Composite film

A composite film and raw material technology, applied in the field of plastic film products, can solve the problems of accumulation of plastic waste, environmental hazards, white pollution, etc., and achieve the effect of ensuring strength and toughness, low requirements, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

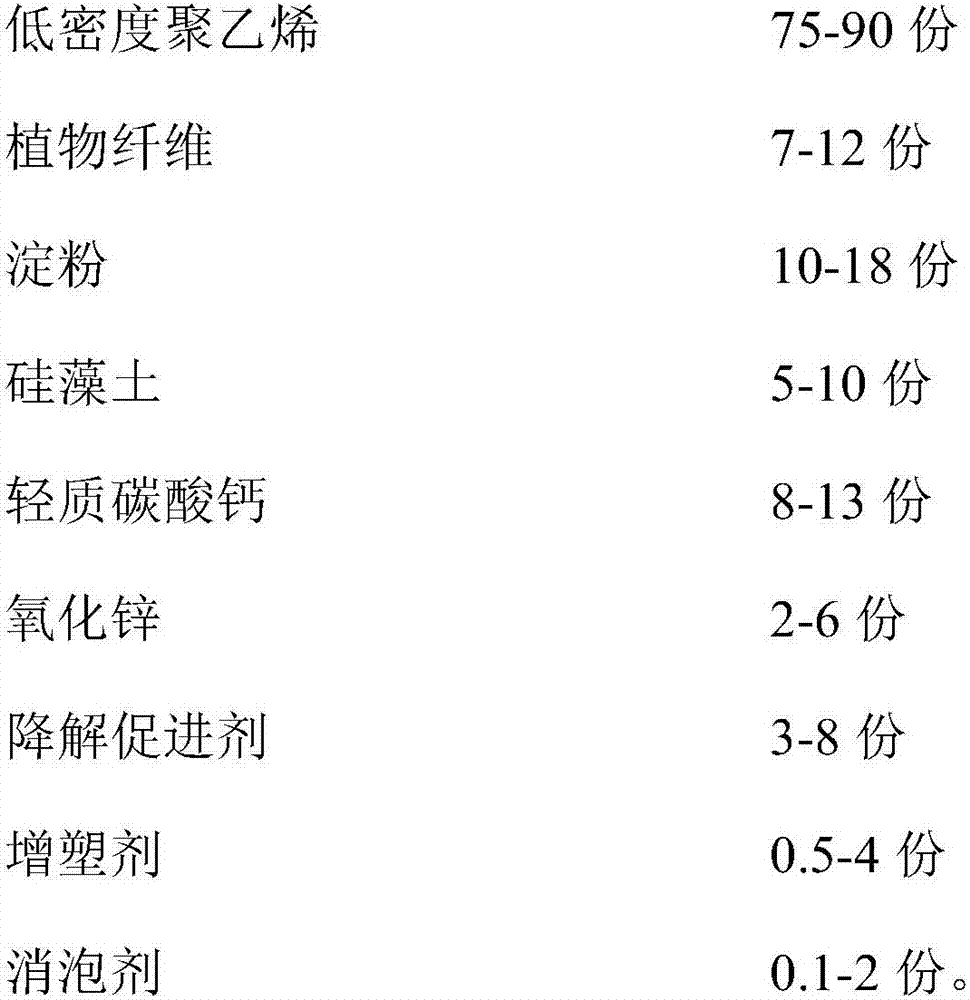

Method used

Image

Examples

Embodiment 1

[0019] A composite film, consisting of the following raw materials in parts by weight: 75 parts of low-density polyethylene, 7 parts of plant fiber, 10 parts of starch, 5 parts of diatomaceous earth, 8 parts of light calcium carbonate, 2 parts of zinc oxide, and a degradation accelerator 3 parts, 0.5 parts of plasticizer, 0.1 part of defoamer.

[0020] The preparation method of composite film, comprises the following steps:

[0021] Weigh the corresponding weight parts of the raw materials respectively, adjust the heating temperature of the high-speed mixer to 80°C, and the speed is 450r / min, add the starch into the high-speed mixer, add an appropriate amount of water, run for 30min, and then heat the The temperature rises to 120°C and the rotational speed is maintained at 500r / min. Add low-density polyethylene, plant fiber, starch, diatomaceous earth, light calcium carbonate, zinc oxide, degradation accelerator and plasticizer into the high-speed mixer, and mix and stir. Aft...

Embodiment 2

[0025] A composite film, consisting of the following raw materials in parts by weight: 90 parts of low-density polyethylene, 12 parts of plant fiber, 18 parts of starch, 10 parts of diatomaceous earth, 13 parts of light calcium carbonate, 6 parts of zinc oxide, and a degradation accelerator 8 parts, plasticizer 4 parts, defoamer 2 parts.

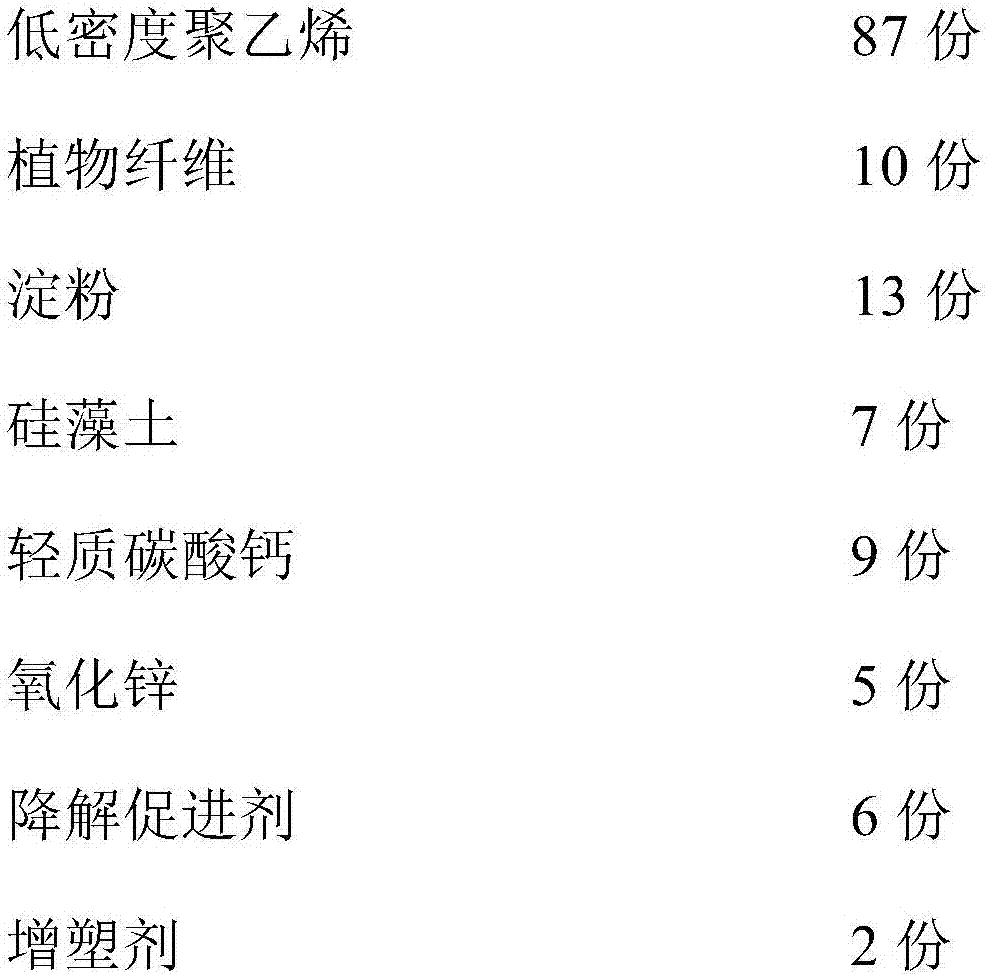

Embodiment 3

[0027] A composite film, consisting of the following raw materials in parts by weight: 87 parts of low-density polyethylene, 10 parts of plant fiber, 13 parts of starch, 7 parts of diatomaceous earth, 9 parts of light calcium carbonate, 5 parts of zinc oxide, and a degradation accelerator 6 parts, 2 parts of plasticizer, 1 part of defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com