Prestressed prefabricated concrete shear wall system and construction method thereof

A concrete shear wall and construction method technology, applied in the direction of wall, building material processing, structural elements, etc., can solve the problems of high precision requirements, long construction period, and many wet operations on site, so as to achieve clear force and reliable connection , the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

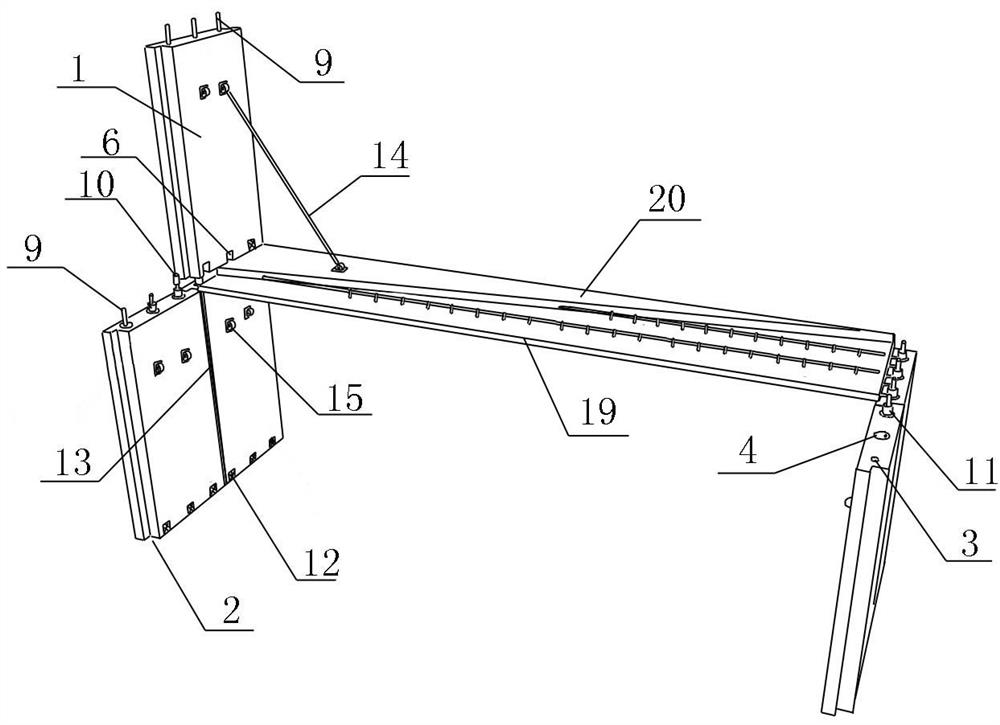

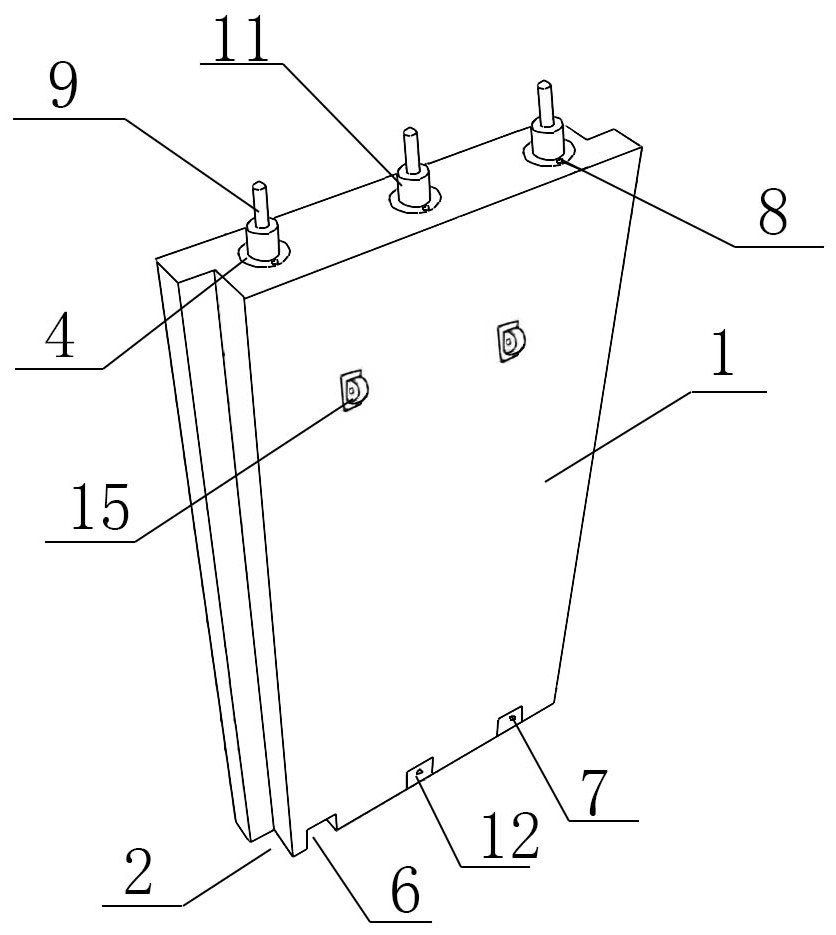

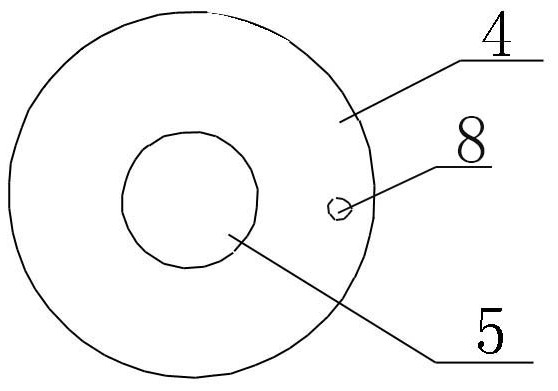

[0044] like Figure 1-4 As shown, this prestressed prefabricated concrete shear wall system includes a group of prefabricated shear walls 1 and prestressed steel bars 9; the splicing connection between the prefabricated shear walls 1; The two sides are respectively provided with grooves 2, and the horizontally adjacent prefabricated shear walls 1 are connected by grooves 2; the inside of the prefabricated shear walls 1 is provided with vertical ribs at intervals along its long axis direction. Tunnel 3; the top of the prefabricated shear wall 1 is pre-embedded with an anchor pad 4 at the position corresponding to the reinforcement tunnel 3; the anchor pad 4 is provided with a perforation 5 and a grout hole 8;

[0045] A gap 6 is reserved at the bottom of the prefabricated shear wall 1, and the gap 6 communicates with the reinforcement channel 3;

[0046] The prestressed steel bar 9 is pierced in the reinforced tunnel 3, and the prestressed steel bar 9 is anchored by the anchor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com