Construction method for controlling grouting reinforcement range in large-porosity huge talus loose body

A technology of grouting reinforcement and large porosity, which is used in earthwork drilling, shaft equipment, wellbore lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

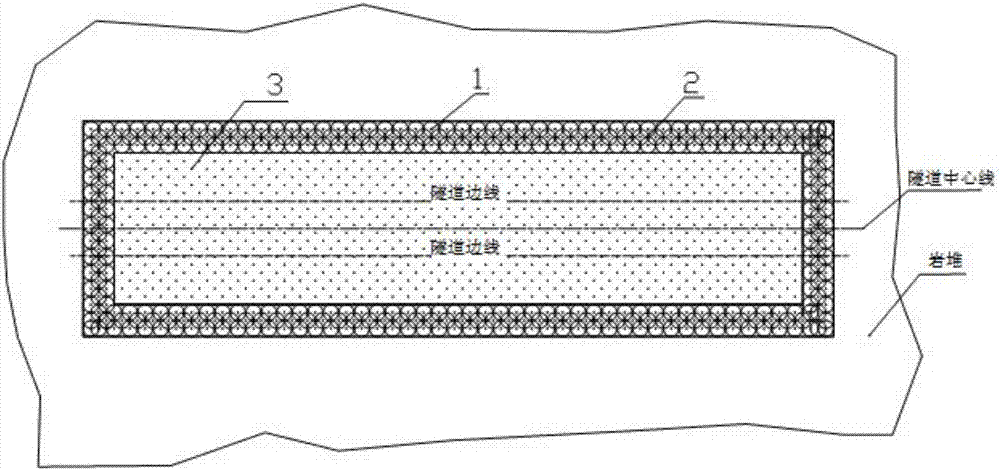

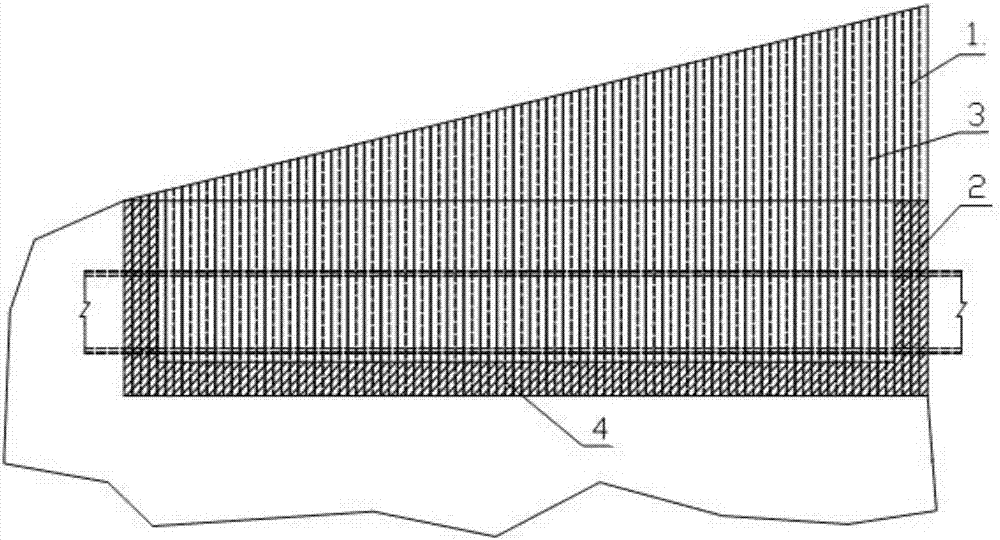

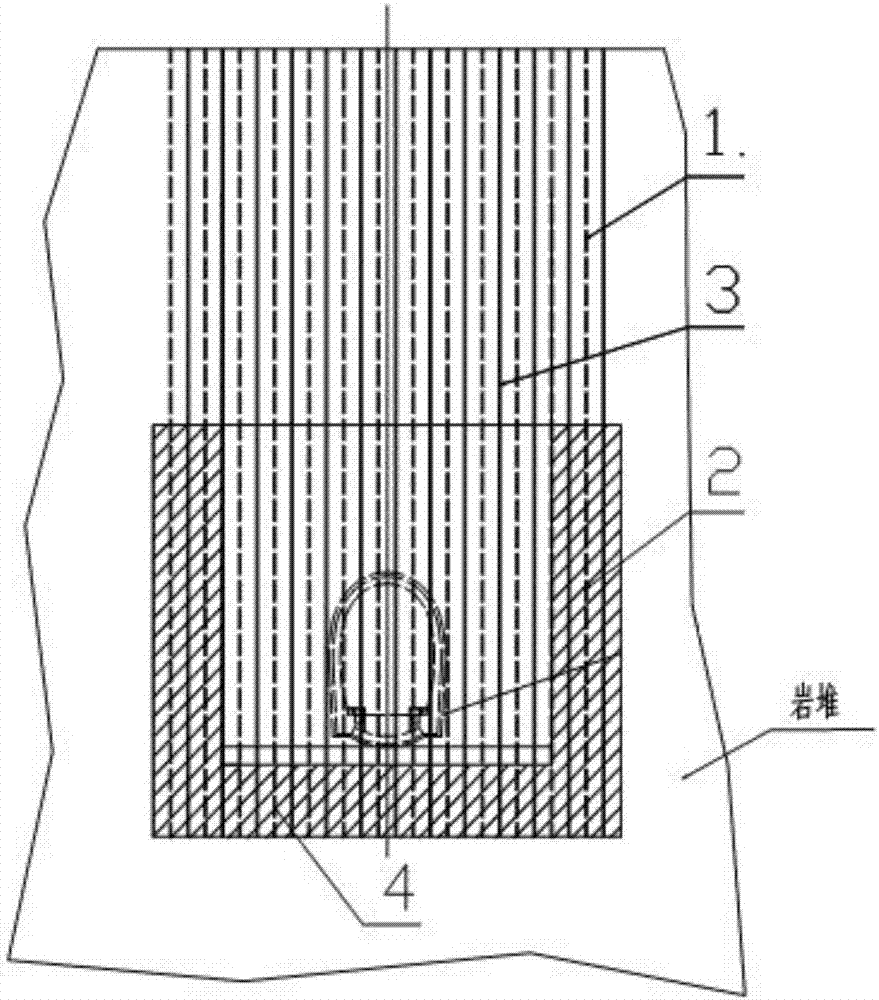

[0018] ① In the grouting reinforcement area of the rock pile, perform segmental leveling to form a multi-stage drilling and grouting platform, and then measure the positions of the three rows of grouting wall drillings (1) in the outermost grouting curtain grouting around the grouting reinforcement area. ②According to the order of first row outside, then row inside, and then row in the middle, use a large follow-up pipe drilling rig to drill holes into the grout-stop curtain grout-stop wall (1). ③ After the hole is formed, install the sleeve valve grouting pipe (5), pull out the drill hole and the pipe, inject the sleeve valve casing material (6), and use quick-setting cement mortar to seal within 1 meter above the top surface of the designed grouting range . ④ When the casing material reaches the grouting strength, insert the grouting core pipe (7), and adopt the sleeve valve pipe layered grouting process according to the drilling sequence, and inject the quick-setting expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com