Method and device for grouting in hole and effectively stopping grout

A technology of grouting and grouting, which is applied in the field of grouting in holes and effectively stops grouting, and realizes grouting in holes and effectively stops grouting. problems, to ensure the effect of stopping pulp, reduce material waste, and achieve good effect of pulping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further explained in conjunction with the accompanying drawings. It should be noted that the purpose of disclosing the present invention is to protect all structural changes and improvements within the concept of the present invention. Within the protection scope of the present invention.

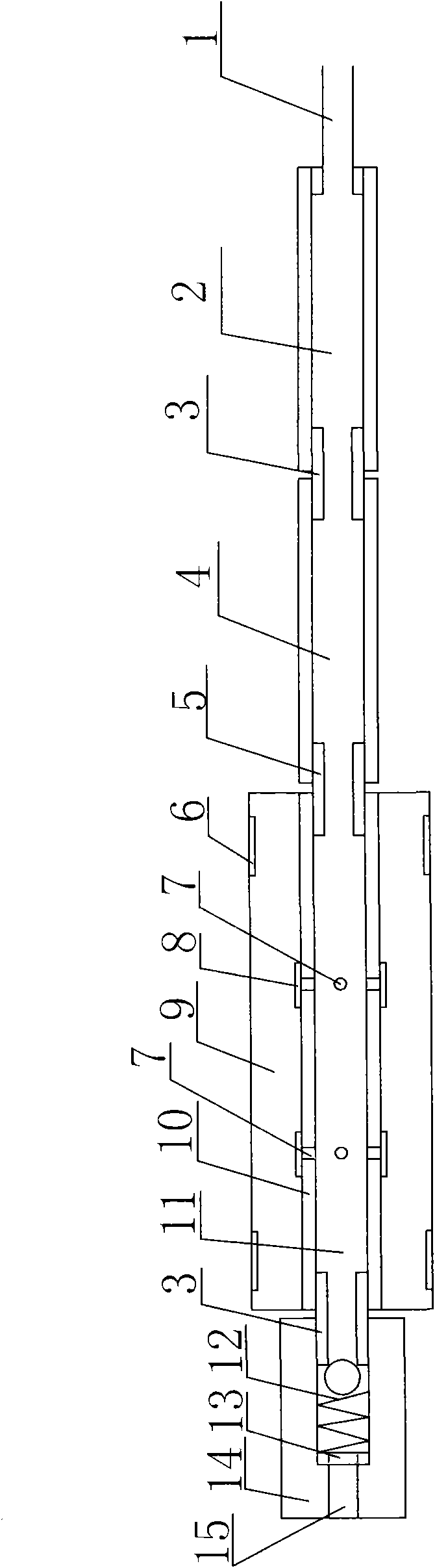

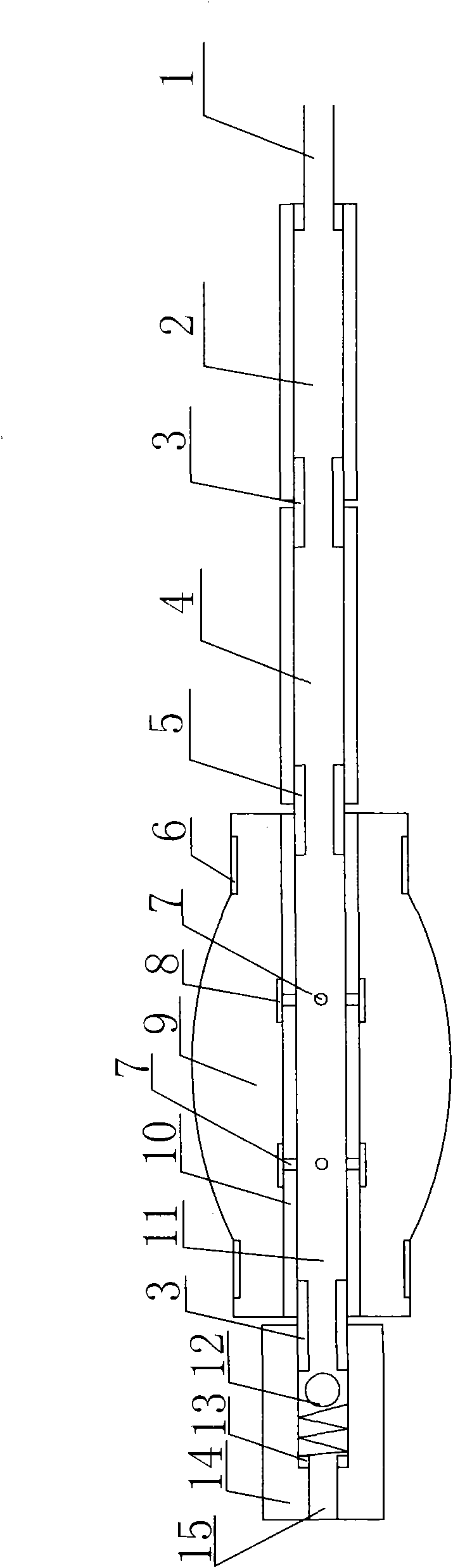

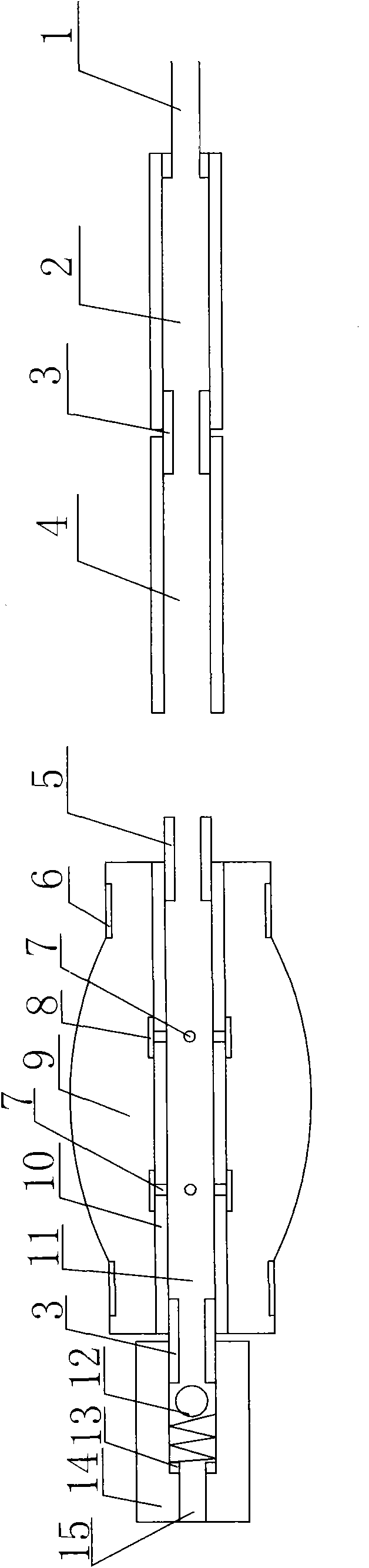

[0031] Such as figure 1 As shown, the grouting device of the present invention includes a grout inlet pipe 1, a grout delivery pipeline, an expansion stop plug 11, and a one-way pressure valve 14 connected in sequence; The positive thread screw at one end of the inner cavity of the steel pipe 2; the other end of the inner cavity of the type I slurry delivery steel tube 2 is connected to one end of the inner cavity of the type II slurry delivery steel tube 4 through the I-type joint 3, and both connections are screwed together with positive thread threads; The other end of the inner cavity of the slurry delivery steel pipe 4 is connected to the expansion stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com