Reinforcement device and reinforcement method for joints of antibacterial water pipes

A reinforcement device and connection technology, which is applied in the direction of pipeline connection layout, pipe/pipe joint/fitting, pipeline protection, etc., can solve problems such as cracks, unreliable firmness, and drinking water leakage at the butt joints of antibacterial water pipes, and reach the heating surface Large size, easy installation, rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

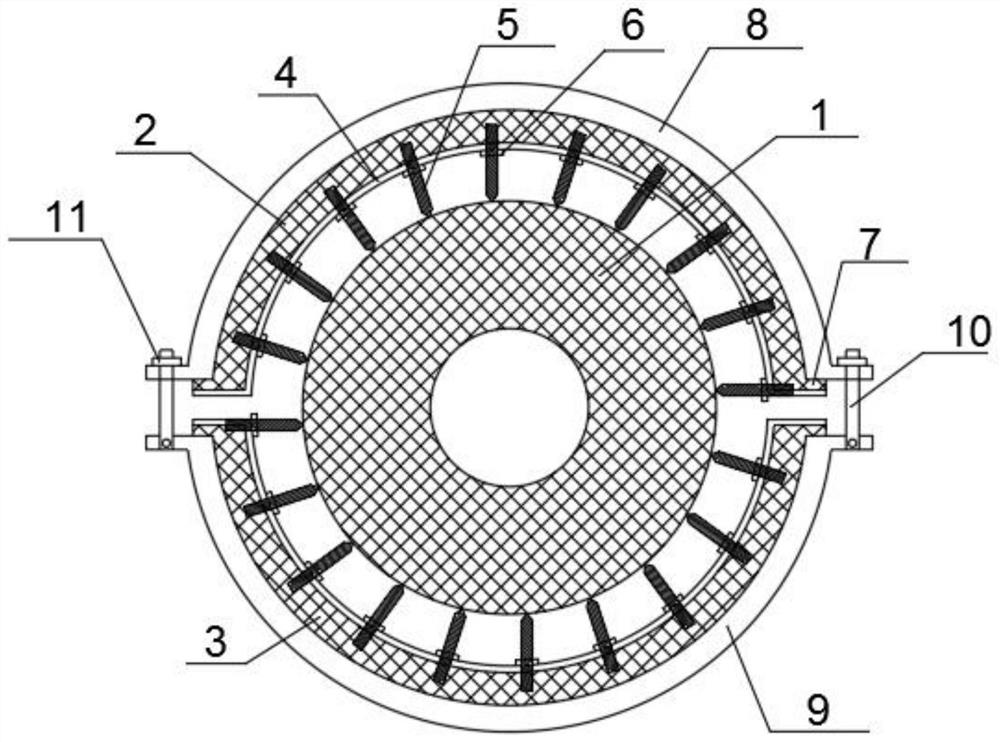

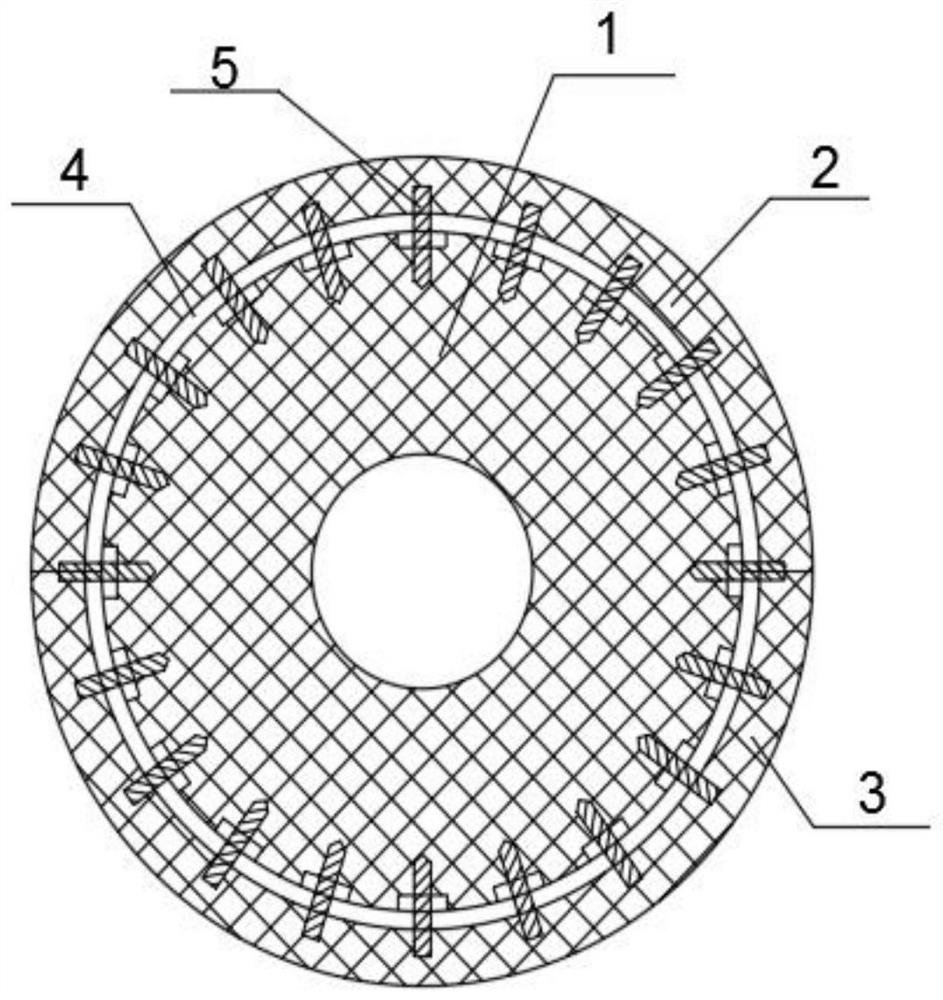

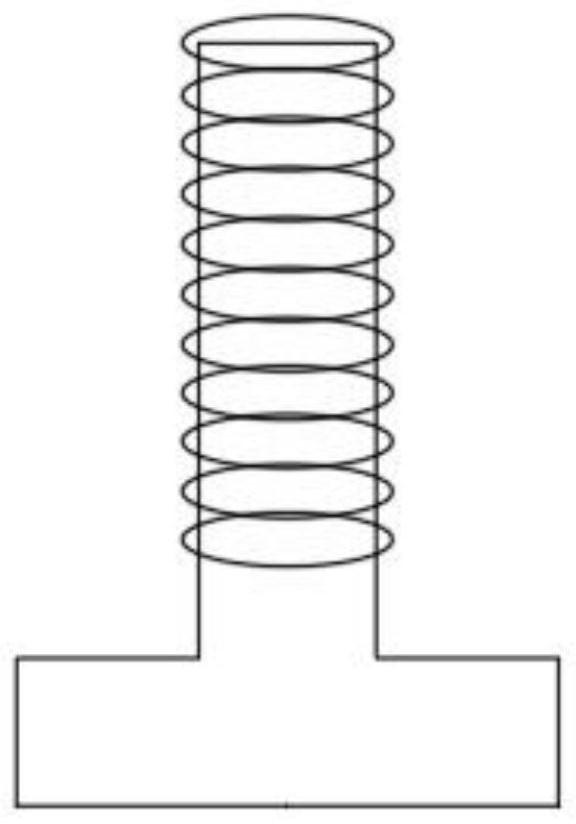

[0033] Such as figure 1 , shown in 2 and 4, the reinforcing device of the present invention includes two identical upper arc-shaped plates 2 and lower arc-shaped plates 3, and the material of the two arc-shaped plates is the same as that of the antibacterial water pipe 1, both of which are PE materials. After the contact part of the follow-up curved plate and the antibacterial water pipe 1 is melted, it can be completely fused to enhance the firmness of the reinforcement. The two ends of the upper curved plate 2 and the lower curved plate 3 are integrally connected with a fastening plate 7, which is also fastened The plate 7 is also made of PE material. Fasteners can be set on the fastening plate 7 to lock the two arc-shaped plates, or the fastening plate 7 can be manually held so that the two arc-shaped plates are spliced at the junction of the antibacterial water pipe 1 It will not fall down when the time is up, and the matching silicone heating sheet 4 is attached and fix...

Embodiment 2

[0035] Such as figure 1 As shown, on the basis of the above-mentioned embodiment, all the exposed external ends of the threaded rods 5 are tapered, so that the threaded rods 5 are not easy to slide on the wall of the antibacterial water pipe 1, and it is also easier to embed the threaded rods 5 after heating. Inside the wall of the antibacterial water pipe 1, the threaded rod 5 and the nut 6 are made of copper, which has a higher thermal conductivity and speeds up the installation efficiency of the reinforcing device.

Embodiment 3

[0037] On the basis of the above-mentioned embodiments, the upper curved plate 2 and the lower curved plate 3 are spliced and directly sleeved on the joint of the antibacterial water pipe 1, and the width position of the middle part of the silicone heating sheet 4 on the two curved plates is 5-10 mm. Just align the junction of the antibacterial water pipe 1, and a gap of one-third of the wall thickness of the antibacterial water pipe 1 is formed between the ends of the two arc-shaped plates. The two arc-shaped plates and the fastening plate 7 will not contact in advance, and the height of the gap is the same as the leakage length of the threaded rod 5, so that it can be judged in time whether the threaded rod 5 is completely embedded in the antibacterial water pipe 1, that is, between the ends of the upper and lower arc-shaped plates. When there is no gap between them, the threaded rod 5 has all entered the antibacterial water pipe 1 inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com