Collapsible loess compaction pile construction device and method capable of reducing thickness of falling soil

A technology of collapsible loess and construction device, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of large thickness of falling soil, unsatisfactory compactness, affecting the construction quality of foundation treatment, etc. The effect of blocking and expanding the grouting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

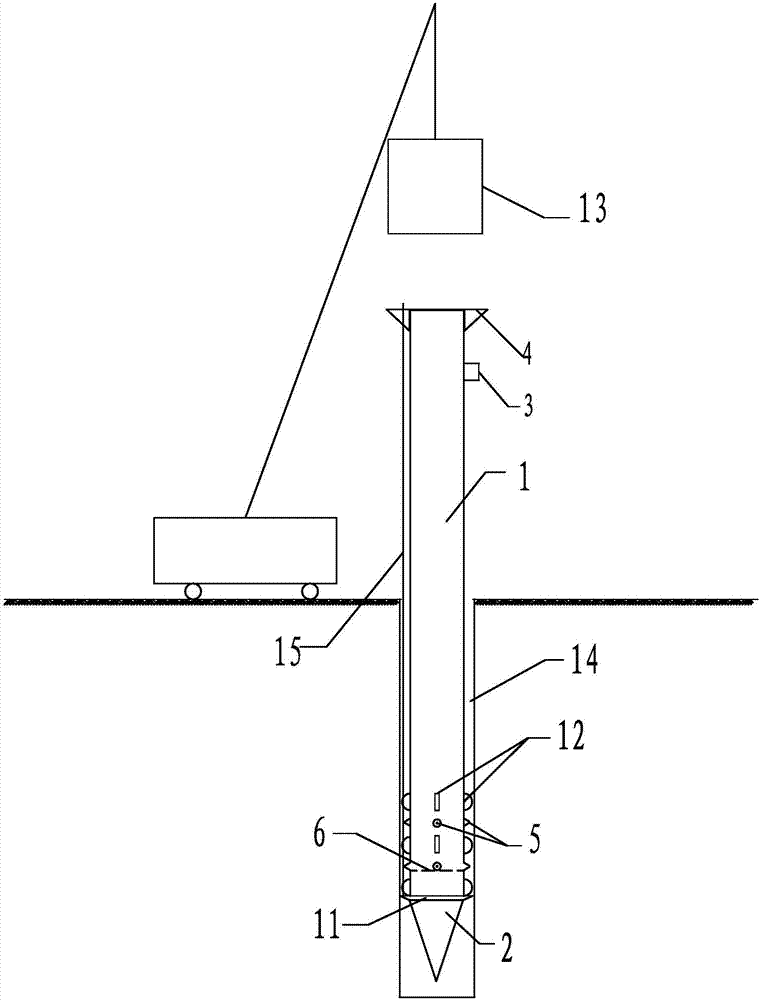

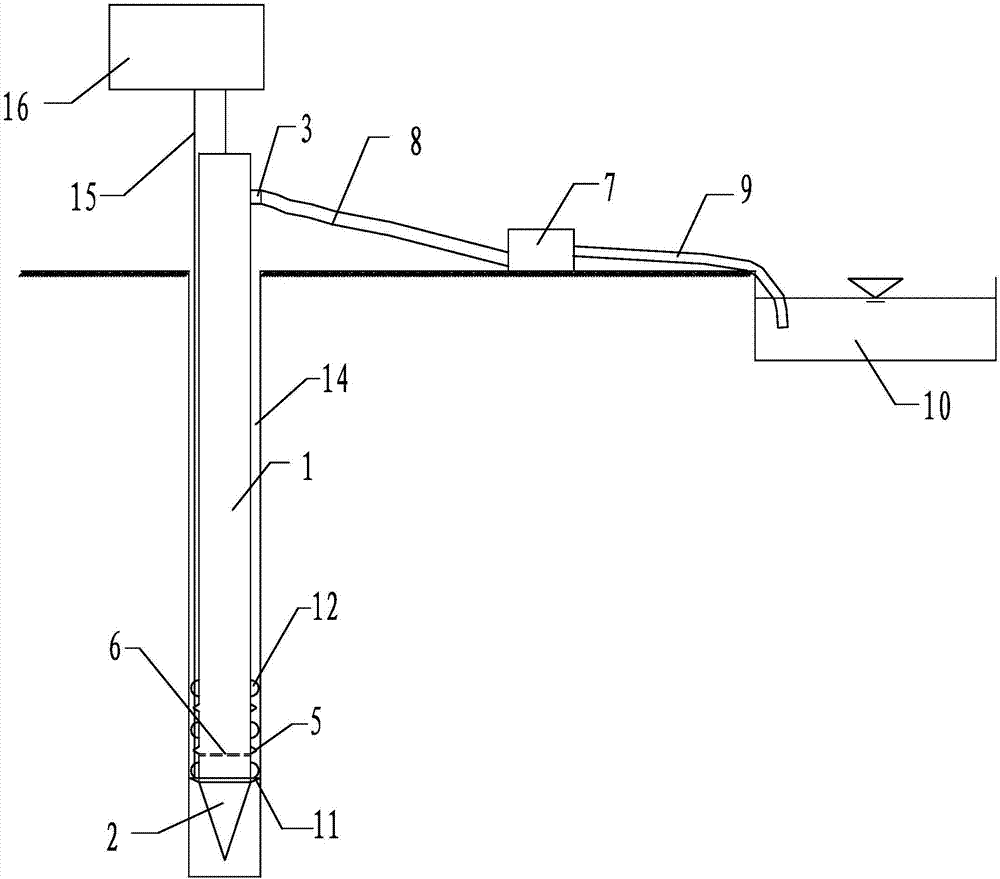

[0041] Example: Take the treatment of a self-weight collapsible loess foundation in Lanzhou New District as an example. According to geological survey and design requirements, it is determined that the area can be treated with lime-soil compaction piles. The pile length is 8m, the pile diameter is 0.5m, and the pile spacing is 1m. The specific implementation process is as follows:

[0042] (1) Leveling the site to be treated during construction, locating the points where compaction piles are to be drilled, making marks, and selecting the location for storing grout;

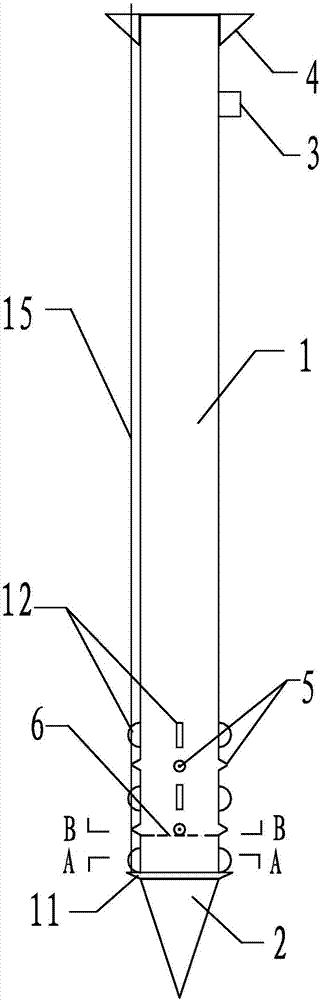

[0043] (2) A protective sleeve 4 is installed on the top of the hole-forming pile pipe 1. The protective sleeve can be directly placed on the top of the hole-forming pile pipe 1, or can be welded on its top to ensure that the protection sleeve 4 is protected during the hammering process. It will not fall off, and will not affect the construction of hammering the hole. Set the expansion ring 11 at the pile tip, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com