Al-Zn-Mg-Cu alloy wire and arc additive manufacturing method

A technology of additive manufacturing and electric arc, which is applied in the field of wire arc additive manufacturing of Al-Zn-Mg-Cu alloy, can solve the problems of performance degradation of additive body, coarsening of microstructure, limited action area of stirring needle, etc. , to prevent overheating, improve mechanical properties, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

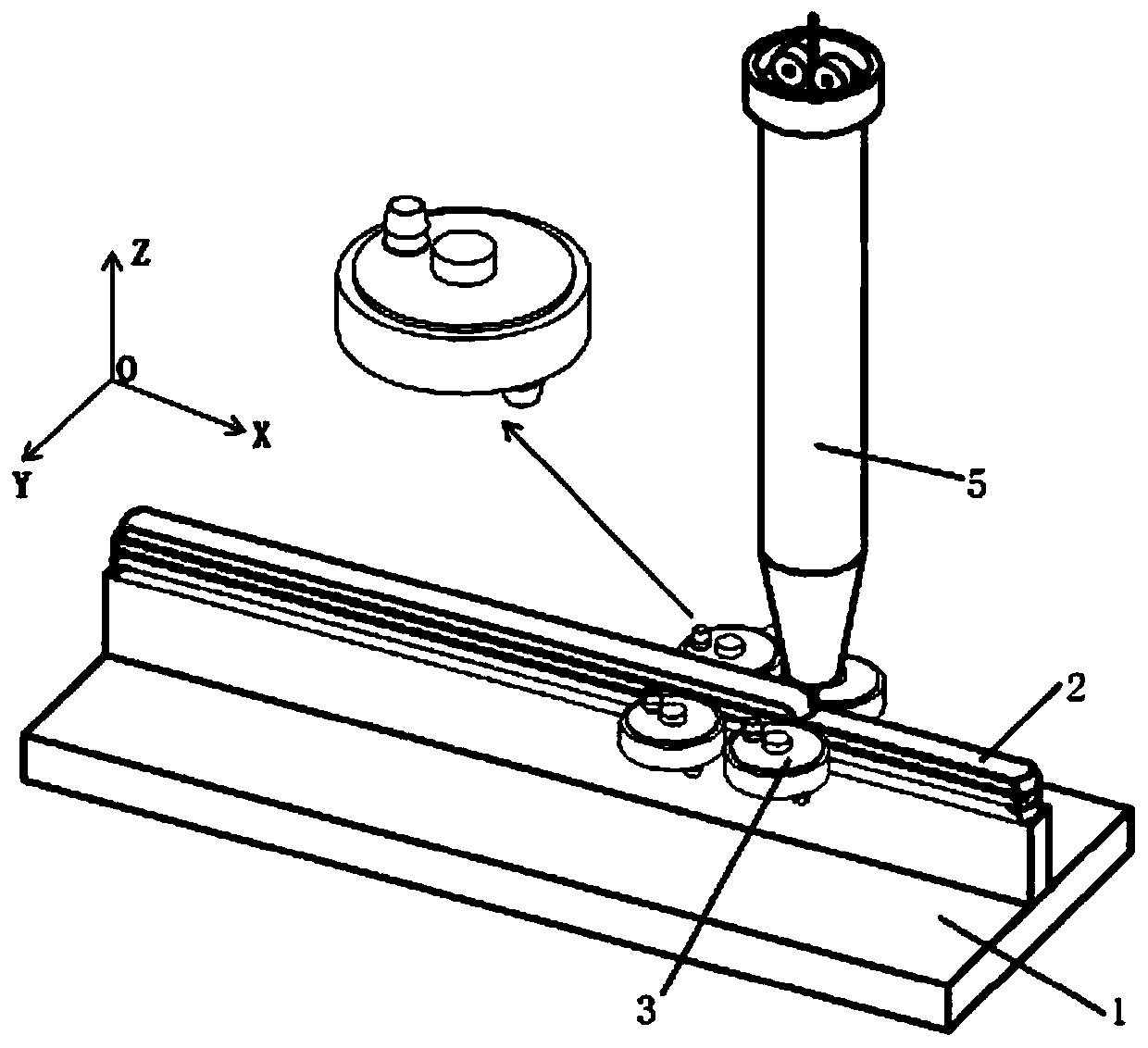

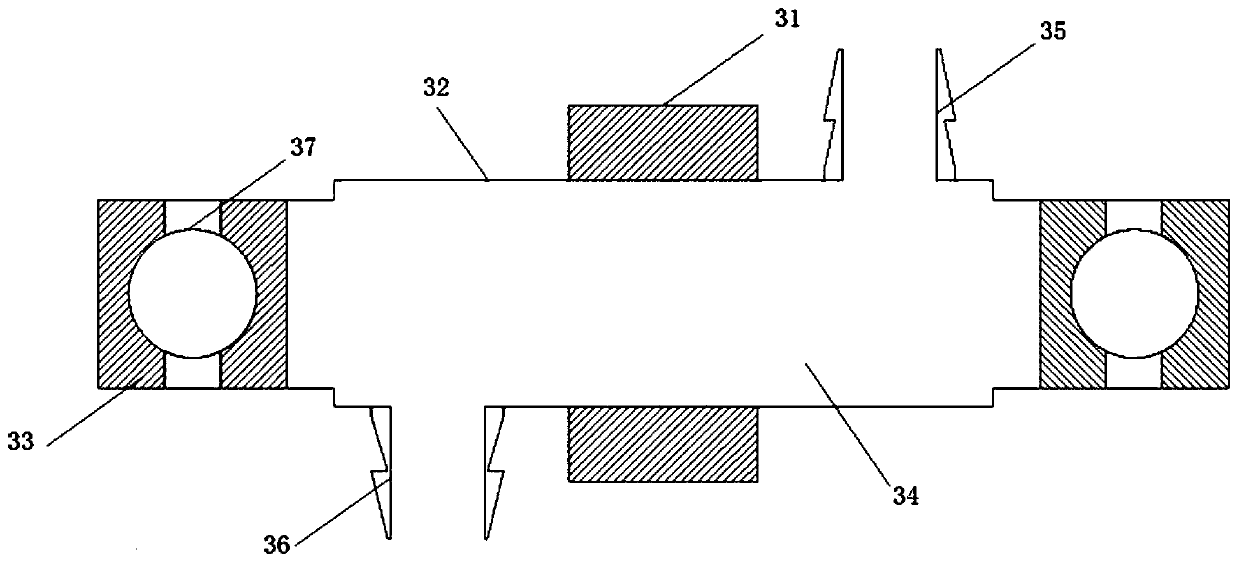

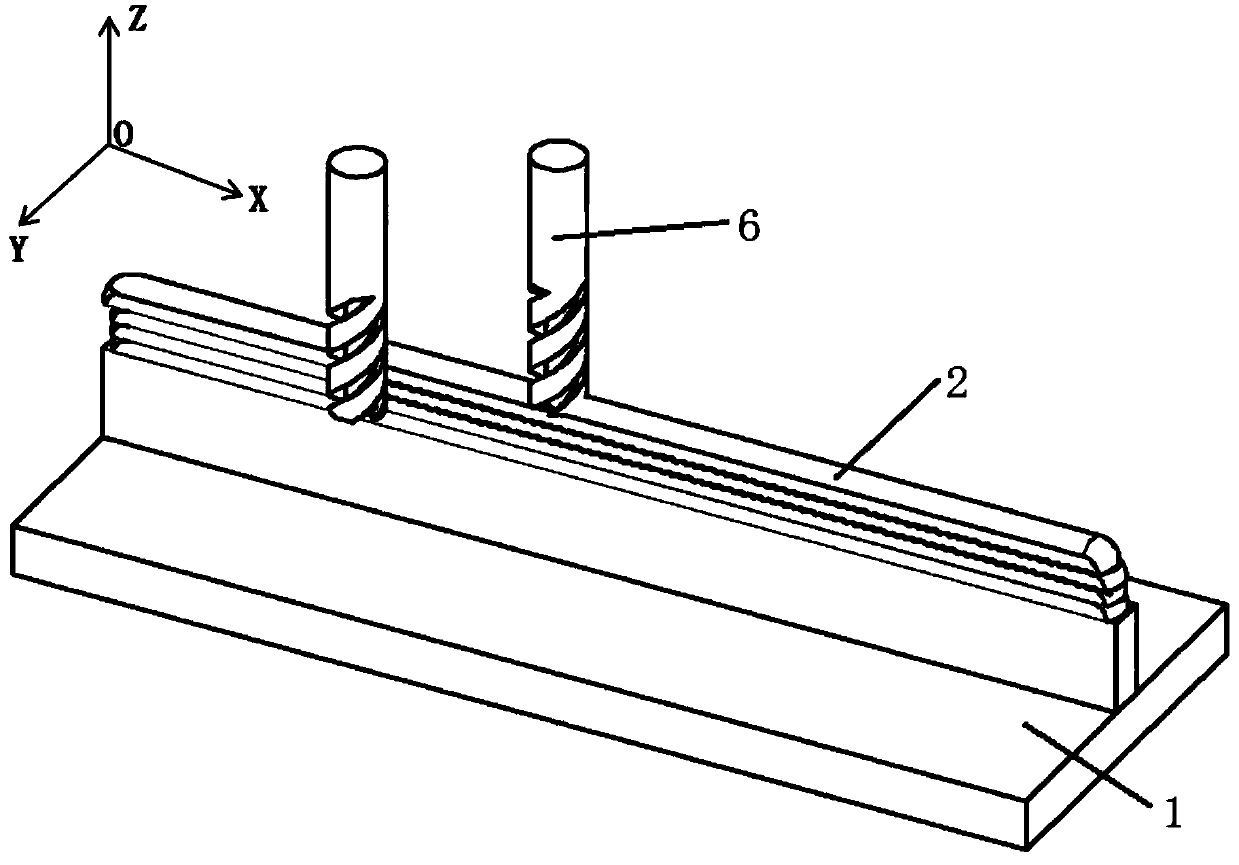

[0030] Such as Figure 1 to Figure 4 As shown, this example provides 7075 (Al-4.5Zn-1.1Mg) aluminum alloy wire arc additive manufacturing method for straight wall, comprising the following steps:

[0031] Step 1. Use cooling roller to assist arc additive forming: Use 3D drawing software to draw a straight wall model with a size of 200mm (length) × 40mm (height) × 12mm (width), and use slicing software to layer the part model Slice processing, obtain layered slice data, use simulation software to simulate layered slice data and optimize the forming path, generate robot control code (or NC code), import robot control code into welding robot, use welding robot, adopt The arc generated by the MIG welding machine is the heat source, and the 7075 aluminum alloy wire arc additive forming is performed on the T-shaped substrate 1 prepared in advance, and a total of 2 to 4 layers are deposited to form a multi-layer deposited metal 2, and the formed multi-layer deposited metal The wid...

Embodiment 2

[0044] This example provides The 7075 (Al-5.2Zn-2.2Mg-1.4Cu) aluminum alloy wire arc additive method for manufacturing straight wall, comprising the following steps:

[0045] Step 1. Use cooling roller to assist arc additive forming: Use 3D drawing software to draw a straight wall model with a size of 200mm (length) × 40mm (height) × 42mm (width), and use slicing software to layer the part model Slice processing, obtain layered slice data, use simulation software to simulate layered slice data and optimize the forming path, generate robot control code (or NC code), import robot control code into welding robot, use welding robot, adopt The arc generated by the TIG welding machine is the heat source, and the 7075 aluminum alloy wire arc additive forming is performed on the T-shaped substrate 1 prepared in advance, and a total of 2 to 4 layers are deposited to form a multi-layer deposited metal 2, and the formed multi-layer deposited metal The width of 2 is 42mm, and the multi-...

Embodiment 3

[0058] Such as Figure 1 to Figure 4 As shown, this example provides 7075 (Al-4.5Zn-1.1Mg) aluminum alloy wire arc additive manufacturing method for straight wall, comprising the following steps:

[0059] Step 1. Use cooling roller to assist arc additive forming: Use 3D drawing software to draw a straight wall model with a size of 200mm (length) × 40mm (height) × 12mm (width), and use slicing software to layer the part model Slice processing, obtain layered slice data, use simulation software to simulate layered slice data and optimize the forming path, generate robot control code (or NC code), import robot control code into welding robot, use welding robot, adopt The arc generated by the MIG welding machine is the heat source, and the 7075 aluminum alloy wire arc additive forming is performed on the T-shaped substrate 1 prepared in advance, and a total of 2 to 4 layers are deposited to form a multi-layer deposited metal 2, and the formed multi-layer deposited metal The wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com