A kind of pipe pile joint joint slurry and its preparation method and application

A technology for stopping pulp and pipe piles, applied in the field of pipe piles, can solve the problems that cannot be used for other purposes, the environment is unfriendly, the straw rope or cotton rope cannot be directly landfilled, etc., and achieves good operability and good pulp stoppage effect. , The effect of good anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

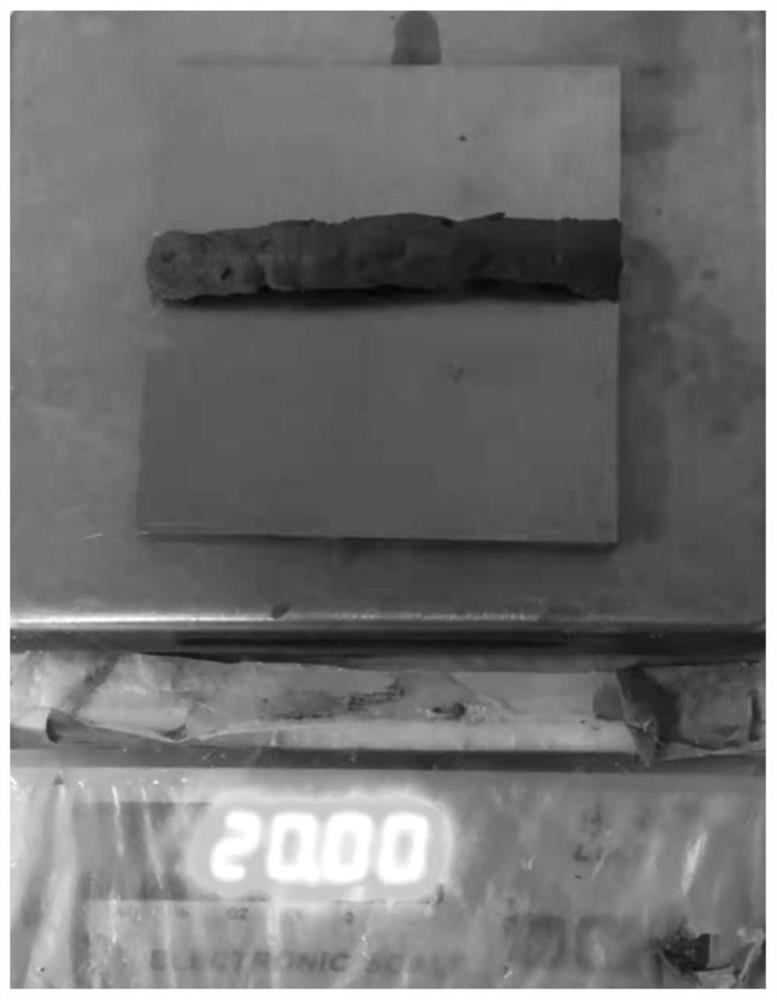

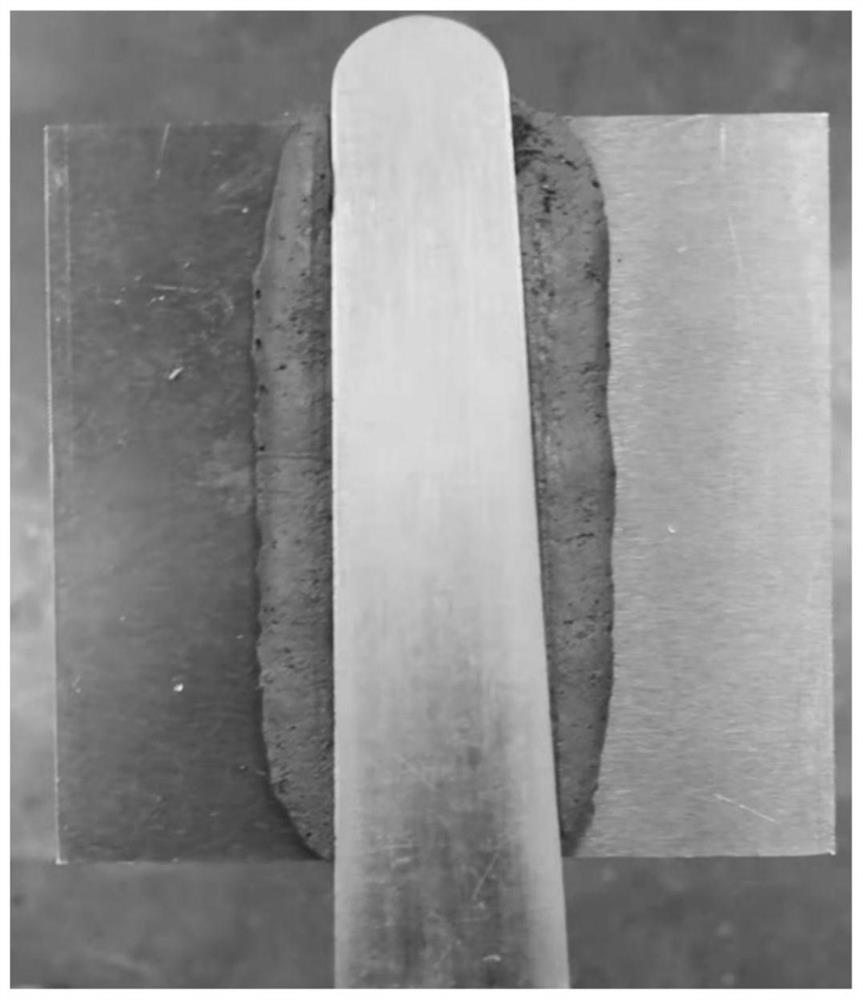

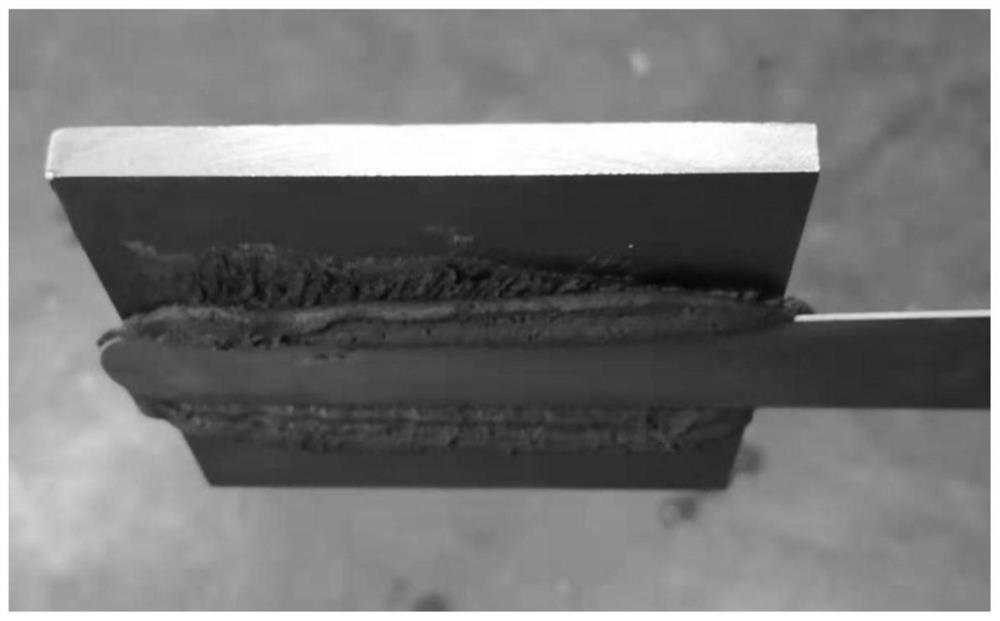

[0037] In this example, a pipe pile joint seam stop slurry is prepared, and the specific process is as follows: 63% fly ash, 1% pregelatinized starch, 0.1% methyl hydroxypropyl cellulose ether by mass percentage (viscosity (20℃) is 100000mPa·s), 1% bentonite, 0.1% polypropylene fiber (about 9mm in length), 2.5% crushed rubber particles (mesh 40-70 mesh) and balance water Stir and mix well to prepare pipe pile joint seam stop slurry.

Embodiment 2

[0039] In this example, a pipe pile joint seam-stopping slurry is prepared. The specific process is as follows: 70% by mass of fly ash, 2% of pregelatinized starch, and 0.5% of methyl hydroxypropyl cellulose ether (viscosity (20℃) is 100000mPa·s), 2% bentonite, 0.5% polypropylene fiber (about 12mm in length), 5% crushed rubber pellets (mesh 40-70 mesh) and balance water Stir and mix well to prepare pipe pile joint seam stop slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com