Improvement structure of tee joint pipe assembly in tunnel crosswalk

A technology of three-way joints and assemblies, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as unsafe and reliable, and achieve the effect of ensuring safety and reliability, reducing service life, and preventing early cracks and water leakage accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

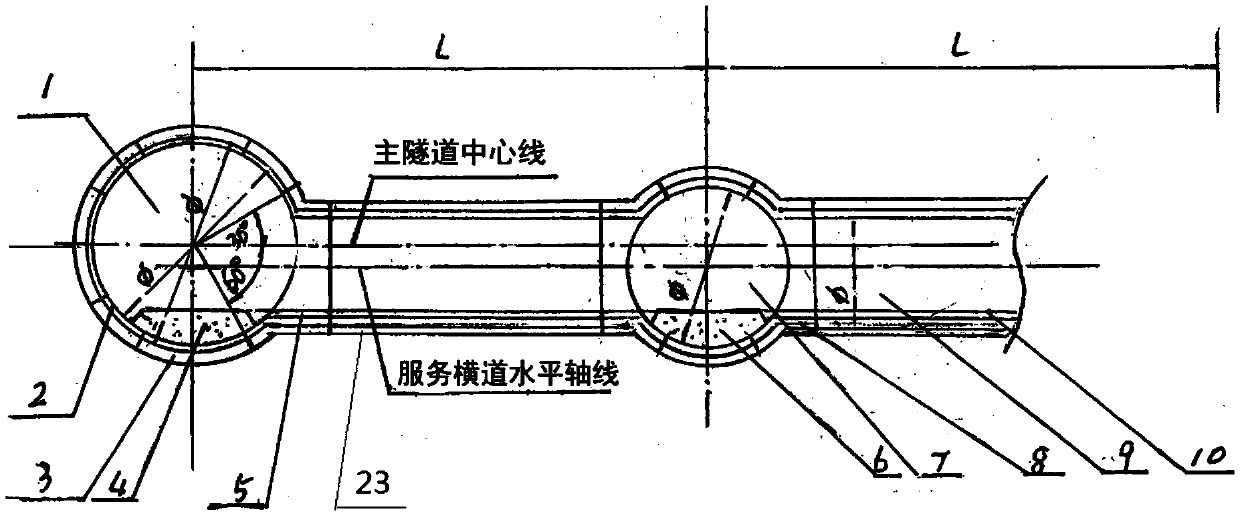

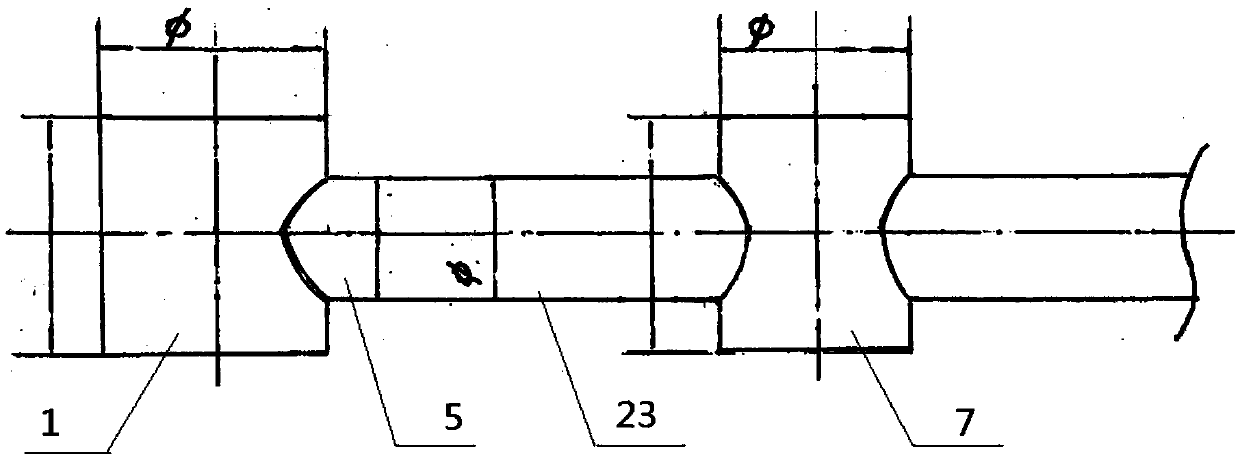

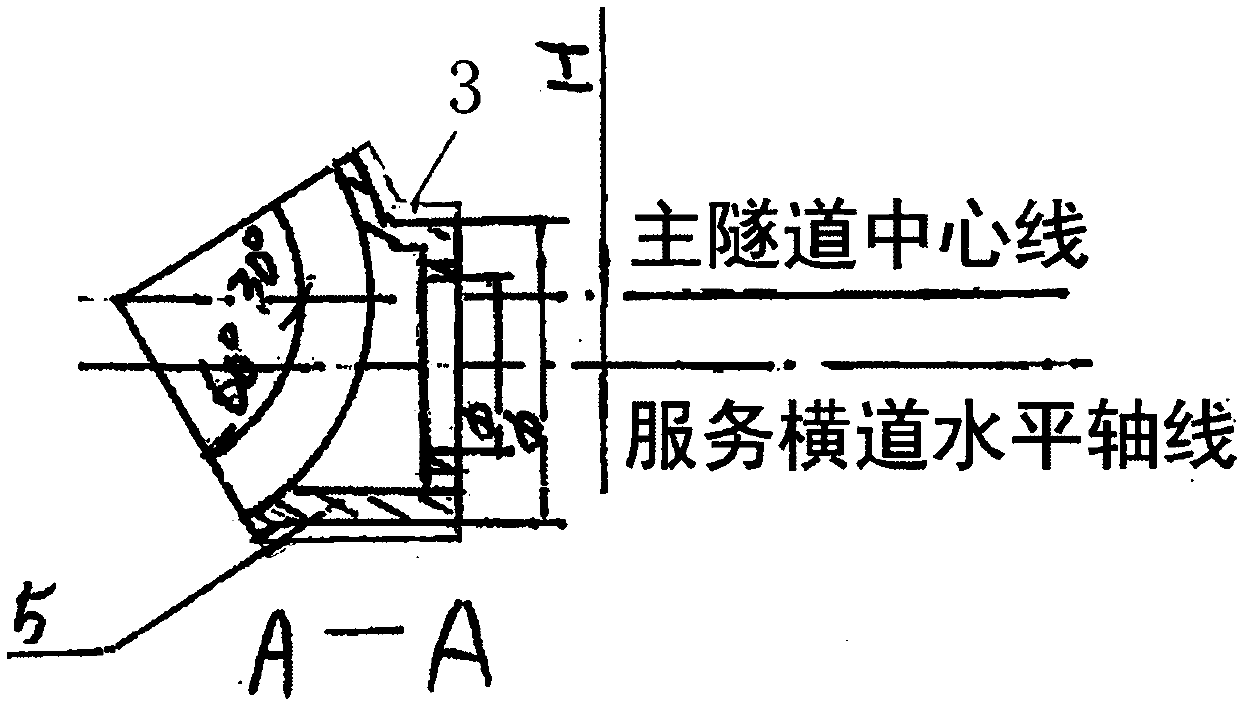

[0037] Such as Figure 1-Figure 9 As shown, the tunnel crosswalk tee joint pipe assembly in this embodiment mainly includes: main tunnel 1, ductile iron frame 2, concrete layer 3, main tunnel subgrade 4, large tee joint pipe 5, service tunnel subgrade 6, service tunnel 7. Small three-way joint pipe 8, transverse pipe gallery 9, connecting transverse road surface 10, stiffener plate 11, positioning shear sleeve 12, radial connecting hole 13, radial frame 14, axial connecting hole 15, sealing groove 16 , Axial frame 17, reinforced grid truss 18, bolt 19, service crossway 23 (such as: cross-section is an elliptical service crossway), etc., the specific structure is as follows:

[0038] A service crosswalk 23 is set between the main tunnel 1 and the service tunnel 7, and the service crosswalk 23 and the main tunnel 1 are connected by a large three-way joint pipe 5. One side of the service tunnel 7 is connected by a small three-way joint pipe 8, and the small three-way joint pipe ...

Embodiment 2

[0045] The difference from Example 1 is:

[0046] Such as Figure 10-Figure 12 As shown, the tunnel crosswalk tee joint pipe assembly in this embodiment mainly includes: main tunnel 1, ductile iron frame 2, concrete layer 3, main tunnel subgrade 4, large tee joint pipe 5, service tunnel subgrade 6, service tunnel 7. Small three-way joint pipe 8, cross passage pipe gallery 9, connecting cross road surface 10, oval service cross road 20, etc. The specific structure is as follows:

[0047] An oval-shaped service crosswalk 20 is set between the main tunnel 1 and the service tunnel 7, and the oval-shaped service crosswalk 20 and the main tunnel 1 are connected and matched through the large three-way joint pipe 5, and the two sides of the service tunnel 7 are respectively connected with the small three-way joint pipe 8 , the oval service crossway 20 and one side of the service tunnel 7 are connected and matched through a small three-way joint pipe 8, and the small three-way joint p...

Embodiment 3

[0049] The difference from Example 1 is:

[0050] Such as Figure 13 As shown, a service crosswalk 23 (such as a service crosswalk with an elliptical cross-section) is set between the two main tunnels 1 and the service tunnel 7, and the service crosswalk 23 and the main tunnel 1 are connected by a large three-way joint pipe, and the service tunnel 7 The two sides are respectively connected with the small three-way joint pipe, the service crosswalk 23 and the service tunnel 7 are connected through the small three-way joint pipe, and the evacuation passage 22 is set in the service tunnel 7 . In addition, the two main tunnels 1 communicate with the service tunnel 7 through a decompression channel 21 .

[0051] The present invention improves the cross-section (circular tube-shaped cross-section) of the channel tunnel into an elliptical vertical structure scheme. Because the construction length of the cross-channels on both sides is only more than 20 meters, it can only be constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com