Ternary-dielectric-filled polymer conductive composite and preparation method

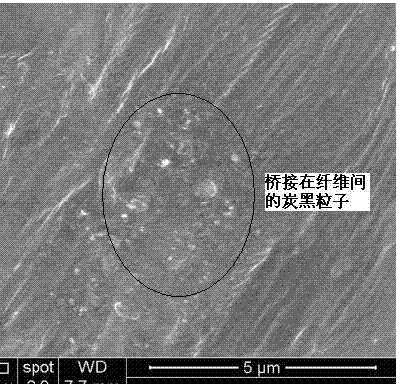

A conductive composite material, medium filling technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of reducing material processing performance, mechanical properties, low compatibility between stainless steel fiber and matrix, fiber and matrix interface Low strength and other problems to achieve the effect of making up for adverse effects, increasing bonding strength, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of a ternary dielectric filled polymer conductive composite material, comprising the following steps:

[0043] The first step: carbon black nickel plating treatment:

[0044] Carry out electroless nickel plating treatment to carbon black surface, carry out surface oxidation, sensitization and activation treatment to carbon black before carbon black nickel plating treatment, it comprises the following steps:

[0045] A. Degreasing: Degrease the carbon black in the alkali solution of sodium hydroxide: 60g / L, sodium carbonate: 10g / L, sodium phosphate: 25g / L, 6501 cleaning agent: 5g / L, temperature: 40-50 ℃, time: 40min, then wash with distilled water at room temperature to remove impurities; B, coarsening: Soak the carbon black after degreasing treatment in ammonium peroxodisulfate: 200g / L; sulfuric acid: 100ml / L roughening solution 10min, the temperature is 60~70℃, then neutralize in 60 g / L sodium hydroxide solution at room temperature, and finally wa...

Embodiment 2

[0058] A preparation method of a ternary dielectric filled polymer conductive composite material, comprising the following steps:

[0059] The first step: carbon black nickel plating treatment:

[0060] Carry out electroless nickel plating treatment to carbon black surface, carry out surface oxidation, sensitization and activation treatment to carbon black before carbon black nickel plating treatment, it comprises the following steps:

[0061] A. Degreasing: Degrease the carbon black in the alkali solution of sodium hydroxide: 50g / L, sodium carbonate: 15g / L, sodium phosphate: 20g / L, 6501 cleaning agent: 3g / L, temperature: 40-50 ℃, time: 30min, then wash with distilled water at room temperature to remove impurities;

[0062] B. Coarsening: Soak the carbon black after degreasing treatment in ammonium peroxodisulfate: 180g / L; sulfuric acid: 80ml / L roughening solution for 15min at a temperature of 60~70°C, and then oxidize it in 100 g / L hydrogen Neutralize with sodium solution, ...

Embodiment 3

[0075] A preparation method of a ternary dielectric filled polymer conductive composite material, comprising the following steps:

[0076] The first step: carbon black nickel plating treatment:

[0077] Carry out electroless nickel plating treatment to carbon black surface, carry out surface oxidation, sensitization and activation treatment to carbon black before carbon black nickel plating treatment, it comprises the following steps:

[0078] A. Degreasing: Degrease the carbon black in the alkaline solution of sodium hydroxide: 55g / L, sodium carbonate: 15g / L, sodium phosphate: 20g / L, 6501 cleaning agent: 4g / L, temperature: 40-50 ℃, time: 50min, then wash with distilled water at room temperature to remove impurities;

[0079] B. Coarsening: Soak the carbon black after degreasing treatment in ammonium peroxodisulfate: 190g / L; sulfuric acid: 90ml / L roughening solution for 20min at a temperature of 60~70°C, and then oxidize it in 50 g / L hydrogen Sodium solution for neutralizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com