A Construction Method for Shallow Buried Tunnels in Loess Gullies

A technology for shallow buried tunnels and construction methods, which can be used in tunnels, earthwork drilling, tunnel lining, etc., and can solve problems such as high moisture content in soil, collapse of tunnel faces, and large deformation of support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

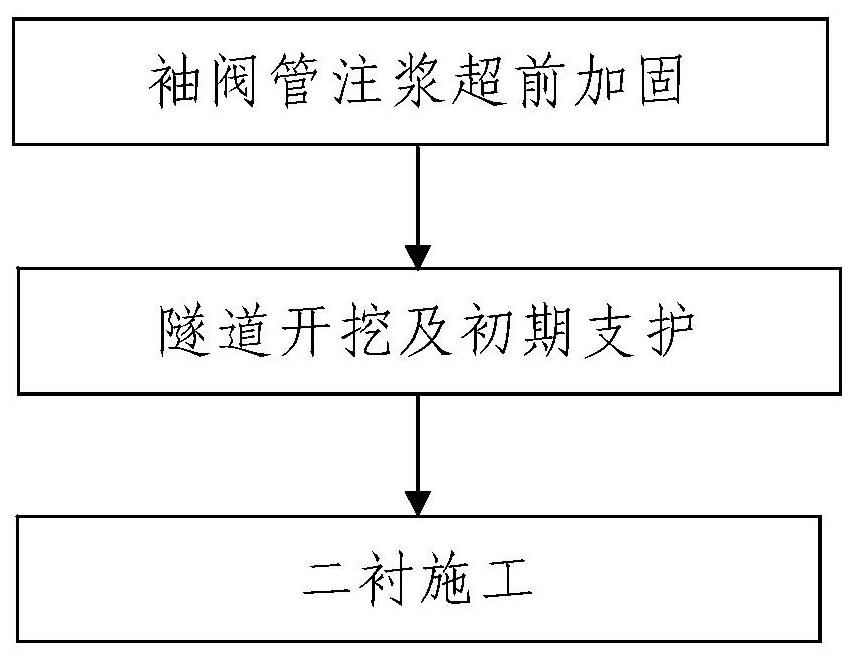

[0095] Such as figure 1 A construction method for a shallow buried tunnel in a loess gully shown, comprising the following steps:

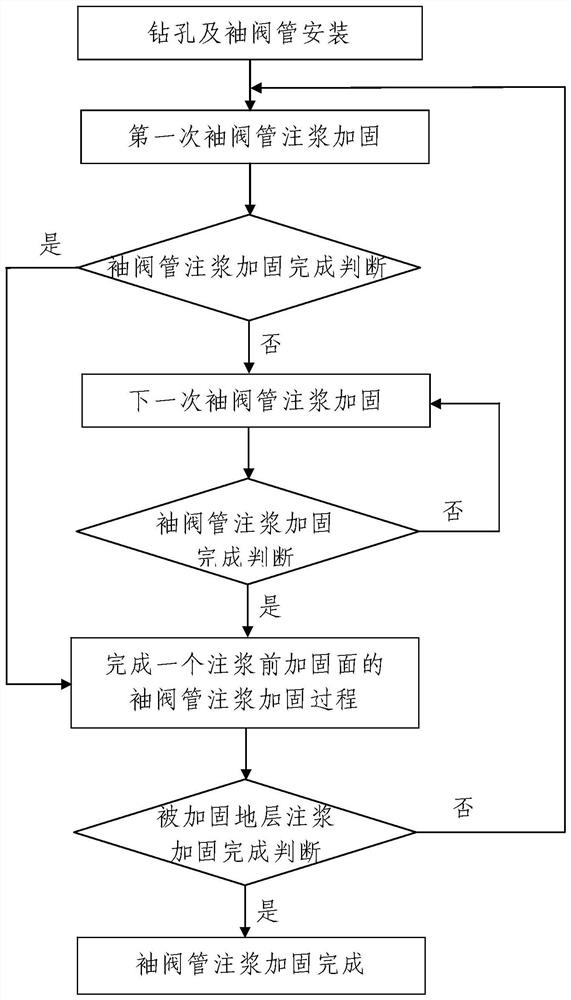

[0096] Step 1. Pre-strengthening sleeve valve pipe grouting: carry out sleeve valve pipe grouting reinforcement to the strata in the construction area where the shallow buried tunnel is constructed;

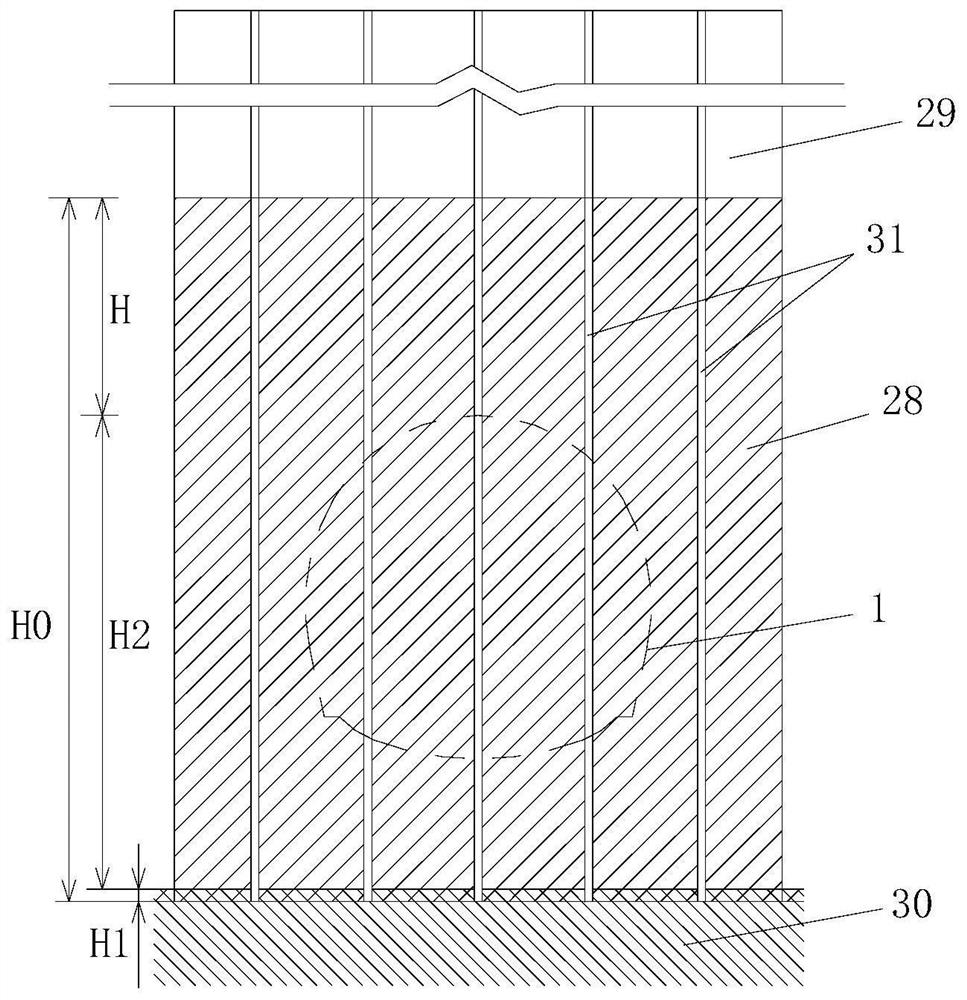

[0097] combine image 3 and Figure 4 , the constructed shallow-buried tunnel is located in the loess gully and passes through the loess stratum 29. The stratum in the construction area of the constructed shallow-buried tunnel is the reinforced stratum 28. It is arranged horizontally with the reinforced stratum 28; the loess stratum 29 is located above the rock stratum 30, and the interface between the loess stratum 29 and the rock stratum 30 is an earth-rock interface;

[0098] The reinforced stratum 28 is arranged along the tunnel longitudinal extension direction of the constructed shallow buried tunnel, and the longitudinal length of the rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com