Double-microcapsule-component conductive adhesive

A technology of microcapsules and conductive adhesives, applied in the field of conductive adhesives, can solve the problems of limited storage life, high requirements for substrates, and low efficiency, and achieve the effect of easy control of parameters and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

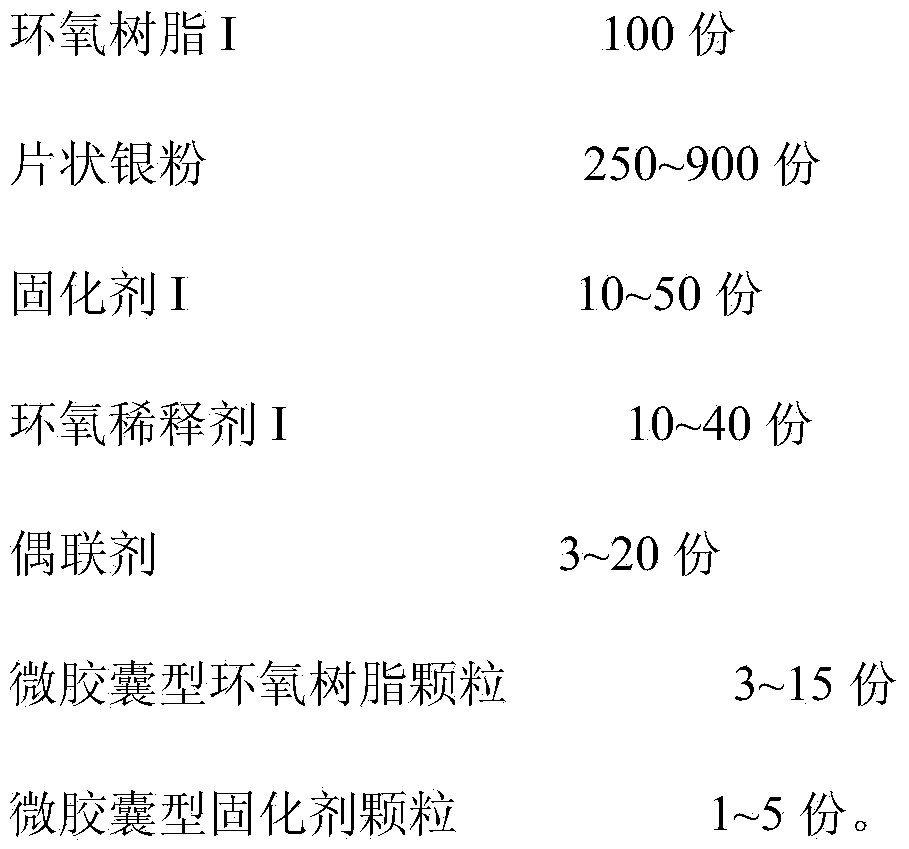

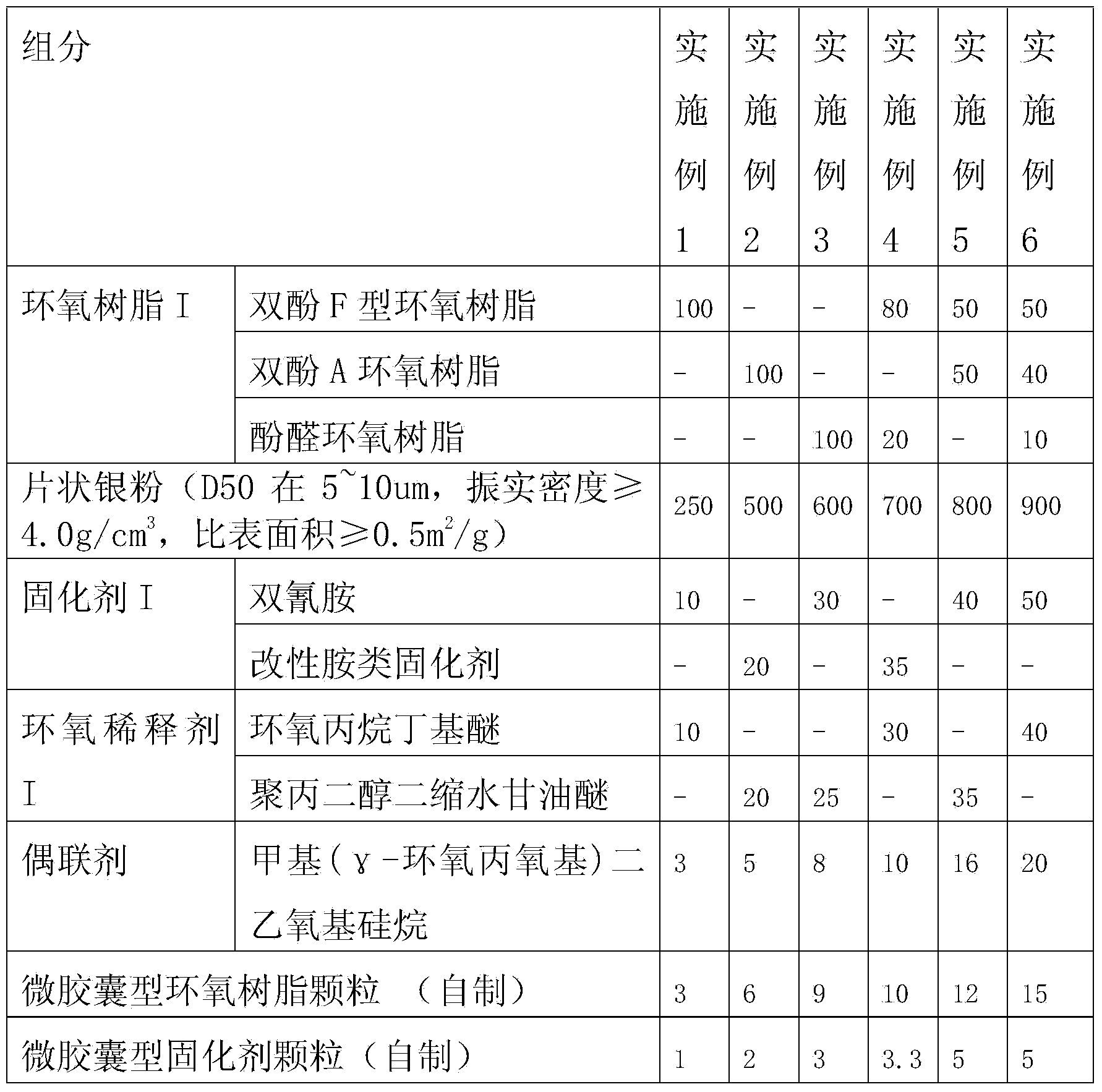

[0032] The present invention is a double microcapsule component conductive adhesive, which consists of epoxy resin I, flake silver powder, curing agent I, epoxy diluent I, coupling agent, microcapsule type epoxy resin particles and microcapsule type The curing agent particles, the parts by weight of each component are shown in Table 1. There are many options for epoxy resin I, curing agent I, and epoxy diluent I, which can meet the curing requirements of conductive adhesives in the temperature range of 60-80°C. Replace the corresponding products in Table 1. Weigh each component according to Table 1, and mix each component uniformly at room temperature to obtain a conductive adhesive.

[0033] Table 1: Content table of each raw material component of conductive adhesive

[0034]

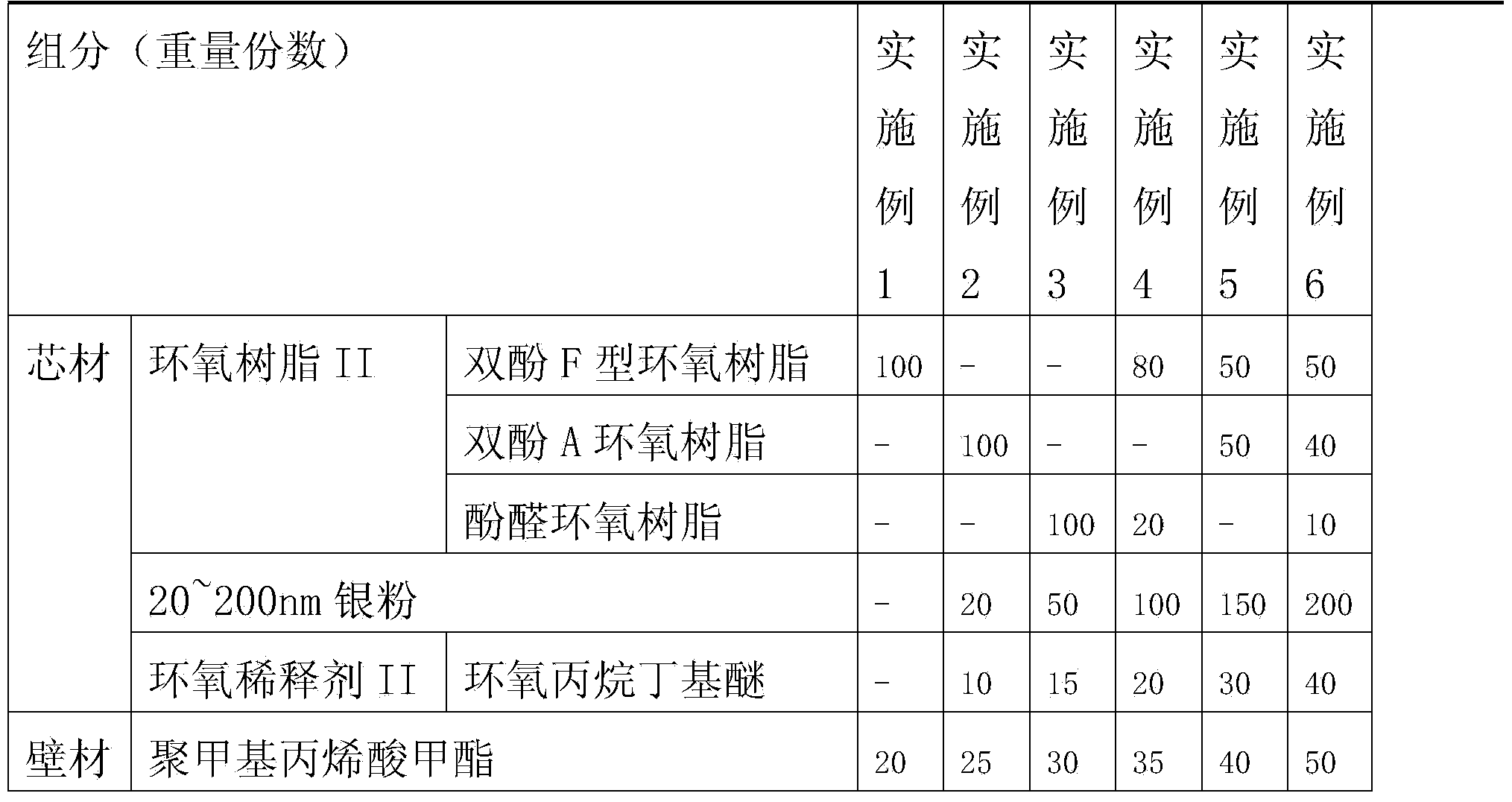

[0035] The wall material of above-mentioned microcapsule type epoxy resin particle is polymethyl methacrylate; Core material comprises epoxy resin II, 20~200nm silver powder, epoxy diluent II acco...

Embodiment 1

[0038] In Example 1, the above-mentioned microcapsule-type epoxy resin particles are prepared by the following steps: Weigh 120g of deionized water, add 1.6g of emulsifier, 0.1g of dispersant, 100g of core material, and 20g of methyl methacrylate monomer to disperse Evenly, heat and stir in a water bath at 50°C to form an O / W emulsion, then add 0.02g initiator dropwise, react for 1h, then stir and cool to room temperature, centrifuge, wash with deionized water, and then vacuum dry at 50°C for 12h, Obtain microcapsule type epoxy resin particle; Wherein, described emulsifier is the mixture of OP-10 and sodium dodecylbenzene sulfonate by weight ratio 3: 1, and described dispersant is polyvinyl alcohol, and described initiator For benzoyl peroxide.

Embodiment 2

[0039]In Example 2, the above-mentioned microcapsule-type epoxy resin particles were prepared by the following steps: Weigh 200g deionized water, add 2.25g emulsifier, 0.15g dispersant, 130g core material, 25g methyl methacrylate monomer dispersion Uniform, heated and stirred in a 65°C water bath to form an O / W emulsion, then added dropwise 0.025g initiator, reacted for 2h, then stirred and cooled to room temperature, centrifuged, washed with deionized water, and then vacuum-dried at 50°C for 24h, Obtain microcapsule type epoxy resin particle; Wherein, described emulsifying agent is the mixture of OP-10 and sodium dodecylbenzene sulfonate by weight ratio 2: 1, and described dispersant is polyvinyl alcohol, and described initiator for ammonium persulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com