Positioning device for attemperator lining hybrid tube

A technology of positioning device and mixing tube, which is applied in the direction of superheating temperature control, steam superheating, steam generation, etc., and can solve the problems of loosening, breaking of positioning screws, and difficulty in assembling positioning screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

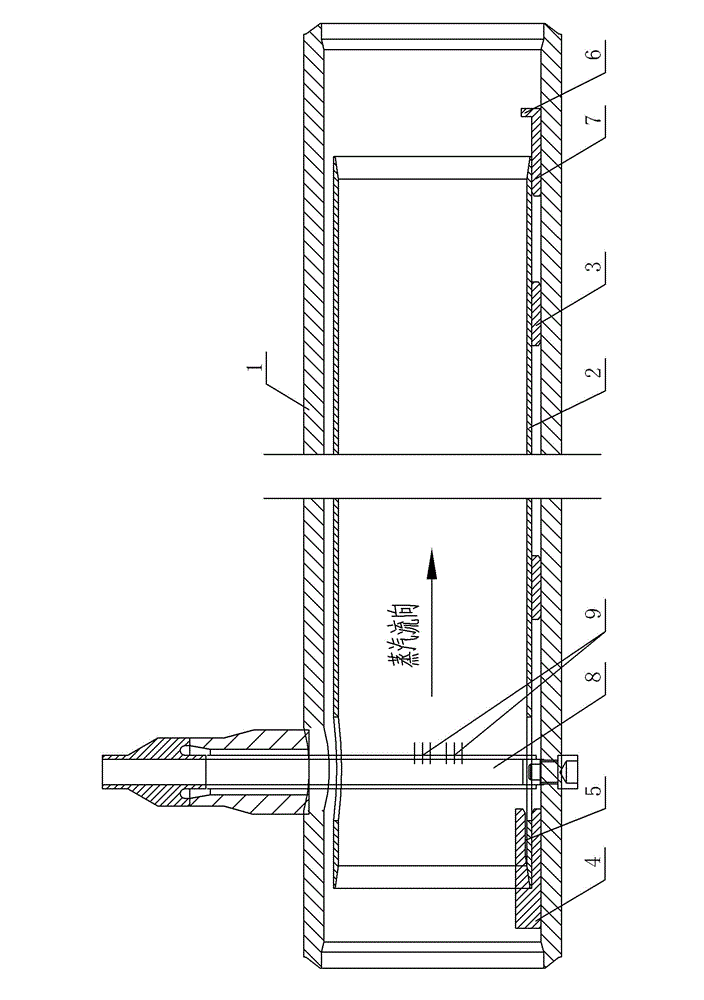

[0009] See figure 1 , which includes a thick-walled header 1 and a lined mixing tube 2, the thick-walled header 1 is set inside the lined mixing tube 2, the outer ring surface of the lined mixing tube 2 is provided with a positioning bump 3, and the positioning bump 3 is tight Adhere to the inner wall of the thick-walled header 1, one side of the inner wall of the thick-walled header 1 is welded with a positioning tank 4, and one end of the lined mixing pipe 2 is installed in the groove 5 of the positioning tank 4, and the thick-walled header The other side of the inner wall of 1 is welded with a stopper 7 with a stopper 6 at the end, and the annulus bottom of the other end of the lining mixing tube 2 is supported on the front upper end surface of the stopper 7 .

[0010] The steam outlet pipe 8 goes through the thick-walled header 1 and goes deep into the inner wall cavity of the lining mixing pipe 2. The steam outlet pipe 8 is located in the inner pipe body of the lining mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com