Reinforced concrete two-ended anchor cable and construction method thereof

A reinforced concrete and anchor cable technology, which is used in earth-moving drilling, installation of anchor rods, mining equipment, etc., can solve the problems of unsatisfactory two-way reinforcement of bag swelling, achieve the effect of large horizontal force and improve the bearing capacity of coal pillars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

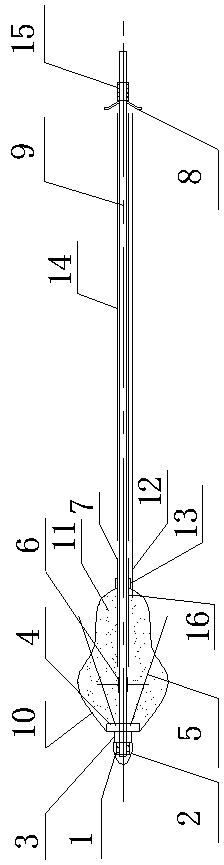

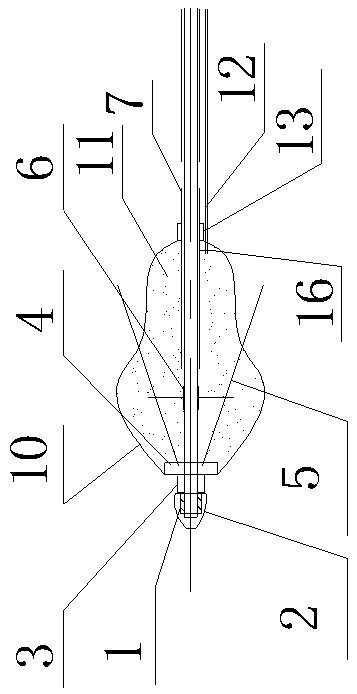

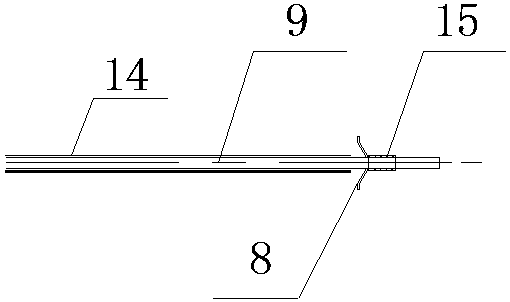

[0041] Specific implementation mode 1: This implementation mode provides a reinforced concrete cross-piercing anchor cable, such as figure 1 As shown, the penetrating anchor cable includes two parts: the front fixed end of the anchor cable and the main anchor cable, such as figure 2 As shown, the front fixed end of the anchor cable is composed of a front lock 1, a guide head 2, a front locking ring 3, a clasp 4, a short steel bar 5, a propeller 6, a short propulsion rod 7, a bladder 10, and a grouting pipe 12 , rear locking ring 13, grouting pipe holder 16, such as image 3 As shown, the anchor cable of the main body is composed of an anchor cable 9, a rear lock 15, a tray 8, and a long push rod 14, wherein:

[0042] The short push rod 7 and the long push rod 14 are sleeved on the outside of the anchor cable 9, and the short push rod 7 is located at the front of the anchor cable 9, and the long push rod 14 is located at the rear of the anchor cable 9;

[0043] The front end...

specific Embodiment approach 2

[0057] Embodiment 2: This embodiment is a further description of Embodiment 1.

[0058] Such as Figure 4 As shown, the snap ring 4 is a cylinder, and three holes with a diameter larger than the short steel bar 5 are drilled near the anchor cable 9, and the hole depth is 10mm, which is mainly used as the force transmission between the short steel bar 5 and the anchor cable 9. , and assist in fixing the position of the short steel bar 5 .

specific Embodiment approach 3

[0059] Embodiment 3: This embodiment is a further description of Embodiment 1.

[0060] The structure of the propeller can be selected according to the size of the borehole. For example, in order to meet the requirements of a small borehole, the propeller can be set as a split structure; if the borehole is large enough, the propeller can be simplified into a single Simple overall.

[0061] Such as Figure 5 As shown, the propeller is composed of three parts: the front seat, the rear seat and the card slot, wherein: the front seat is provided with a gap in the radial direction, the rear seat is provided with a reserved slot corresponding to the gap in the radial direction, and the upper part of the card slot There is an inner ring, and the side of the front seat close to the snap ring and the side of the rear seat close to the short push rod are reserved with a reserved tube with an inner diameter of 3~4cm slightly larger than the anchor cable. The reserved tube of the front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com