Direction and location slurry injection reinforcing method for particular area in giant rock heap loose body with large porosity

A technology of grouting reinforcement and large porosity. It is applied in the direction of earthwork drilling, mining equipment, tunnels, etc. It can solve the problems of safety accidents, no adhesive force, easy local collapse in excavation, etc., and achieve the grouting position and grouting Quantity control, easy grouting position and grouting volume, and good orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

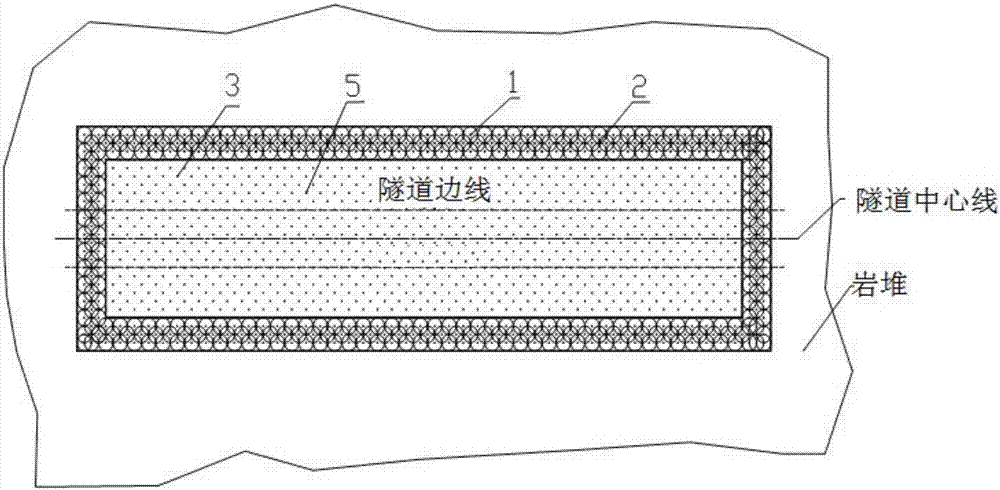

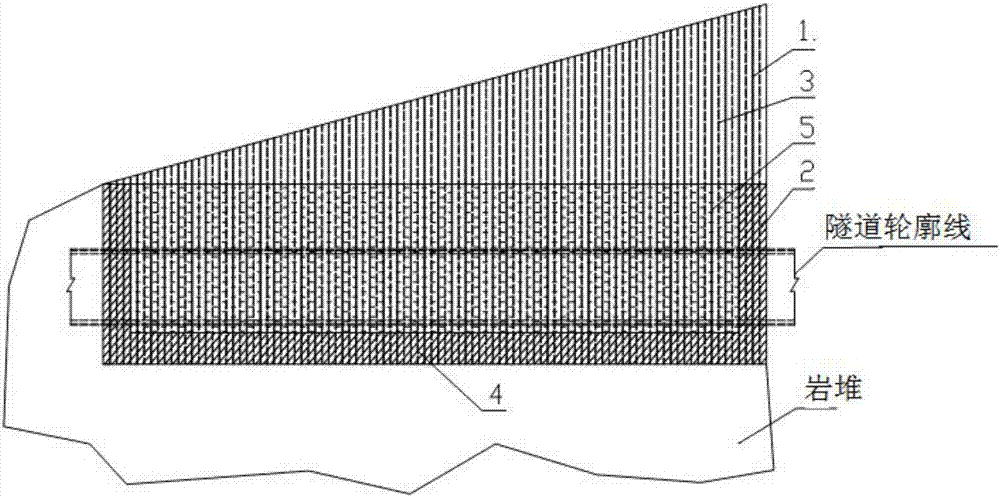

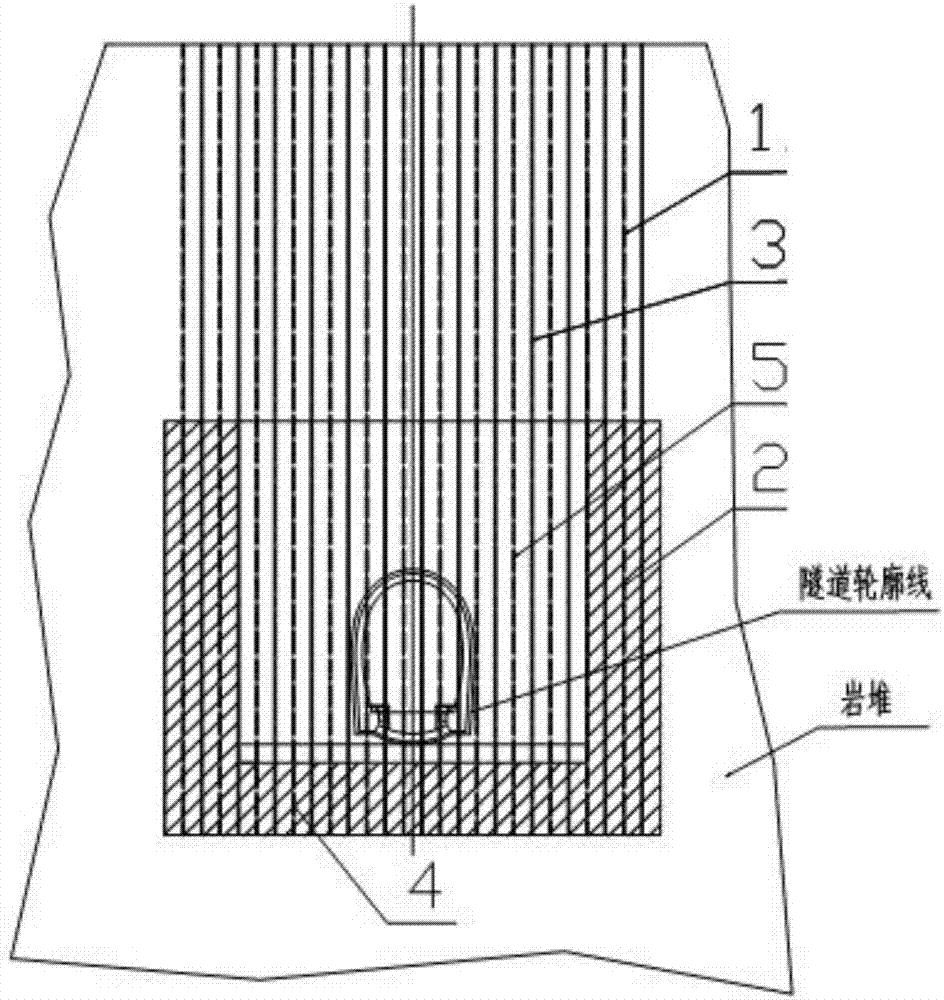

[0022] ① Form a multi-stage drilling and grouting platform in the rock heap grouting reinforcement area, and then measure the position of the grouting curtain grouting wall drilling (1) around the grouting reinforcement area. ②Drill holes (1) in the surrounding curtain grouting wall, and inject quick-setting expansion grout (Naite Reinforcement No. Ⅱ) layer by layer using the sleeve valve layered grouting process to complete all the curtain grouting wall drillings (1) After the grouting, the surrounding grouting curtain wall (2) is formed. ③According to the method and steps in ②, carry out grouting drilling (3) drilling in the grouting reinforcement area and grouting at the bottom 3 meters of the grouting curtain wall (4) at the bottom of the hole. After the grouting is completed, the grouting curtain wall (4) at the bottom of the grouting reinforcement area is formed. ④The bottom grout-stop curtain wall (4) is closed with the surrounding grout-stop curtain wall (2) to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com