Grouting connecting structure of prefabricated part and construction method thereof

A technology of prefabricated components and grouting connections, which is applied to the processing of building components, building structures, and building materials. It can solve problems such as failure to detect in time, evaporation and loss of grouting material moisture, and achieve the effect of convenient observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

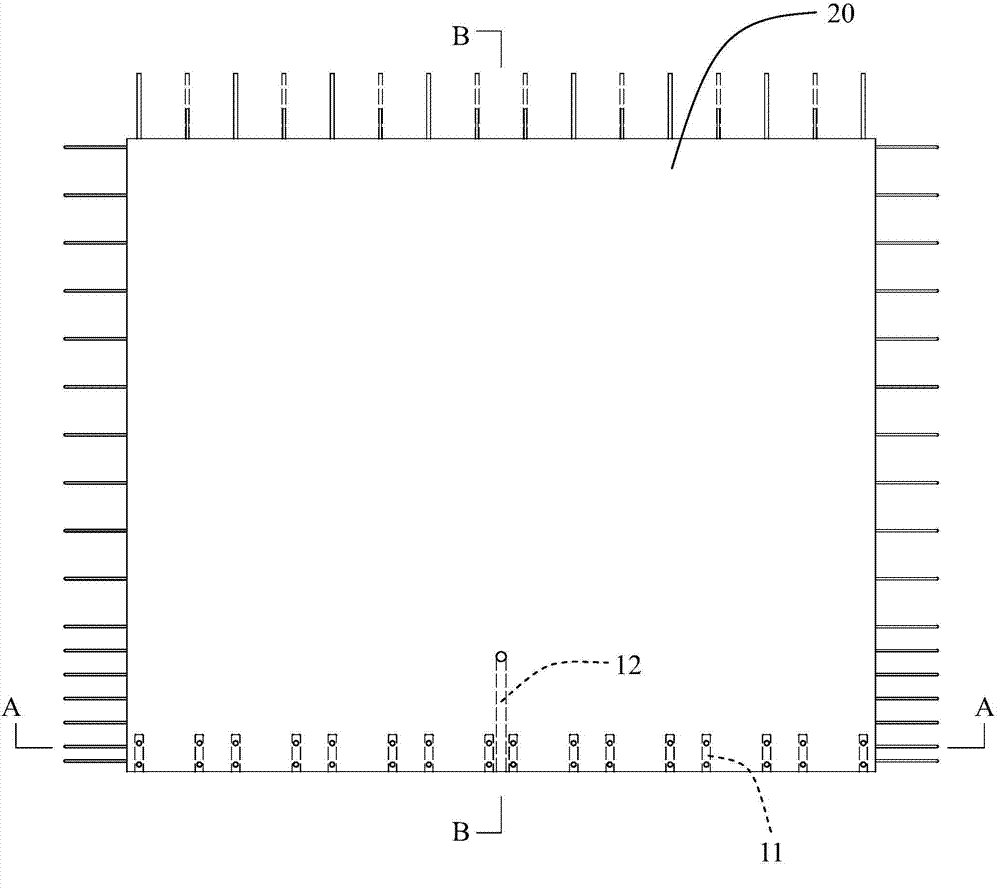

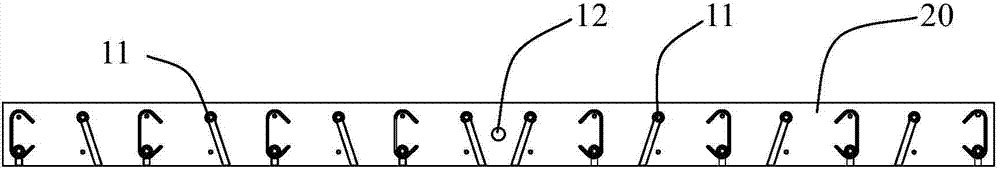

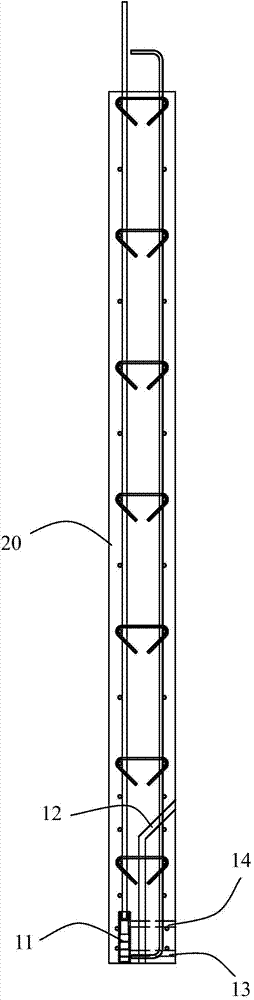

[0029] see first Figures 1 to 3 As shown, the grouting connection structure of the prefabricated component of the present invention is mainly composed of a grouting sleeve 11 embedded in the bottom of the prefabricated component 20 for inserting butt-jointed steel bars, and an observation tube 12 embedded in the bottom of the prefabricated component 20 .

[0030] Cooperate Figure 4 and Figure 5 As shown, the grouting sleeve 11 in this embodiment is a half grouting sleeve, and it is also applicable to other grouting sleeves such as full grouting sleeves. Insertion, the interior of the grouting sleeve 11 forms a grouting space, the lower part of the grouting sleeve 11 is provided with a grouting port 111, the upper part of the grouting sleeve 11 is provided with a grouting port 112, and the grouting port 111 and the grouting port 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com