Novel composite type groutable anchor rod

A grouting bolt and composite technology, which is used in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of different hole sizes, small end of grouting range and tail grouting time difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

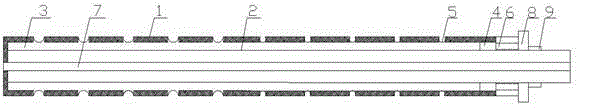

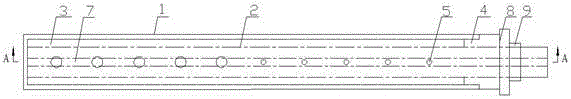

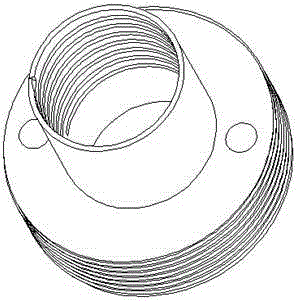

[0012] (The grouting retaining ring is threadedly connected with the inner rod body and the outer casing through the inner and outer threads respectively to ensure its integrity. The inner rod body and the tail of the outer casing have no gap to prevent the grout from flowing into the return chamber 7 through the gap between the two, causing Backflow illusion) When installing, first install according to the ordinary anchor rod installation process, drill holes, place anchoring agent in the drill holes, and then place the anchor rod in the drill hole (the depth of the drill hole should be longer than the length of the anchor rod, so that the anchor rod The rod is completely submerged in the drill hole to ensure the anchoring effect when the nut is tightened on the backing plate). When grouting, the grout can be injected into the grouting cavity 3 between the outer casing 1 and the inner rod body 2 through the grouting hole 6 on the retaining ring. The grout is injected into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com