Machining method of bottom sealing hoop for fabricated pile cap construction

A processing method and prefabricated technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of construction limited by moisture, low template support and dismantling efficiency, affecting installation progress, etc., to achieve convenient and efficient installation, and prevent slurry good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

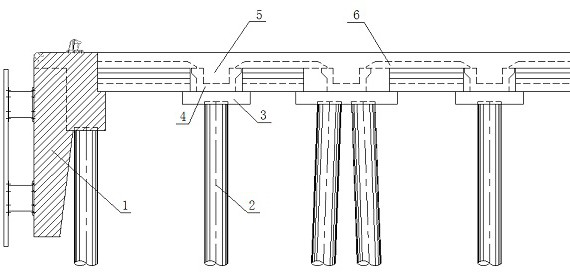

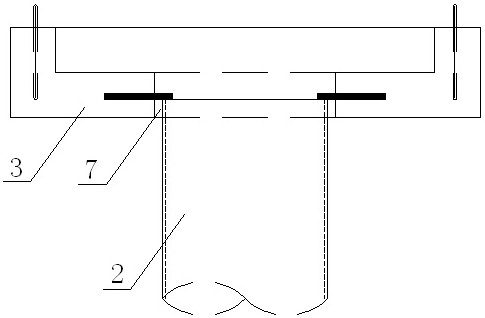

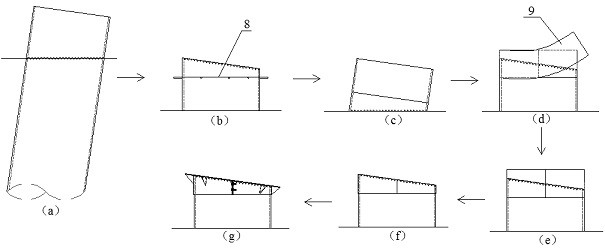

[0037] combine image 3 , Figure 4 , Figure 5 and Image 6 As shown, a method of processing the bottom cover hoop for the construction of an assembled pile cap, through the following steps:

[0038] 1) Mold selection

[0039] The cut steel pipe pile head is used as the mold for the hoop processing, and the straight pile is used directly; the incision of the inclined pile head is ground and smoothed, and the supporting steel bar 8 required in the hoop processing process is welded, and the supporting steel bar 8 is Ø12mm* 10cm;

[0040] 2) Selection of hoop material

[0041] In order to ensure that the hoop is easy to bend, the material of the hoop is 3mm thick thin steel plate 9, the straight pile hoop needs to be cut into a 10cm wide thin steel strip, and the inclined pile hoop needs to be cut into a 33cm wide thin steel strip;

[0042] 3) hoop processing

[0043] Place the long side of the thin steel plate 9 around the hoop to process the mold and place it on the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com