Tunnel gushing body excavation method

A technology of inrush and tunnel, which is applied in the field of tunnel inrush excavation, can solve problems such as construction difficulties, poor slope stability, and poor integrity, and achieve the goals of improving construction progress and safety, low excavation cost, and fast construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

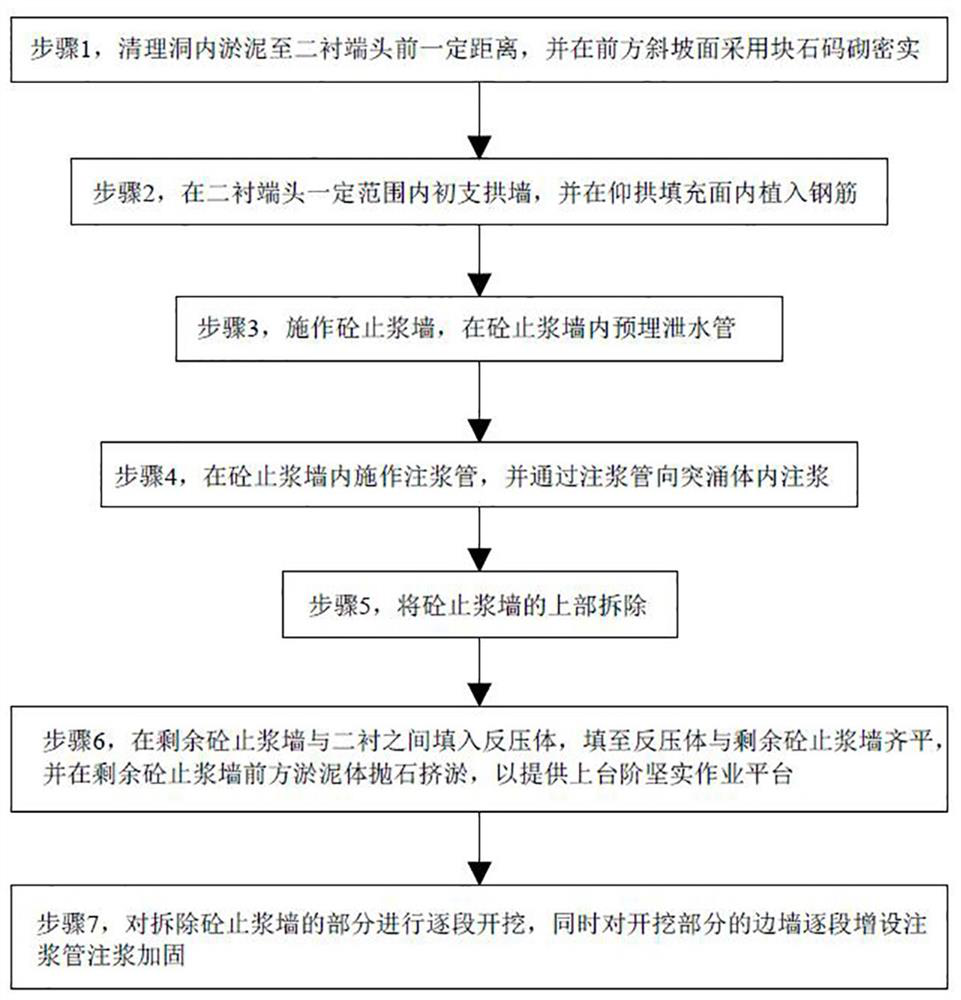

[0028] A method for excavating a tunnel inrush body includes three stages:

[0029] The first stage

[0030] Step 1. Clean up the silt in the cave to 2m before the end of the second lining (D1K78+904), and use block stones to build densely on the front slope;

[0031] Step 2. Plant C20 steel bars on the first support arch wall and invert arch filling surface within 2m of the end of the second lining. The length of the steel bars is 80cm (50cm implanted, 30cm exposed) and the spacing is arranged in a plum blossom shape of 30cm*30cm;

[0032] Step 3. Make a 2m thick C20 concrete grout stop wall, and pre-buy two rows (no less than 8, 3 above and 5 below) drainage pipes in the grouting wall, and the diameter of the pipes is not less than 100mm;

[0033] Step 4. Apply 1.0m*1.0m spaced advanced horizontal grouting pipes (32 pieces in total)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com