Patents

Literature

30results about How to "Good slurry effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

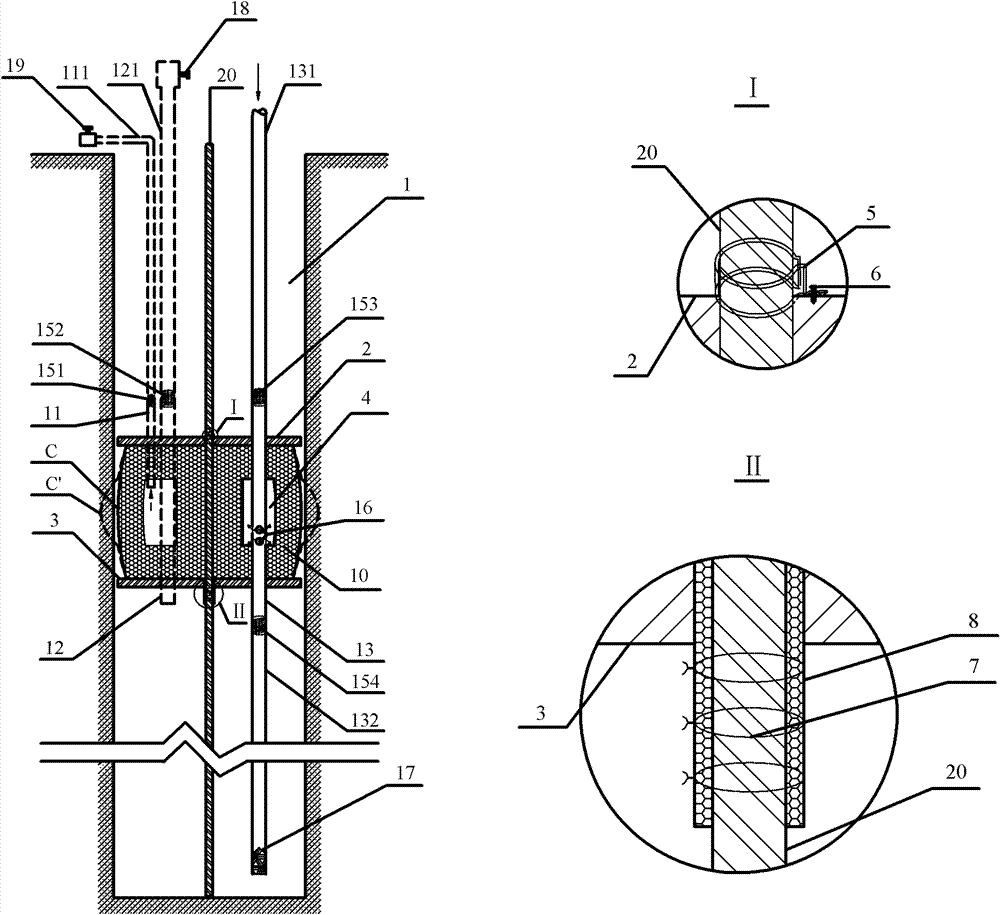

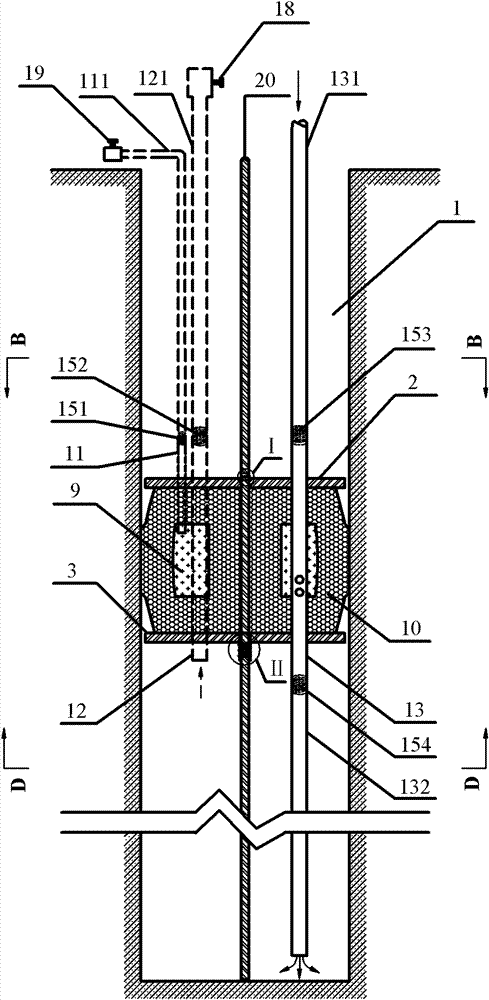

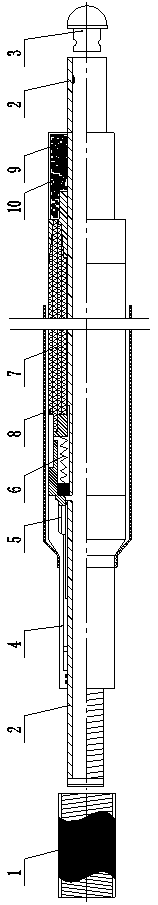

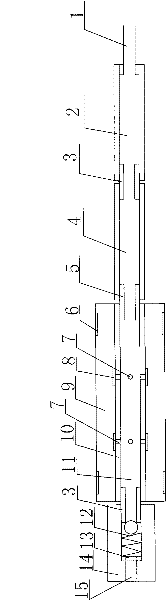

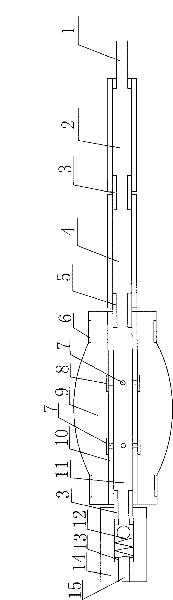

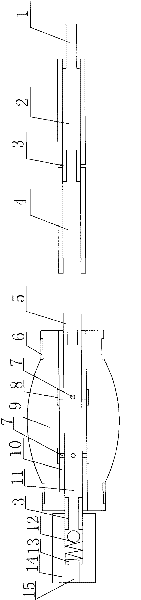

Method and device for grouting in hole and effectively stopping grout

ActiveCN101768974AIncrease or decrease lengthIncrease or decrease quantityFoundation engineeringSteel tubeGrout

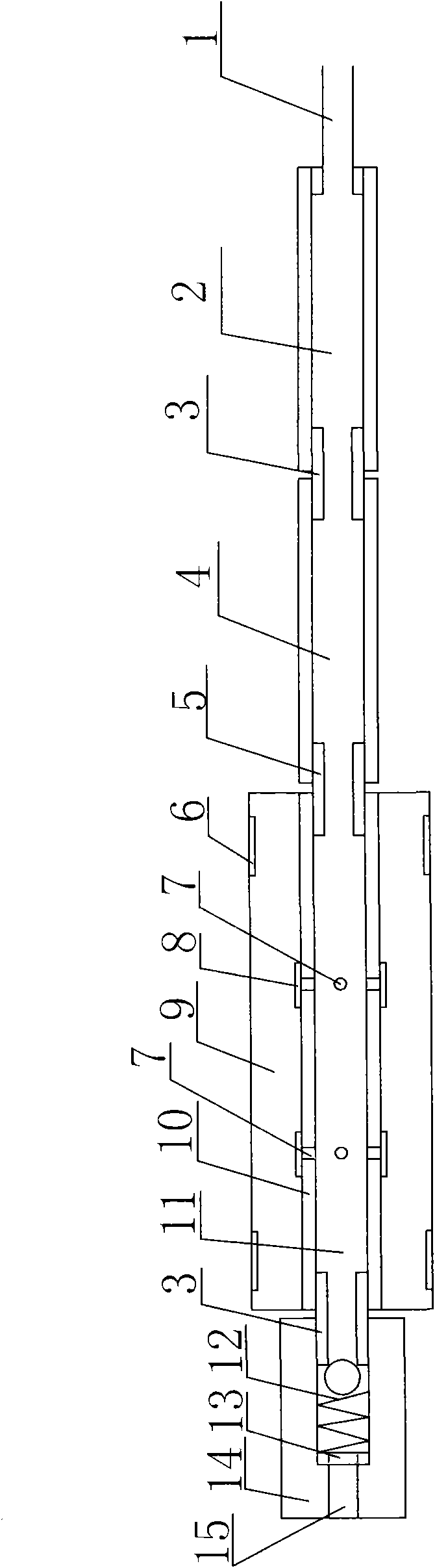

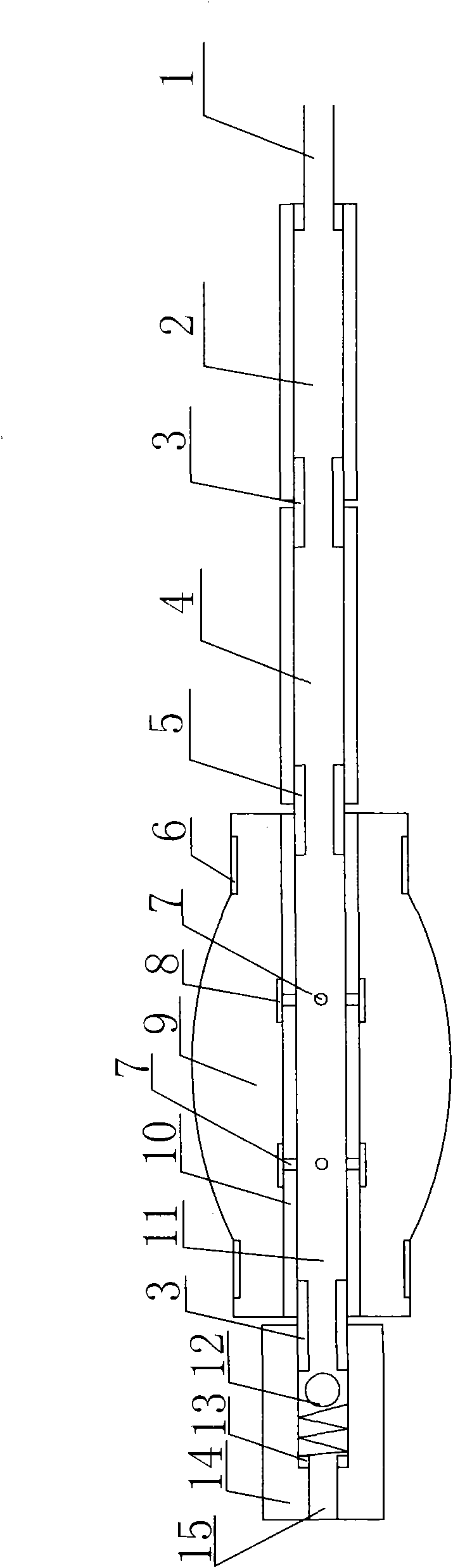

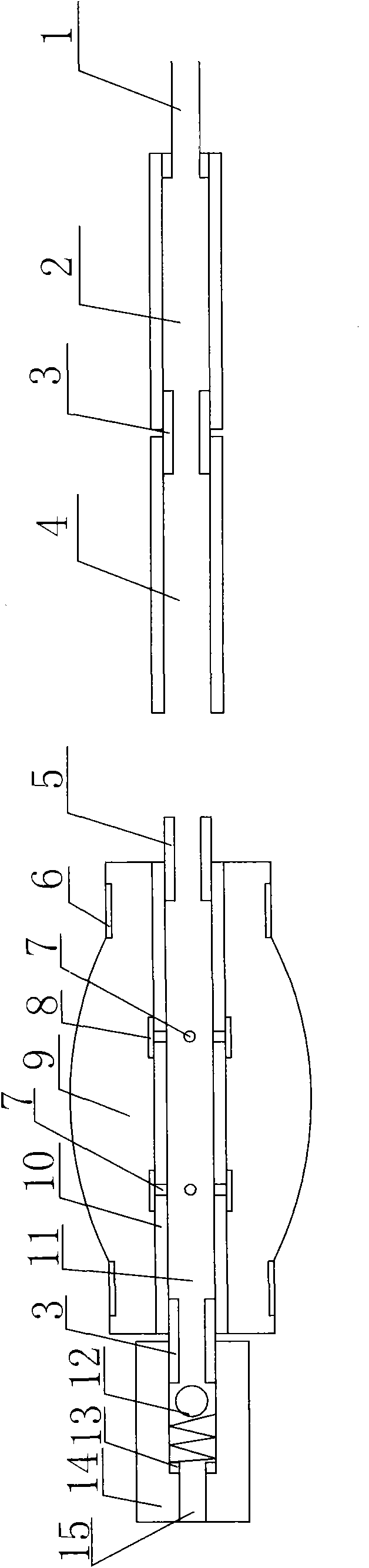

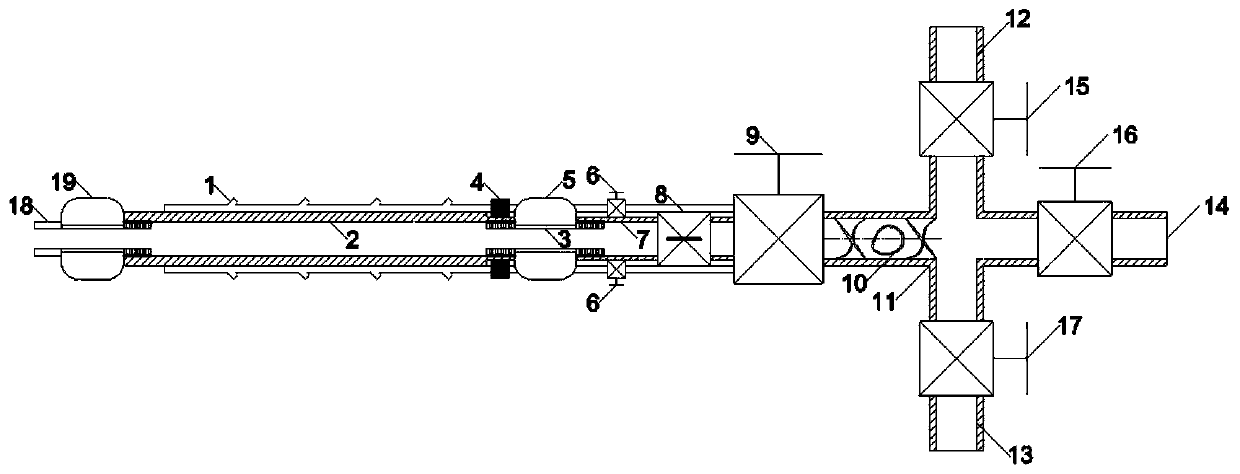

The invention discloses a method for grouting in a hole and effectively stopping the grout. The method is divided into two main action processes, namely grouting and stopping the grount and comprises the following steps: drilling a hole, grouting, expanding with an expansion rubber plug, grouting and disassembling. The device for realizing the method for grouting in the hole and effectively stopping the grout comprises a grout inlet pipe (1), a grout pipeline, an expansion stop-grouting plug (11) and a single-way pressure valve (14) which are sequentially connected, wherein the grout pipeline and the expansion stop=grouting plug (11) as well as the expansion stop-grouting plug (11) and the single-way pressure valve (14) are connected by joints. The technology can stop the grout at any section in the grouted hole with good effect. Besides, steel grout transmission pipes can be conveniently removed from the device, thereby reducing the waste of the materials while ensuring the grout stopping effect.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Preparation method of oxidative cationic modified starch slurry

The invention provides a preparation method of oxidative cationic modified starch slurry, which comprises the following steps of: firstly, dissolving starch into water to prepare starch milk; secondly, using an oxidant namely sodium hypochlorite to perform oxidation reaction with the starch to obtain oxidized starch; thirdly, removing chlorine; fourthly, adopting a cationic etherifying agent to perform etherification reaction; and finally, performing dehydration and drying. When the modified starch prepared from the starch serves as the slurry, the slurry not only has the characteristics of high fluidity, low viscosity and high concentration usage of oxidative starch slurry, but also solves the problem that the oxidative starch has poor thermal stability through quaternary ammonium etherification, and simultaneously, the slurry additionally obtains the following advantages that: the adhesiveness to a warp is significantly improved; the serous membrane forming capacity is strong, and the slurry is difficult to break and burst; the paste viscosity is stable, and the fluidity is good; the slurry has certain hygroscopicity, and has high co-solvency with a synthetic slurry; a membrane is easy to be dissolved in water, and is easy to desize; and paste solution has high thermal stability, is not influenced by high heat fusing, and the like.

Owner:内蒙古奈伦农业科技股份有限公司

Method for preparing modified starch by oxidation and succinic anhydride esterification

The invention provides a method for preparing modified starch by oxidation and succinic anhydride esterification. The method comprises the following steps of: dissolving starch into water to form starch milk, performing oxidation reaction on sodium hypochlorite oxidant and starch to obtain oxidized starch, then removing chlorine, performing esterification reaction by adopting succinic anhydride, and finally dehydrating and drying the reaction product to obtain the modified starch. When the modified starch prepared by the method is used as starch size, the modified starch has the properties of good fluidity, low viscosity and high-concentration use of the oxidized starch; and because the succinic anhydride esterification solves the problem of poor thermal stability of the oxidized starch, the modified starch has the advantages that: adhesion of warps is remarkably improved; a size film has strong forming capability, good mechanical strength and extensibility; the paste has stable viscosity and good fluidity; the size has certain moisture absorption property; the modified starch has good co-solvency with a synthetic size; the film is easy to dissolve in water, and de-sizing is easy; and the paste has high thermal stability, is not affected by high-temperature melting and the like.

Owner:内蒙古奈伦农业科技股份有限公司

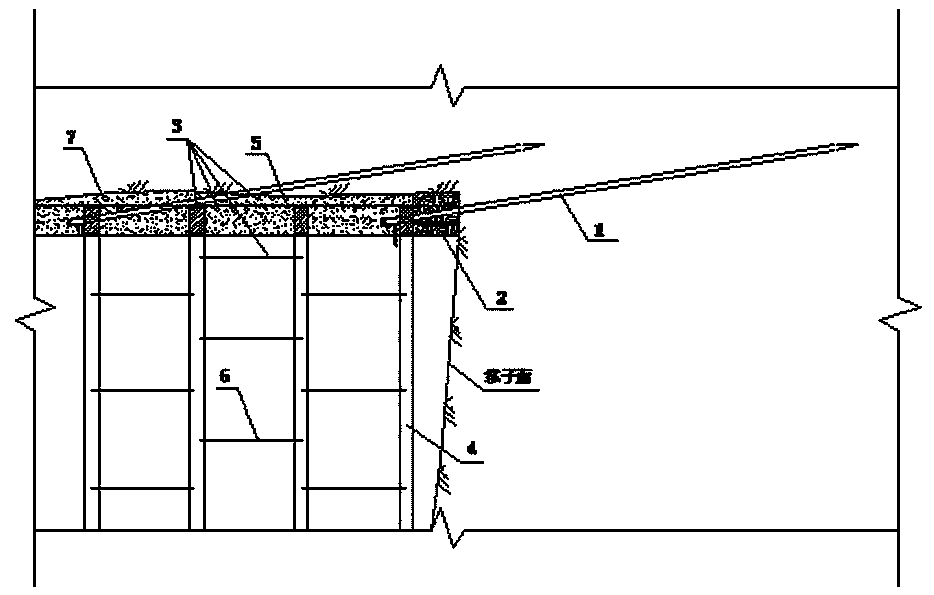

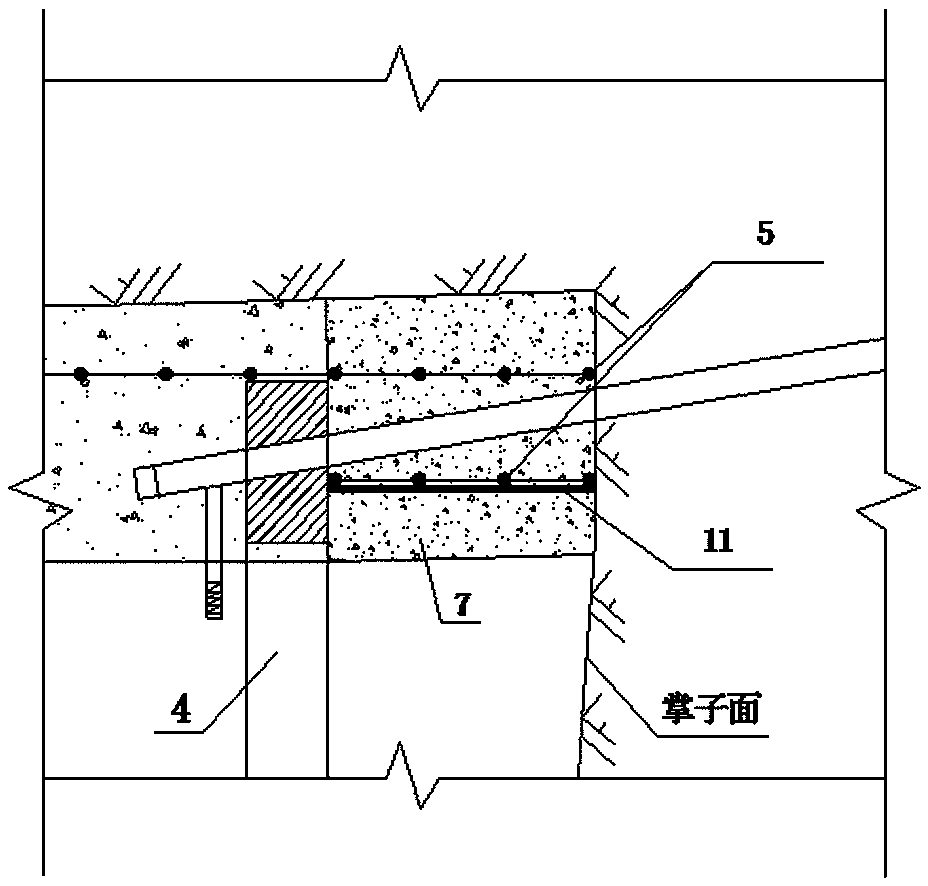

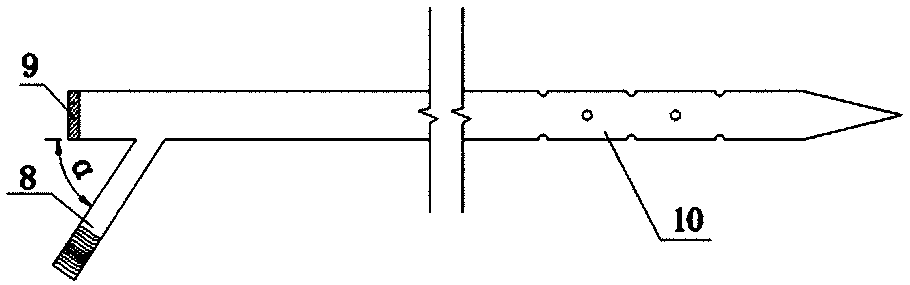

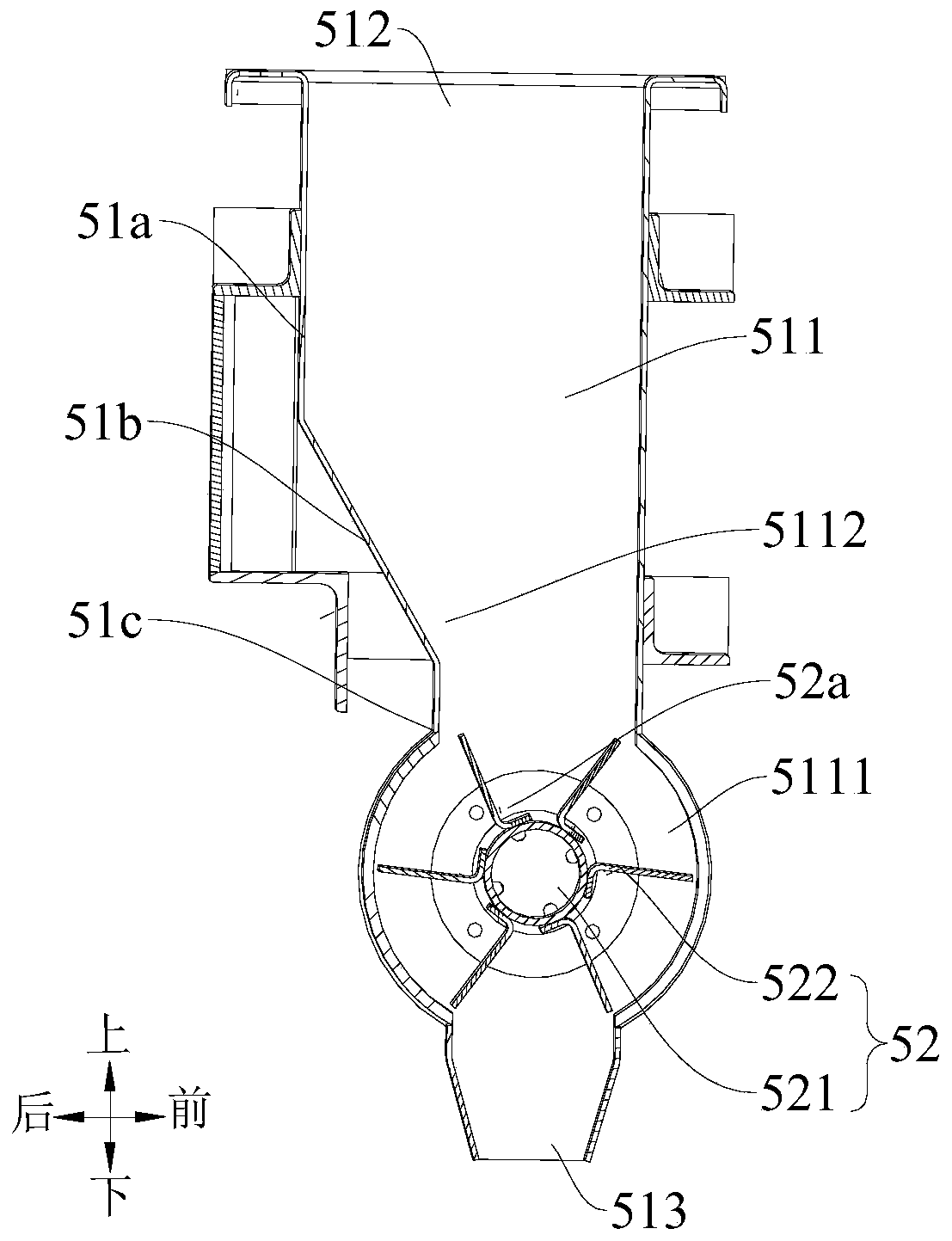

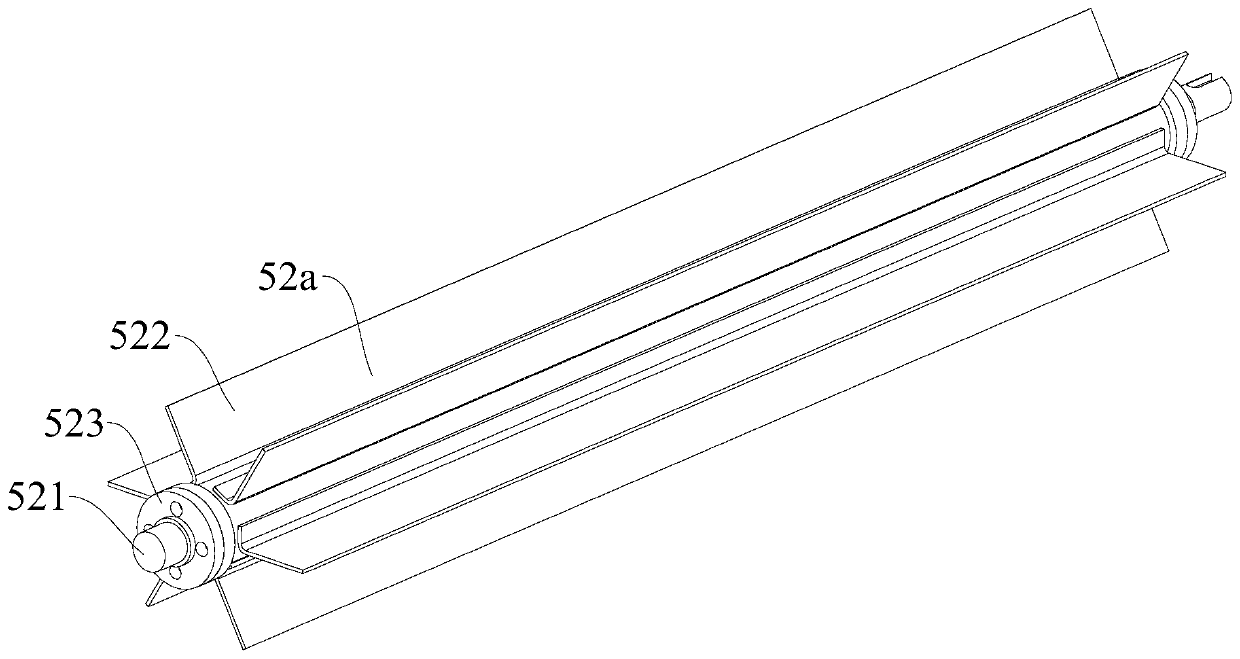

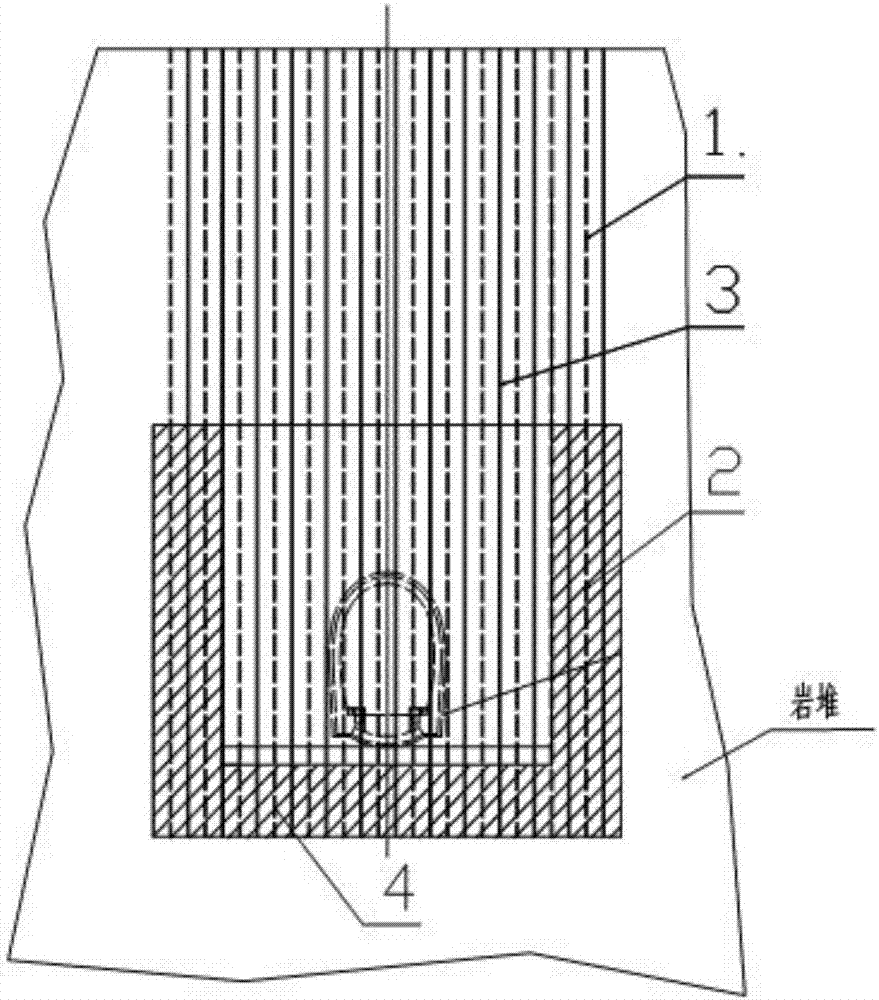

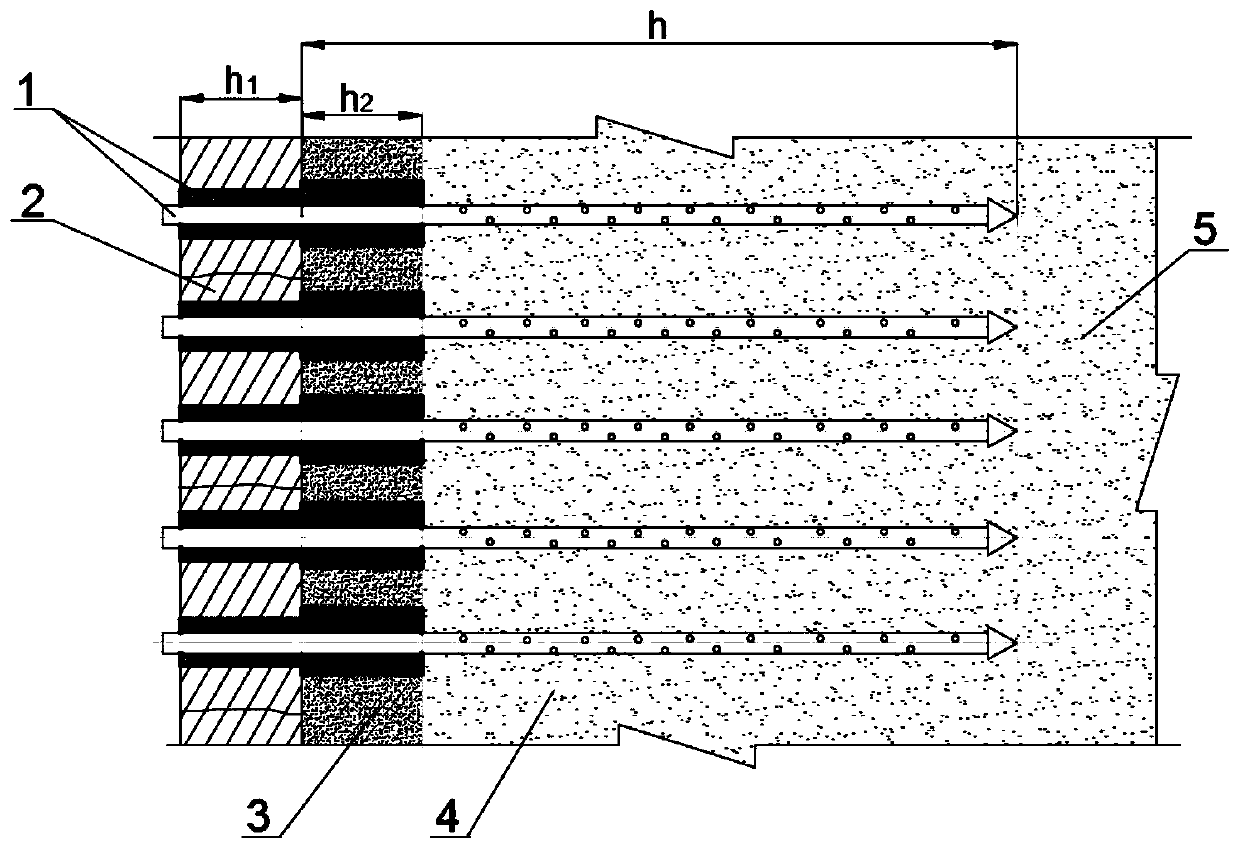

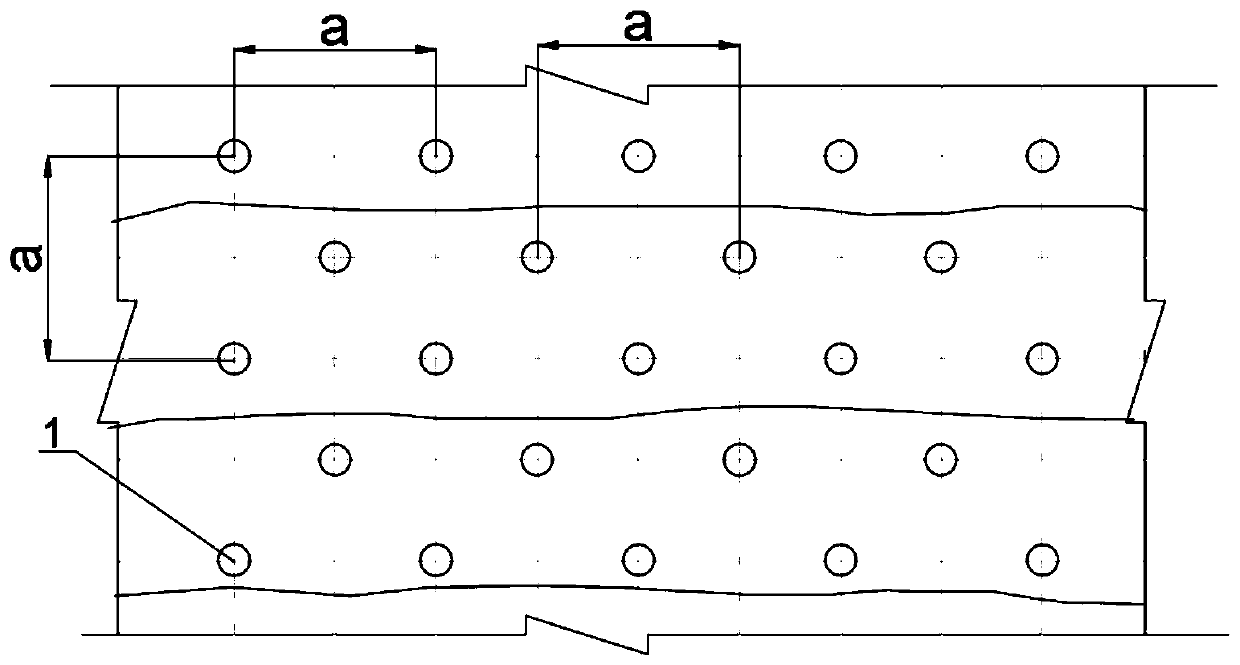

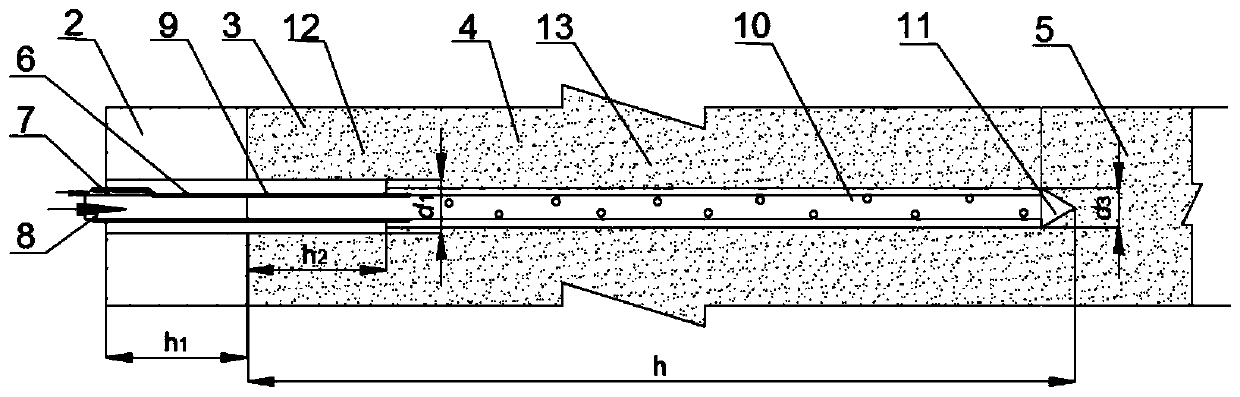

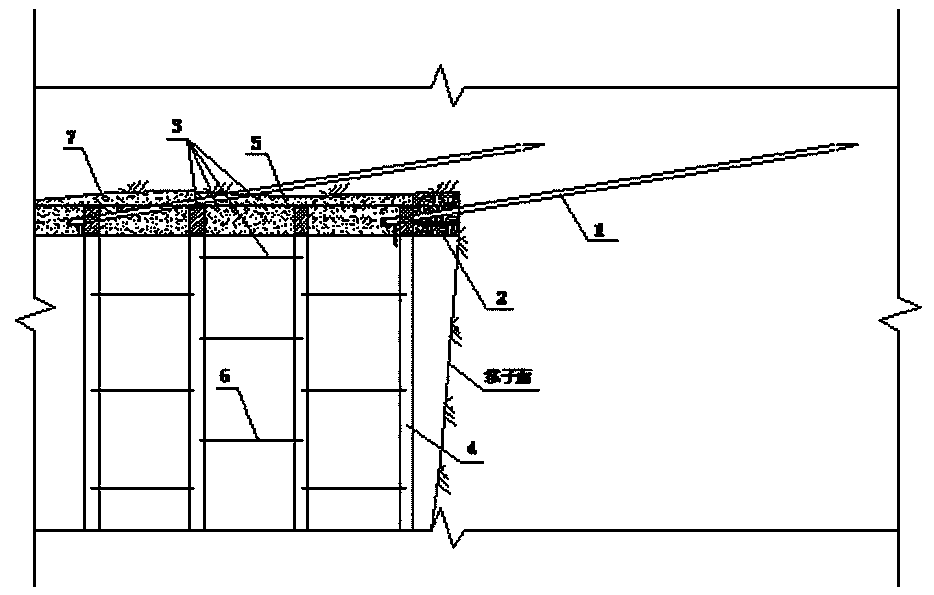

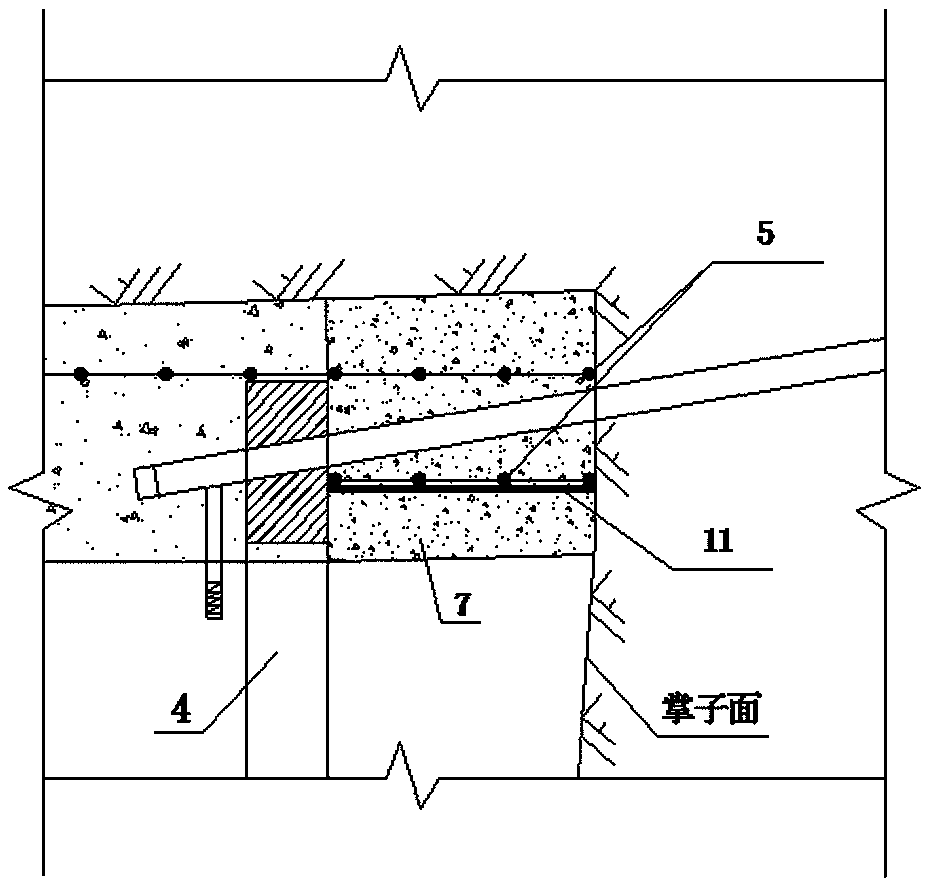

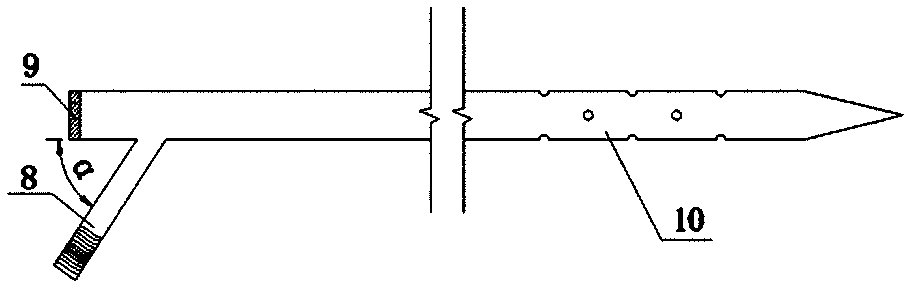

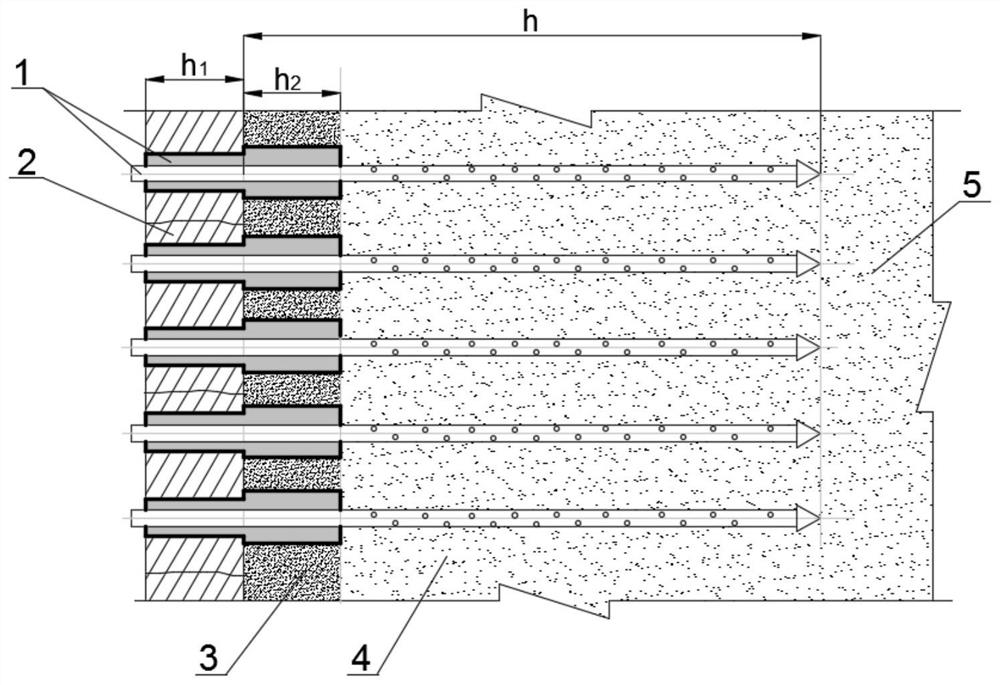

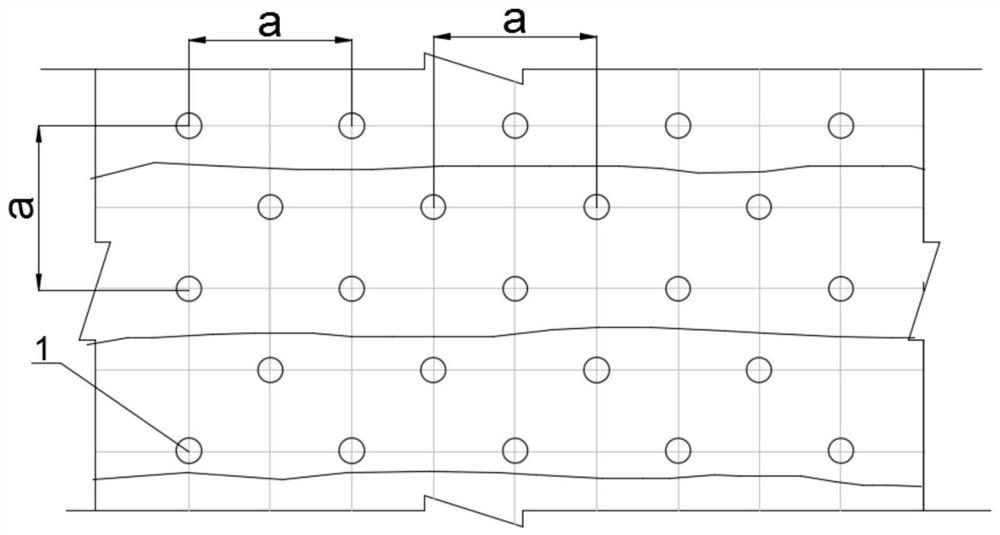

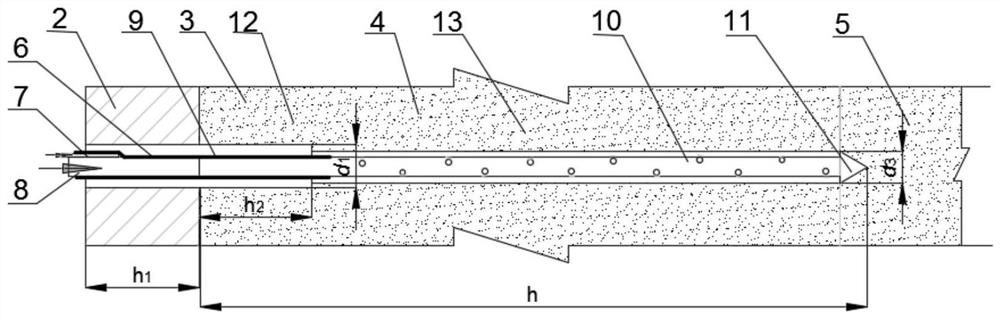

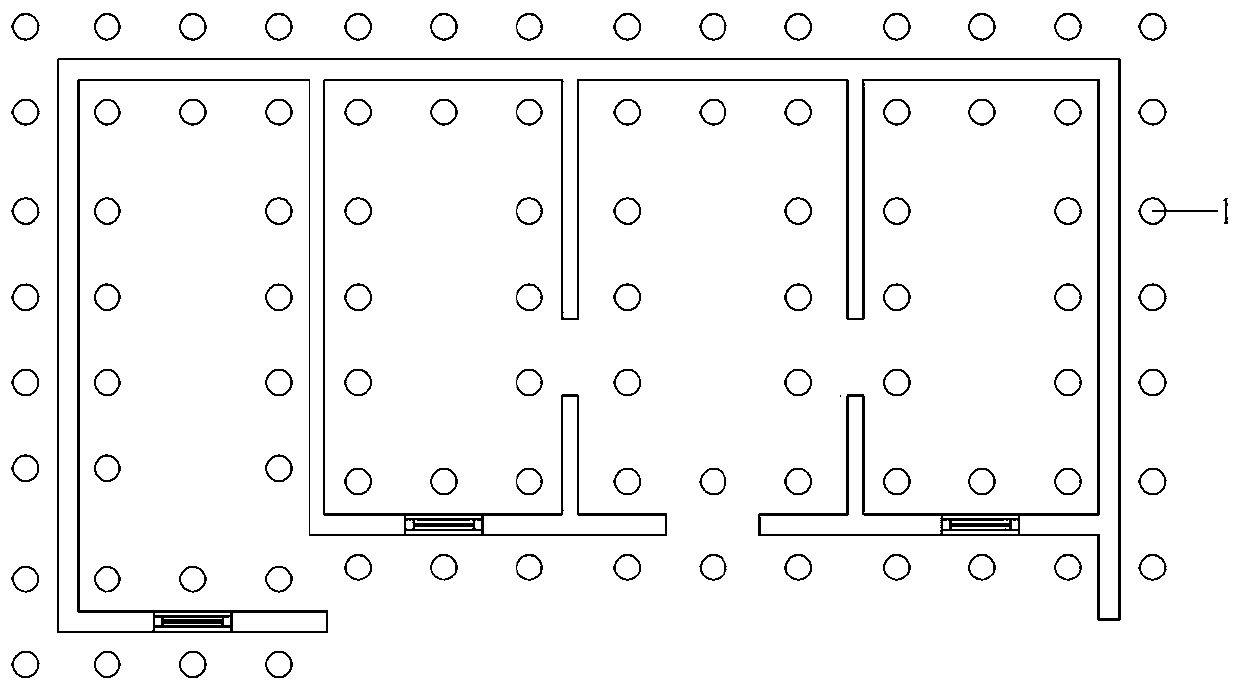

Advanced small pipe grouting structure and construction method thereof

ActiveCN109139048AGood slurry effectQuick closureUnderground chambersTunnel liningRock tunnelApplication time

The invention relates to the technical field of tunnel construction, in particular to an advanced small pipe grouting structure and a construction method thereof. According to an advanced small pipe,quick closure of a primary support can be ensured, a grout stopping wall and the primary support form an integral stress structure and are tightly attached to a tunnel face, so that the stability of the tunnel face is increased, the safety risk of the tunnel face is greatly reduced, and soft rock tunnels and special geological tunnels excavated by blasting are facilitated; and the grouting structure is simple, the application of the grout stopping wall basically does not occupy the application time of the primary support, the grout stopping wall can be applied synchronously with the primary support, the construction speed is high, rapid grouting can be realized, a great deal of time is saved and the construction progress is speeded up compared with the set of the grout stopping wall alone,and grout stopping wall can be used as a part of the primary support without dismantling after the grouting of the advanced small pipe is finished. The advanced small pipe is factory processed, and has convenient and quick installation and grouting. The grout stopping wall is of an integral structure, has good grout stopping effect, can bear large grouting pressure, and greatly ensures the grouting effect of the advanced small pipe.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

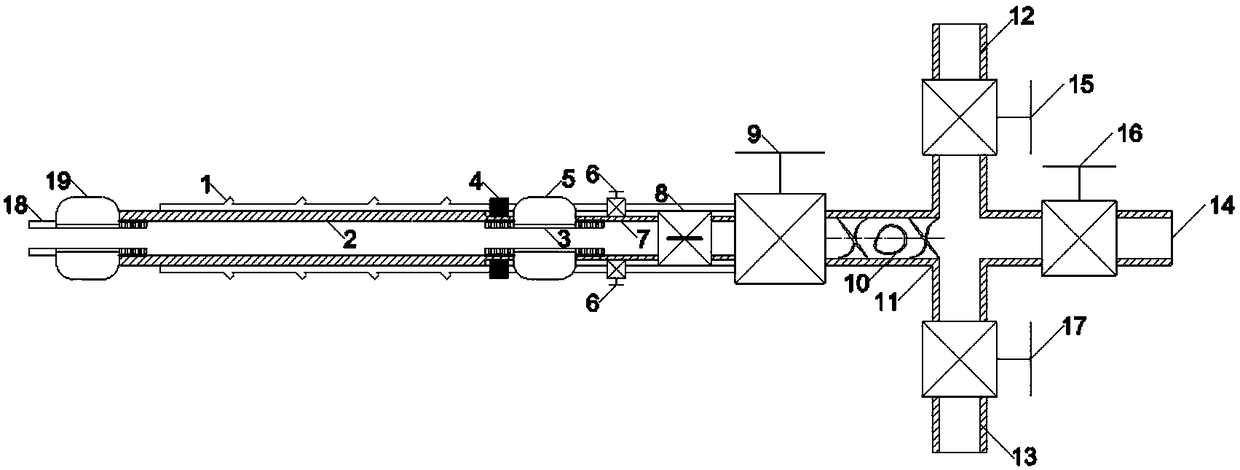

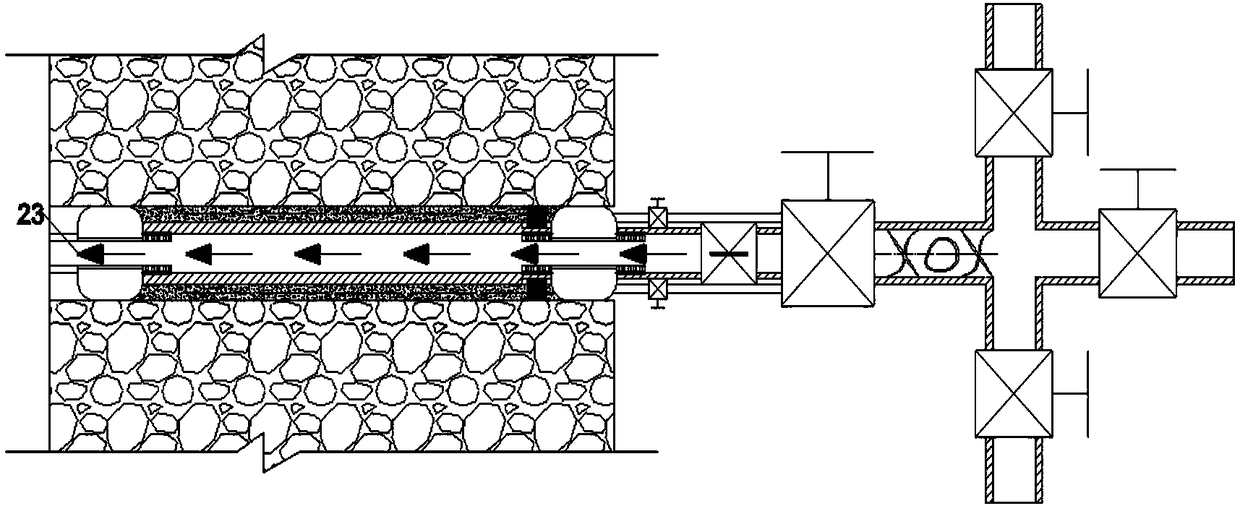

Convenient grouting sleeve device suitable for backwall grouting and use method

ActiveCN108166993AChange the method of applicationEasy to handleUnderground chambersTunnel liningEngineeringFront loading

The invention relates to a convenient grouting sleeve device suitable for backwall grouting and a use method thereof. The grouting sleeve device can be divided into a front-loading grouting pipe set,a stop grouting expansion rubber sleeve and direct set, an intermediate connecting device and a grout inlet pipeline. The front-loading grouting pipe set includes an ordinary steel tube with an internal thread at one end and four small-bore grout sealing tubes welded at the periphery and provided with overhanging ports of 45-degree inclined angle on the outer wall; a four-way device of the grout inlet pipeline is a stainless steel four-way device with valves at each of end ports, and three end ports are a grout A end port, a grout B end port and a pressure relief end port; and a tube head cover is a round pipe plug device with an external thread at one end, and a grouting hole can be plugged after the tube head cover is screwed. Compared with existing devices, the convenient grouting sleeve device suitable for the backwall grouting successfully realizes the convenient handling of end sockets, the recycle of the device and the rapid restoration of the wall surface, greatly improves thework efficiency, reduces the cost expenditure, and can be widely used in backwall grouting construction.

Owner:SHANDONG UNIV

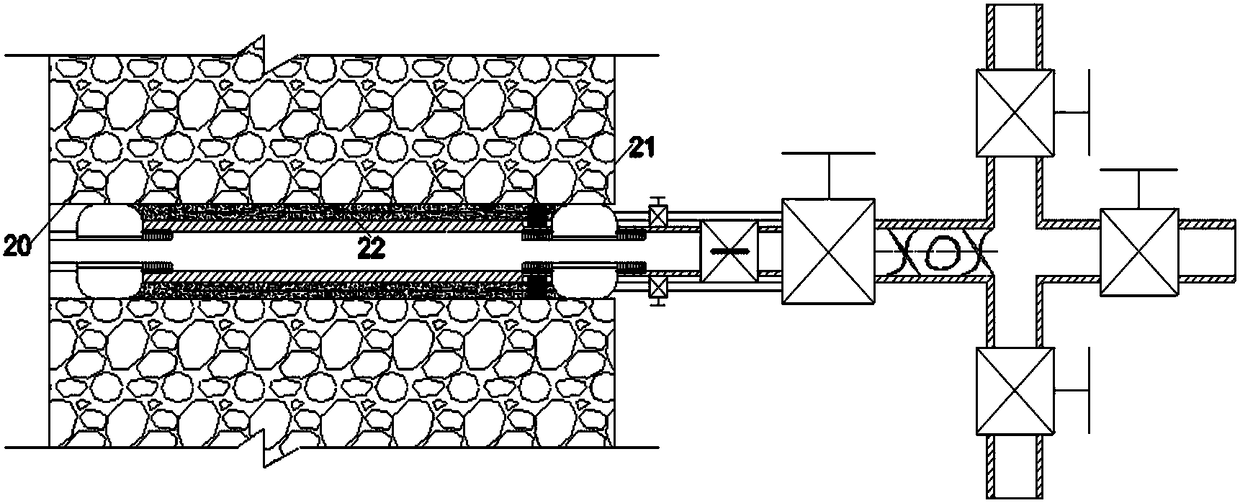

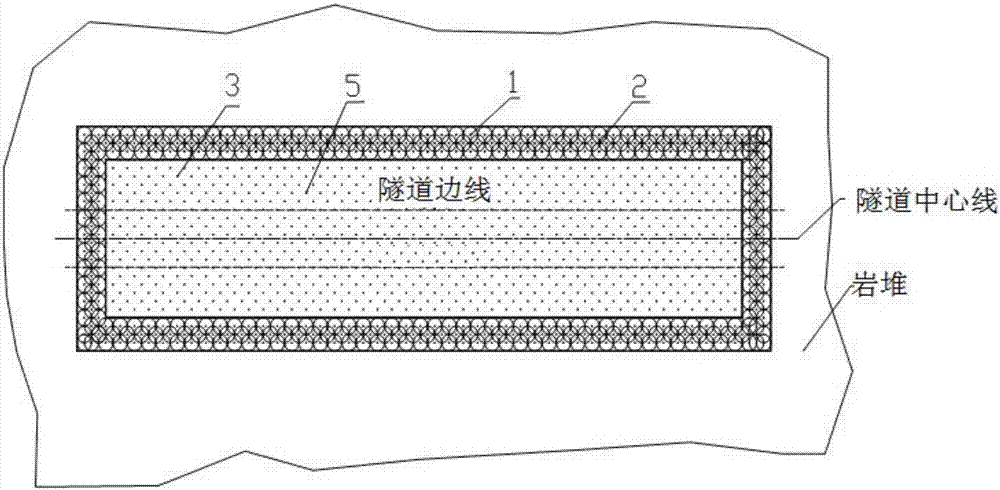

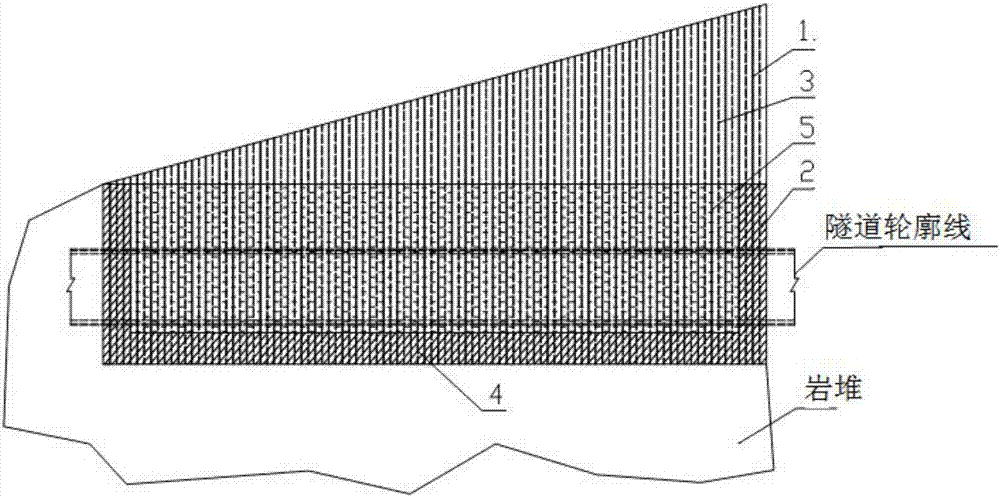

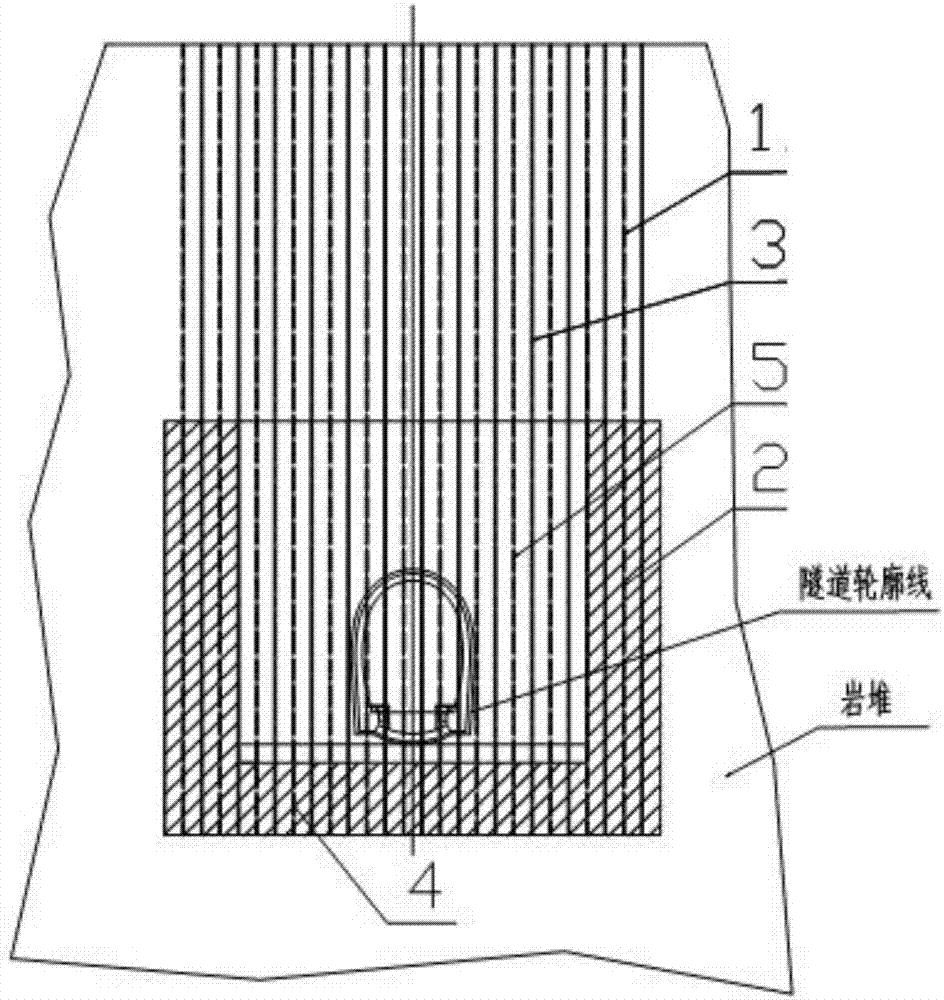

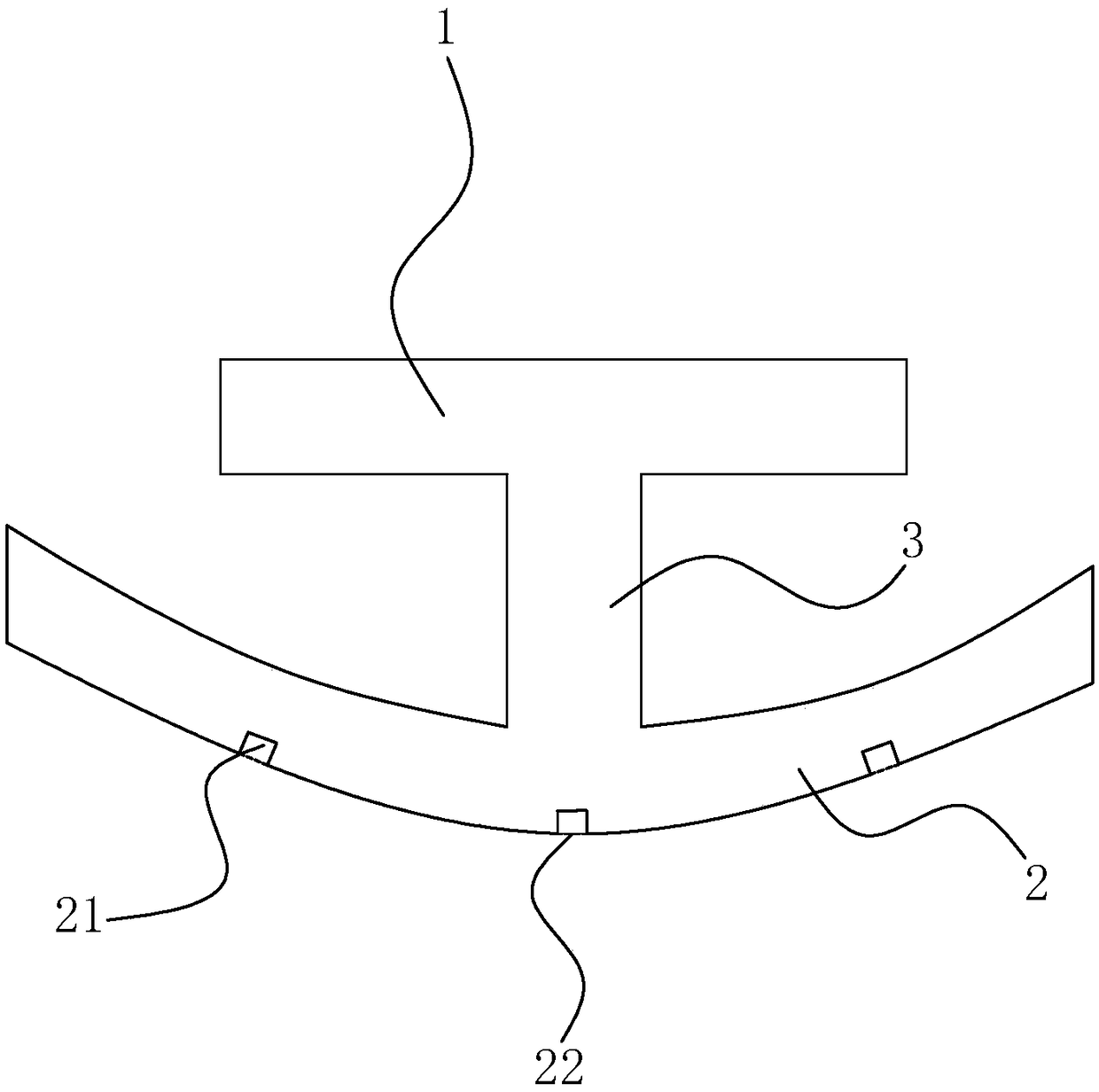

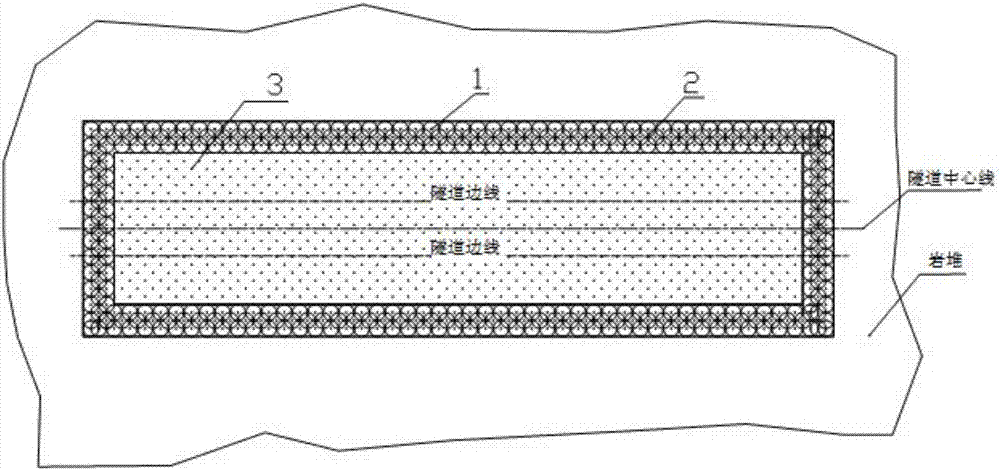

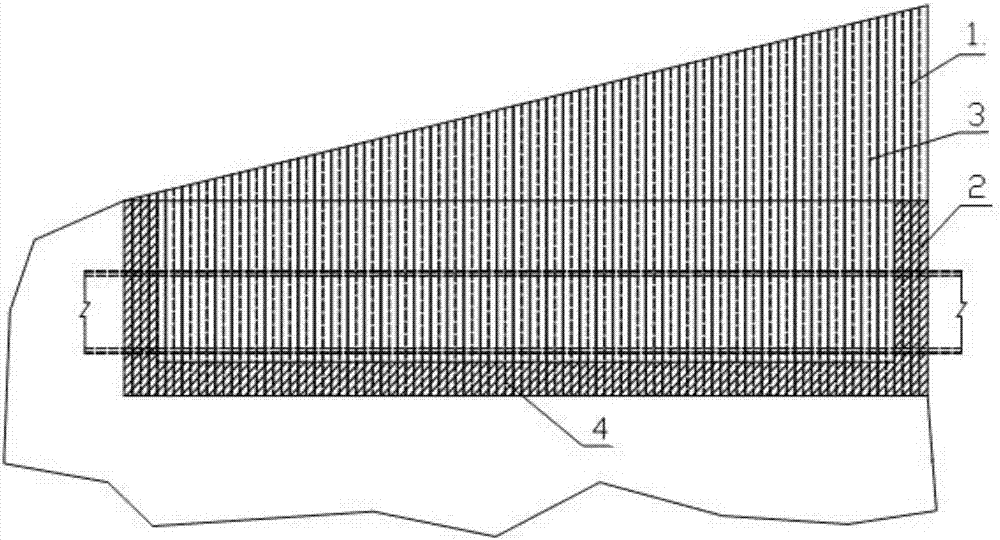

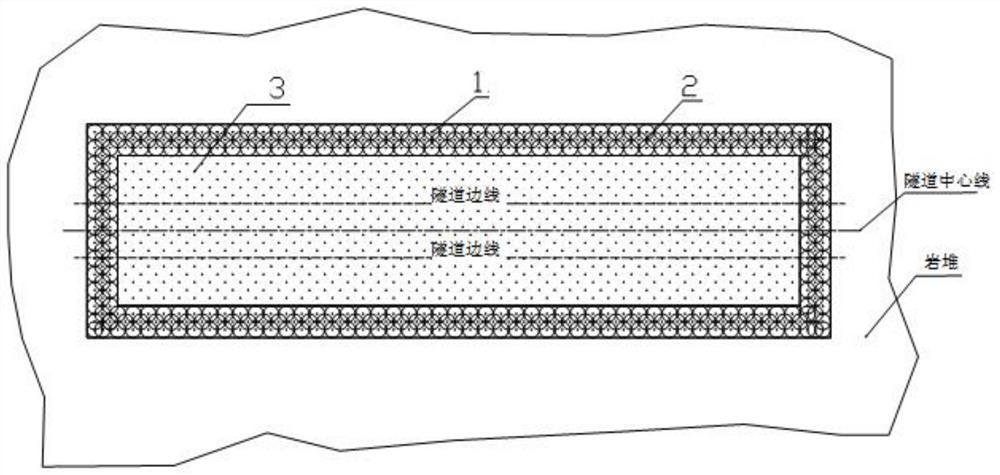

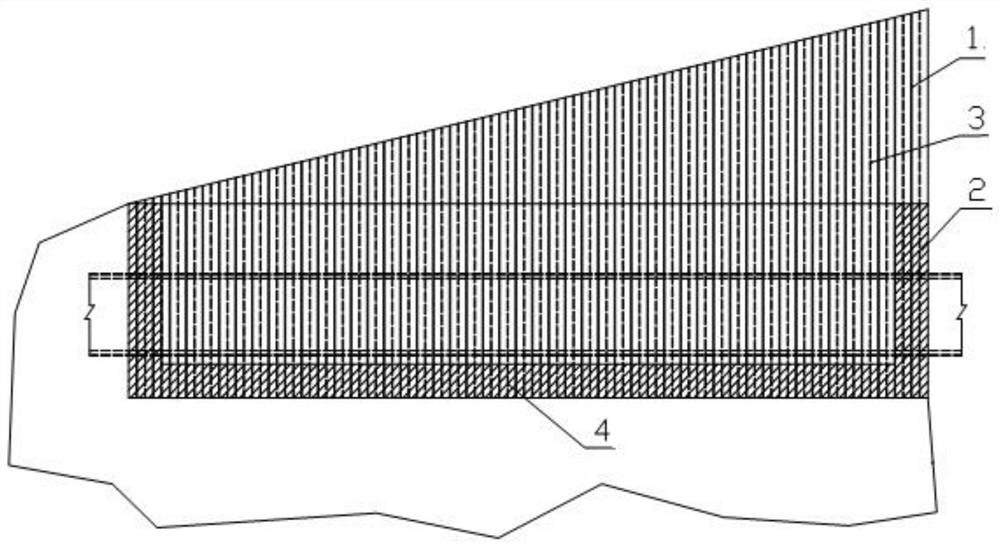

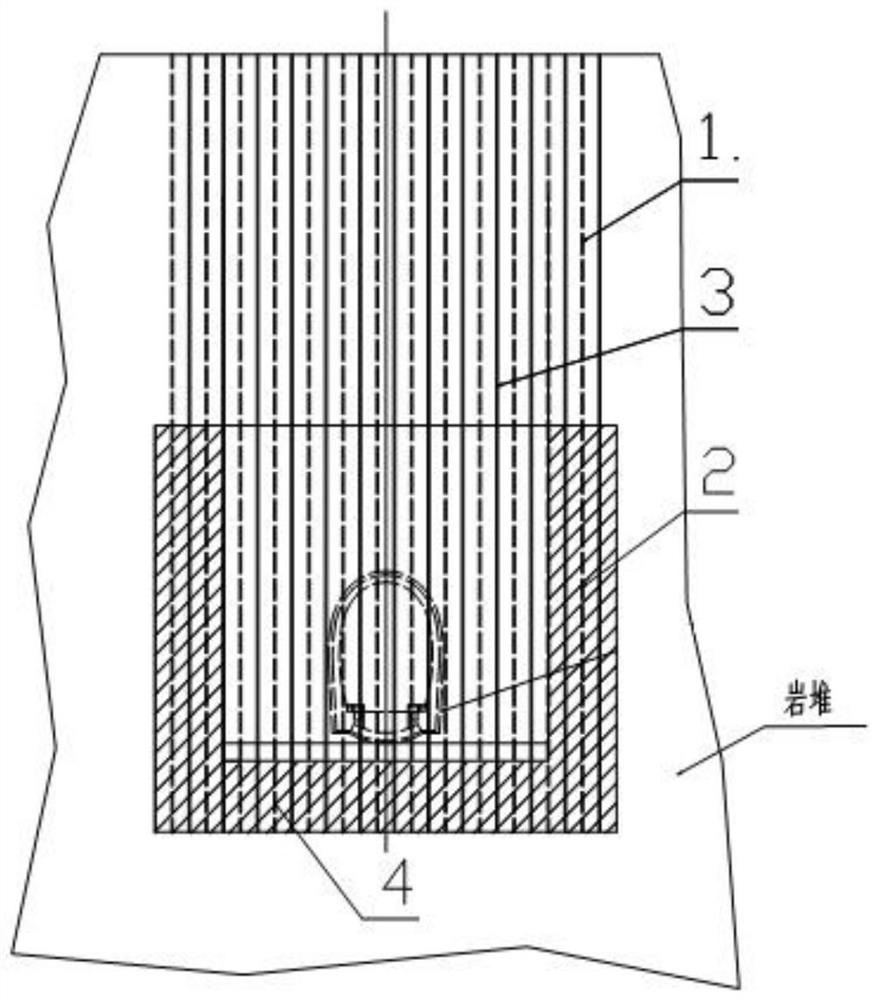

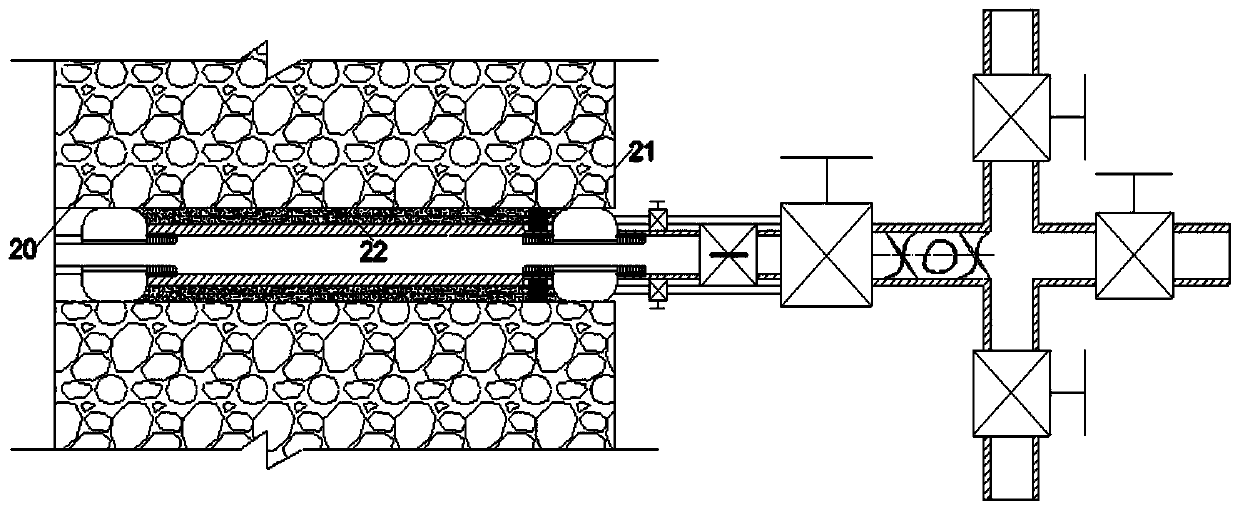

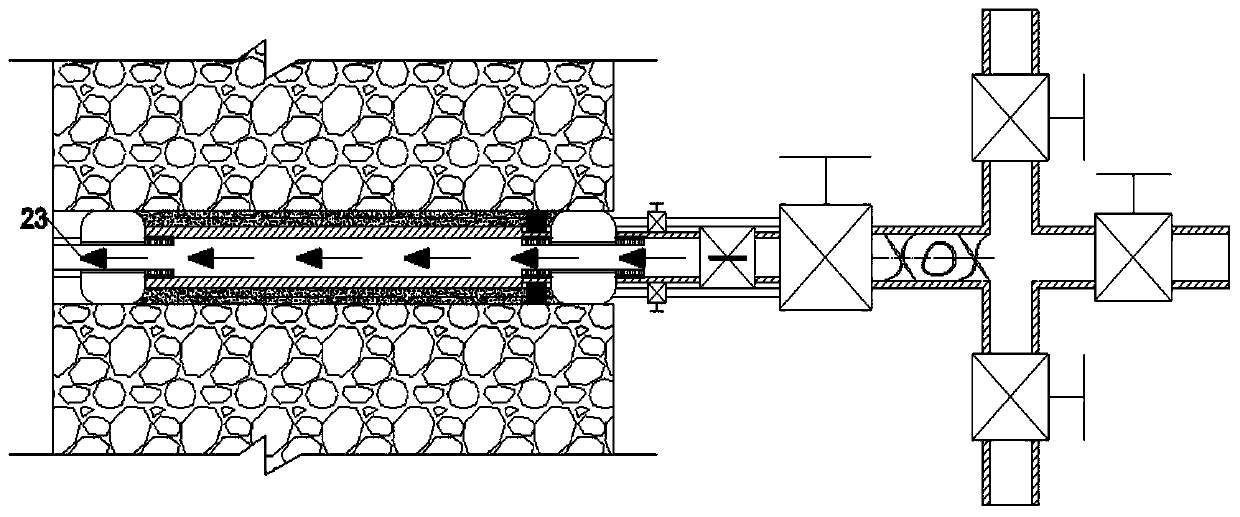

Direction and location slurry injection reinforcing method for particular area in giant rock heap loose body with large porosity

The invention discloses a directional positioning grouting reinforcement method for a specific area in a large rock heap loose body with a large porosity. Sleeve valve layered grouting process is adopted, and quick-setting expansion grout is injected layer by layer to form a surrounding grout-stop curtain wall. The bottom grout-stop curtain wall is closed with the surrounding grout-stop curtain walls to form a "U"-shaped grout-stop curtain that limits the grouting reinforcement range of the rock pile. Cement water glass double slurry is used for grouting construction of "U" type grout-stop curtain inside the grout-stop curtain. Finally, ordinary cement slurry is used in the double-layer "U" grout-stop curtain to carry out the grouting reinforcement construction of the rock heap loose body. The invention has good economical efficiency, and can effectively prevent a large amount of grout from being lost due to the overhead structure in the loose rock heap in the ordinary grouting process through the application of the "U"-shaped grouting curtains on the inner and outer layers of the grouting area. The speed is fast, the work efficiency is high, and the total management cost is low.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

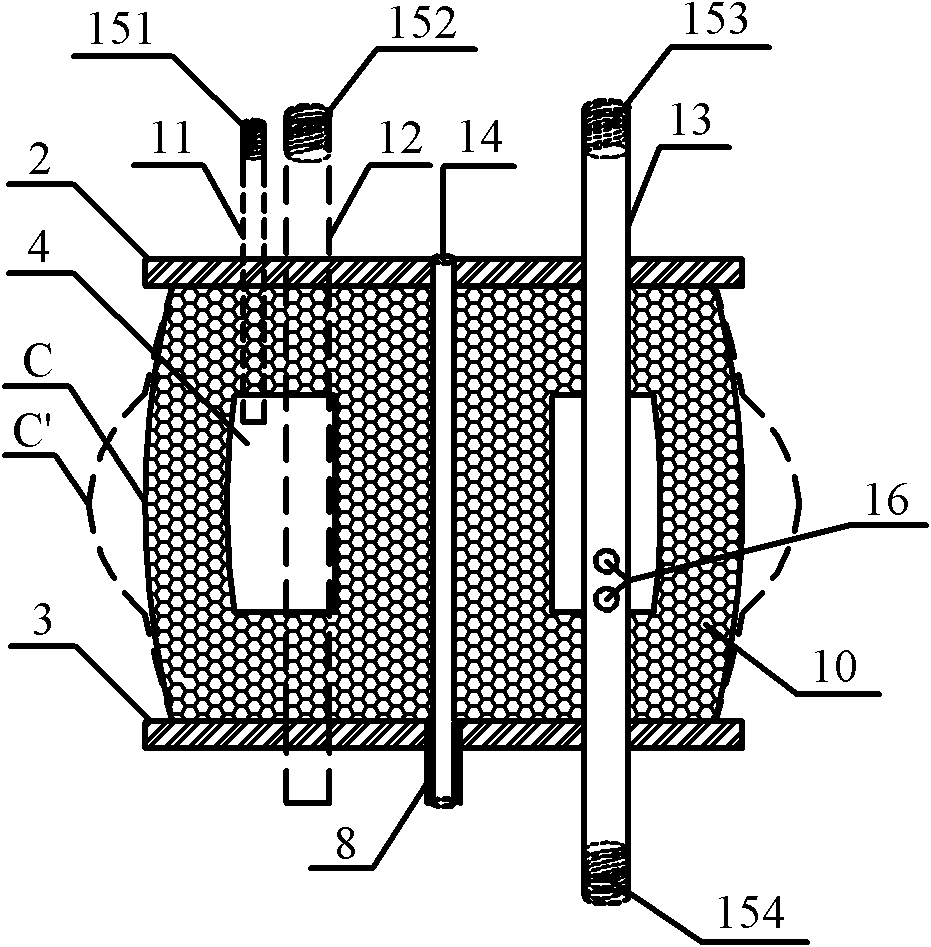

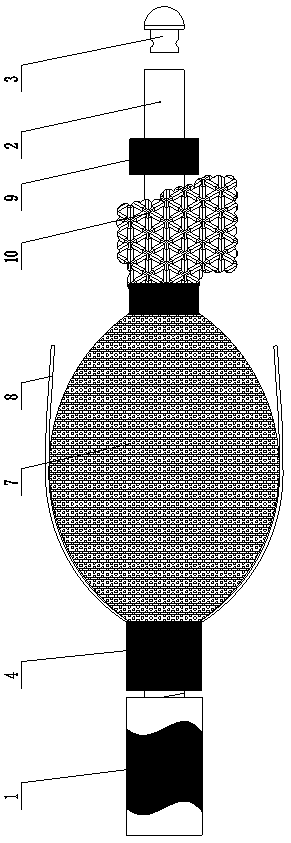

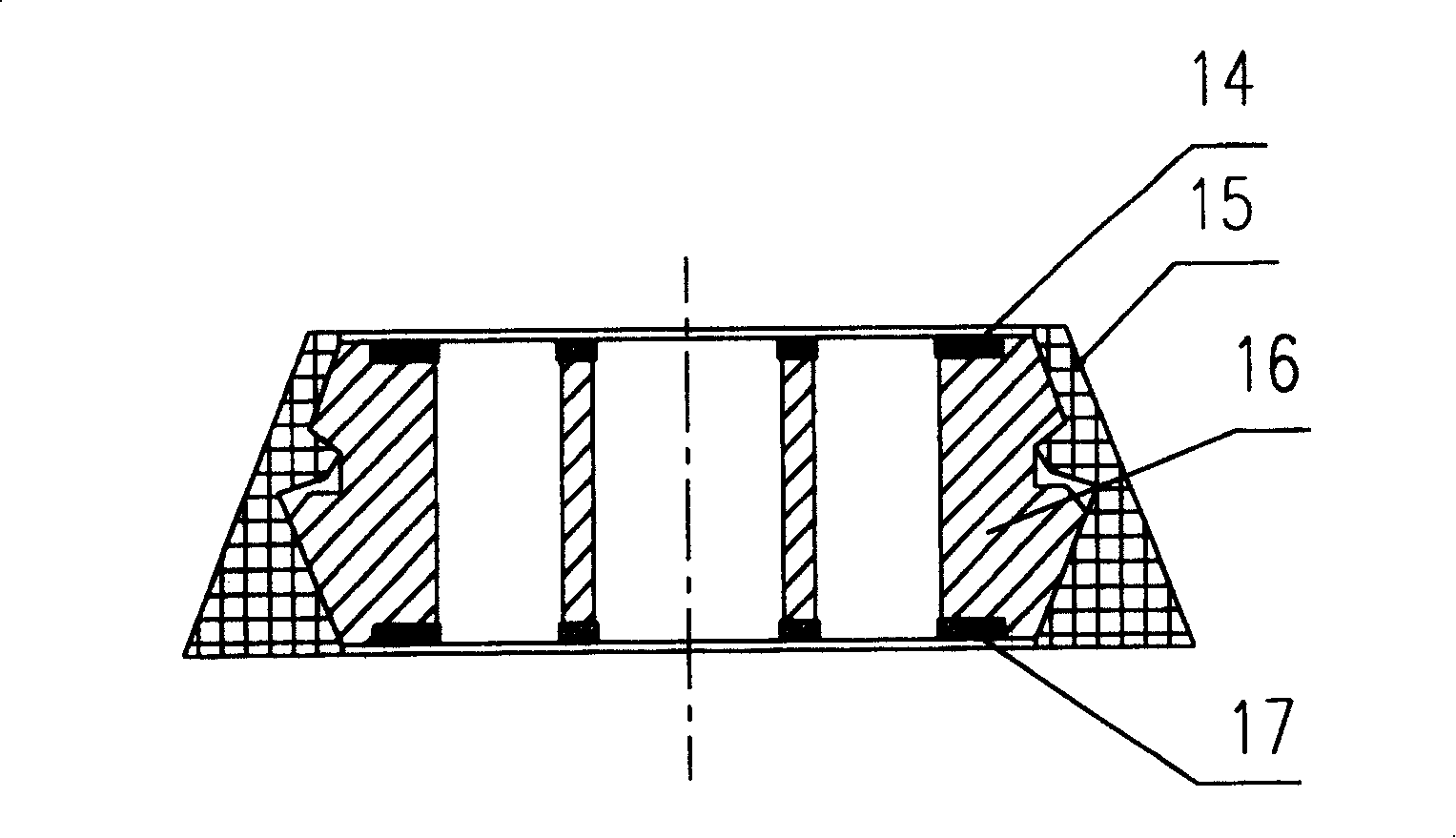

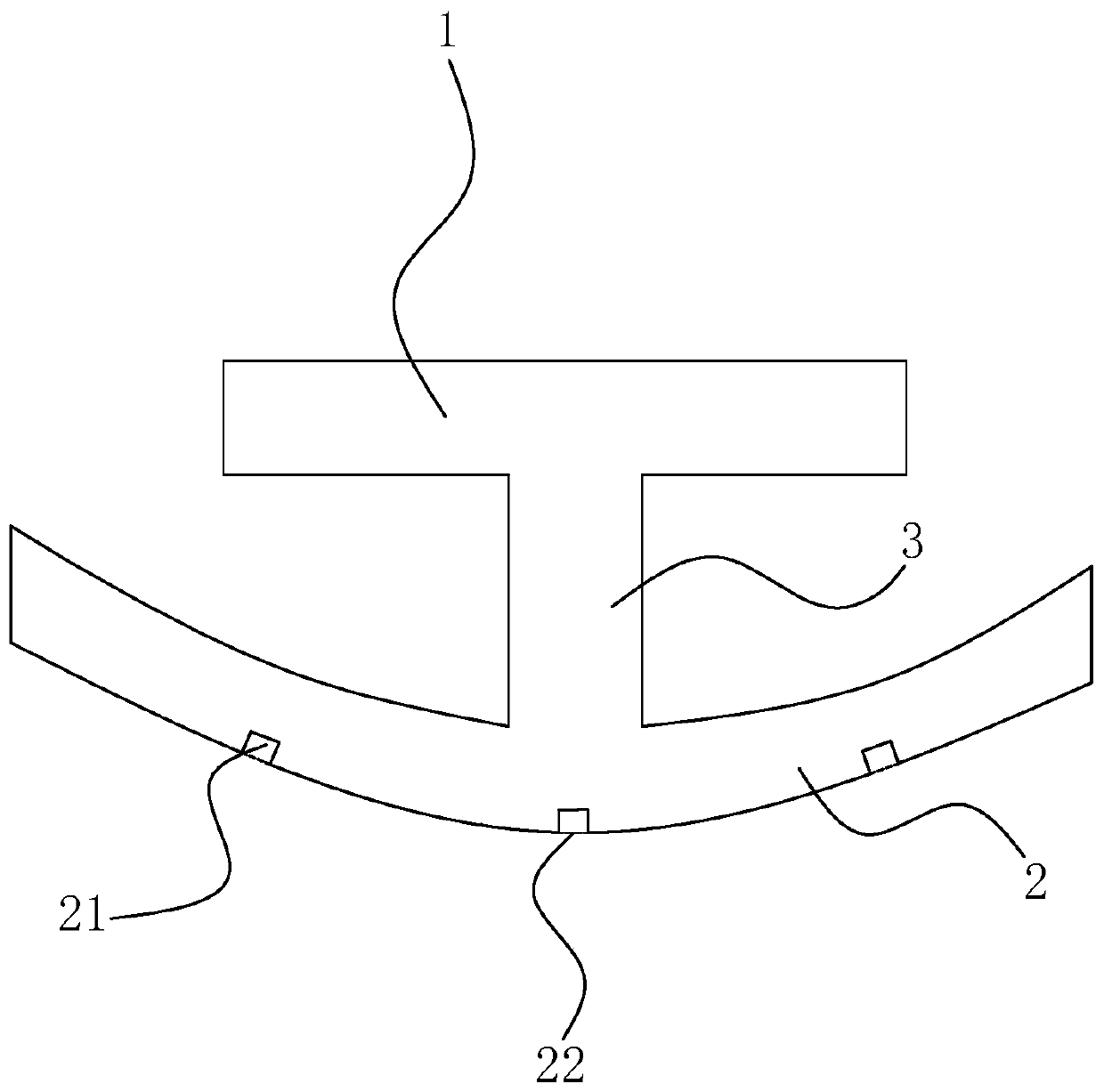

Grouting-stopping plug and system for anchor rod (anchor cable)

The invention discloses a grouting-stopping plug for an anchor rod (anchor cable), which mainly comprises an upper metal positioning plate (2), a lower metal isolating plate (3), a rubber body (10), an air bag exhaust pipe (11), a drilling exhaust pipe (12) and an injection pipe (13), wherein core regions of the upper metal positioning plate (2), the lower metal isolating plate (3) and the rubberbody (10) are provided with anchor rod (anchor cable) holes (14), an air bag (4) is arranged inside the rubber body (10), and the bottom of the rubber body (10) is provided with a rubber jacket (8) used for preventing grouting-stopping liquid from overflowing along the anchor rod (anchor cable). The grouting-stopping plug and system has the advantage that the defect of poor grouting-stopping effect or even complete ineffectiveness caused by connection degumming among all parts, cover shedding, abrasion, air bag eversion and the like in the traditional grouting-stopping plug is fundamentally overcome due to the integral rubber body (10) which is used as the main body of the grouting-stopping plug, the design is reasonable and economic, the structure is simple, the installation and operation is convenient, the leakproofness is reliable and the grouting-stopping effect is good.

Owner:UNIV OF SCI & TECH BEIJING

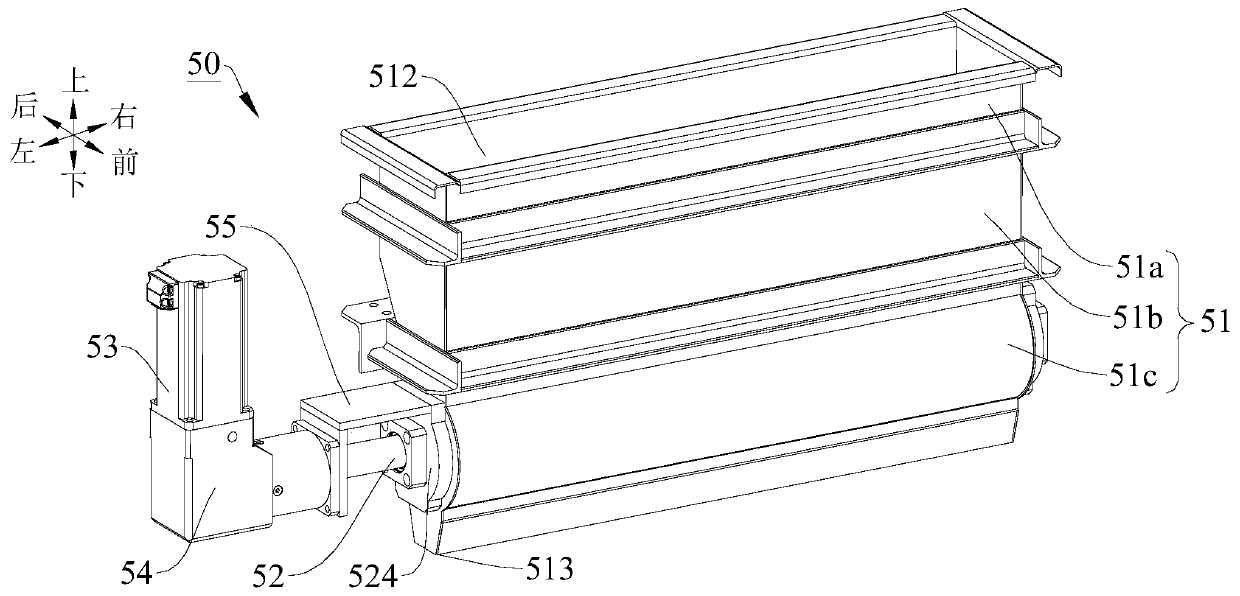

Leveling robot and slurry supplementing device thereof

InactiveCN110541551AGood slurry effectConvenient construction workBuilding constructionsEngineeringSlurry

The invention discloses a leveling robot and a slurry supplementing device of the leveling robot. The slurry supplementing device comprises a slurry storage tank, a slurry discharging gear and a slurry supplementing driving part. A containing cavity is formed in the slurry storage tank. An inlet and an outlet which communicate with the containing cavity are formed in the slurry storage tank, wherein the inlet is used for slurry adding, and the outlet is used for slurry discharging. The slurry discharging gear is located in the containing cavity and is rotatably connected to the slurry storagetank. A plurality of spaced tooth grooves are formed in the slurry discharging gear in the circumferential direction and are suitable for slurry containing. The slurry supplementing driving part is arranged on the slurry storage tank, and is connected with the slurry discharging gear. The slurry supplementing driving part drives the slurry discharging gear to rotate to discharge slurry from the outlet. According to the leveling robot and the slurry supplementing device, the slurry supplementing driving part is arranged to drive the slurry discharging gear to rotate, so that uniform, quantitative and controllable discharge of the slurry can be realized; a better slurry supplementing effect is brought to the leveling robot; and the construction operation of the leveling robot is facilitated.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

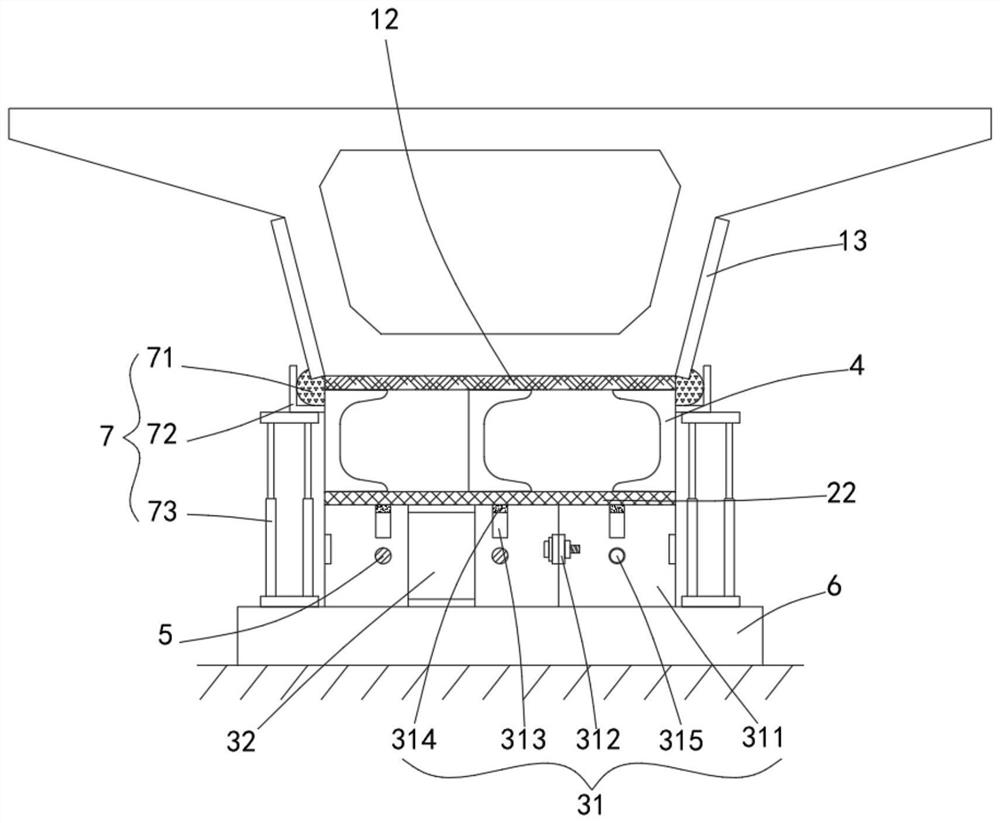

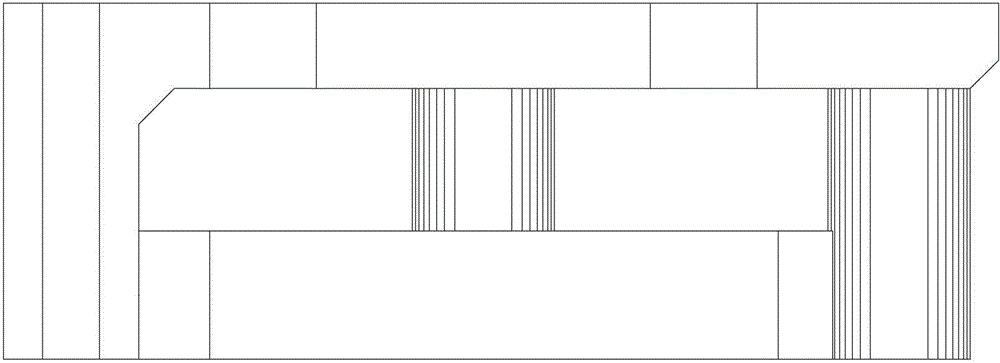

Joint grouting-stopping device for steel-concrete combined section and construction method thereof

ActiveCN108660934AGuaranteed seam stop effectImprove stabilityBridge structural detailsBridge erection/assemblyHanging basketStops device

The invention discloses a joint grouting-stopping device for a steel-concrete combined section and a construction method thereof, and relates to the technical field of joint grouting-stopping construction. The joint grouting-stopping device for the steel-concrete combined section and the construction method thereof aim at solving the problem that when a steel structure of the steel-concrete combined section is mounted, a hanging basket and a side formwork are both dismantled, and no good grouting-stopping measure is set to ensure the concrete construction quality. According to the technical key points, the joint grouting-stopping device comprises an upper wing plate; a lower wing plate is arranged below the upper wing plate parallelly, the centers of the upper wing plate and the lower wingplate are connected with a vertically-arranged supporting plate, the lower wing plate is in a U shape, and an opening of the lower wing plate faces the upper wing plate; and the lower wing plate is formed by manufacturing and machining a polyurethane-type water swelling elastic waterproof material. During construction, the supporting plate and the lower wing plate are clamped into the joint, thenthe upper wing plate is fixed to the two sides of the joint, the lower wing plate is bent towards the upper wing plate under the action of the downward pressing force to closely abut against the twoside walls of the joint, and accordingly the grouting-stopping effect can also be ensured while construction is facilitated.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

Construction method for controlling grouting reinforcement range in large-porosity huge talus loose body

ActiveCN107013231AReduce configuration requirementsSolve the problem of drilling easily stuck drillUnderground chambersTunnel liningPorositySleeve valve

The invention discloses a construction method for controlling a grouting reinforcement range in a large-porosity huge talus loose body. The positions of grouting holes of a grouting stop curtain on the periphery of a grouting reinforcement area are measured; a large pipe-following drill machine is adopted to drill the grouting holes of the grouting stop curtain in a jumping mode; a sleeve valve bush shell material is filled; grouting core pipes are inserted, grouting of the grouting stop curtain holes is completed row by row, then a grouting stop curtain wall defining the periphery range of a grouting reinforcement area is formed; the grouting holes in the grouting reinforcement area are drilled row by row in a jumping mode, and after 3 meters of grouting at the bottoms of all the grouting holes is completed, a bottom grouting stop curtain wall of the grouting reinforcement area is formed; the bottom grouting stop curtain wall is crossly closed with the peripheral grouting stop curtain wall, and finally a U-shaped grouting stop curtain controlling the grouting reinforcement range is formed. By forming the U-shaped grouting stop curtain on the periphery of the specific grouting reinforcement area, loss of a large amount of slurry in a common grouting process due to the aerial construction in the talus loose body can be effectively prevented, the construction speed is high, the working efficiency is high, and the overall management cost is low.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

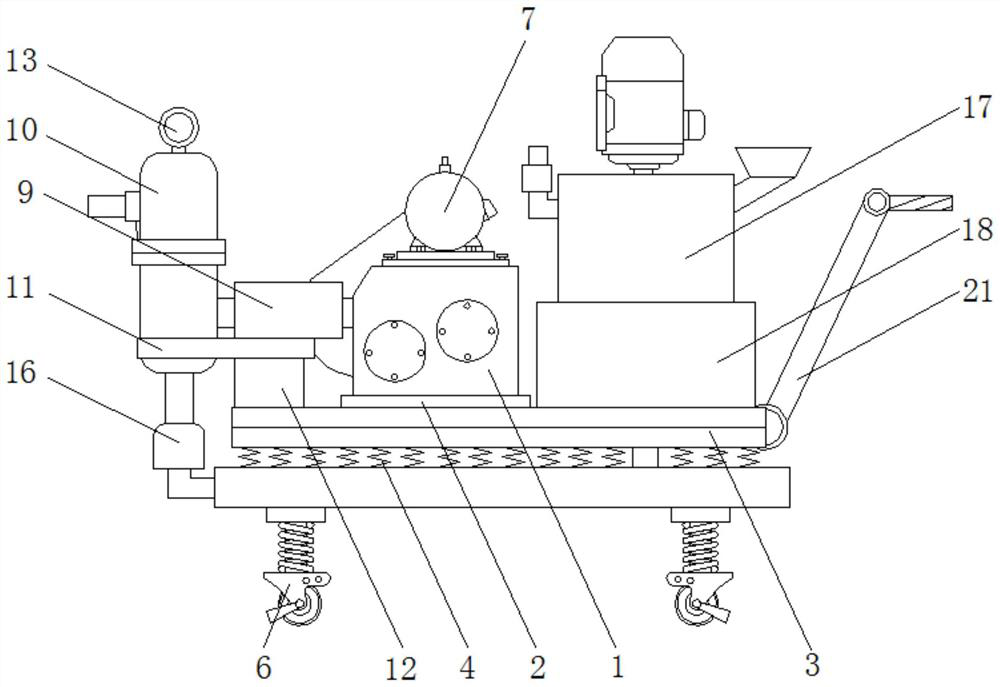

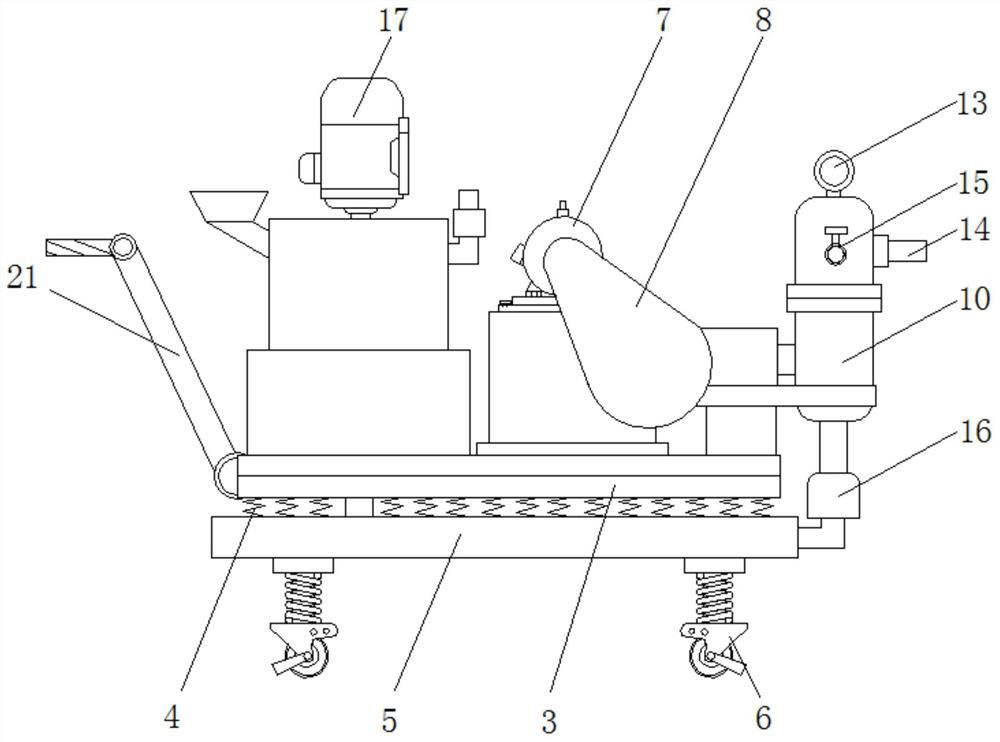

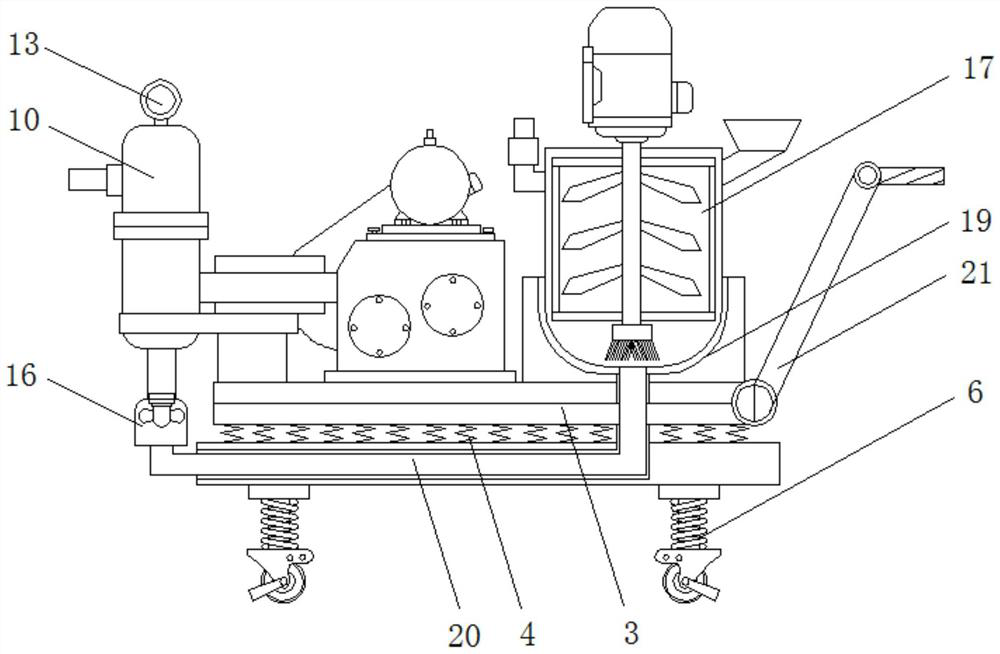

Movable grouting pump with stirring function

InactiveCN113232162AAvoid unstable working conditionsReduce vibrationPositive displacement pump componentsUnderground chambersClassical mechanicsElectric machinery

The invention discloses a movable grouting pump with the stirring function. The movable grouting pump comprises a grouting pump body, a pure copper motor, a grouting cylinder, a fixing block, a pressure gauge, a stirring mechanism, a containing groove, a discharging pipe and an adjusting mechanism, wherein the grouting pump body is fixedly connected with a damping plate through a fixing plate, and the damping plate is fixedly connected with a bottom plate through a first damping spring; the pure copper motor is arranged above the grouting pump body; one side of the grouting cylinder is fixedly connected with the grouting pump body through a piston material cylinder; the fixing block is arranged above one side of the damping plate; the pressure gauge is arranged at the top end of the grouting cylinder; a pressure relief valve is arranged on the other side of the grouting cylinder; the stirring mechanism is arranged on one side of the grouting pump body; and the containing groove is formed in a containing platform. According to the movable grouting pump with the stirring function, a moving mechanism and a stirring mechanism are arranged, the moving mechanism conveniently drives the grouting pump body to move through rolling wheels, the stirring mechanism conveniently and evenly stirs cement mortar, and grouting of the grouting pump is facilitated.

Owner:XUZHOU BOAN TECH DEV +1

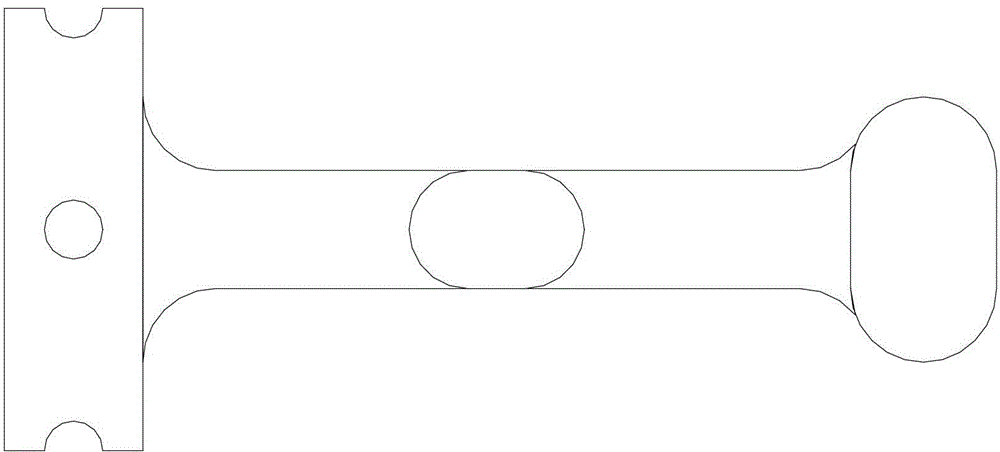

Reducing self-adaptive expansion grouting device and reinforcing method for cracking and breaking position of tunnel second liner

ActiveCN110778332ASolve the technical problems of grouting reinforcementHigh strengthUnderground chambersTunnel liningUltimate tensile strengthSelf adaptive

The invention discloses a reducing self-adaptive expansion grouting device and a reinforcing method for the cracking and breaking position of a tunnel second liner. The device comprises a body and a damper. The damper is arranged on the end portion of the body. The body is overall of a tubular structure, and the body is sequentially provided with a grout outflow section, a first expansion section,a second expansion section and a grouting section in the direction away from the damper. Multiple grout outlets are evenly distributed in the grout outflow section. The diameter after expansion of the first expansion section is larger than that of the second expansion section. By means of the grouting device, compaction grouting and splitting grouting can be simultaneously achieved, and by meansof compaction and splitting filling, the overall strength and the safety of reinforced surrounding rocks are improved.

Owner:SHANDONG UNIV

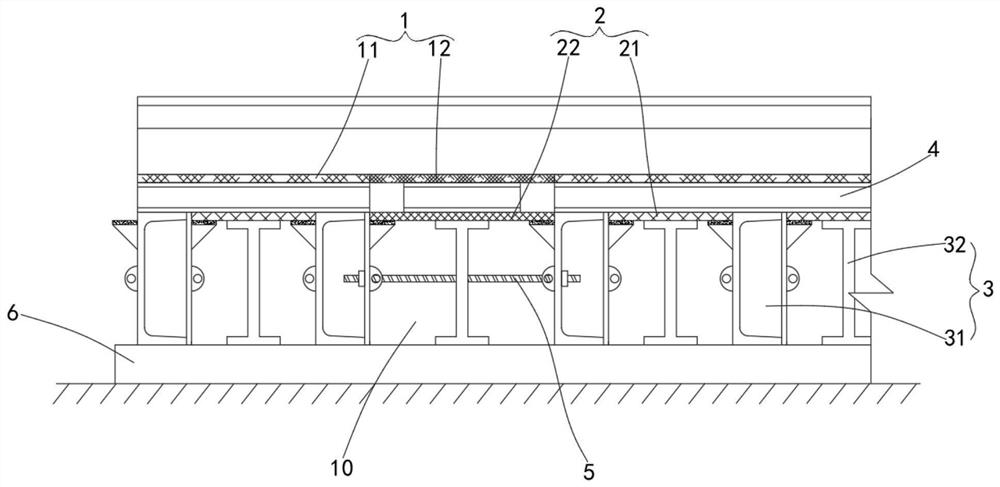

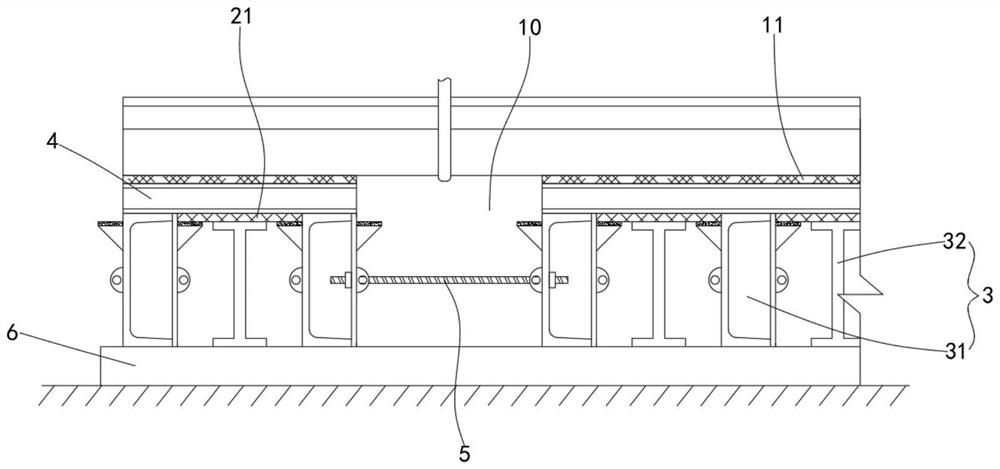

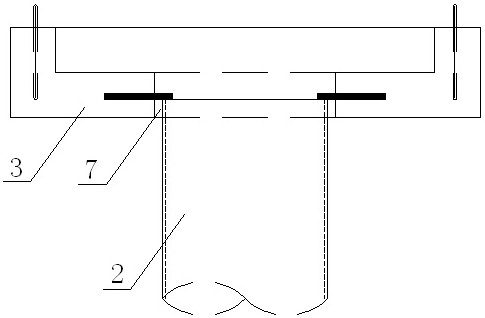

Precast beam construction system and method

ActiveCN113059685AEasy to liftSolve the problem of slurry leakageMoulding surfacesMould fastening meansArchitectural engineeringStructural engineering

The invention provides a precast beam construction system. A supporting assembly comprises a plurality of first supporting bodies, the first supporting bodies are fixedly connected to the portion between first bottom dies and a base table, a gap is formed between every two adjacent first supporting bodies, and at least one gap is a hoisting portion; a die further comprises a second bottom die, the second bottom die is fixedly arranged in the hoisting portion, the two ends, in the extending direction of a precast beam, of the second bottom die abut against the ends of the adjacent first bottom dies respectively, and the edges of the two sides of the upper surface of the second bottom die abut against the bottoms of two side dies; the supporting assembly, a bridge plate and the die are sequentially laid on the base table from bottom to top, and the longitudinal length and the transverse width of a precast pedestal can be freely adjusted according to the length and the width of the precast box beam; and meanwhile, the hoisting portion is arranged in the construction system, all assemblies laid in the hoisting portion are independent of non-hoisting portions, therefore the precast beam can be exposed only by detaching all the assemblies laid in the hoisting portion, and hoisting is facilitated.

Owner:武汉联展达岩土工程技术有限公司

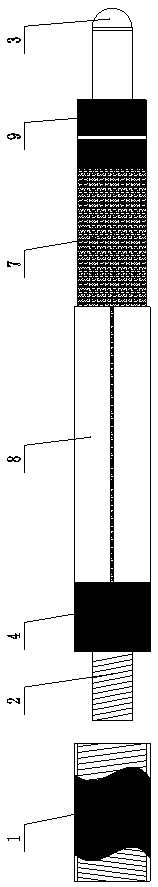

Coal mine underground deep hole quick sealing and grouting device

The invention discloses a coal mine underground deep hole quick sealing and grouting device and belongs to the technical field of coal mine underground grouting and hole sealing. The grouting device is high in engineering timeliness and grouting speed and large in diffusion radius and can achieve the objective of single-hole sectional continuous grouting. A one-way valve joint is of an internal thread structure with a forward thread at one end and a reverse thread at the other end, the reverse thread of the one-way valve joint is connected with the front end of a grouting central pipe, a sealing cover is hermetically mounted at the rear end of the grouting central pipe in a sleeved manner, a top cap, a turnbuckle, a one-way valve and a rubber sleeve are sequentially and fixedly mounted onthe outer wall of the grouting central pipe in a sleeved manner, the front end of the one-way valve is abutted against the top cap and the turnbuckle, each of two ends of the rubber sleeve is clampedand shaped through an iron core and an iron loop, an upper iron core on the rubber sleeve is fixed on the grouting central pipe, a lower iron core movably sleeves the grouting central pipe, and an inlet of the one-way valve is communicated with the inside of the grouting central pipe while an outlet of the same is communicated with the rubber sleeve.

Owner:刘彦俊

Concrete slab construction process in storage yard

InactiveCN105951982AAdjust vertical tiltAdjust straightnessForms/shuttering/falseworksBuilding material handlingYardDeckle

The invention discloses concrete slab construction process in a storage yard. Through concrete slab construction process in the storage yard, a host of process improvements can be made on manufacture and erection of a template, concrete control, installation of drive rods and processing of slab slits such that the template is convenient and rapid to erect and dismount and vertical inclination and straightness of the temperature can be flexibly regulated. The template is firmly fixed and has good pulp-checking effect. The drive rods are accurate in positions and straightened. The top surface of the slab is flat without crack. Top-loosening and aggregate exposure can be avoided so that problems such as corner missing, deckle edges, laps of slab slits and rainwater the drive rods are prevented and the drive rods are not corroded. The quality and appearance quality of the concrete slab construction are ensured in order to provide experience to concrete slab construction in the storage yard.

Owner:CCCC FIRST HARBOR ENG +1

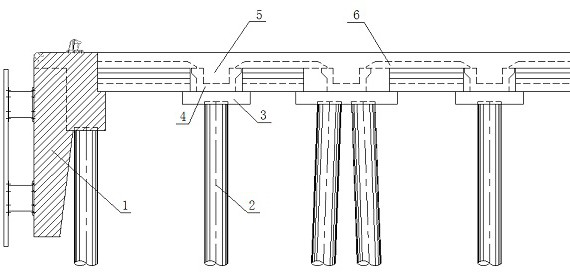

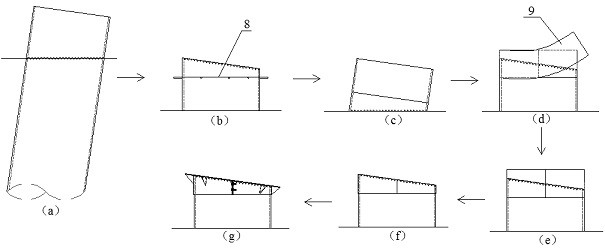

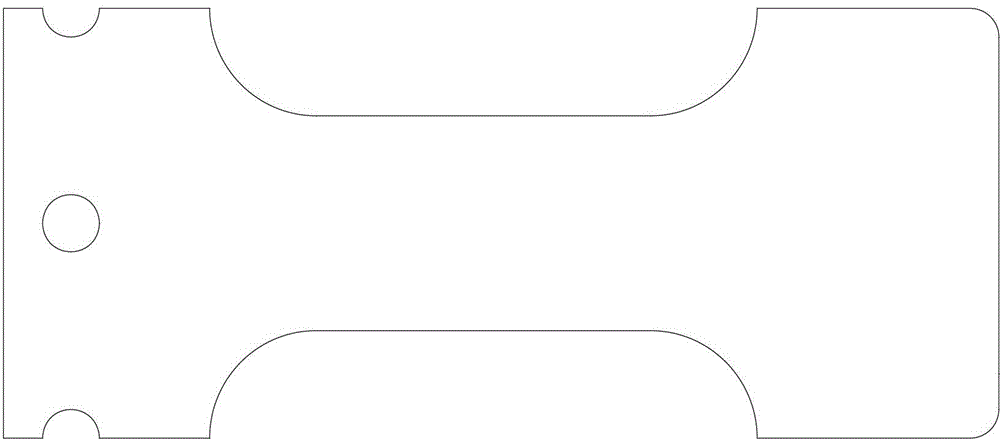

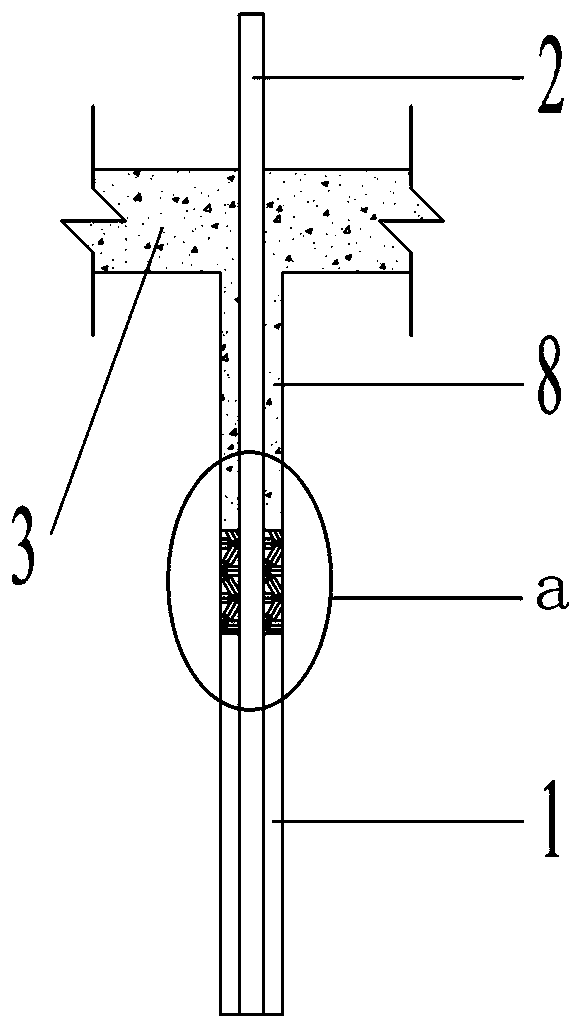

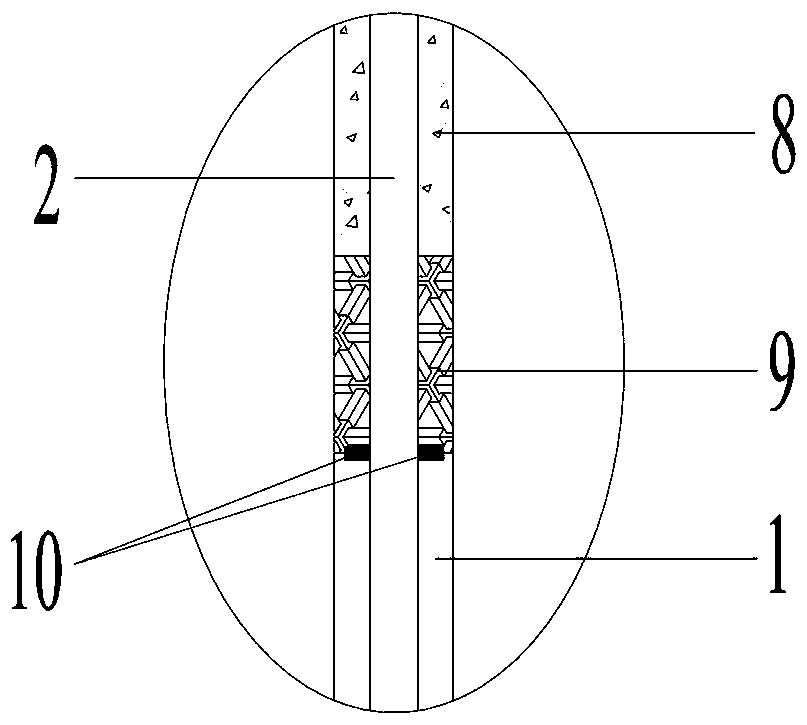

Machining method of bottom sealing hoop for fabricated pile cap construction

PendingCN112431191AEasy and efficient installationGood slurry effectBulkheads/pilesPile capArchitectural engineering

The invention discloses a machining method of a bottom sealing hoop for fabricated pile cap construction. The method includes the steps of (1) selecting a mould; (2) selecting a hoop material; (3) machining the hoop; (4) selecting an annular blocking plate material and discharging; (5) welding an annular blocking plate; (6) welding connecting bolts and cutting; and (7) stopping gouting. Accordingto the machining method of the bottom sealing hoop for fabricated pile cap construction, when the bottom sealing hoop is applied to assembly type pile cap construction, the bottom sealing hoop is convenient and efficient to install (12 sets of bottom sealing hoops can be installed in a single set every day and under the condition that the bottom sealing hoop is affected by damp levels), and the grout stopping effect is good.

Owner:NO 5 ENG CO LTD OF CCCC FIRST HARBOR ENG

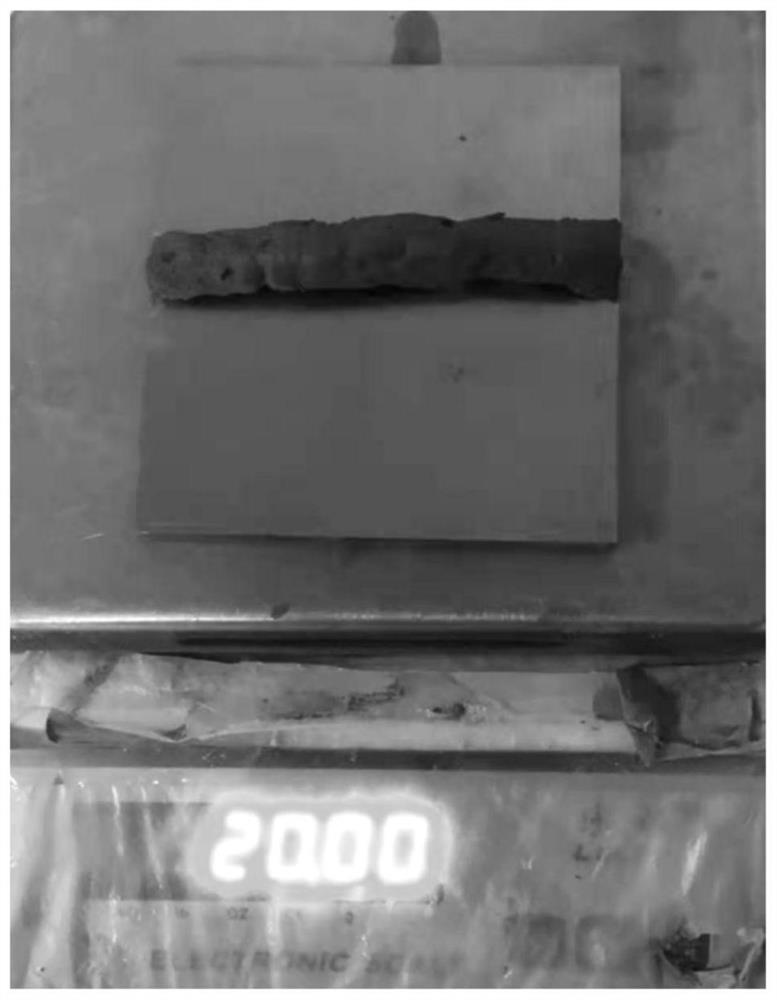

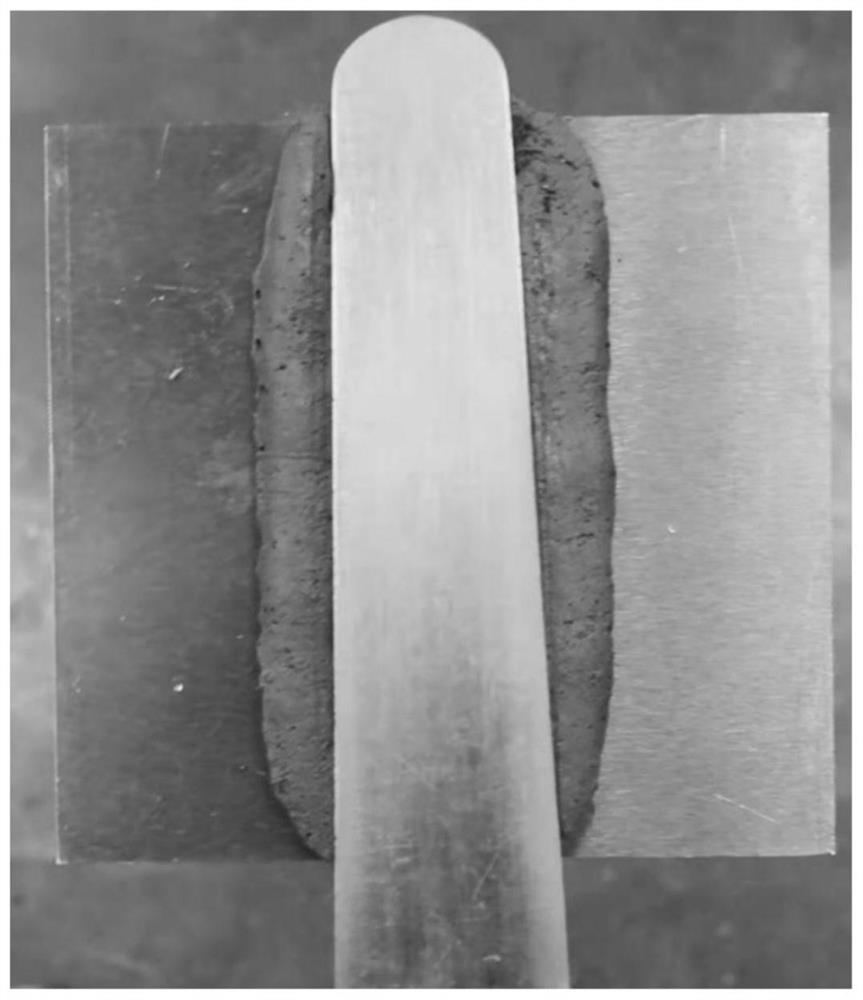

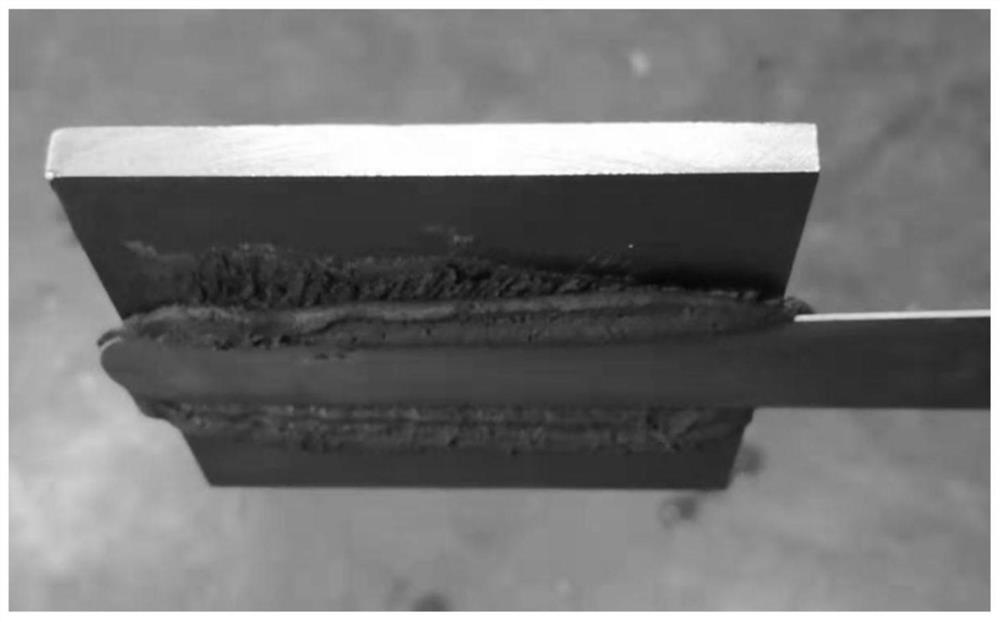

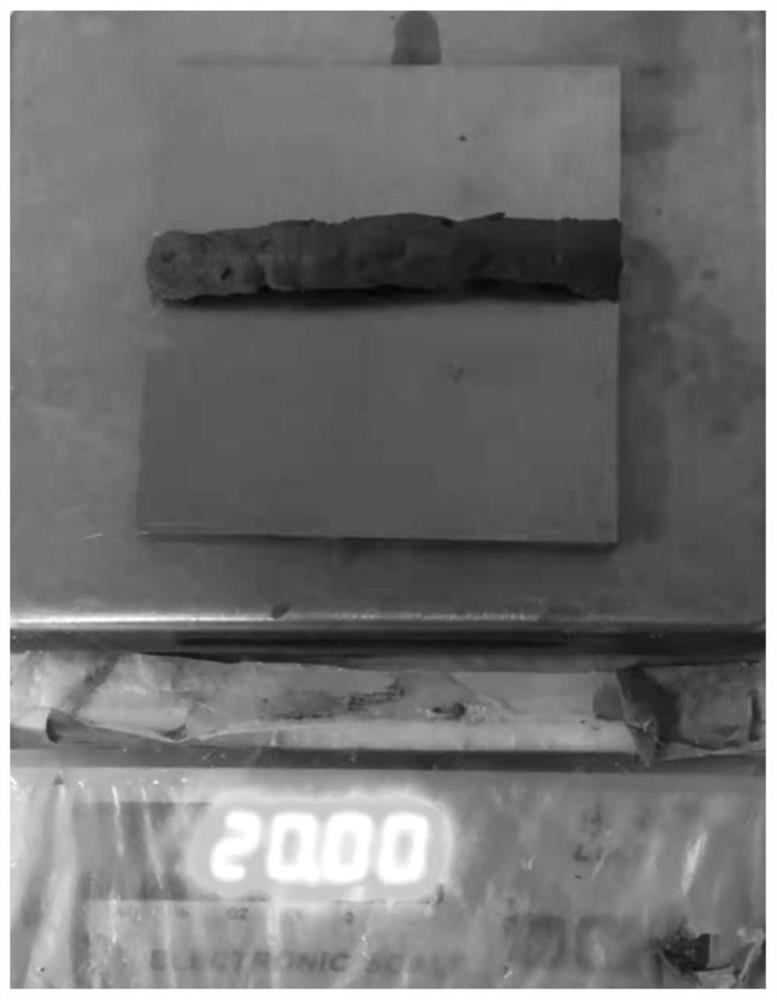

Tubular pile joint closing and grout stopping slurry as well as preparation method and application thereof

ActiveCN112759310ANot easy to throw outOvercome the impact of the work environmentSolid waste managementCentrifugationWorking environment

The invention discloses tubular pile joint closing and grout stopping slurry as well as a preparation method and application thereof, and belongs to the technical field of tubular piles. The tubular pile joint closing and grout stopping slurry has little elasticity, can only fill gaps after being clamped by a mold, cannot cause mold deformation caused by the fact that the gaps are jacked up, and is good in deformation resistance; and the slurry has certain viscosity, so that the slurry is not easily thrown out of gaps during centrifugation, and a good slurry stopping effect is achieved. And meanwhile, too large viscosity cannot be generated on the mold, and the slurry can form blocks after being evaporated to dryness, so that the slurry can be smoothly removed during demolding and cleaning, and the defects that the working environment is influenced due to flying dust generated when the powdery slurry is removed are overcome.

Owner:GUANGDONG SANHE PILE CO LTD

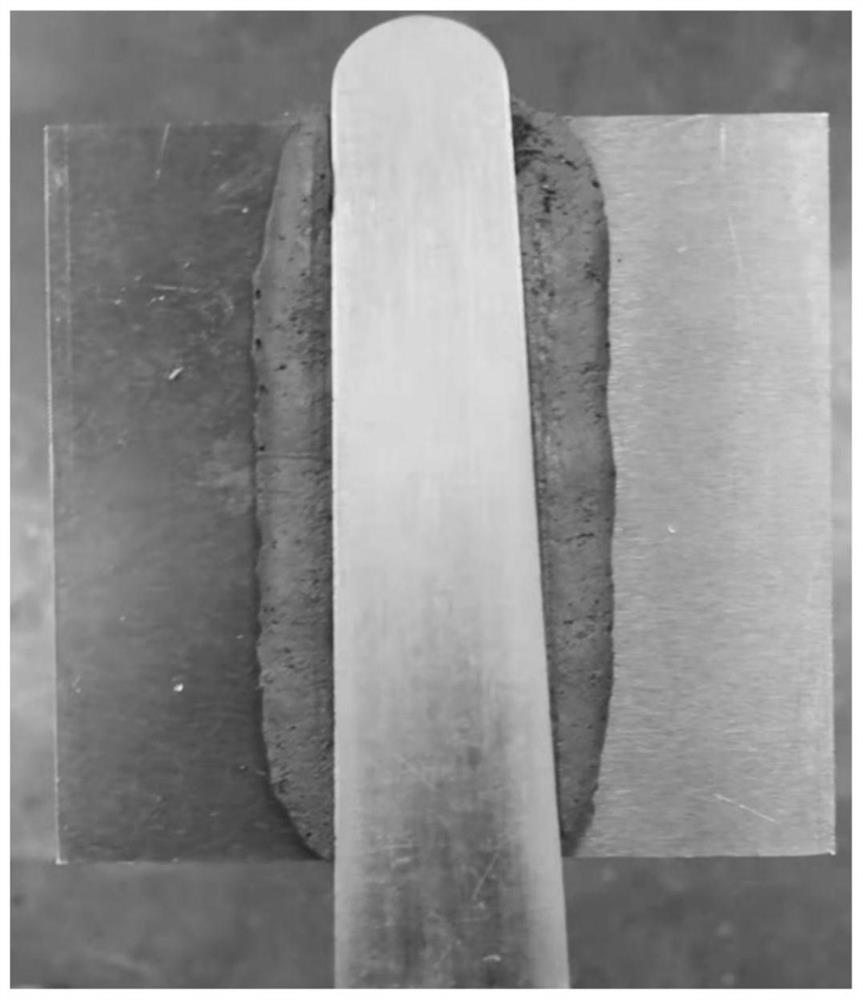

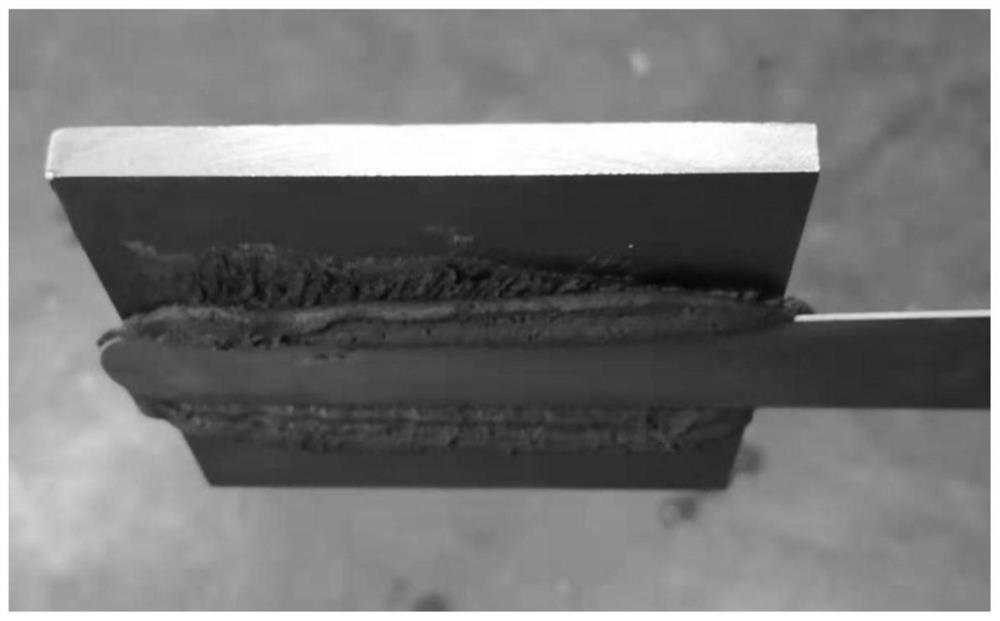

Rubber blanket slurry stopping process for position of prefabricated part protruding bars

InactiveCN106042172AFix loose or droppedGood slurry effectAuxillary shaping apparatusRebarPolypropylene

The invention discloses a rubber blanket slurry stopping process for the position of prefabricated part protruding bars. Polypropylene slurry stopping strips are replaced by rubber slurry stopping blankets, the rubber slurry stopping blankets of which the diameter is equal to that of the protruding bars can be selected according to the diameter of the protruding bars during operation, the protruding bars are sleeved with the rubber slurry stopping blankets, positions of the rubber slurry stopping blankets are adjusted so that circular washers of backseats of the rubber slurry stopping blankets can be closely attached to an inner formwork, no gap exists between the rebars and the rubber slurry stopping blankets as well as between the rubber slurry stopping blankets and the formwork, and the slurry stopping effect is achieved. Due to the fact that cylindrical rubber rings can well wrap the rebars in a fastening mode, and meanwhile baffle pieces are arranged on the rear portions of the rubber slurry stopping blankets, so that the phenomenon of loosening or falling of slurry stopping materials caused during adjustment of the length of the rebars and vibration is well eliminated, and the better slurry stopping effect is achieved.

Owner:CCCC FIRST HARBOR ENG +1

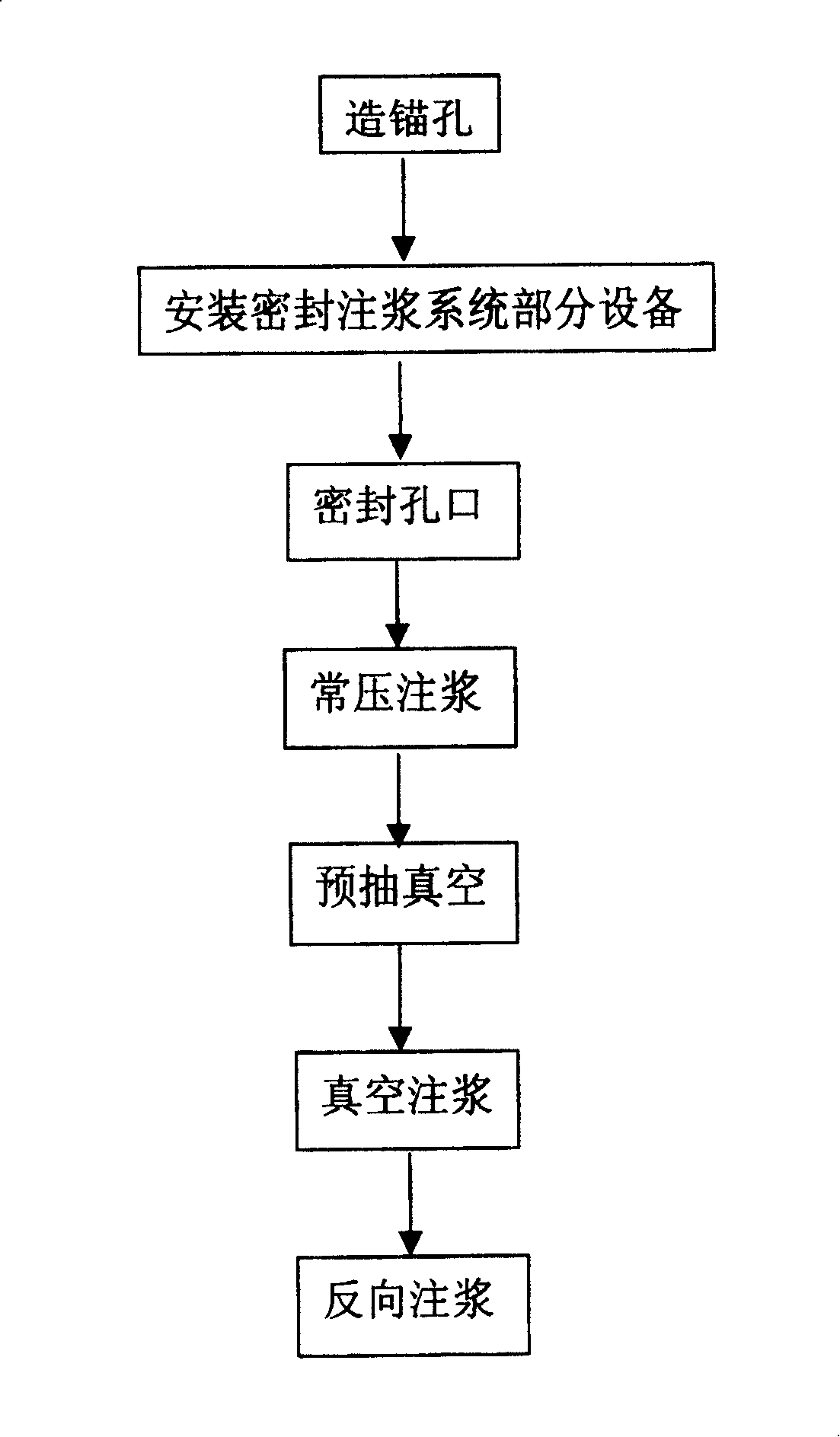

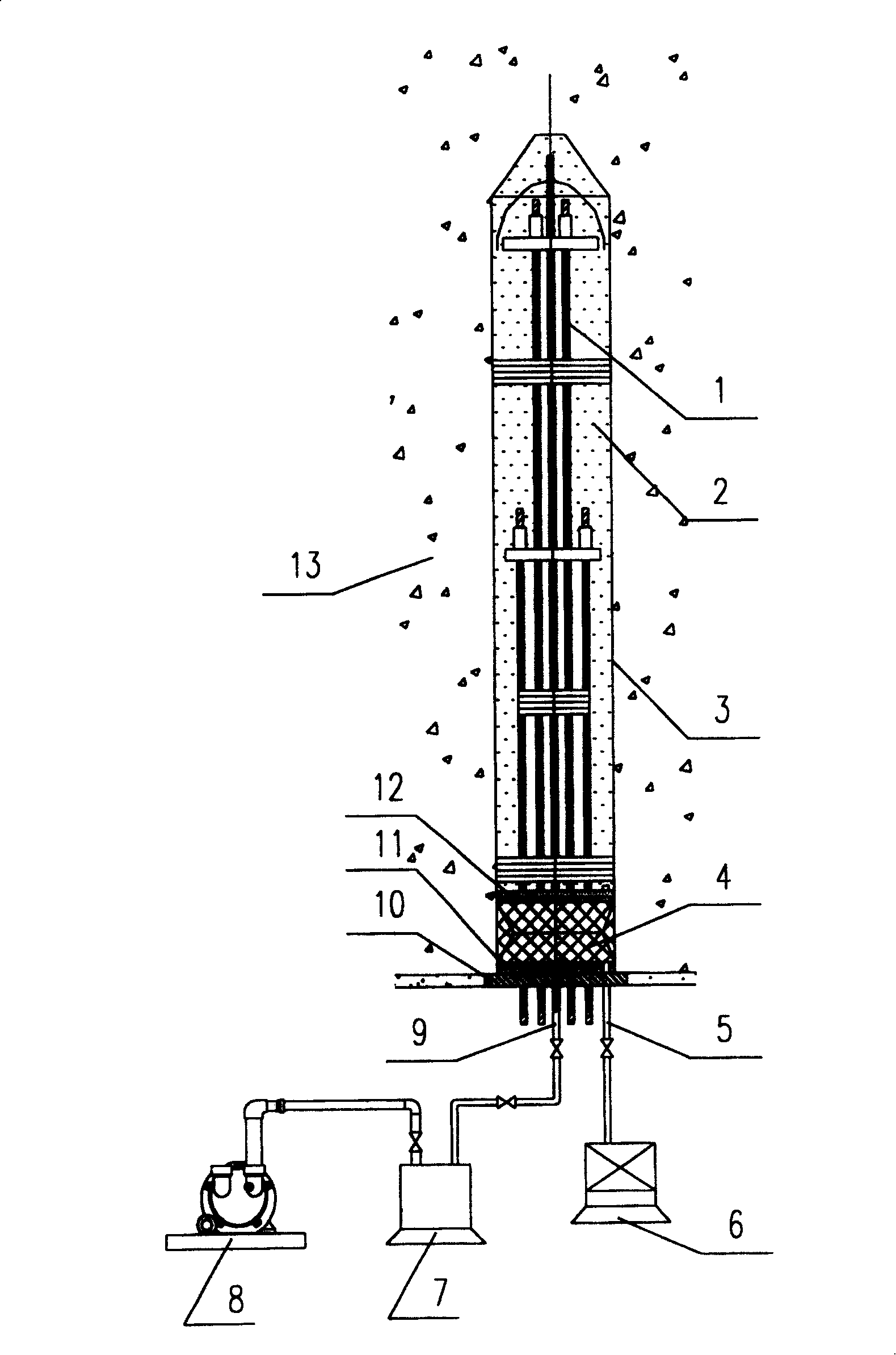

Vertical pipe vacuum pre pressing bidirectional slip casting method and sealed slip casting system thereof

The invention is a vertical-tube vacuum-precompression bidirectional slip casting method, comprising the steps of making hole, installing seal slip casting system, sealing orifice, normal-pressure slip casting, prevacuumizing, vacuum slip casting, reverse slip casting, and so on; the seal slip casting system includes anchor hole, anchorage cable, orifice grout sealer, vacuum pump, slip casting pump, sealing plate, slip casting tube and vacuum tube, the orifice grout sealer situated at the orifice of the anchor hole, the sealing plate situated on the end surface of the orifice, epoxy resin poured between the sealing plate and the orifice grout sealer, the orifice grout sealer being bowl-structured, and one or more orifice grout sealers linked in series in the same or counter direction and closely fitting anchor hole wall, the vacuum tube passing through the sealing plate and the orifice grout sealer to reach the top of the anchor hole, and the slip casting tube passing through the orifice grout sealer and 30-40cm higher than the internal end surface of the orifice grout sealer.

Owner:LIUZHOU OVM MASCH CO LTD

A kind of advanced small conduit grouting structure and construction method thereof

ActiveCN109139048BGood slurry effectQuick closureUnderground chambersTunnel liningArchitectural engineeringRock tunnel

The invention relates to the technical field of tunnel construction, in particular to an advanced small pipe grouting structure and a construction method thereof. According to an advanced small pipe,quick closure of a primary support can be ensured, a grout stopping wall and the primary support form an integral stress structure and are tightly attached to a tunnel face, so that the stability of the tunnel face is increased, the safety risk of the tunnel face is greatly reduced, and soft rock tunnels and special geological tunnels excavated by blasting are facilitated; and the grouting structure is simple, the application of the grout stopping wall basically does not occupy the application time of the primary support, the grout stopping wall can be applied synchronously with the primary support, the construction speed is high, rapid grouting can be realized, a great deal of time is saved and the construction progress is speeded up compared with the set of the grout stopping wall alone,and grout stopping wall can be used as a part of the primary support without dismantling after the grouting of the advanced small pipe is finished. The advanced small pipe is factory processed, and has convenient and quick installation and grouting. The grout stopping wall is of an integral structure, has good grout stopping effect, can bear large grouting pressure, and greatly ensures the grouting effect of the advanced small pipe.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Different-diameter self-adaptive expansion grouting device and reinforcement method at the cracked and damaged part of the second lining of the tunnel

ActiveCN110778332BSolve the technical problems of grouting reinforcementHigh strengthUnderground chambersTunnel liningClassical mechanicsSlurry

The invention discloses a different-diameter self-adaptive expansion grouting device and a reinforcement method for the cracked and damaged part of the second lining of the tunnel. It includes a body and a damper, and the damper is arranged at the end of the body; In the direction of the damper, the slurry outlet section, the first expansion section, the second expansion section and the grouting section are arranged in sequence; several slurry outlet holes are evenly distributed on the slurry outlet section; the expanded diameter of the first expansion section greater than the expanded diameter of the second expansion section. The grouting device can realize compacting grouting and splitting grouting at the same time, and improves the overall strength and stability of the reinforced surrounding rock through compacting and splitting filling.

Owner:SHANDONG UNIV

A construction method for medium-controlled grouting reinforcement range of large-porosity giant rock heap loose body

ActiveCN107013231BReduce configuration requirementsSolve the problem of drilling easily stuck drillUnderground chambersTunnel liningSleeve valveEngineering

The invention discloses a construction method for controlling the grouting reinforcement range in a huge rock heap loose body with large porosity, measuring and setting the grouting hole positions of the grouting curtain around the grouting reinforcement area. Use a large-scale pipe drilling rig to drill into the grouting curtain grouting hole. Inject the sleeve valve housing material. Insert the grouting core pipe and complete the grouting of the grouting curtain holes row by row to form a grouting curtain wall that limits the surrounding area of the grouting reinforcement area. Rows of jump holes are drilled into the grouting holes in the grouting reinforcement area. When the grouting at the bottom 3 meters of all the grouting drilling holes is completed, the grouting curtain wall at the bottom of the grouting reinforcement area is formed. The bottom grout-stop curtain wall is cross-closed with the surrounding grout-stop curtain walls, and finally forms a "U"-shaped grout-stop curtain that controls the scope of grouting reinforcement. The "U" grout-stop curtain wall formed on the periphery of the specific grouting reinforcement area can effectively prevent the loss of a large amount of grout caused by the overhead structure in the loose body of the rock pile when the ordinary grouting process is used. The construction speed is fast, the work efficiency is high, and the total management cost is reduced. Low.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

A joint grout stop device for steel-concrete combined section and its construction method

ActiveCN108660934BGuaranteed seam stop effectImprove stabilityBridge structural detailsBridge erection/assemblyArchitectural engineeringEngineering

The invention discloses a joint grouting-stopping device for a steel-concrete combined section and a construction method thereof, and relates to the technical field of joint grouting-stopping construction. The joint grouting-stopping device for the steel-concrete combined section and the construction method thereof aim at solving the problem that when a steel structure of the steel-concrete combined section is mounted, a hanging basket and a side formwork are both dismantled, and no good grouting-stopping measure is set to ensure the concrete construction quality. According to the technical key points, the joint grouting-stopping device comprises an upper wing plate; a lower wing plate is arranged below the upper wing plate parallelly, the centers of the upper wing plate and the lower wingplate are connected with a vertically-arranged supporting plate, the lower wing plate is in a U shape, and an opening of the lower wing plate faces the upper wing plate; and the lower wing plate is formed by manufacturing and machining a polyurethane-type water swelling elastic waterproof material. During construction, the supporting plate and the lower wing plate are clamped into the joint, thenthe upper wing plate is fixed to the two sides of the joint, the lower wing plate is bent towards the upper wing plate under the action of the downward pressing force to closely abut against the twoside walls of the joint, and accordingly the grouting-stopping effect can also be ensured while construction is facilitated.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

One-time prefabricated construction method of double-column wave-dissipating body

ActiveCN103171052BSolve common quality problemsSimplify on-site construction proceduresBreakwatersQuaysEngineeringPrefabrication

The invention discloses a double-column wave-dissipating body one-time prefabricating construction method which comprises the following steps: (1) prefabricating a concrete bottom tire; (2) paying off and bottoming; (3) binding steel bars; (4) erecting a template; (5) hoisting top steel bars; (6) reserving a lifting hole; (7) grouting the template; (8) concrete pouring; (9) removing the template; and (10) maintaining. According to the double-column wave-dissipating body one-time prefabricating construction method, by adoption of the one-time casting molding of set combined spliced steel template, the novel lifting design and the grouting method, the field construction process is simplified, various quality problems in the traditional prefabricating process for the double-column wave-dissipating body are solved, the working efficiency is improved, the cost is saved, and an obvious effect is achieved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

A convenient grouting sleeve device suitable for grouting behind walls and its application method

ActiveCN108166993BChange the method of applicationEasy to handleUnderground chambersTunnel liningEngineeringFront loading

The invention relates to a convenient grouting sleeve device suitable for backwall grouting and a use method thereof. The grouting sleeve device can be divided into a front-loading grouting pipe set,a stop grouting expansion rubber sleeve and direct set, an intermediate connecting device and a grout inlet pipeline. The front-loading grouting pipe set includes an ordinary steel tube with an internal thread at one end and four small-bore grout sealing tubes welded at the periphery and provided with overhanging ports of 45-degree inclined angle on the outer wall; a four-way device of the grout inlet pipeline is a stainless steel four-way device with valves at each of end ports, and three end ports are a grout A end port, a grout B end port and a pressure relief end port; and a tube head cover is a round pipe plug device with an external thread at one end, and a grouting hole can be plugged after the tube head cover is screwed. Compared with existing devices, the convenient grouting sleeve device suitable for the backwall grouting successfully realizes the convenient handling of end sockets, the recycle of the device and the rapid restoration of the wall surface, greatly improves thework efficiency, reduces the cost expenditure, and can be widely used in backwall grouting construction.

Owner:SHANDONG UNIV

A kind of pipe pile joint joint slurry and its preparation method and application

ActiveCN112759310BNot easy to throw outOvercome the impact of the work environmentSolid waste managementCentrifugationClassical mechanics

The invention discloses a grout-stopping slurry for joint joints of pipe piles and a preparation method and application thereof, belonging to the technical field of pipe piles. The pipe pile joint seam-stopping slurry of the present invention has a little elasticity, can only fill the gap after being clamped by the mold, and will not cause the gap to be lifted up, causing the mold to deform, and has good deformation resistance; The viscosity of the slurry makes it difficult for the slurry to be thrown out of the gap during centrifugation, and achieves a good slurry stop effect. At the same time, it will not cause excessive viscosity to the mold. After the slurry is evaporated to dryness, it can form a block, so that the slurry can be released smoothly when it is demolded and cleaned, so as to overcome the dust generated when the powder slurry is removed, which affects the working environment.

Owner:GUANGDONG SANHE PILE CO LTD

Method and device for grouting in hole and effectively stopping grout

The invention discloses a method for grouting in a hole and effectively stopping the grout. The method is divided into two main action processes, namely grouting and stopping the grount and comprises the following steps: drilling a hole, grouting, expanding with an expansion rubber plug, grouting and disassembling. The device for realizing the method for grouting in the hole and effectively stopping the grout comprises a grout inlet pipe (1), a grout pipeline, an expansion stop-grouting plug (11) and a single-way pressure valve (14) which are sequentially connected, wherein the grout pipelineand the expansion stop=grouting plug (11) as well as the expansion stop-grouting plug (11) and the single-way pressure valve (14) are connected by joints. The technology can stop the grout at any section in the grouted hole with good effect. Besides, steel grout transmission pipes can be conveniently removed from the device, thereby reducing the waste of the materials while ensuring the grout stopping effect.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Hole sealing structure for reinforcing shallow foundation through grouting method and construction technology thereof

The invention discloses a hole sealing structure for reinforcing a shallow foundation through a grouting method and a construction technology of the hole sealing structure, and belongs to the field ofshallow foundation reinforcing. The problem that sealing of a shallow foundation grouting hole is unreasonable is solved. The hole sealing structure comprises a grouting stop plate, grouting stop ribs, grouting holes, a hole sealing positioning belt and hole sealing concrete, the grouting holes penetrate through the grouting stop plate and an outdoor grouting stop plate to be evenly distributed on the two sides of a foundation wall, a positioning device is fixed to the grouting pipe so as to determine the position of the hole sealing positioning belt, the outdoor grouting stop plate is linearly arranged along the outer wall of the foundation wall, and the grouting stop ribs are embedded into foundation soil along the outdoor grouting stop plate. The construction technology of the hole sealing structure comprises the steps of early-stage preparation, foundation ditch excavation, drilling, grouting pipe installation and hole sealing. The grouting stop effect is good, construction is easy and convenient, shallow foundation bearing capacity and stability are greatly improved, the construction cost is low, and economic benefits are remarkable.

Owner:ZHENGZHOU UNIV

Method for preparing modified starch by oxidation and succinic anhydride esterification

InactiveCN101880335BImprove liquidityHigh viscosityFibre treatmentHigh concentrationMoisture absorption

The invention provides a method for preparing modified starch by oxidation and succinic anhydride esterification. The method comprises the following steps of: dissolving starch into water to form starch milk, performing oxidation reaction on sodium hypochlorite oxidant and starch to obtain oxidized starch, then removing chlorine, performing esterification reaction by adopting succinic anhydride, and finally dehydrating and drying the reaction product to obtain the modified starch. When the modified starch prepared by the method is used as starch size, the modified starch has the properties ofgood fluidity, low viscosity and high-concentration use of the oxidized starch; and because the succinic anhydride esterification solves the problem of poor thermal stability of the oxidized starch, the modified starch has the advantages that: adhesion of warps is remarkably improved; a size film has strong forming capability, good mechanical strength and extensibility; the paste has stable viscosity and good fluidity; the size has certain moisture absorption property; the modified starch has good co-solvency with a synthetic size; the film is easy to dissolve in water, and de-sizing is easy;and the paste has high thermal stability, is not affected by high-temperature melting and the like.

Owner:内蒙古奈伦农业科技股份有限公司

Preparation method of oxidative cationic modified starch slurry

InactiveCN101875701BImprove liquidityImprove thermal stabilityFibre treatmentHigh concentrationSlurry

The invention provides a preparation method of oxidative cationic modified starch slurry, which comprises the following steps of: firstly, dissolving starch into water to prepare starch milk; secondly, using an oxidant namely sodium hypochlorite to perform oxidation reaction with the starch to obtain oxidized starch; thirdly, removing chlorine; fourthly, adopting a cationic etherifying agent to perform etherification reaction; and finally, performing dehydration and drying. When the modified starch prepared from the starch serves as the slurry, the slurry not only has the characteristics of high fluidity, low viscosity and high concentration usage of oxidative starch slurry, but also solves the problem that the oxidative starch has poor thermal stability through quaternary ammonium etherification, and simultaneously, the slurry additionally obtains the following advantages that: the adhesiveness to a warp is significantly improved; the serous membrane forming capacity is strong, and the slurry is difficult to break and burst; the paste viscosity is stable, and the fluidity is good; the slurry has certain hygroscopicity, and has high co-solvency with a synthetic slurry; a membrane is easy to be dissolved in water, and is easy to desize; and paste solution has high thermal stability, is not influenced by high heat fusing, and the like.

Owner:内蒙古奈伦农业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com