Self-seal heat-preservation-layer-free outer side cavity structure for water pan and air conditioner with self-seal heat-preservation-layer-free outer side cavity structure

A technology of sealing structure and water receiving tray, applied in the application, household heating, household heating and other directions, can solve the problems of unfavorable branch operation, high cost, increase assembly parts and other problems, and achieve the effect of avoiding condensation and dripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

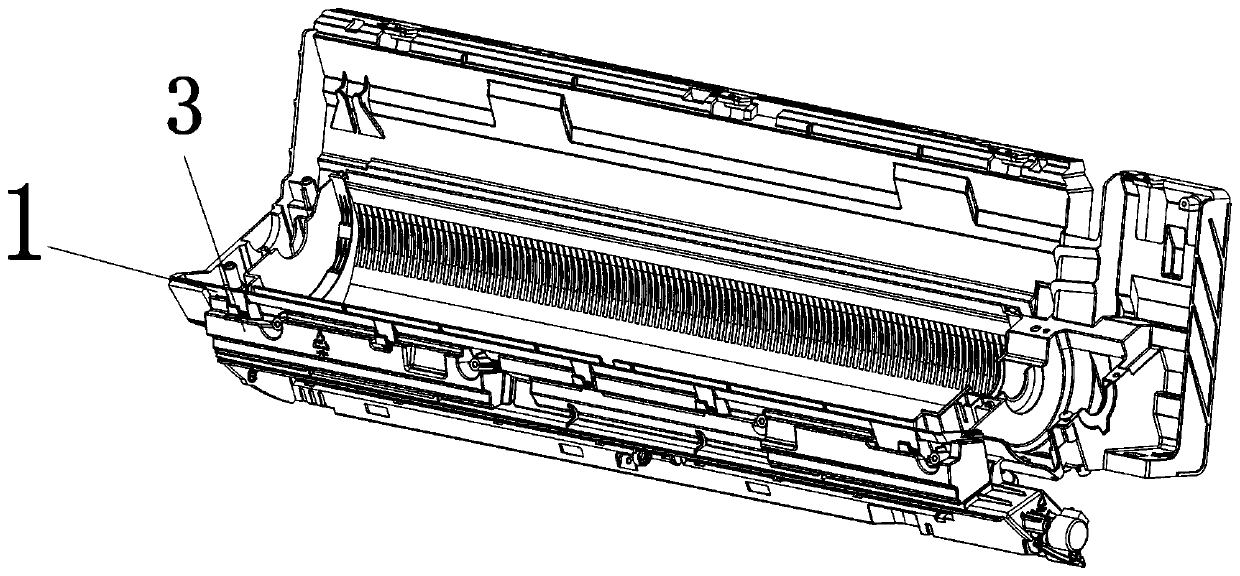

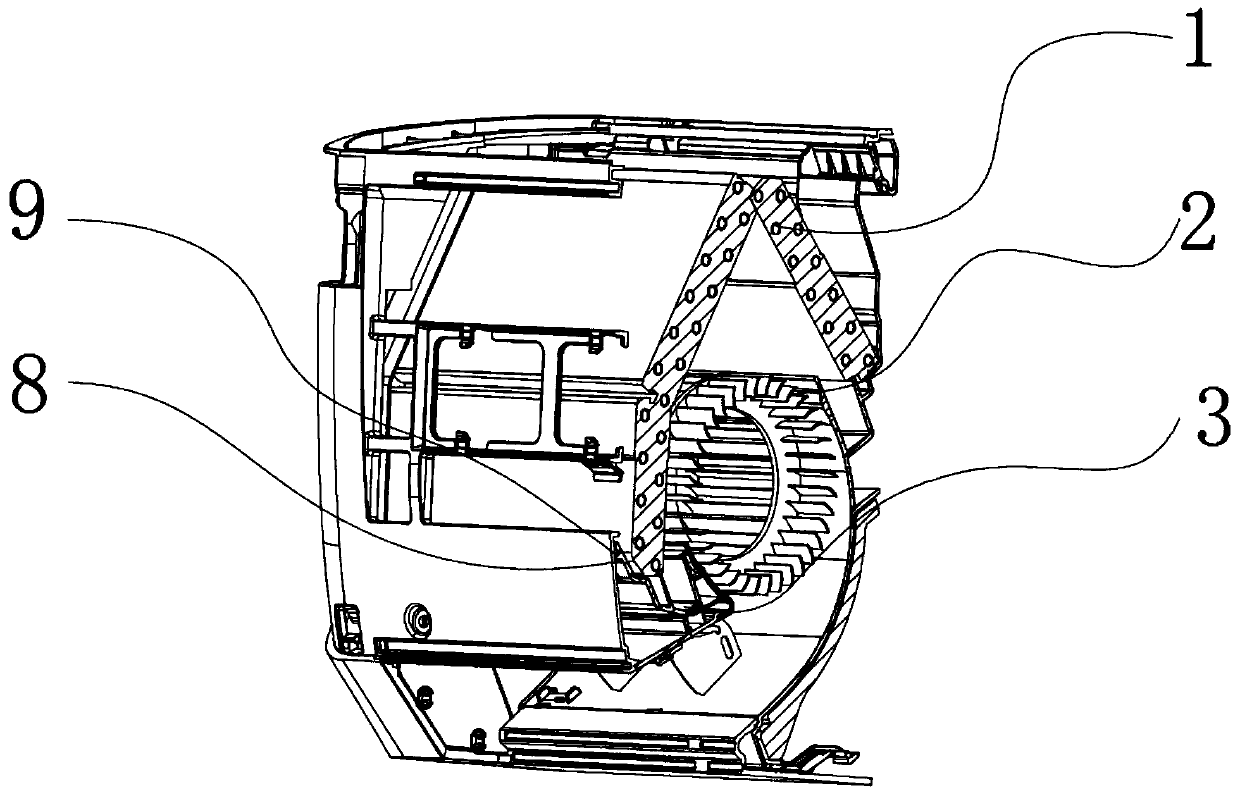

[0026] The outer cavity structure of the self-sealing insulation-free layer used for the water tray includes the matching indoor unit shell 4 and the water tray 3 for receiving condensed water on the evaporator, and the surface of the matching indoor unit shell 4 and the water tray 3 A cavity sealing structure is provided between the outer surfaces. A casing cover 5 is installed on the casing 4 of the supporting indoor unit through fasteners, a sealing structure is provided between the casing cover 5 and the water receiving tray 3, and the casing cover 5 and the sealing structure are connected along the water receiving tray. 3. The surface extends in the front-back direction or in the left-right direction to form the sealed structure of the cavity.

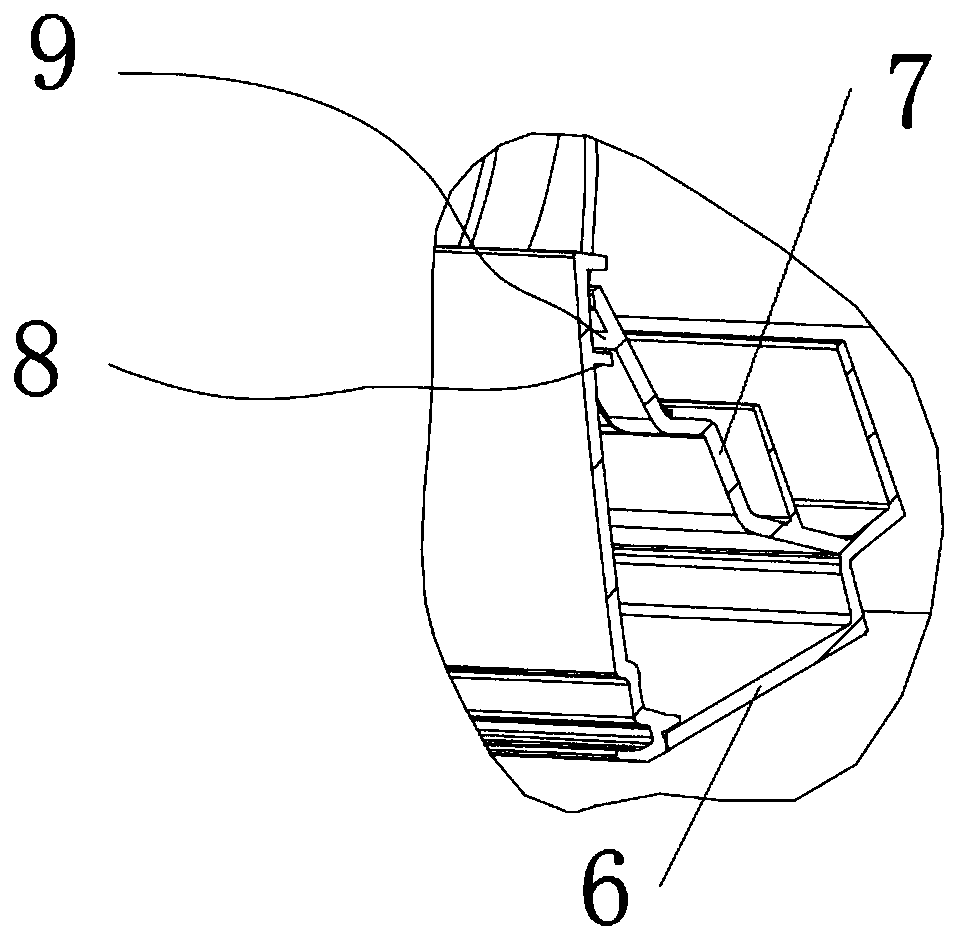

[0027] The water tray 3 includes a base 6 and a support plate 7 , and an angle is formed between the base 6 and the support plate 7 .

[0028] The sealing structure includes a first groove 8 extending horizontally on the support ...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the sealing structure includes a third convex groove extending horizontally on the support plate 7, and the inner wall of the housing cover plate 5 is provided with a fourth convex groove extending horizontally. , the third protruding groove and the fourth protruding corrugation, the third protruding groove and the fourth protruding corrugation are not marked in the figure, can refer to the first embodiment, the lower end of the shell cover plate 5 is provided with the first horizontally extending Two corrugations 10 , the second corrugation 10 is pressed against the free end surface of the support plate 7 .

[0031] Implementation three

[0032] The difference between this embodiment and Embodiment 1 is that the sealing structure is to realize the self-sealing of the parts on the outer side of the water tray 3 through the design of the injection mold and the injection molding machine tool with a gas-assist...

Embodiment 5

[0036] Another technical solution of the present invention is achieved as follows: the air conditioner includes an indoor unit, the indoor unit is provided with an indoor evaporator component 1 and an internal unit cross-flow fan 2, and the indoor unit housing 4 is provided with any of the above-mentioned The outer cavity structure of the self-sealing insulation-free layer used for the water receiving tray 3.

[0037] After the patent seals the outer surface of the water tray 3 with a full enclosure, it can prevent the flowing air containing a large amount of water from entering the outer surface of the water tray 3, thereby avoiding the need to cancel foam and sponge insulation on the outer surface of the water tray 3. After layering, the air in the cavity formed between the outside of the water receiving tray 3 and the inner machine casing continues to circulate, and when the circulating air contains moisture, when the air contacts the outside of the water receiving tray 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com