Cooling, moisturizing and grouting integrated device and method for mass concrete

A large-volume concrete and concrete technology, applied in construction, infrastructure engineering, etc., can solve the problems of no good solution for concrete cracks, unavoidable internal cracks, and impossibility of concrete moisturizing and maintenance, so as to avoid temperature rise cracks and low cost , to achieve the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

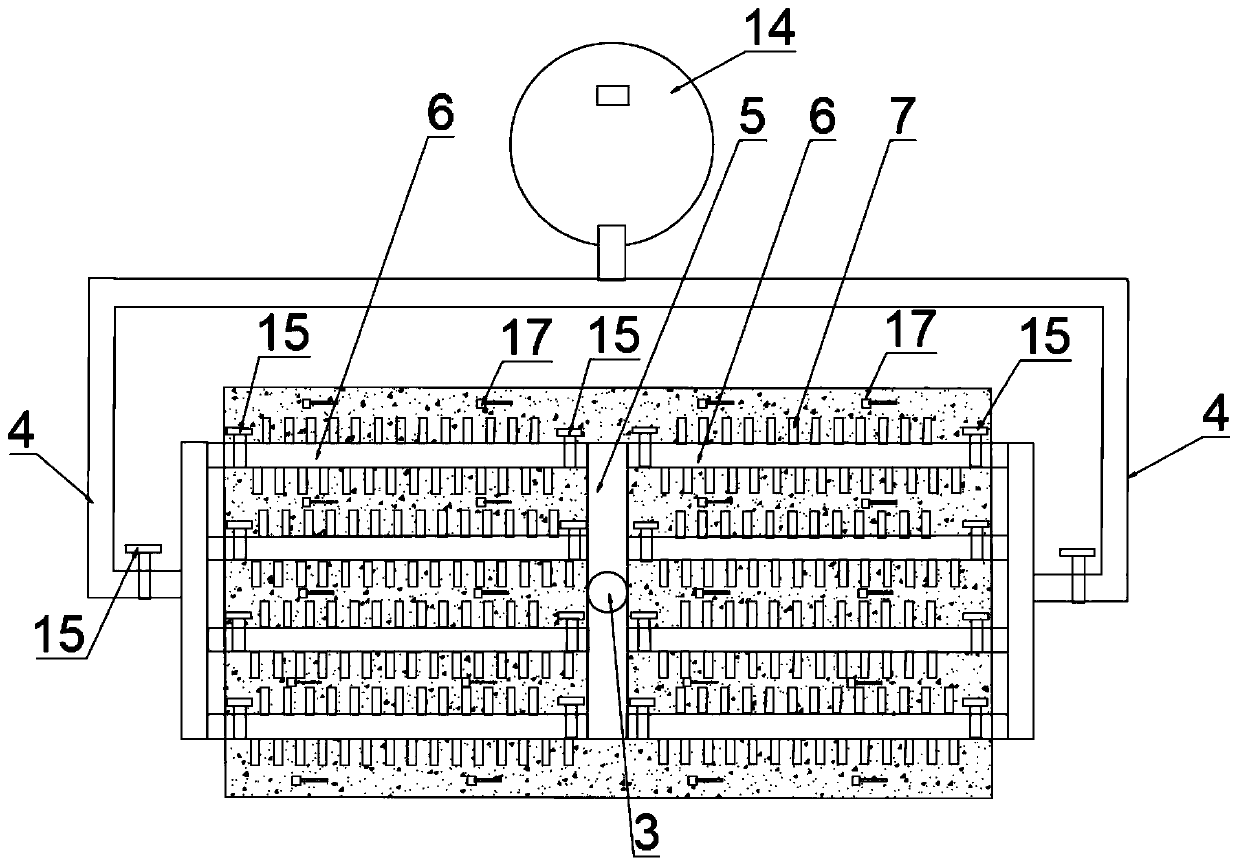

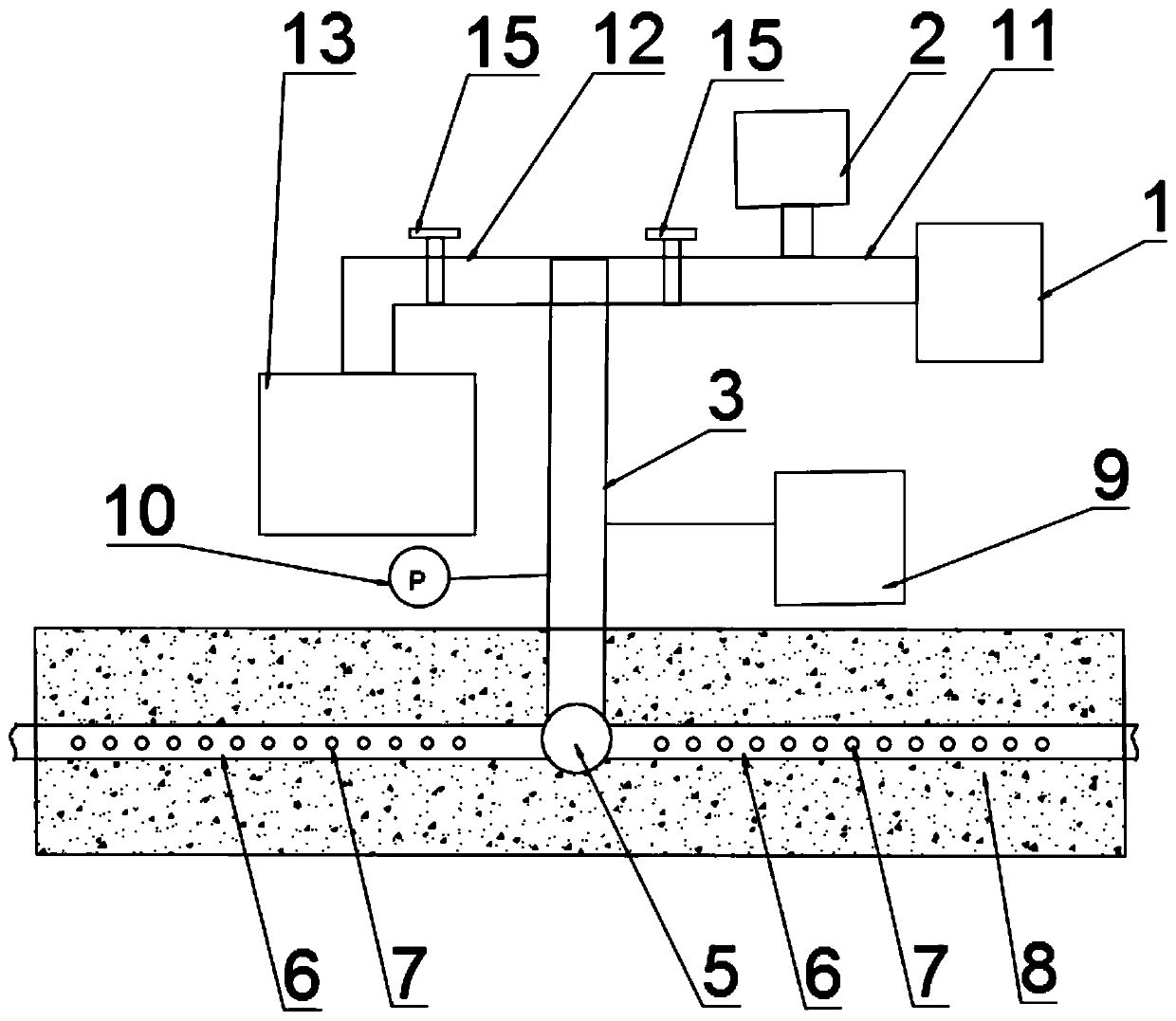

[0044] Such as Figure 1-3 As shown, the integrated device for cooling, moisturizing and grouting of large-volume concrete of this embodiment includes an air refrigerator 1, an atomizer 2 and an air-conditioning pipe; the air-conditioning pipe includes an air inlet pipe 3, an air outlet pipe 4, and a pre-buried concrete The air-conditioning buried pipe includes the air-conditioning main pipe 5, the air-conditioning branch pipe 6, and the air-conditioning branch pipe 7. The air-conditioning main pipe 5 is arranged horizontally in the middle of the concrete 8 and the middle of the air-conditioning main pipe 5 is connected with one end of the air intake pipe 3 on the surface of the vertical concrete 8; The air pipe 3 is provided with a pressurizing pump 9 and a pressure gauge 10, and the other end of the air inlet pipe 3 is connected to the low-temperature atomization channel 11 and the ultra-fine cement slurry grouting channel 12 respectively through a three-way pipe. The low-tempe...

Embodiment 2

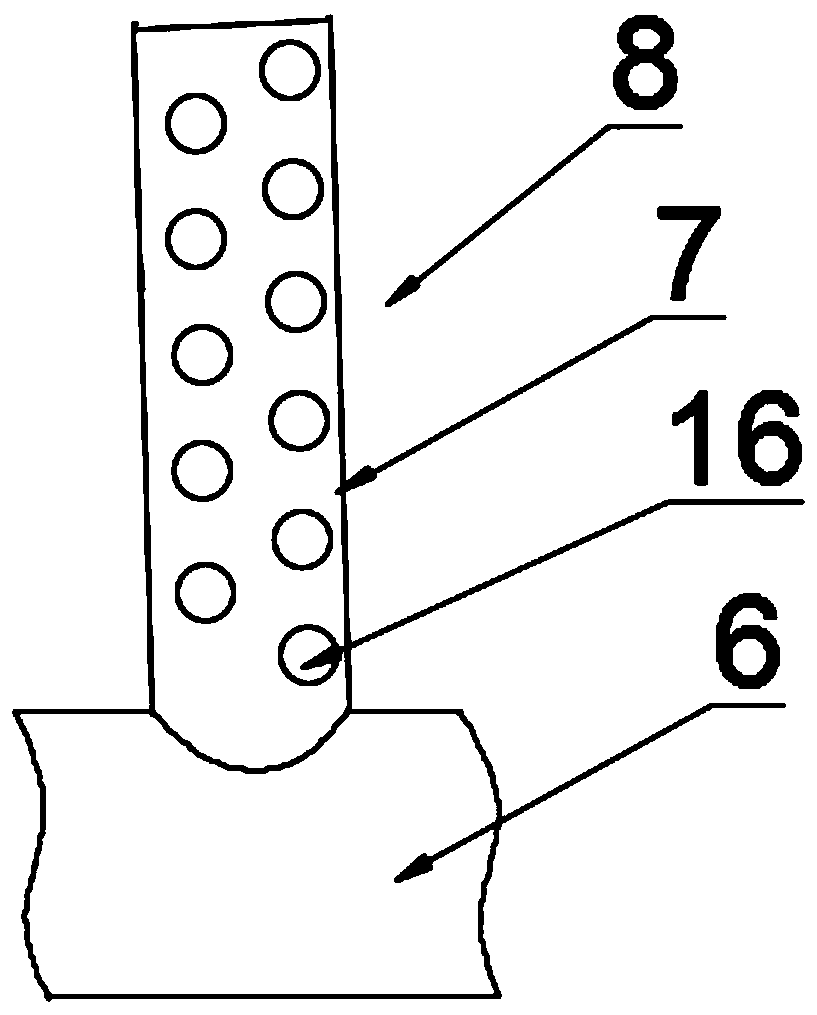

[0049] Such as Figure 4-7 As shown, compared to Embodiment 1, the cold air branch pipe 7 of this embodiment is provided with a one-way valve 18 for controlling the atomized water droplets or ultrafine cement slurry in the cold air branch pipe to flow into the concrete 8 unidirectionally from the air vent 16. The one-way valve includes a vent 1801, an elastic baffle 1802 and a stop 1803. The elastic baffle 1802 is arranged behind the vent 1801, and the stop 1803 is located on the side behind the elastic baffle 1802. The elastic baffle can be made of an elastic rubber sheet, more preferably an elastic material that is breathable and impermeable. When the pressure pump is working, the pressure of the cold air branch pipe is greater than the air pressure in the pores, and the elastic baffle is deformed and bent to the side and back, so that the air vent opens, and atomized water droplets or ultra-fine cement slurry enter the concrete from the cold air branch pipe. When vacuuming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com