Method for manufacturing buckling restrained braces

A technology of buckling constraints and manufacturing methods, which is applied in the field of buckling-constrained support manufacturing, can solve problems such as low production efficiency and complicated manufacturing processes, and achieve the effects of improving production efficiency, enhancing aesthetics, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] A method for fabricating a buckling-constrained brace, comprising the steps of:

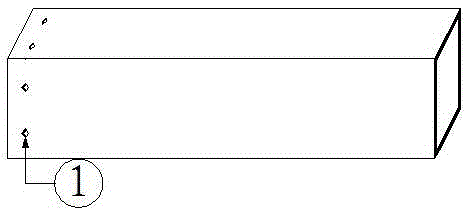

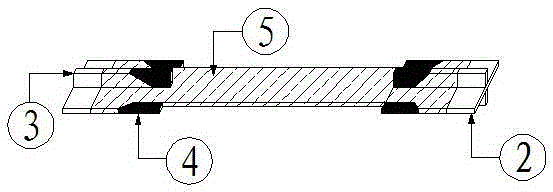

[0021] 1) Fabricate buckling-restrained braced assemblies as required, such as Figure 1 to Figure 4 As shown, it includes a sleeve, a core plate 2, a stiffener 3, upper and lower sealing plates, and bolt holes 1 are correspondingly provided on one side of the sleeve and the upper sealing plate;

[0022] 2) Weld the side of the sleeve without bolt hole 1 and the lower sealing plate with planer mouth, and the weld seam is polished and smooth;

[0023] 3) The stiffener 3 is welded on the upper and lower sides of the middle of the two ends of the core plate 2 by planing, and the weld seam is polished flat. After the welding is completed, the core plate 2 is corrected to avoid deformation caused by welding; the stiffener 3 and the core plate 2 The compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com