Juicer transmission shaft sleeve and manufacturing method thereof

A transmission shaft and juice machine technology, which is applied in household machinery for filtering food, household utensils, applications, etc., can solve problems such as heat generation, mutual wear of equipment, insufficient lubrication of transmission shaft sleeves, etc., achieve simple and convenient processing technology, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

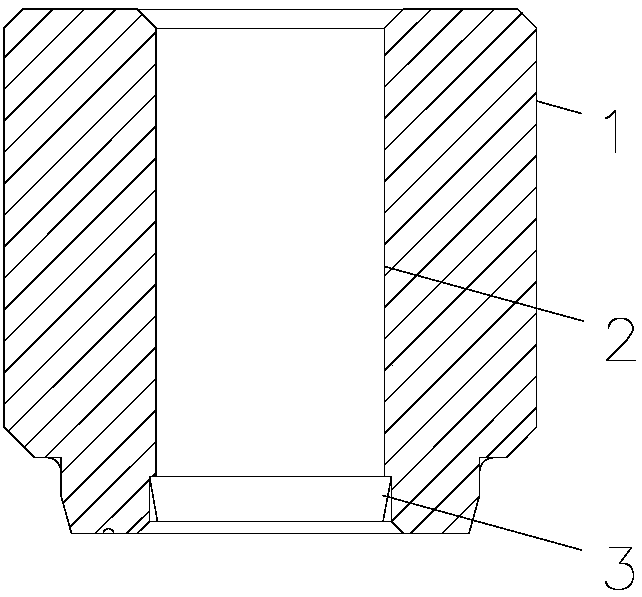

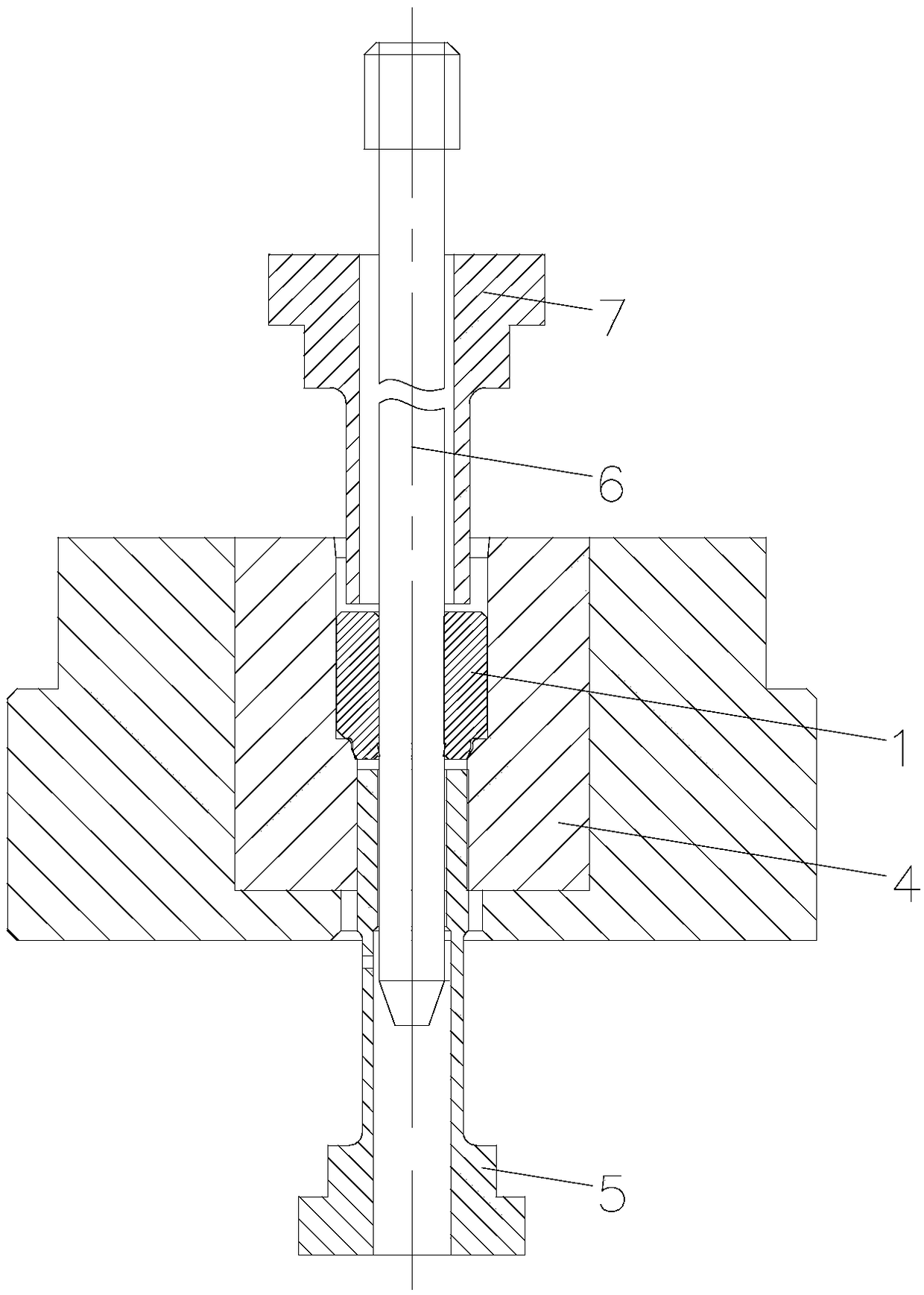

[0014] Such as Figure 1-2 Shown, a fruit juice machine drive shaft sleeve, including a body 1, the body 1 is opened with a through hole 2, the through hole 2 extends from the upper surface to the lower surface along the axial direction of the body 1, the through hole An oil storage tank 3 is opened on the inner peripheral wall of the body 2, and the cross-sectional area of the oil storage tank 3 gradually decreases from the inside to the outside along the axial direction of the body 1 .

[0015] The closing slope of the oil storage tank 3 is 5° to 25°.

[0016] A manufacturing method for processing the above-mentioned fruit juice machine transmission shaft sleeve, comprising the following steps: S1. When stamping the fruit juice machine transmission shaft sleeve, place the fruit juice machine transmission shaft sleeve in the mold 4, and the thimble 5 on the mold 4 The top is located at the end of the oil storage tank 3 on the drive shaft sleeve of the fruit juice machine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com