Power plant boiler spiral slag removal device and installation method

An installation method and technology for power plant boilers, which are applied in the field of engineering installation, can solve problems such as equipment interface position deviation installation cumulative error, impact on unit safety and long-term stable operation, and low water quenching effect of slag, so as to ensure sealing performance, free expansion, Reasonable and compact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

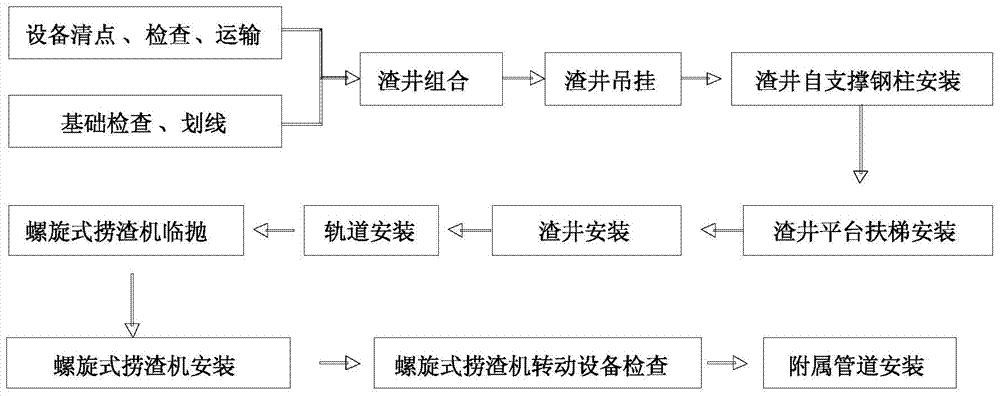

[0059] In view of the existing defects, the applicant drew on the installation experience of the slag removal machine, and in view of the installation characteristics of the spiral slag removal device, summarized and formed a set of simple, fast and effective installation methods to solve common quality problems such as air leakage and expansion. And improve the construction efficiency.

[0060] What is developed is an installation method for the spiral slag removal device, in which the spiral slag removal device includes a spiral slag remover, a slag crusher, a slag well and a slag well self-supporting steel column and other equipment.

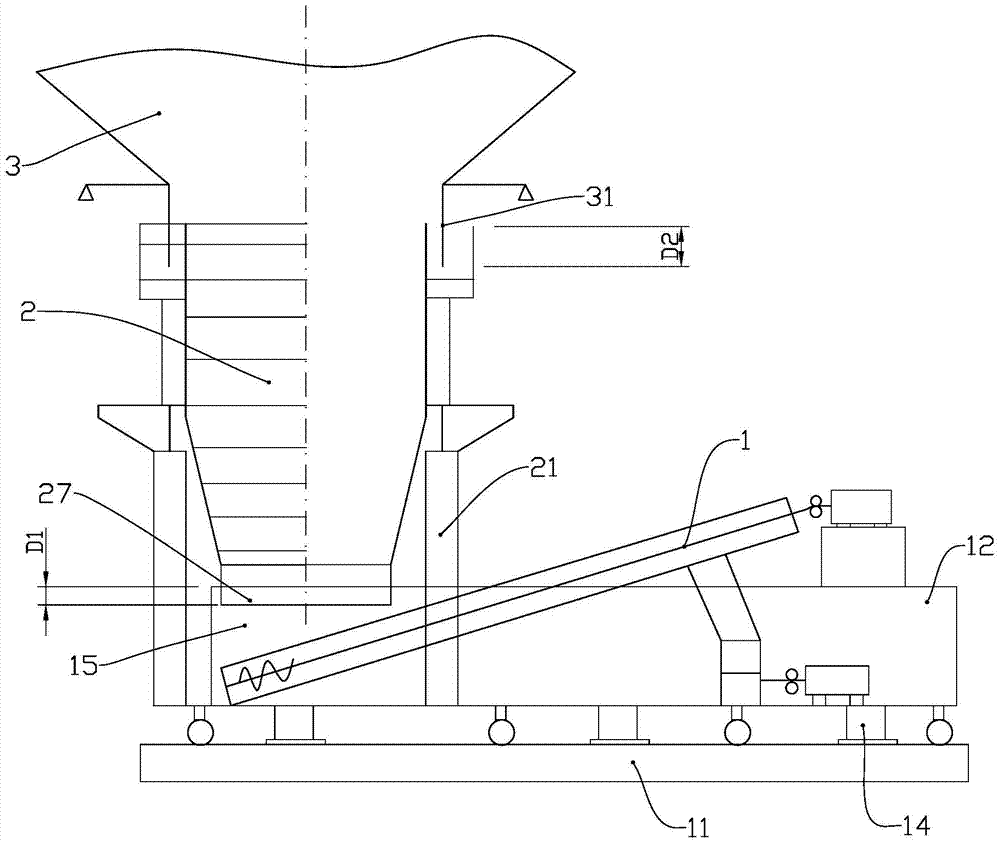

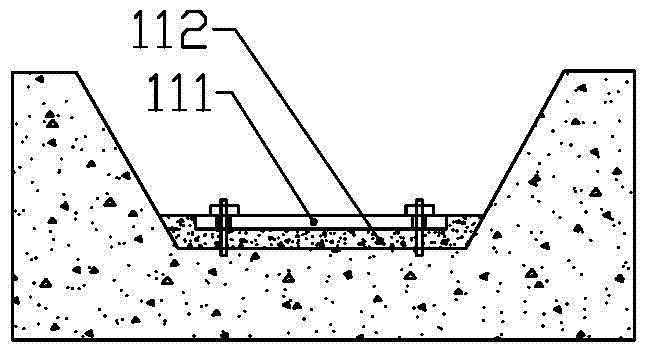

[0061] Such as Figure 1 to Figure 7 As shown, the basic principle is that, according to the structural characteristics of the screw slag remover 1, the screw slag remover track 11 is installed before the installation of the screw slag removal device, and the screw slag remover 1 is pre-placed at the corresponding position. , The slag well 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com