Sunken tube reinforcement device for shaft construction

A reinforcement device and sinker technology, which is applied in shaft equipment, shaft lining, mining equipment, etc., can solve problems such as inability to reinforce, and achieve the effects of simple structure, short construction period, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

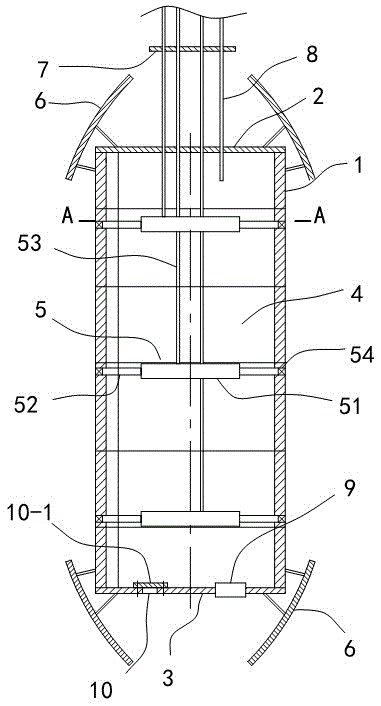

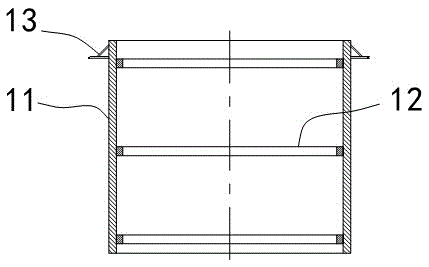

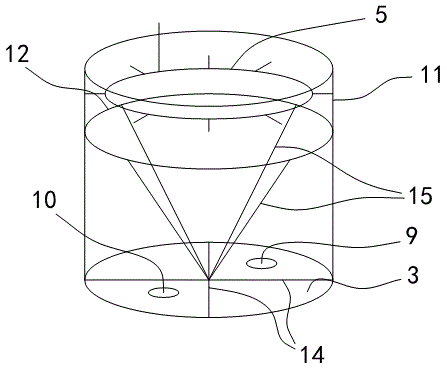

[0019] The specific embodiment of the sunk cylinder reinforcement device for shaft construction of the present invention is as follows: Figure 1-Figure 5 As shown, the device comprises a cylindrical barrel surrounded by a vertically extending cylinder body 1, a top plate 2 sealed and fixed on the top of the cylinder body 1, and a bottom plate 3 sealed and fixed on the bottom end of the cylinder body 1, the cylinder body 1, the top plate 2 and the bottom plate 3 are all made of steel plates and are sealed and fixed by welding, so that a closed inner cavity 4 is formed inside the barrel body 1. In this embodiment, the barrel body 1 of the cylindrical barrel is a single section bent by several steel plates. The steel rings 11 are fixed and connected sequentially. The two single-section steel rings 11 are welded and fixed by internal and external full welding process. The outer surfaces of the upper parts of each single-section steel ring 11 are symmetrically fixed with lifting lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com