LED (Light Emitting Diode) lamp module radiator

An LED lamp module, LED lamp technology, applied in lighting and heating equipment, cooling/heating device of lighting device, lighting device, etc. The effect of large heat dissipation area, weight reduction, and convenient cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

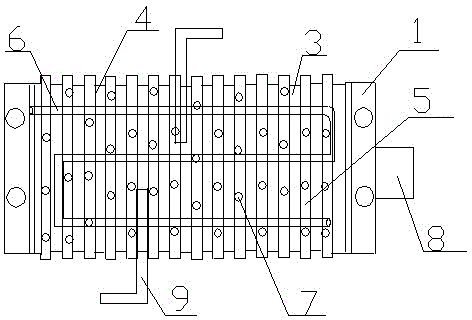

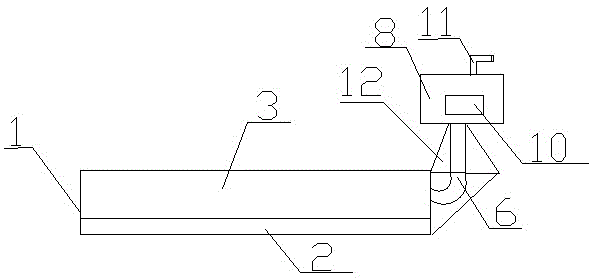

[0013] Such as figure 1 figure 2 The LED lamp module radiator includes a lamp holder template 1, an LED lamp panel 2 is provided on one side of the lamp holder template 1, a heat dissipation substrate 3 is provided on the other side of the lamp holder template 1, and a lamp holder One side of the template 1 is provided with an LED light panel 2 and the other side is provided with a heat dissipation substrate 3, which is conducive to timely transferring the heat generated by the LED light panel 2 to the heat dissipation substrate 3, and the heat dissipation through the heat dissipation substrate 3 is more convenient and efficient. 3 is provided with a groove 4, and the groove 4 is provided to facilitate the installation and disassembly of the heat sink 5, and also facilitates the cleaning work in the future. The groove 4 is provided with a heat sink 5, and the thickness of the heat sink 5 is The heat sink 5 with a thickness of 3mm-5mm is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com