Tailing pond overflow culvert anti-seepage method

An overflow culvert and anti-seepage technology, applied in the field of tailings pond flood discharge system governance, can solve problems such as easy deformation and cracking at the culvert wall or culvert pipe interface, and achieve the effect of improving bearing performance, improving effect and reducing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

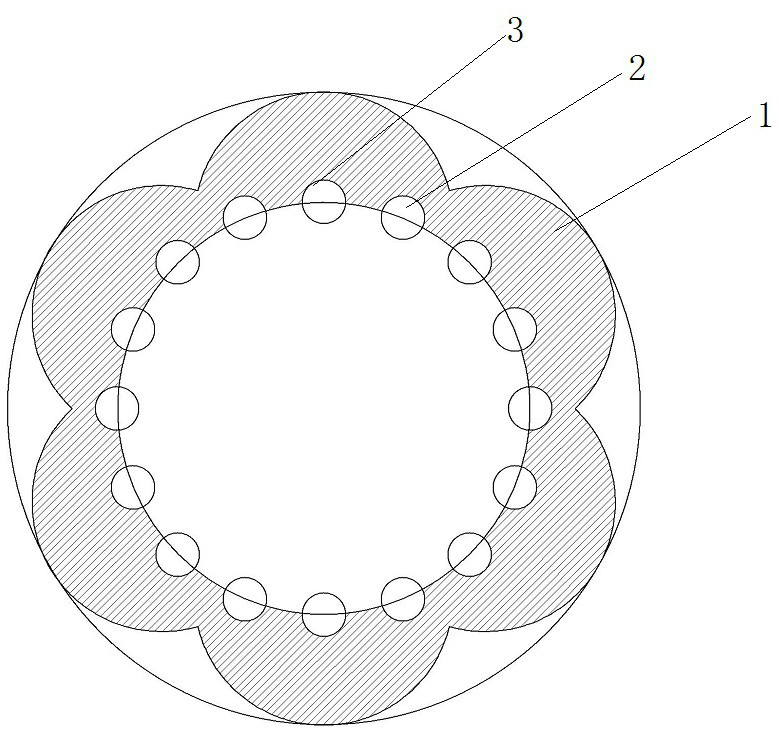

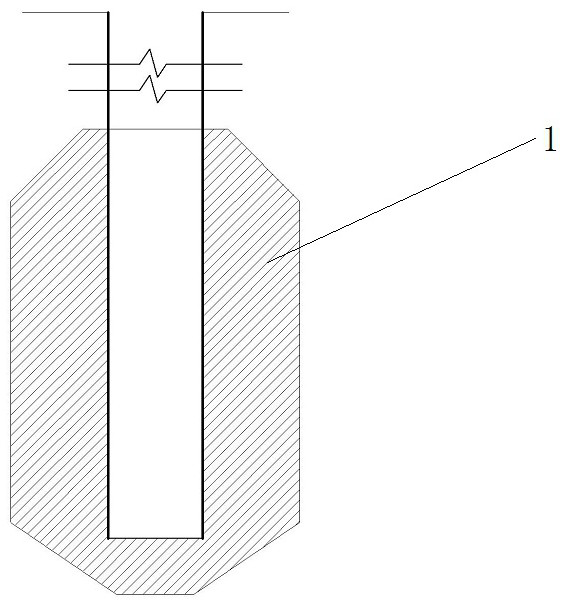

[0029] like figure 1 and figure 2 As shown, two rows of grouting holes are drilled in the vicinity of the leakage or injection point of the concrete pouring joints on the culvert wall, and each row includes 8 grouting holes, that is, 8 deep holes are drilled, and shallow holes 3 are also drilled. There are 8. The hole depth of deep hole 2 is 1.5m, the hole depth of shallow hole 3 is 0.5m, and the hole depth is reduced according to the actual situation in the lower part of the culvert.

[0030] The axis of the deep hole 2 is 75° to the culvert wall 1, the axis of the shallow hole 3 is 65° to the culvert wall 1, and the effective diffusion radius of each deep hole intersects with the effective radius of each shallow hole.

[0031] In a specific embodiment, deep holes are drilled first, and then shallow holes are drilled. Before drilling the shallow holes, it is necessary to ensure that grouting has been completed in each deep hole. In addition, before drilling the weak area ...

Embodiment 2

[0036] The difference between this embodiment 2 and the above-mentioned embodiment 1 is only:

[0037] The hole depth of the deep hole 2 is 2.5m, and the hole depth of the shallow hole 3 is 1.5m. The axis of the deep hole 2 is 70° to the culvert wall 1, and the axis of the shallow hole 3 is 70° to the culvert wall 1. The effective diffusion radius of each deep hole and the effective radius of each shallow hole still intersect.

[0038] The grouting pressure is controlled at 1.25MPa, and in the cement-water glass double-liquid slurry for deep hole injection, the water glass adopts an alkaline water glass with a modulus of 3.2 and a Baume degree of 45. In cement slurry, the water-cement ratio is in the range of 1:1. In the chemical slurry, the ratio of liquid A to liquid B is 10:5.

Embodiment 3

[0040] The difference between this embodiment 3 and the above-mentioned embodiment 1 is only:

[0041] The deep hole 2 has a hole depth of 1.5 m, and the shallow hole 3 has a hole depth of 1 m. The axis of the deep hole 2 is 65° to the culvert wall 1, and the axis of the shallow hole 3 is 75° to the culvert wall 1. The effective diffusion radius of each deep hole and the effective radius of each shallow hole still intersect.

[0042] The grouting pressure is controlled at 1.1MPa, and in the cement-water glass double-liquid slurry for deep hole injection, the water glass adopts an alkaline water glass with a modulus of 2.8 and a Baume degree of 40. In cement slurry, the water-cement ratio is in the range of 0.9:1. In the chemical slurry, the ratio of liquid A to liquid B is 10:3.

[0043] Of course, the anti-seepage method for the overflow culvert of the tailings pond of the present invention is not limited to the above three embodiments. For shallow holes, when grouting, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com