., and achieve the performance of finished products and high surface quality, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the double-sided dark battery foil comprises the following steps:

[0032] (1) Add the raw materials of the double-sided dark battery foil into the melting furnace for melting, and the melting preparation conditions are as follows: the melting temperature is 730-760°C to obtain the aluminum alloy melt;

[0033] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 7.0-7.5mm, and cool it to room temperature;

[0034] (3) When the cast-rolled billet is cold-rolled by a cold rolling mill to a thickness of 1.8-4.0mm, homogenization annealing treatment is performed: the annealing temperature is 550°C, and the holding time is 25h;

[0035] (4) After the homogenized annealed aluminum coil is cooled to room temperature, it is cold rolled to 0.9-1.9mm in separate passes;

[0036] (5) After the aluminum coils in step (4) are cold-rolled in separate passes, they are recoiled and trimm...

Embodiment 1

[0042]A double-sided dark battery foil, comprising the following raw materials in mass percentage: Si: 0.105%, Fe: 0.416%, Cu: 0.0333%, Mn: 0.0213%, Mg: 0.005%, Ti: 0.0206%, Al: 99.36% .

[0043] The preparation method of the double-sided dark battery foil comprises the following steps:

[0044] (1) Add the raw materials of the double-sided dark battery foil into the melting furnace for melting. The melting preparation conditions are as follows: the melting temperature is 750°C to obtain the aluminum alloy melt;

[0045] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 7.0mm, and cool it to room temperature;

[0046] (3) The cast-rolled billet is cold-rolled by cold-rolling mill to thicknesses of 3.3mm and 1.8mm, and homogenized annealing treatment is carried out: the annealing temperature is 550°C, and the holding time is 25h;

[0047] (4) After the homogenized annealed aluminum coil is cooled to ro...

Embodiment 2

[0053] A double-sided dark battery foil, comprising the following raw materials in mass percentage: Si: 0.127%, Fe: 0.419%, Cu: 0.0343%, Mn: 0.0214%, Mg: 0.005%, Ti: 0.0267%, Al: 99.33% .

[0054] The preparation method of the double-sided dark battery foil comprises the following steps:

[0055] (1) Add the raw materials of the double-sided dark battery foil into the melting furnace for melting. The melting preparation conditions are as follows: the melting temperature is 750°C to obtain the aluminum alloy melt;

[0056] (2) Input the molten aluminum alloy into the casting and rolling machine, cast and roll it into a billet with a thickness of 7.5mm, and cool it to room temperature;

[0057] (3) The cast-rolled billet is cold-rolled to a thickness of 4.0 mm through the cold-rolling mill and then subjected to homogenization annealing treatment: the annealing temperature is 550°C, and the holding time is 25 hours;

[0058] (4) After the homogenized annealed aluminum coil is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com