Assembling type concrete column base node structure and construction method thereof

A technology of concrete columns and node structures, which is applied in the direction of building structure and construction, can solve the problems of column foot damage, deformation capacity and insufficient mechanical properties, reduce the degree of damage, ensure construction speed and quality, and improve energy consumption Effect of capacity and ductility levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

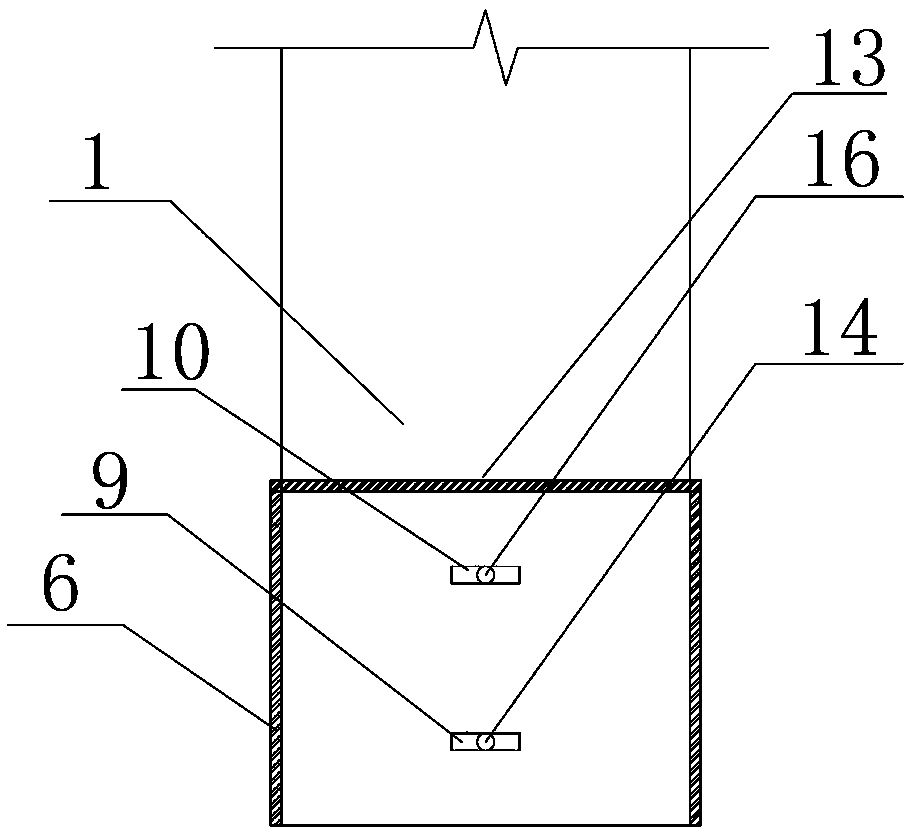

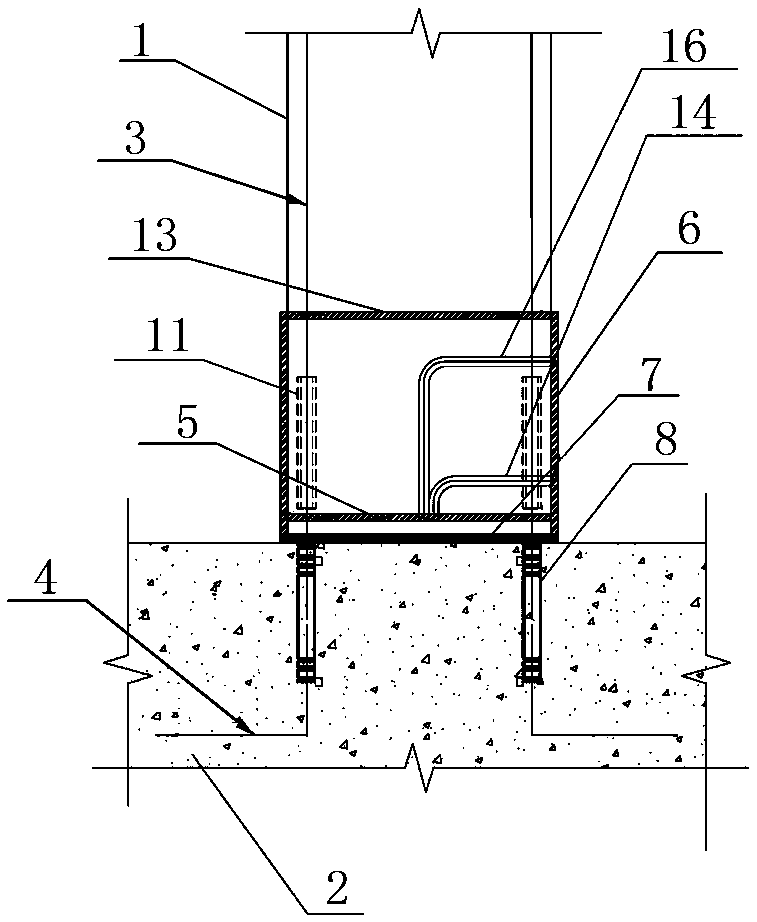

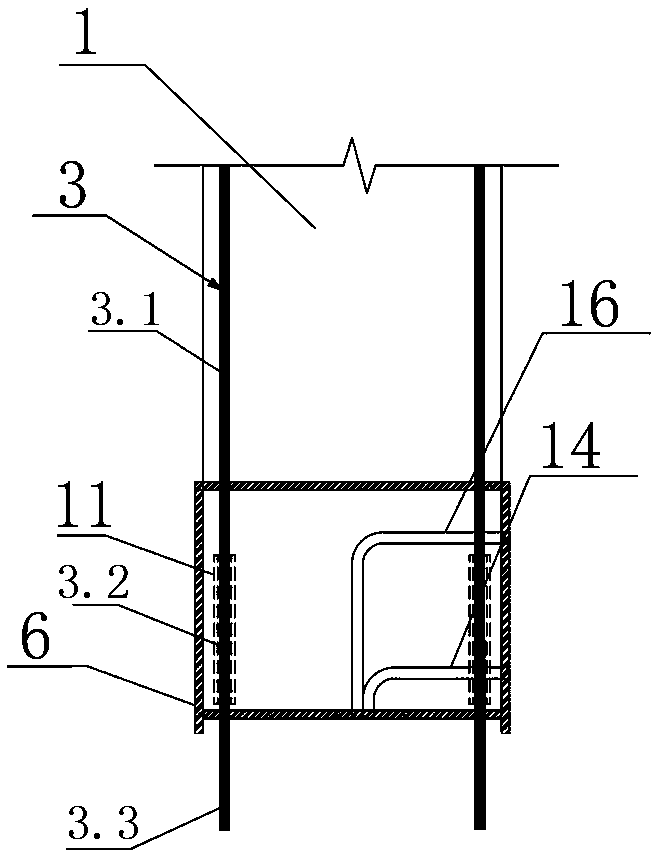

[0047] Such as Figure 1-8As shown, this prefabricated concrete column base node structure includes a reinforced concrete foundation 2 and a prefabricated reinforced concrete column 1 connected to the top of the reinforced concrete foundation 2; the top surface of the reinforced concrete foundation 2 corresponds to the prefabricated reinforced concrete column 1 The position of the connection is the rough surface 15; in the reinforced concrete foundation 2, a foundation anchoring reinforcement 4 is provided at the position corresponding to the vertical reinforcement 3 in the prefabricated reinforced concrete column 1, and a vertical anchoring reinforcement 4 is set on the upper part of the foundation anchoring reinforcement 4 Grouting sleeve 8; the top of the grouting sleeve 8 is flush with the top of the reinforced concrete foundation 2;

[0048] The lower part of the prefabricated reinforced concrete column 1 is provided with a circle of outsourcing steel plate 6 along the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com